Angle grinder (grinder) BOSCH GWS 9-125 S. Photo 220Volt

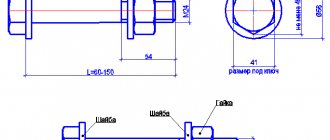

Due to their simplicity and versatility in use, grinders have gained popularity among both amateurs and professionals . To maintain an angle grinder in working condition during operation, it is necessary to carry out various repair work, often involving the replacement of defective units and parts with new spare parts and components. If the clamping nuts are unscrewed abnormally (using, for example, a chisel, hammer and other similar tools), they may lose not only their appearance, but also their ability to perform their functions. Well-known manufacturers of angle grinders on the market produce various spare parts for them , among which locking devices are not in last place.

What is a clamp nut?

An angle grinder is a convenient, transportable and reliable tool, intended for cutting and grinding stone, ceramic, metal and sometimes wood surfaces. Working with an angle grinder only from the outside looks relatively simple and understandable; in practice, it requires certain abilities and knowledge. When using an angle grinder, a specialist must be as careful and focused as possible. If you do not adhere to established safety rules and work technologies, then you are guaranteed to suffer various injuries. Failure to follow the required precautions can leave a worker crippled for life.

Of course, when developing any of the modifications of angle grinders, manufacturing companies strive to maximally insure the user when using the tool, but you yourself should use the mechanism carefully and have an understanding of its certain properties. A very significant aspect when choosing an angle grinder is the type of clamping fastener installed on it.

This small component of the design may well “bestow” a few minutes (this is in the best case scenario), and under unfavorable conditions – even 30 minutes of “suffering” associated with unscrewing it. Therefore, before purchasing an angle grinder, you need to focus on such a seemingly insignificant element as a nut.

I bought myself a super nut for an angle grinder, it turned out to be a very convenient thing. It became interesting and I took the nut apart and looked at what was inside it; inside there was a complex mechanism for fixing the nut. But the most interesting thing is that with this nut the disk does not jam and the nut can be unscrewed without a key.

Read also: Electric oven built-in power connection

Modifications of clamping nuts

Some manufacturers have paid serious attention to the issue of a tight fastener on an angle grinder and have eliminated it. For example, the DeWALT sander has an improved mechanism and a clamping fastener that can be easily and quickly unscrewed even after prolonged use of the device. Like the manufacturers of angle grinders, the creators of clamping nuts are also in constant search. The famous German company AEG has improved the clamping fastener.

As a result, using a fastener from this company, you can forget about discomfort; the fastener turns away quickly and without much effort, at any moment. And now you don’t have to think about how to free the jammed circle or what’s left of it. Everything is quite simple: a special thrust bearing is mounted into the quick-release nut from AEG, which will not allow the fastener to tighten spontaneously and jam the circle.

Tags: super nut, super nut for an angle grinder, super nut for an angle grinder.

Comments 28

I use this one, but I forgot about the problem of unscrewing it.

Interesting thing. It really looks like a miniature dual-mass flywheel.

Workers usually place a cigarette pack cardboard under the nut

You can buy from 600 rubles.

But they don’t take root on real objects. (they are in the box).

This nut is heavier and slightly larger than a regular one. This is often disruptive and critical.

A regular nut can be tightened and loosened just as well without a wrench if you pull it by the disk, you just need to get the hang of it and a little experience...

PS angle grinders are different, for example the Hilti 125 has a very abrupt stop, as a result the nuts unwind and fly away along with the disc...

Never interfered. If you catch a wedge, you won’t be able to unscrew it with every gas tool. Moreover, if the disk crumbles, then there is no point in pulling. Nothing has ever flown away. Everything works fine, there is nothing in the box, there are basically no boxes.

I speak from experience (personal + observation of others). Now I have 3 pieces. grinders 125mm. A wired professional Bosch, which has such a nut included, and 2 pieces of Hilti, for which I bought these nuts... Of course, they are very convenient, but in fact, no one uses these nuts...

As an aside, in favor of a regular nut: — The quick-release nut is larger in diameter, rests against and cannot clamp some flap sanding discs (with sandpaper). — All people are lazy, as a rule they saw with a disk until they get stuck... The quick-clamping nut is larger and starts to interfere earlier. — The tiler uses a diamond disc, the smaller the mass on the shaft, the more exquisite the movements...

And by the way, if the disk lifts up and there is an impact, it is not a fact that the quick-release fastener will turn away with your hands. (a key is needed). And the nut is very good, when I’m not in a hurry, I use it sometimes...