Scope of application and operating principle

Laser cutting machines are often used in enterprises that produce advertising materials. They are also used in such areas as construction, mechanical engineering, aircraft manufacturing, shipbuilding, and light industry.

This is not to say that this equipment is too difficult to operate. First, the necessary drawing of the workpiece is made manually. The base is then mounted on the laser engraving and cutting machine table. The necessary work is carried out by a special laser head. In this case, there is no mechanical contact between the tool itself and the workpiece.

The beam, which is heated to a high temperature, produces cutting. At the cutting site, the metal will melt and be removed by a stream of gas.

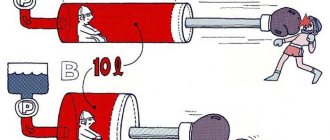

rabbit machine

Rabbit Semiconductor is a leader in the manufacturing of processor modules. The company's products are designed for cases where the capabilities of the equipment exceed the capabilities of control microprocessors. At the same time, installing an industrial computer is not economically profitable.

The photo shows a Rabbit laser cutting machine

This applies to the greatest extent to high-precision, but not very powerful equipment, designed for complex work with material in a small volume. Engraving, cutting, and the formation of 3D images on small parts are typical representatives of this category.

Specifications

The type of laser is gas-discharge, as it is one of the most economical and operates in two modes. Laser power – 40 W. In SC series models it is possible to install a more powerful laser - 80 W, 130 W.

In the SG series, the basic kit includes two laser tubes. In this way, you can reduce work time by processing two parts at once. Or use a method of combining rays to obtain an image inside a mass of material. This method is only suitable for silicate or crystal glass.

Worktable size – the HX series refers to mini-machines. Here the size of the desktop does not exceed 300*420 mm. In other lines, sizes range from 300*500 to 1600*900 mm. In some models, with a small desktop size, a roll feeding function is provided. This allows you to process voluminous sheets without preliminary cutting.

Project files are loaded via the USB port. In this case, constant contact with the PC is not required: the files are loaded into the working memory along with the specified settings.

Possibilities

Rabbit laser machines are designed for processing non-metallic materials: wood, plywood, fabric, paper, plastic and, of course, plexiglass. The functions performed by the machine are standard:

- Cutting – the thickness of the cutting line is 0.1 mm. Depending on the power, the thickness of the sheet of material ranges from 5 mm to 25 mm.

- Engraving – positioning accuracy is no more than 0.01 mm. In this way, an engraving of ideal precision and minimal depth is obtained, for example, on paper.

- The software allows you to download files from your work computer, flash drive or other media.

Advantages

In addition to the standard advantages of laser engraving machines - cutting accuracy, processing speed, absence of material losses and equipment wear, equipment from Rabbit has additional advantages:

- It is possible to replace laser heads with more powerful ones, which is very economical.

- Ease of management is one of the fundamental features of Rabbit processor modules.

- The required voltage is only 220 V.

Types of laser heads

Various tools are used in such equipment. For laser cutting, 3 types of heads are used:

- Solid state. This head is heated using a high-voltage discharge lamp. They operate either in pulsed or continuous generation mode.

- With diode pumping. This is new equipment. Discharge lamps are not used here. Instead there are LEDs. These are more expensive mechanisms, but safer and easier to use. There are no high voltage elements in machines with such heads.

- CO2 lasers. This is the most modern equipment. It is also used for cutting aluminum.

The secret life of laser engravers

Although we do not see them on every corner, the results of their work surround us everywhere. The quality and speed of work provided by laser machines in many industries remain unattainable by traditional processing methods. Laser markers, engravers, welding and metal cutting machines, etc. The list is truly huge and lasers continue to take over the world.

But, Petka, there is a nuance(s). Like all science-intensive stories, laser technology has already acquired enough rumors and myths about its limitless capabilities. There really are a ton of possibilities (or two), but no one has canceled physics.

Armed with a keen desire to find out how it all works, it was decided to go to the St. Petersburg office for comments. They have been developing laser engravers and markers for 15 years and probably understand something about them.

Lots of photos under the cut.

Look to the root

We must immediately remember the most important thing in this entire engraving and marking story: only fiber lasers can provide us with the necessary parameters for industrial use in metalworking. There is no real alternative to them yet. Gas, solid-state and other lasers work great, but in other applications.

