Autonomous sewerage is the only way to achieve an acceptable level of comfort in a country house. The reason for this is simple: in most country and country villages there are no central sewage disposal systems. The central part of the autonomous sewage system is the treatment plant - septic tank. In order for the system to function properly, septic tank maintenance is necessary.

Regardless of which septic tank option was chosen for installation on a suburban area, this installation must be periodically maintained. But the maintenance algorithm will depend on what operating principle the treatment plant uses.

The easiest way is to sign a service agreement for an autonomous treatment plant with a company that repairs septic tanks, but you can do the work, or some of it, yourself.

How to properly care for your Topas autonomous sewer system

This autonomous treatment facility operates in automatic mode, so there is no need to carry out daily maintenance of the Topas septic tank, however, it is necessary to follow a certain list of tips and care rules.

It is necessary to carry out periodic visual monitoring of the operation of the local treatment plant (WTP) by removing the top cover from it. As a preventative measure, the walls of the secondary settling tank should be cleared of sludge. This operation can be performed with a broom.

How often to maintain a Topas septic tank and the required actions

Let's look at how to maintain a Topas septic tank:

- Once a day, it is necessary to visually monitor the correct operation of the system through a removed mug. If the treatment plant has a light signaling system, it is controlled using it.

- Once every 7 days, it is also necessary to monitor the purified liquid in the system by means of observation.

- Once every three months. During this period, the sludge should be cleared from the stabilizer by means of an airlift. If you have a system whose productivity is up to 3 m³ per day, then the walls of the secondary settling tank can be cleaned of sludge, as already said, with a broom. If you have a structure with a more powerful capacity (processing from 4 m³ per day), then to clean it you will need to use either a sewer truck or use a fecal pump.

- Once every 6 months. If within three months the excess sludge biomass has not been removed from the stabilizer using an airlift, then it is necessary to carry out a purification procedure using a drainage pump. In addition, the hair catcher, liquid airlift, as well as the filtration system for large unpurified liquids are cleaned.

- Once every 2 years. According to reviews from users of the Topas septic tank, it is advisable to inspect all bolted and screw connections of all compressors, as they can become loose and lead to improper operation of the system.

- Once every two to three years. Air Mac compressor membrane should be checked and replaced.

- Once during a five-year period, cleanup measures are carried out - it is necessary to eliminate excess mineralized sludge from the equalization tank and aeration tank.

- Once every 10 years, the aeration elements of the structure are replaced.

Attention! The sludge from the system must be pumped out once every 3 and 6 months. Of course, it is better to approach this event wisely - as it gets dirty, but at least once every six months!

How is a Topas septic tank cleaned?

Cleaning a Topas septic tank is not very difficult. First of all, unscrew the plug located on the airlift sludge stabilizer hose.

After which the equipment switches to operation in the “direct cycle” mode, thanks to which the sludge mass from the sludge stabilizer system is pumped out on “autopilot”; do not forget to take care of the container where the drainage will be carried out in advance.

As a rule, during purification, the yield of sludge mass is approximately 50% of the stabilizer volume. Due to the fact that the pumped sludge is in a state of aerobic stabilization in the container, it is a good way to fertilize your site.

Attention! If the sludge mass is removed using a drainage pump, the stabilizer is completely emptied, so this operation is not recommended to be carried out frequently, maximum once every six months.

How is the process of cleaning the filtration system from untreated large wastewater carried out? To do this, disconnect the air hose and remove the filter holder. After this, the hose is removed in the same way as the airlift of unclean water. After this, it must be washed and blown.

If during system operation the liquid level in the equalizing tank rises and tends to the emergency float, this may indicate a malfunction in the functioning of the equipment. Due to the fact that the device has an alarm system, you will be notified in a timely manner if problems arise in the device.

