Glossary of terms - what the customer needs to know about forging.

Communication with any specialist significantly expands not only the horizons, but often the customer’s vocabulary. When you turn to the workshop for forged elements for your own country house, you will definitely encounter some new concepts for you. In order not to confuse the masters with the wording of their questions and to easily understand what they are telling you, we have compiled a small dictionary of basic “blacksmithing” terms.

Brothers Johann and Georg Schmidberger in their forge in Molln, Austria. © Lisi Niesner/Reuters

General concepts

Metals and alloys used in artistic forging are iron, steel, copper, bronze, brass, tin, aluminum.

Malleability is a property of metals that allows them to be susceptible to forging and other types of metal processing. The main indicators of malleability are resistance to deformation and ductility.

Corrosion resistance is the ability of a metal to resist exposure to an aggressive environment.

The rigidity of forged structures is the property of forged parts of metal structures not to change geometric dimensions under external influence.

Advantages and disadvantages of artistic forging

Advantages of artistic forging elements

Making forged products allows craftsmen to embody their wildest creative ideas in metal. Using his own sketches or reproducing copies of generally recognized masterpieces, the blacksmith-artist creates works of applied art that are unique in their beauty. Even elements of artistic forging repeated many times by a master will, upon close examination, turn out to be different from each other.

Household items, interior and landscape design elements are not only beautiful and utilitarian in their purpose, but also quite durable and can serve their owners for decades.

Architects have long noted the ability of artistic forging elements to be combined with any building materials, be it brick, concrete, natural stone, wood and others. Order forged products for your garden, country house or city apartment and see for yourself their versatility. A large architectural form or small designer items will decorate the interior and exterior of your home and give it a respectable look.

Disadvantages of artistic forging elements

Artistic forging has almost no disadvantages, but we still note what you need to be prepared for when ordering a forged product:

- high cost of finished goods;

- long production cycle;

- difficulty in producing a large batch of identical products.

Elements: forged and cast

Often, to reduce the cost of the product, it is proposed to “assemble” the structure from ready-made elements. Or the description of a project made from your picture mentions names that are unfamiliar to you. Most often these are classic decorative elements of forged products.

This may upset some, but forged elements are usually made in China. Wholesale suppliers bring batches of elements for blacksmiths to order from extensive catalogs.

Acanthus leaf is a classic decorative element depicting the leaf of a southern plant. Balusters are shaped columns connected at the top by railings. In blacksmithing they are used in the manufacture of railings for stairs, balconies, and terraces. Flowerpot decoration, stylized as a vase or basket. Volute element in the shape of a curl. Wider - a spiral-shaped motif in architecture, often with a peephole inside. Monogram are the initial letters of proper names, connected to each other in an openwork pattern. A garland is a motif made from an interweaving of flowers, leaves and fruits, sometimes intertwined with a ribbon. Cartouche is an element in the form of a scroll or shield with curled edges. Bracket (forged) is an artistically designed part or structure that is attached to the wall and serves as a support for something. A medallion is an oval or round frame for any image, as well as the design itself, a relief ornament, enclosed in such a frame. Finishing is a decorative completion of the upper part of a pillar, stand (balls, peaks, cones, etc.). The end is a classic element of artistic forging, the final part of a forged product, characterized by a drawn-out end (often a delicate curl with decreasing thickness). Palmette motif in the form of a stylized multi-lobed palm leaf. A rosette motif that looks like a round stylized image of a flower with identical petals. Solomon's spiral (basket, cone) is a decorative element formed from thin rods, spirally twisted and forming a hollow openwork “cocoon”. Flowers One of the most popular motifs in artistic forging. Most often they are made in parts, after which they are assembled into an artistic pattern using welding, riveting or soldering.

It wouldn't hurt to know that

Rapport is a repeating element of an ornament. A module is an artistic and decorative element (or fragment) taken as the basis for constructing the same repeating pattern. A link (section) is a part of a metal fence or fence, delimited by two posts or posts.

Blacksmithing techniques

Basic forging operations used in metal forging technology:

- Sedimentary.

- Landing.

- Drawing.

- Break-in.

- Rolling out.

- Firmware.

- Overclocking.

Sedimentary forging work involves reducing the height of the workpiece and increasing its cross-sectional area.

Upsetting is essentially a partial settling of the workpiece. It is used when some thickenings need to be made on the metal surface. This is achieved by reducing the length of the workpiece.

Broaching is another technological method of processing metal using the forging method. This operation involves lengthening the workpiece. This reduces the cross-sectional area.

Rolling on a machine

Rolling in blacksmithing involves giving the workpiece the shape of a cylinder. During the process of metal deformation, the workpiece rotates around its axis.

Rolling - processing of a ring blank. When it is necessary to increase its internal and external diameters, the metal is rolled out on a mandrel by reducing the wall thickness.

In blacksmithing, broaching is used to produce a through hole through the use of a punch.

Dividing is the operation of obtaining a wider workpiece. Essentially, the metal for forging is flattened on the surface of the anvil with a hammer, moving across the axis of the product.

There are also many other techniques by which the required product shapes are obtained.