The question arises: what is so remarkable about fiber lasers? Firstly, it is the excellent quality of optical radiation. After 100,000 hours of operation, the change in laser characteristics will be either negligible or non-existent. Although this does not mean that you can not follow him at all.

Mini Marker 2. The most popular machine of the Laser Center. The laser is hidden in the red box below.

But the main thing is the wavelength of the generated radiation and how it interacts with materials. The canonical carbon dioxide laser operates at wavelengths of 9.6-10.6 microns. Such radiation is well absorbed by organic matter, so for medical use they are better suited than fiber lasers operating at approximately 1-1.5 microns. Strictly speaking, the wavelength is like a passport, an identification document for a laser. Depending on the wavelength, materials interact with radiation differently. There are only three options: radiation can be absorbed, reflected or transmitted. A textbook example is glass, which absorbs UV waves, but perfectly transmits the visible range of the spectrum. The option we are interested in: radiation with a wavelength of 1.064 microns is almost completely absorbed by steel, and with a wavelength of 10.6 microns it is reflected. And if we take plexiglass, everything will be exactly the opposite (10.6 - absorbed, 1.064 - passes through).

Demo plate of the Mini Marker 2 machine. Such plates are designed to show the maximum capabilities of the machine (image quality, color work, etc.) and are made right in front of you.

And the third important parameter is the diameter of the spot at the irradiation focus. For the same emitted power and focal length, a fiber laser has a smaller spot, and therefore the absorbed energy density is approximately 100 times higher (circle area) than an a-laser. This makes working with metals even more convenient.

And finally, the small dimensions of the emitting body. Especially when compared with gas lasers.

And to end the introduction on a positive note and make our compatriots proud: the leader in the development and production of fiber lasers is the IPG Photonics corporation, created by MIPT graduate student V.P. Gapontsev. In general, you can take it by default: you see a laser, look for the trace of Russian physicists =)

The process of engraving the plate from the previous photo. It's done in literally a couple of minutes.

By the way, the fiber laser market is now estimated at about 2 billion dollars, of which 1.5 is IPG. And a small piece of this corporation, NTO IRE-Polyus, from which fiber lasers began, ranks tenth among non-commodity exporters in Russia. Ninth - Rosoboronexport. Draw your own conclusions.

Materiel

Now let's figure out what a fiber laser is.

When talking about a ruby, fiber or any other laser, we mean the active medium that generates laser radiation. Three minutes about what a laser itself is.

You can cut these cute things out of wood and plastic with a laser.

In 1964, Soviet scientists Nikolai Basov and Alexander Prokhorov, together with the American Charles Townes, were awarded the Nobel Prize for the creation of the laser. They discovered that in some substances, when irradiated with electromagnetic energy, electrons begin to move to higher energy orbits. And during the return transition to a lower energy orbit, they emit photons with an energy of one quantum. What is one quantum? This is the energy of one photon =) Next, the main magic happens: if a flying photon hits another electron located at a high energy level, a new photon is produced, completely identical to the one that hit it, and it will fly in the same direction. Next, these two photons knock out four, they knock out eight, and so on, until the so-called shutter is opened at the border of the active substance, and a radiation stream consisting of absolutely identical photons flies out of the substance. All this happens at the speed of light, so in modern lasers the pulse duration can be measured in pico- and femtoseconds (these are -12 and -15 degrees, respectively).

The very first (literally) engraving machine sold. They specifically looked for him and bought him back.

Now a little math. Let's assume we have a standard 10 W average power fiber laser with a pulse duration of 100 nanoseconds (-9) and a pulse frequency of 20 kHz. The energy of one pulse is 1 mJ. The spot diameter is 50 microns.

And if you look closely at this impulse, it turns out in a second. we transferred 1 mJ. And if you work like this without stopping for a whole second, then we get 10,000,000 (times) of 0.001 J (this is energy). Total 10,000 W. You can imagine what the material feels like when 10 kW is pumped into every 50 microns.

Here, in-depth engraving technology is being developed to produce three-dimensional images of amazing clarity. A kind of 3D printer in reverse. The process can last several days, during which the products cannot be touched. Therefore, in the laboratory they are as heavy as possible.

