Groups of metalworking equipment

Among the metalworking equipment of the main groups (turning and milling), it is worth highlighting others:

- sawing and circular cutting machines;

- band saws, capable of longitudinal sawing of workpieces;

- vertical drilling, in which the spindle is located at the top;

- drilling and slotting;

- grinding and cross-cutting machines for high-quality surface processing.

What these units have in common is that they work with any metal. They are also united by the presence of a bed on which the main “unit” – the metalworking element – is installed. The device has an electric motor, a feed platform, various clamps, and working equipment - according to the specifics of the technological operation being performed.

Next to the massive and large industrial options, mobile desktop machines and mini-machines for metal processing used in jewelry and engravers look very compact.

Milling classification

There is no clear classification of this type of metalworking, since the work performed is very diverse.

In addition to division by type of machine (laser processing, turning and milling on a mechanical machine), the following can be distinguished from the main types of gradations:

- according to the location of the workpiece - horizontal, vertical milling and angled milling;

- by type of cutter used - face, end, peripheral, shaped;

- in the direction of rotation of the cutter relative to the movement of the workpiece - along or counter.

The last type of classification is applicable for milling of massive parts, when the initial milling of the metal is carried out using a counter method, and for the final finishing of the part a passing method is used.

Versatile Equipment Capabilities

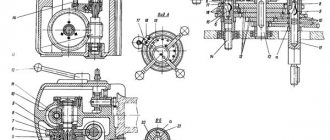

Among materials processing equipment, metal CNC milling machine is the most commonly used. The most common type of such machine is a cantilever milling machine. It is characterized by the presence of a console. This rigid body part is capable of moving the carriage along the bed guides. In such a CNC machine, the spindle of the unit cannot move or makes little movement. All the work of moving in space is performed by a table with a fixed part.

Most cantilever milling machines (with horizontal or vertical processing) are universal. They mill parts from steel blanks, cast iron and non-ferrous metals. Operators have a choice from a variety of cylindrical, disk, shaped, angular, face, end and other cutters for the production of small batches, or produce products in large serial batches.

For example, on a 6P82 cantilever milling machine it is easy to process any workpiece. In addition, it is possible to expand the functionality of the machine using a rotary round table, overhead heads from among universal and dividing heads, and using other devices.

The maximum dimensions of workpieces that can be processed on these machines are 800x240x370 mm. You can select any cutting speed with a milling cutter (interval 31.5 - 1600 rpm). Thanks to the table, which rotates ±45° around the vertical axis, it is possible to mill the workpiece (without repositioning) at various angles, which contributes to the accuracy of parts production and high productivity.

The fact that this machine is automated makes it possible for factories to establish multi-machine maintenance.

Instructions for beginner CNC machine operators – “SPRUT-Technology”

This is called parametric modeling.

To get acquainted with such programs, follow the links: Inventor SolidWorks OnShape Compass 3D Creo

Recommended programs (CAD systems): when choosing a program, you should think not only about simplicity, but also about prospects and functionality. For designers without experience, I recommend drawing 3D models in the Tinkercad web application. Tinkercad works in browsers that support 3D functionality: Chrome, Firefox, Yandex.

Stage II - explain to the machine how to process the workpiece to produce a part

After receiving the model, you need to explain to the machine how (at what speed, what tool, and most importantly, along what trajectory) to process the workpiece to obtain the planned part. All this is called a technological process. To write the technical process, CAM systems are used or, as it is called, a CNC program.

To write a technical process, I recommend that you use the SprutCAM program. This is a full-featured professional CAM system from a domestic developer, indispensable for programming CNC machines for beginners

For small productions there is a special offer available - SprutCAM Practik. These are programs for CNC machines in Russian running Mach3, NCStudio, LinuxCNC and analogues. The SprutCAM Practik installer can be downloaded for free.

- The task is to explain to the machine how to process the part

- The solution is to write a technical process in a CAM system

In the CAM system, the trajectory of the tool is determined, then this information is translated into a specialized G code language (in the figure), which the CNC machine itself understands.

Requirements for control systems

To ensure high feed rates and movements of the milling cutter, digital controllers are needed that can control the processes of acceleration and braking. Together with the built-in remote control of an industrial PC, they can operate without human intervention. And if they are connected to the company’s computer network, even remote monitoring is possible.