Finishing of forged products

Burnishing is a heat treatment of a metal product with preliminary application of special chemicals to its surface: acids and oils. As a result, the metal is covered with a blue-black oxide film. Etching is the creation of a design, pattern, or inscription on a metal object using caustic chemicals. Inlay decoration of metal forged products with other non-ferrous metals or precious stones. Notching is a decorative metal treatment that involves applying “dashes” to the surface. Used to create fine figured designs, for example, depicting veins on plant leaves. Patina is an oxide-carbonate film that has a color tint (silver, bronze, green). Patina is formed under the influence of the environment, while at the same time protecting the metal from destruction. It has decorative value especially in the production of semi-antique forged items. Corrugation is one of the methods of decorative finishing of forged products using blacksmith tools (rough engraving). Filigree decorative finishing of metal products with patterns made of twisted wire.

Palace of Solemn Registration of Births, St. Petersburg

Compound

Elements:

A clamp is an element connecting several rods or other forged elements. Today it is used only in manual hot forging. Bindra is a wire used to temporarily (before welding or soldering) connect elements of a forged product. A rivet is an iron rod that is cylindrical in shape with a head at one end; used for connecting forged elements and parts.

Methods:

Riveting is one of the oldest methods of joining forged metals, when individual parts are connected using rivets. Soldering is the process of introducing solder (molten material) between metal parts, which has a melting point lower than the parts being fused, resulting in a strong connection being formed. Welding is a method of joining metal products by jointly deforming them after heating the welding points. Previously, a forge was used for this; today gas and electric welding are more often used.

Individual forging elements and their production

Each individual component of a forged product has its own manufacturing technology. Elements can be produced hot or cold using blacksmith techniques.

With the hot method, blanks for objects are heated to malleable temperatures (800-1300 degrees), as a result of which it is easier to obtain the required shape.

However, many forging elements are produced using a cold process. This technology involves the use of torsion, bending and other methods without high-temperature heating of the workpieces. Only sometimes can workpieces be heated to 200-250 degrees during cold processing.

The advantage of cold metal processing is greater precision in the manufacture of parts and the absence of material loss (in the form of scale).

Hot forging of elements is easier in terms of obtaining the required shapes.

Also, in the manufacture of forged product elements, forge welding technology is used, when individual parts are heated and connected to each other by hammer blows. However, today this technique is most often replaced by electric welding of metal.

What elements of forged products are made using these methods and techniques?

Processing of forged products

Quenching is the rapid cooling of steel heated to a very high temperature; gives the product hardness and other necessary qualities. Cleaning is the mechanical removal of scale, weld beads, welding spatter and other metal defects from a forged product. Matting by sandblasting is the treatment of the surface with a jet of sand supplied under pressure, which allows you to level the surface and make it rougher (to improve the adhesion of paints and varnishes). Anti-corrosion treatment is the coating of metal surfaces with a thin layer of another metal, alloy, or non-metallic material to form an anti-corrosion coating to protect against corrosion. Primer is the application of a preliminary coating to a forged product to improve adhesion (sticking) of the main protective or decorative coating. Painting is the application of a protective or decorative (often these functions are combined) coating to a product. Galvanic coating is a metal film applied to the surface of metal products using the electroplating method to give them hardness, wear resistance, anti-corrosion, anti-friction, and decorative properties (zinc plating, anodizing, chrome plating, nickel plating, oxidation). The method is not widely used due to its high cost.

Louvre, France, 17th century

Rolled material

What the blacksmith will make the product from.

A semi-finished metal rod, a blank for the production of parts using plastic deformation or cutting. Depending on their purpose, the rods have a cross-section of round, rectangular, hexagonal, less often trapezoidal, oval or segmental in shape.

- Square - a square rod with a diameter of 8 to 25 mm.

- Round timber - a rod of round cross-section.

* A change in the cross-section of a standard square rod from 20?20 to a strip of 30?5 and then to a strip of 20?10 can only be achieved using the forging method. Round timber blank with a diameter of 50 mm, used for turned parts. A strip of rod of rectangular cross-section, half in relation to the square. A profiled dimensional piece of a product obtained by rolling, pressing, molding (flexing) between rolls. Profile section - a section along a line perpendicular to the long side of the segment; varies in width. Forging is an intermediate blank or product obtained by forging or die stamping. Depending on their characteristics, forgings are divided by cross-section - square, rectangular, polygonal and round, as well as by manufacturing method - stamped and forged.

Technologies

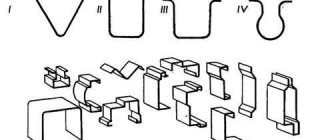

Forging is one of the main types of metal forming using heat. According to the technology, they distinguish between hot (processing of hot metal), cold (deformation of cold metal blanks), and mixed (use of forged, finished cast and welded elements). Die forging is a method of processing iron in which the required shape is obtained by pressing prepared materials into a special metal mold. Casting is the process of producing shaped castings by filling prepared molds with molten metal. Cast elements (balls, peaks, etc.) are often used in parallel with forged elements and are integral parts of fences, gates, and railings. Stamping is a type of metal forming in which the formation of a forging from a heated workpiece is carried out using a special tool - a stamp. A blank stamp for the production of standard repeating elements required in large quantities (for example, the same type of curls for a fence). Torsion (twisting) is a method of processing metal rods to give a decorative appearance. Rods with a thickness of no more than two centimeters, pre-annealed and cooled in air, can be twisted in a cold state using simple technologies.