Now we remember Chinese lasers, which produce a spot several times larger. If the radius of the spot is three times larger, its area is nine times larger, it turns out that, other things being equal, the Chinese laser will operate not at 10 W, but at ~1 W (this is still a positive scenario).

Now a little about the fiber laser itself. As you might guess, here the role of the emitting body is played by a long piece of optical fiber. Not exactly the same one that the Internet is running to you now, but the essence is the same, it’s just that the fiber structure is very different. What is the beauty of a fiber laser - the elementary cooling of the active medium. While engineers are puzzling over the problem of uniform cooling of a flask with gas or an entire crystal, there is no such problem at all with string optics. In fact, you can simply wrap it around a round piece of aluminum, call it a radiator, and the cooling problem is solved.

What happens in the end? My camera cannot convey the degree of detail of the images, but believe me, their perfect clarity literally cuts the eye.

Another easily solved problem is radiation pumping. An LED is soldered to the fiber, another one is soldered through a coupler, then another and another, and so on as many times as necessary until we get the desired flow.

Money issue

Why do laser engravers arouse maximum interest among production owners? Strange as it may seem, people always have a finite amount of money and maximum interest in the cheapest technology that gives an acceptable result. Therefore, if we take a conventional thousand laser machines, 900 will be for marking and only 100 for cutting, welding and other additive technologies.

Laser cutting machine at work. The final product is not a lattice, but what was in the empty cells.

As we agreed earlier, most likely, all laser modules are from the same manufacturer. So, all that remains is to learn how to benefit from it. To do this, we need to assemble a machine that consists of a marker field and a vertical rod along which the optical system will move (together this is called a scanner system). This mobility is needed to set focus. Or rather, the system’s focus is constant, but the marked products are all of different thicknesses, and this must be taken into account.

Why not fix the optics at one point? The answer is again in money - it is much easier to make a boom with a motor than to invent a lens with a variable focal length. The power supply and laser can be hidden in the base of the machine, after which all that’s left to do is change all the parts many times in search of the best combinations and write the software (sarcasm sign).

An example from medicine. A pin is installed in the holder, on which a very special microrelief is engraved, so that it is easier for the cells of surrounding tissues to attach to it. This manipulation greatly increases the effectiveness of the pin.

In the case of laser center machines, everything is written under Windows, because Most productions work on Microsoft technologies and there is no desire to start a format war with them. The market decided, as they say now.

The question of curved surfaces

An attentive reader will ask a question - you say that the product should be in focus. This means that its surface should be quite smooth. But let's look at the banal handle, it's round! How to apply an inscription on such a curved surface? Absolutely the right question!

I completely forgot what this thing is called, but everything is clear here. Using traditional methods, doing this is very time-consuming, expensive and difficult.

To do this, we need to consider how the optical part of the engraver works. If we put a regular lens in the lens, the beam will be focused into a sphere. In principle, everyone should know this from a school physics course. But what they don’t talk about in school is that it is possible to design a lens in such a way that the beam begins to focus into a plane. Of course, closer to the edges of the plane, the beam will go slightly out of focus, without this there is no way. But this is already a conversation about tolerances and errors. You can fight this by creating more and more complex lenses, but this is economically unjustified (not again, but again).

High-tech plastic nozzle for focusing. A better and simpler thing has not yet been invented in the world. Seriously.

How then to deal with this? No way! A well-focused laser beam allows us to achieve near-micron precision. Even if this accuracy drops to several micrometers towards the boundary of the working field, we will not see this without a microscope. Therefore, if we need really high accuracy, we can artificially limit the size of the working field so that the beam remains within the required errors. Hence an important conclusion: the machine can either have high resolution or work with curved planes. Harvesters that can do both equally well have not yet been invented.

All industrial machines come with their own frame, where an uninterruptible power supply is necessarily integrated. He has exactly one task: to remember the last action and turn off the machine. When power is returned, processing will continue from the same point.