Causes of cloudy water and changes in purification quality

A similar phenomenon can occur as a result of incomplete wastewater treatment:

- As a rule, the problem of turbid water arises at the initial stage of putting a treatment plant into operation. This problem should resolve itself within a month until sufficient sludge has formed.

- If the reason for the deterioration in the quality of wastewater arose as a result of a decrease in the pH level or chemical contamination, which arose, for example, due to a rapid drop in temperature, due to intensive washing with aggressive detergents (especially antibacterial), then the operation of the system should return to normal within 24 hours, without your participation.

- In addition, you may encounter the fact that the wastewater is consistently cloudy, what’s wrong this time? This condition may indicate that there is a significant lack of clean air in the activation system (this problem may arise due to a lack of tightness in the oxygen distribution network), or the plant is operating in a state of massive overload.

Topas septic tank maintenance - video

Causes of septic tank breakdowns

Septic tanks are designed to solve problems of wastewater disposal from houses in suburban areas. The design and principle of operation of the product is strikingly different from the sewage system used in the city.

The purifier is an autonomous system of one or more interconnected containers into which wastewater flows. The specificity of the structure lies in the presence in modern products of special microbes that decompose organic inclusions and disinfect tanks. Solids that are not processed fall to the bottom.

Violation of the operating conditions of the product and poor quality maintenance lead to the death of microflora and improper operation of the purifier, as well as to mechanical breakdowns. Therefore, all family members need to learn the rules for using the sump tank to avoid emergency situations.

The septic tank easily processes the following waste:

- Toilet paper;

- Dirty water from washing machines;

- Kitchen waste;

- Drains from the bathroom.

The device quickly fails for the following reasons:

- Remains of vegetables and fruits, waste from cleaning wild mushrooms, medications, alcohol, acids and alkalis, and fuels and lubricants are thrown into the septic tank. All these substances destroy aerobic bacteria.

- Non-degradable items entering the sump tank - plastic bags, packaging materials, cigarette butts, construction waste (cement, sand, etc.). Inorganic substances interfere with the functioning of the device.

- Using personal care products that should not be thrown into the purifier. For such a sewer system, it is allowed to use only products labeled “for septic tanks.”

- Draining water from filters into the system, which was purified with substances based on potassium permanganate and other oxidizing agents.

- Accumulation of large amounts of pet hair in tanks.

Failure to comply with the rules of operation and care of the septic tank, as well as installation technology, leads to mechanical breakdowns of parts and components of the device.

Most often it is necessary to repair purifiers in the following cases:

- Pump failure. The pump can be damaged by solid waste accidentally entering the tank.

- The preventive inspection of structural elements - communications, drainage pump and other parts - was performed poorly. If maintenance is carried out conscientiously, defects can be detected in the initial stage of destruction and the creation of an emergency situation can be prevented.

- As a result of incorrect installation, forces are applied to the walls and pipes of the septic tank, which lead to their deformation. Unplanned loads significantly reduce the service life of the device. Under the influence of bending moments, the pipes become depressurized - they burst or separate at the joints. The problem arises if, when installing the housing, the bottom of the pit was not filled with cement-sand screed.

- If the pipelines are assembled incorrectly. Connecting live pipes can lead to their destruction.

- Constructed from concrete rings and bricks, tanks often leak due to damage during construction. Sometimes the upper part of the septic tank is destroyed due to poor-quality insulation.

- When a septic tank is used for a long time, silt and other solid deposits accumulate in the pipes. The situation can get even worse if large fragments get into the tank and clog the communications. To return the device to working condition, you will have to dig up the pipes and change them.

- Failure of mechanical systems due to flooding of the area. The consequences can become very dangerous if the liquid gets close to the electrical components of the device.

- Airlift clogging occurs when a large amount of wastewater containing inorganic matter is discharged. In this case, the liquid cannot move to the next compartment, it stagnates, and an unpleasant odor appears.