Today, controller developers have robust, real-time versions of Windows NT that take full advantage of the Internet. CNC systems use stepped microprocessors, making it possible to process 1100 5-axis blocks per second. In addition, preliminary processing of information in programs that involve machining parts with a milling cutter with a large amount of data will not be necessary.

As for tooling systems, it is feasible to monitor the condition of milling tools, the data of which is transmitted back to the controller. Now one device for automatic tool changer can serve several machines.

There are advantages of HAAS CNC system for milling machine. It is intuitive and easy to learn in a short time. This precision equipment, operating with increased accuracy, has a large number of standardized components, which helps reduce the cost of its maintenance.

How to choose a CNC router

Before purchasing a metal milling machine, you need to study their technical characteristics. To do this, you should log into the chipmaker portal and get acquainted with the machine passports in electronic form in the Catalog. The site is also called the Metal Forum, as there you can find everything you need for metalworking.

Anyone who has already milled blanks to produce metal products has received a lot of advice and valuable recommendations from experienced specialists in this field on the forum. Topics related to the saturation of the machine tool market are actively discussed with newcomers.

It is worth noting that machines with a wide range of uses find their consumers who have different financial capabilities.

The cost of devices is related to many parameters:

- dimensions and weight of workpieces;

- configuration of parts, accuracy and quality of surfaces after processing;

- processing modes (we are talking about spindle speed, power and torque);

- planned volume of parts production.

A cantilever type milling machine can serve its owner for a long time in a small workshop. But large CNC machining centers are intended for heavy engineering and aerospace industries. Milling equipment is used to process a wide range of body parts of any complexity, stamps and 3D molds.

Cantilever CNC milling cutters for metal are available in many models. Among the most popular is the inexpensive vertical machine 6R13FZ. Its table working surface dimensions are 400×1600 mm, it moves along coordinates at high speed - 2400 mm/min, and has a main drive power of 7.5 kW.

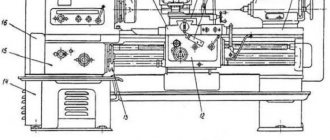

Its main unit is a frame with a console on vertical guides. The machine is also equipped with a gearbox, a spindle, a table with a sliding slide and a gearbox. The movement is carried out by a hydraulic motor.

Horizontal milling machines also belong to the console type. They are effective when the number of technological operations is limited, and it is necessary to process mainly flat and shaped surfaces.

What should you consider when choosing equipment?

When choosing equipment, you should take into account a number of characteristics, especially when it comes to buying a home machine. Devices used for industrial purposes are usually selected by a group of specialists.

Blank size

A home machine cannot process large parts as quickly as possible. Its functionality is limited. To begin with, the consumer evaluates which parts by size configuration he will work with. Generally, a small benchtop unit with a horizontal table will satisfy the needs of cutting common workpieces. But if you need to grind a crankshaft, brake discs, or an unusual corner, you will need a device with a vertical axis.

Universal milling machines are chosen by those who have a home workshop. Numerically controlled - too difficult to use on your own.

Power

The power displayed by the router is considered to be operating efficiency. But it’s worth considering not only how many parts were made and how long it took, but also the connectivity options. Not all home appliances will be connected to a 380 V network, which is typical for industrial lines. For independent use, 220 V power options are available, which will save you from pulling an additional cable.

Drilling diameters

Drilling diameters are directly determined by the types of tools used. Some of the backup machines, especially those dating back to before 1990, are not equipped with the ability to replace them with tools from another manufacturer. Modern equipment allows you to insert tools from another company, which gives a wide field for work. Drilling diameter is an important characteristic for a home machine.

Weight

Milling machines in production weigh from 2-2.5 tons, there may be variations in a smaller or larger direction. It is clear that these are not suitable for use at home, even if you put them in the garage. Now mini versions are sold, with the help of which a beginner and an experienced craftsman can carry out metal work. They weigh from 300 kilograms. Of course, weight directly determines functionality. With the smallest weight, only small parts can be turned, because low-power structural units are used.

If you want your workshop to be universal and have the same functionality as an industrial one, then buy a machine that is functional, but not the largest in size. By equipping it with new parts and tools, you can increase the scope of use.