Another important point is the size of the laser spot. No matter how well we tune the optics and the laser source, we will never get an infinitesimal point. This will always be a spot, the size of which depends on the optical system, the wavelength of the laser and the quality of the laser emitter itself. This is the very reason why IPG Photonics has become a virtual monopolist on the market. They manage to make lasers whose spot can be tens of times smaller than their Chinese counterparts. And a smaller spot means more power over its area, higher efficiency, etc. Moreover, the distribution of energy in the spot is not uniform, but according to the Gaussian distribution, but here we risk falling into unnecessary jungle.

One of the production laboratories. People had already left, but some of the engravers were busy with their work. Working for several days without a break is normal for them.

Therefore, with a pen (and other non-critically curved surfaces) everything is simple - without a microscope we will not see that the edges of the engraving on the slope will be blurred a little more than on the upper part on which the focus is set. In laser industry slang, this is called constriction - the height difference with which a given machine can work. And there are products (for example, the finest meshes used in vascular surgery, called stents), where accuracy is critical and such products are cut exclusively from flat blanks. There are many specific nuances here: if we work with multilayer electronics, where the layer thickness reaches 10 microns, we even have to take into account the material of the surface on which the workpiece is located. With thermal expansion of 2mm per meter for every 20 degrees, the base material is considered unsuitable. Therefore, a granite slab (of a certain type of granite) can be used as a substrate: excellent thermal coefficient and certain vibration resistance.

An example of a machine assembled on a granite bed.

About materials

If you look at the packaging of almost anything manufactured in a factory, you will most likely find traces of a laser marker. And most likely it will be a black alphanumeric code. Does this mean that when marking, the laser burns away the top layer of the material, leaving behind ash, decay and despondency? No. If we assume that this is so, such inscriptions could simply be erased, but they stick like a glove. Let's figure out what's going on.

When developing technologies that require micron precision, everything is controlled by a microscope.

In the previous paragraph we have already mentioned the laser spot size. Everything here seems simple. If you want more power, make a small spot; if you don’t need more power, you can get by with a larger one. But for some reason we forgot about the materials with which the laser interacts, and the technical processes, of which there are many: evaporation, melting, etc. But now we are only interested in one thing - changing the structure of the material.

Deadly number - eucariot puts his hand directly under the laser beam. However, the hand was not cut off, not burned, or anything at all happened: the radiation is not in focus, so its power is dissipated over a large surface. But if he had lowered his hand...

While physicists are looking for the spot size by looking at the Gaussian distribution (yes, there it is again), opticians have simply assigned it. Where the radiation falls by a factor is where the boundary of our optical beam is located. But this time the common people were in pain. It is important for us to simply determine the place (and its boundaries) where our technical process takes place. And here all the attention is on the object we are shining on. Each material reacts differently to different wavelengths and radiation powers. For example, if a pigment activated by a certain wavelength is added to plastic (paint, etc.), it acquires an interesting property. We place such a product under the laser, the base material does not react in any way to the incoming radiation, and the pigment is “activated” right inside the material, i.e. we only work with him. At the end of the day, our product will be without any damage to its integrity, but with an inscription integrated into the very structure of the material. This is very valuable in industries with aggressive environments, where the paint inscription can be erased, and the stamping can become dirty to the point of being unreadable. In the photo, for example, there is a tag for a cow. Until the tag itself falls apart, the inscription will remain readable. It is made of polypropylene, which interacts very poorly (read in no way) with the fiber laser, but the additives in it are just waiting to be irradiated. They take on all the energy that is transferred to polypropylene. It turns out to be a kind of intermediary.

Those cow tags with indelible images and other plastic products.

Everyone who has had their tattoos removed with a laser has encountered the opposite story: laser radiation penetrates the skin without interacting with it in any way, but is absorbed by the paint, destroying it. All use of lasers in cosmetology, surgery and other medicine is based on the transparency of the skin for certain wavelengths.

Tarnish colors

Another interesting application of laser engravers is the creation of colored designs on metal. The technology is based on tarnish colors and let's figure out what it is.

As we all know, metals like to interact with the atmosphere - this is called oxidation. Some metals oxidize quickly, some slowly, but if it is heated, oxidation will always occur here and now.

An example of possible colors on a specific product.