Fencing of Z.G. Morozova’s mansion on Spiridonovka, Moscow

Metal processing techniques

Rolling is the transformation of wire into a narrow strip by rolling it in special rollers, one of the classic techniques of artistic forging. Drawing is a metal forming process in which round or shaped workpieces are pulled through a hole whose cross-section is smaller than the cross-section of the workpiece. Knockout is the bending of a part on a mold using hammer blows with preheating. Cutting out (cutting) is the production of parts of a given shape from sheet metal using cutting tools by cutting. Punching is cutting out parts of a certain shape or part of a workpiece using a sharp tool (chisel, blacksmith axe, etc.). Bending changes the shape and geometry of the metal, performed without preheating. Under the influence of force, the workpiece bends and deforms, its outer layers are stretched, and its inner layers are compressed. Rolling is a form of pressure processing of metals and metal alloys, which consists of compressing them between rotating rolls of rolling mills. Chopping is the process of working metal using a special blacksmith axe, chisel or undercut. One of the technical methods of artistic forging, the result of which is the cutting off of a part of the metal along the outer contour of the workpiece. Straightening (straightening) of rolled products, wire, long forgings, stampings, castings, machined parts to eliminate distortions and other defects. Embossing is the artistic processing of metal, the production of drawings, inscriptions, images, which consists of knocking out a certain relief on a plate.

Kinds

Forged elements are parts of different shapes, sizes and purposes. Some categories of elements serve purely for decoration , others to add functionality and practicality . There are parts that successfully perform both functions . The elements harmoniously complement different products and designs, including doors. We will describe below exactly which structures are appropriate to decorate with decorative details.

Beautiful entrance

To give the façade of a building individuality, it is recommended to use products with forged elements. With the help of decorative parts it is possible to create an interesting composition , which is attached to the structure by welding. Products of different shapes, dimensions and materials are successfully complemented with elements.

Wooden entrance door with forged elements and stained glass. Photo by IP Komarichev

A popular option are entrance doors with forging and glass. Such structures are metal structures with glass inserts, on top of which there is a forged ornament.

Massive

Forged elements are perfect for massive doors made of wood and metal. Such solid products, after decoration, acquire an original design . In addition, decorative details “remove” excessive roughness and brutality.

Solid wooden door with glass window and forged elements. Photo Iron Age

Interior

Often the interior needs to be complemented with bright accents. An interesting solution from a design point of view are doors with forged elements. Decorative details look great both on products that are standard in style and size, as well as on non-standard designs.

Interior door with glass and forged elements. Citadel Photos

Metal (iron, steel) with finishing

Doors made of metal and steel are most often decorated with forged elements. The use of decorative details helps transform the product, giving it a special mood. Thus, a standard design model acquires original features, and a luxurious product with a well-designed design looks even more attractive.

Door with forged elements. Photo Hephaestus03

Wooden

Wood and forged elements are the most popular, sought-after and harmonious combination. It is advisable to supplement wooden structures not only with decorative elements, but also to equip them with functional parts:

- forged hinges for doors;

Wooden door with forged figured hinges and a knocker handle. Citadel Photos

- forged door handles;

- forged ironwork;

Forged leather. Photo Exclusive

- forged locks.

Forged castle. Photo Blacksmith shop

The lines and shapes of the forging stand out clearly against the wood, giving the structure an individual design.

Door grilles

The door grille is a canvas consisting of intersecting metal strips or rods. Forged grilles on doors can have different shapes and sizes:

- Popular are small products designed to be placed on the outside or inside of glass inserts.

Entrance door with glass and wrought iron bars. Photo Lefty

- Often there are large gratings, comparable in size to the door leaf. Lattice doors are transparent structures that reliably protect against penetration into the home, but do not protect the owners of the house from prying eyes. Therefore, such products most often play the role of a second door located in front of the main structure.

Forged lattice door. Photo Hovhannisyan Eduard (Art-Fe - artistic forging)

Decorative grilles above the door

A popular solution is to place a wrought iron grille above the door. For example, an arched opening is filled with a rectangular door, and in the upper part there is a semicircular lattice . It is important to note that in such cases the door can be made of metal (steel) or wood.

Forged lattice above the door. Photo by PE Kolesnik

In addition, the grille can be located separately from the doorway, i.e. in a small window.

Artistic and cold forging

To decorate a door you need a fairly large number of forged elements. To quickly produce them, cold forging technology is used. The metal (without preheating) is subjected to bending and stamping. Processing of workpieces is carried out on special machines. As a result, the client receives template design parts that are not original in design, but are sold at low prices.

Connoisseurs of unique design solutions should submit a request to create elements using hot forging. Processing metal by hand allows you to produce original parts that have a higher value. It will take the craftsman considerable time to make them.