- Poor quality equipment installed on the product quickly fails. The problem arises when you want to save money and purchase cheap equipment. Inexpensive mechanisms may turn out to be defective, which becomes a problem for organizing the uninterrupted functioning of the device. Treatment plants do not respond well to frequent shutdowns, and unplanned shutdowns are guaranteed to put the septic tank out of action.

- Long periods of time between filter washings. Severe clogging makes it impossible to clean them; the part will have to be replaced.

- Operation of sedimentation tanks when pumps are not working. Most often this happens when there is a power outage. If the pumps do not operate for a long time, the sediment at the bottom of the receiving chamber will thicken and seriously impair the purification of water already in the storage tank.

- The septic tank was operated for a long time in an overloaded mode, which is not allowed by the operating rules of the device. If you plan to do a large wash, spread it out over several days.

- Serious damage to the product can result from its repair by non-professionals who do not know the design and operating principle of the sump.

Using a Topas septic tank in winter (cold season)

Topas autonomous sewage stations are equipped with a heat-insulating cover. The design of the VOC provides for the operation of the system in the winter months with fecal wastewater, whose temperature characteristics meet the permissible minimum values.

To ensure uninterrupted and reliable operation of the system, it is necessary that the temperature of the liquids does not fall below 3 degrees above zero.

Please note that additional procedures to ensure the operation of the Topas station in winter are not required if the temperature does not fall below 25 degrees below zero and at the same time at least 20% of household wastewater is supplied to the system.

We also note that if wastewater does not enter the system at all, it will begin to become conserved and will also lead to the death of bacteria for the septic tank.

What to do if the ambient temperature is below the permissible threshold required for optimal operation of the treatment plant (i.e. below 25 degrees below zero)?

In this case, it is recommended to implement additional measures to protect VOCs and not leave everything to chance. For this purpose, a special insulated cover is prepared, which is installed on top of the cleaning station to ensure the temperature required for its uninterrupted operation.

Topas 5 station structure

Wastewater treatment is carried out by anaerobic bacteria. All cleaning filters are located in an analogue of a cesspool and are built inside the body itself, which will last a long time, since it is made of polypropylene.

The body part includes:

Reception compartment;- Section where wastewater settles;

- Aerotank;

- A system from which, upon completion of cleaning, liquid is released into the external environment.

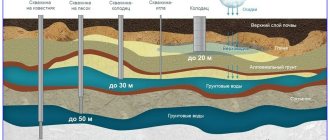

In the area where the Topas 5 Standard system (with gravity outlet) will be installed, there must be a low or normal groundwater level. The soil should have been sandy or sandy loam. The sewer pipe must pass at a maximum depth of 85 cm underground.

In other cases, we recommend buying a “Topas 5 PR” septic tank (with forced drainage). It can be installed in any soil and it does not matter what the soil level is in the area. In this system, purified water, having accumulated in an additional chamber, is removed by a pump. The sewer pipe must also pass at a maximum depth of 85 cm underground. The price of Topas 5 PR is higher than that of a standard installation, however, if the site has a high groundwater level, it is better to purchase it.

If there is a need to install a septic tank deeper, then it is worth considering the option of purchasing a Topas 5 Long biological wastewater treatment station (up to 120 cm).

Station energy consumption

If there are no sudden voltage drops in the local network, Topas will operate in normal and uninterrupted mode.

In the event of a power outage for no more than four hours, such a period will not greatly affect the operation of the device. However, at such a moment it is better not to use the system in intensive mode in order to prevent the treatment plant from overflowing.

If the shutdown occurs for longer periods of time, aerobic reactions begin to occur in the septic tank, which can result in an unpleasant odor . This is not the worst thing, since there is a risk of rapid overflow of the system. It is recommended to pay special attention to the system during such a period.

To avoid such troubles, it is advisable to install converters that have a stabilizing effect on the voltage in the network. They should be connected directly to the generator. This system solution would be the optimal solution, given that the operation of the treatment plant requires minimal power consumption (up to 1.5 kW/day).