When white light interferes with thin oxide films, it seems to us that the surface has changed its color. The effect is well known to absolutely everyone who has ever heated any piece of iron or examined a fresh weld: rainbow stains appeared on the metal. Color directly depends on the thickness of the oxide film, which means that if we know the properties of the metal and at what temperature a film of what thickness is formed, then by arranging local heating and combining colored dots, we can create color images in the manner of an inkjet printer. In reality, everything is somewhat more complicated and films are fused onto each other, but within the framework of this article we will not go into such details.

The strength of these patterns is limited by the strength of the oxide layer, and they all fade over time due to the natural processes of new films forming on top of old ones. But as long as everything is fresh and the colors are bright, it looks very impressive.

At the top you can see a plate with a palette of possible colors and shades.

To what extent are domestic machines domestic?

A question that cannot be avoided when talking about domestic production, so let's see how it really is.

85% of the cost of the machine is the laser. The laser is made here, in the Moscow region, at the same NTO “IRE-Polyus” from which PG Photonics began, which was founded by our own physicists.

Optics (glasses and mirrors) are also made independently, only the glass is bought in England. Unfortunately, we do not have optical production facilities that provide the required quality. Engines and precision mechanics for scanners are made by three companies in the world (two English and one German), so they are purchased there.

All software is written in Russia from scratch.

Assembly area. All machines are completely hand-assembled.

This is the structure of good domestic laser machines. Whether or not to criticize domestic machine tool builders who develop and assemble machine tools from foreign components is a personal matter for everyone. You just need to understand that some of the components are simply not available on the domestic market. If we take the entire domestic machine tool industry, which does at least something and declares its products as domestically produced, their market share is estimated at approximately 8%, i.e. for the most part, they cannot even meet the needs of the domestic market, not to mention exporting their products.

The brain of a laser engraver.

About competition with the Chinese

You will be surprised, but she is not there. But specifically in industrial metalworking and fiber lasers. Over there, yes, for about 8 years now it’s been like a circus with horses and machines doing everything. The market situation is quite interesting now. On the well-known Aliexpress there are many machines for about 250,000 rubles. They are pretty lousy, repeat each other and are only suitable for home experiments. There are industrial-grade machines, they cost 2-3 times more, and no one brings them here legally. Of course, there are successful followers of business coaches and business youth who made a beautiful landing page, drove them to China, took beautiful photos there for the catalog and sell machines for a million. True, upon closer examination it turns out that the parameters of these machines are not very different from those on AliExpress, but this is everyone’s business. Someone also has to pay for a landing page with photos.

Next is the question of the target audience. If someone buys a DIY machine for their workshop, they are not competing with industrialists. This is just a machine for some of your small needs. If you buy a machine from guys with a beautiful landing page for production, then most likely you will fall into the scheme. Perhaps outright fraud with tenders, when equipment is purchased simply by the number of boxes. Perhaps you are dooming yourself to eternal repairs by paid specialists with constant visits to the client and additional adjustments of the equipment. And in the area of large industry, where the characteristics and results are not just important, but critical, there is a struggle between three pillars: bad (objectively bad), but cheap from China, expensive and good from Europe, good and cheaper than from Europe, but from Russia .

Manufactures that really delve into the characteristics of equipment and carefully select it have made their choice and domestic machines are sold to Europe, America and the rest of the world.

Engraver's head during assembly

Instead of output

This is the story about domestic laser engravers. Not too detailed, somewhat superficial, but the topic of laser processing is huge, and it’s difficult to cover everything at once. There are no representatives of the Laser Center on Habré, but I will forward all the questions from the comments to them. Or, if there is a well-wisher with an invite, we will invite them here for a fruitful conversation and, perhaps, ask them to reveal other secrets of their industry.

UPD : Invites have been found and sent, so we are waiting for first-hand answers. Thanks everyone.

Walking away and not engraving everything you can reach is the choice of cowards!

Main functions

The table of modern laser equipment is usually end-to-end. On such tables you can process workpieces of various lengths. Modern machine designs can be supplemented with various elements to increase functionality.

It can be:

- lifting table, thanks to which you can increase the height along the Z axis;

- rotating mechanisms that are used for processing cylindrical products;

- honeycomb surfaces designed for working with small workpieces.

The laser engraving machine can be automated thanks to the use of CNC. Such mechanisms will be expensive, but they will be more productive and convenient to use.

Using CNC machines, errors in engraving or cutting can be minimized. We can say that they are simply impossible to allow, since control occurs thanks to special software specially developed for such equipment. Difficulties can arise only due to errors made during the development of sketches.

There is no need to perform any manual work on such equipment. The operator’s main task is to monitor the smooth operation of the equipment and monitor the quality of the workpieces produced. Such machines are usually equipped with remote control.

CNC laser machines: features, advantages, device

A CNC laser machine is equipment that carries out all the necessary work with great precision. Automation of machine control makes it possible to use it in various fields: furniture, advertising, souvenirs, construction, mechanical engineering. CNC machines contain a special program in which workpiece drawings are created. After this, the workpiece appears on the working surface of the machine. Next, using a laser head, the part is cut out along the contour of the workpiece, if necessary, engraving is applied.

Features of laser machines

In laser machines, a laser beam is responsible for cutting. It is similar to a plasma arc, but processes a smaller area. The beam cuts hard and soft materials - paper or polyethylene. Using a laser beam you can achieve:

- Melting. The process occurs when working with metal and plastic workpieces. In the place where the laser is used, the area is blown. This is done using air or neutral gas.

- Evaporation. By means of pulses, the laser beam produces a boil on the surface. As a result, instead of the formation of chips, metal evaporation occurs.

- Decompositions. The laser beam can have an effect on materials that are resistant to heat. This treatment should not be used on materials that release toxic substances when decomposed.

You can insert any workpiece into the laser machine, make an inscription on it or apply a design. A drawing of a suitable format must be downloaded to the device. But many engravers manage to do such work through external media.

How does a laser tank

The laser machine has an executive tool. It is driven by a stepper motor. A program and a numerical control device are responsible for its operation.

In general, the CNC controls all elements of the machine:

1 laser tube. 2. Emitter head. 3. Reflective mirrors. 4. Focusing lens. 5. Focusing mechanisms.

The laser machine consists of: 1. Solid frame. 2. Horizontal work surface. 3. A mobile portal with a head through which the laser beam passes.

The high energy of the focused beam allows it to penetrate the material and cut it. That is, it changes the structure of the material. Such features of the machine are reflected in cutting and engraving activities. For a laser machine, the type of material is selected according to its power.

Using laser equipment you can cut: 1. Plywood. 2. Trees. 3. Acrylic. 4. Polyester. 5. Skin. 6. Glass. 7. Double-layer plastic. 8. Veneer and other materials.

Since the cutting tool is a laser beam, materials of different densities can be cut. And the output is products of various designs and sizes. Laser equipment is increasingly being used in unusual industries.

Advantages

Cutting with mechanical equipment is accompanied by the formation of dust and chips, which clog and dull machine parts. This complicates further work and increases its cost, since new equipment is required. When laser equipment is used, such problems can be avoided by properly configuring the cooling system.

The advantages of laser machines lie in the following:

1. They do not require complex maintenance. 2. They have a long service life. 3. The machines are easy to operate. 4. With their help, you can process materials of different sizes, shapes and densities without damaging them. 5. Processing is carried out with high quality. 6. When working, dust and chips do not form on them. 7. Their high precision processing does not cause large losses of material. 8. They are profitable to keep. 9. They are practically silent. 10. Easy to use.

When working with a laser, deformations at the edges of the workpiece are eliminated and less material is consumed. Compared to other types of equipment, laser machines are superior in terms of speed and cutting accuracy. The equipment has to be reconfigured if changes need to be made - any change is made to the layout.

The technology of laser machines is constantly improving. For example, souvenir products can be produced on LiMark machines, which are a good example when comparing price and quality.

Our specialist consultants will be happy to help you select the necessary equipment that will meet your tasks. You just need to contact us in any convenient way:

Send a request by email

Call: 8-800-555-14-45, +7-499-577-00-92

Write to messenger: +7-967-097-61-13, +7-967-097-61-15

Machine tools for metal

For cutting and engraving from this raw material, models with CO2 tools are often used. Laser equipment can be used for stainless steel, steel, brass, copper, aluminum. Such units have high beam power.

The modern market is filled with equipment of this type, designed for cutting metal sheets whose thickness is 2 cm. Each type of metal has its own cutting and engraving technology. For example, equipment for cutting stainless steel has units with which parts are treated with nitric acid. This substance can protect metal from fire and oxide.

For copper, machines with powerful working tools are used. Laser cutting on such equipment is done at low speeds. To work with copper, solid-state heads are used.

Processing steel or brass on a laser machine is the simplest. These metals do not require additional devices. Setting up the equipment is quite simple.

Laser cutting process

For laser cutting of metals, technological installations based on solid-state, fiber lasers and gas CO2 lasers operating in both continuous and pulse-periodic radiation modes are used. The industrial use of gas laser cutting is increasing every year, but this process cannot completely replace traditional methods of metal separation.

Compared to many of the installations used in production, the cost of laser cutting equipment is still quite high, although recently there has been a tendency towards its reduction. In this regard, the laser cutting process becomes effective only if there is a justified and reasonable choice of the area of application, when the use of traditional methods is labor-intensive or completely impossible.

Laser cutting is carried out by burning through sheet metal with a laser beam. This technology has a number of obvious advantages over many other cutting methods:

- The absence of mechanical contact allows the processing of brittle and deformable materials;

- Materials made of hard alloys can be processed;

- High-speed cutting of thin sheet steel is possible;

- When producing small batches of products, it is more expedient to laser cut the material than to make expensive molds or casting molds for this;

- To automatically cut the material, it is enough to prepare a drawing file in any drawing program and transfer the file to the computer of the installation, which will withstand errors of very small quantities;

Machine cost

The price of such equipment is influenced by many factors. The cost of a small model ranges from 90 to 100 thousand rubles. A more powerful machine with various accessories will be more expensive - from 200 to 500 thousand rubles. and higher.

Modern laser machines are reliable, high quality and productive. They are convenient to use for medium and small workshops. The price for purchasing equipment of this kind can be quite high, but due to the savings in material and speed of work, the payback of the machine will be quick.

Business plan: laser cutting of plywood

How to organize a business using a laser machine? Let's consider a case using the example of a production facility where plywood is cut.

You can install a laser device in a small warehouse, but fire safety standards must be taken into account. Then you need to find reliable suppliers of consumables, that is, the plywood itself. Every time you buy a batch of plywood, you should check the quality of the board - the accuracy of the design, the accuracy of processing and the strength of the finished product depend on this.

Before implementing the project, you should develop a cutting model on a computer, and then transfer the data to the machine.

The financial aspects of a business depend on the goals that the company sets for itself and the equipment chosen. As an example, let’s evaluate what you need to buy when using a large, powerful (100 W) LaserSolid 1080 Pro laser machine. The price of the device is 465,000₽.

The workroom must have a powerful exhaust hood, since cutting plywood produces a lot of dust and smoke. Space should be provided not only for the machine, but also for the materials used. At a minimum, you will need a room of 10 square meters. m. The cost of renting or purchasing premises depends on the region.

In addition to the machine, it is necessary to purchase a circular saw, because plywood sheets are much larger in area than the working area of the machine. You will need a grinder to remove carbon marks after cutting. We will also add the cost of the plywood itself.

Metal cutting with a laser: features of the method

In factories and workshops, various methods of cutting blanks from sheet metal with certain parameters are used. The most accurate and preferred method is the use of a laser system.

The cutting method itself is, in essence, cutting a workpiece from sheet metal of the required shape and in a certain quantity. Various methods are known that make it possible to obtain certain blanks from metal sheets. But many of them (for example, manual machines or metal shears) do not guarantee sufficient accuracy.

If there is a need to process sheet metal, and accuracy is important, then only a laser machine can help. Laser cutting is a method of cutting a metal sheet of a certain thickness using a high power laser.

The separation process occurs through a focused laser beam onto a specific area of the metal. At the point of contact, the temperature of the material rises to the melting point. The surrounding areas do not change their temperature, which allows the edge of the workpiece not to deform. The cutting line is accurate and quite thin, which allows you to save on consumables.

The basic operating principle of a cutting laser is to burn through a metal sheet with a high-temperature and precisely concentrated beam. The molten metal from the treated area is removed by a directed air flow or flows down randomly.