70

Category: Technologies and solutions

Workplace safety is the number one issue in industrial plants. Plants, whether refinery or chemical, have specific protocols in place that require constant monitoring of systems and the wearing of personal protective equipment (PPE) by employees. At the same time, equipment at technological installations must also have a number of safety functions: automatic light or sound alarms, the presence of safety valves.

The level of security at an enterprise depends, among other things, on:

- customer decisions to invest in the safety of employees and processes;

- the human factor, that is, the literacy and attentiveness of the personnel who are involved in the selection, purchase, installation and operation of equipment;

- the equipment itself, its design and technical characteristics.

In this article we will look at how a safety pressure gauge works and how its design protects the operator in the event of a Bourdon tube rupture. We also show a unique solution from a French pressure gauge manufacturer, tell you which standard safety pressure gauges meet, and provide excerpts from ANSI/ASME B40.100-2013 for a better understanding of the problem.

The material will be useful to everyone who is directly involved with parametric types of failures: technologists, process operators, shop managers. And also to plant managers, as employers, and purchasing specialists.

Operating principle of the pressure gauge

Pressure measuring instruments can be classified according to the following characteristics:

- Type of pressure measured

- Operating principle of the pressure gauge

- Purpose

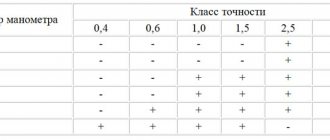

- Accuracy class

Pressure gauges contain a sensitive element that senses elastic deformation due to pressure. The design of a mechanical pressure gauge is characterized by the type of measuring element. It may contain a Bourdon tube, membrane, capsule or other deformation elements.

Why is a safe pressure gauge important?

A pressure gauge is a device that measures the pressure of a liquid or gas. This is a simple mechanical tool for technologists and personnel who service the system directly in the workshop. In essence, the pressure gauge duplicates the measuring function of a pressure sensor. The difference is that it does not transmit a signal to the controller, but shows the current value.

Explosion of a pressure gauge is a common problem in industrial production, which leads to accidents: if a pressure gauge explodes, a hazardous environment and fragments of the device itself can hit the operator.

The number of explosions and, most importantly, industrial injuries can be reduced by the use of safe pressure gauges and their correct use: correct selection of the range and the absence of pressure surges, fatigue and strong vibrations.

Operating principle of a pressure gauge based on the deformation of a Bourdon tube

This is the most commonly used principle in mechanical pressure measurement. The pressure "element" used is often called a Bourdon tube, named after the French engineer Eugene Bourdon, who used this functional principle in the mid-19th century. It uses an elastic spring, a c-shaped, curved tube with an oval cross section.

The operating principle of the pressure gauge is as follows. When the internal space is under pressure, the cross-section thus changes in the direction of a circular shape. The stresses that are created in this process increase the radius of the C-tube. As a result, the end of the tube moves approximately two or three millimeters. This deviation is the magnitude of the pressure. It is transferred into a movement that turns the linear deflection into a rotational movement and, by means of a pointer, makes it visible on the scale. There are different variations of Bourdon tubes. The C-shaped bent Bourdon tube can operate at pressures up to 60 bar. For higher pressures, helical or spiral Bourdon tubes are used. Depending on the geometry of the material thickness, the pressure can reach up to 7000 bar.

Bourdon tube: in detail in simple language

A Bourdon tube is an elastic element in instrumentation that allows monitoring pressures of all levels used in industry. It senses changes in pressure and converts these changes into mechanical movement. A Bourdon tube is usually connected to a pressure gauge, which displays the change in pressure on a graduated scale.

C-shaped Bourdon tube

The Bourdon tube is not an independent measuring device, but an auxiliary element that is installed in the measuring device. It allows you to create the pressure difference necessary to measure the flow rate of a liquid, gas or steam. Bourdon tube pressure gauges are the most common measuring instruments due to their low cost, versatility and high reliability.

Made from a variety of metals, including bronze, brass, and stainless steel. The choice of material is determined by the application environment and the level of measured pressure: the higher the pressure, the stronger the material.

Operating principle of a pressure gauge with a diaphragm measuring element

The operating principle of a pressure gauge with a membrane measuring element is as follows. The deformation from the measuring element is transmitted through the rod to the tube-sector mechanism, and then to the pointer. The membrane is a round corrugated sheet of metal, which has a larger area compared to a Bourdon tube pressure gauge. The membrane can be either welded to the top of the membrane chamber or fixed between two flanges, this allows it to absorb pressure forces from one side. This operating principle of the pressure gauge ensures that high overload pressure is maintained, and this is achieved due to the fact that the upper part of the chamber acts as a limiter.

Bourdon tube: in detail in simple language

A Bourdon tube is an elastic element in instrumentation that allows monitoring pressures of all levels used in industry.

It senses changes in pressure and converts these changes into mechanical movement. A Bourdon tube is usually connected to a pressure gauge, which displays the change in pressure on a graduated scale. C-shaped Bourdon tube

The Bourdon tube is not an independent measuring device, but an auxiliary element that is installed in the measuring device. It allows you to create the pressure difference necessary to measure the flow rate of a liquid, gas or steam. Bourdon tube pressure gauges are the most common measuring instruments due to their low cost, versatility and high reliability.

Made from a variety of metals, including bronze, brass, and stainless steel. The choice of material is determined by the application environment and the level of measured pressure: the higher the pressure, the stronger the material.

Operating principle of a pressure gauge with a capsule measuring element

The principle of operation of a pressure gauge with a capsule measuring element is similar to the principle of operation of pressure gauges with a Bourdon tube. Here, two round corrugated sheets of metal welded together are used as a sensing element. The measured medium acts on the inside of the capsule and, based on the resulting movement of the sensing element, the determined pressure is displayed on the dial.

You can find out more about the device here.

Video

Accurate readings of pressure gauges and thermometers | What should you pay attention to?

Video

How does a pressure gauge work? Comparison of a Bourdon tube with a membrane

Spring Pressure Gauge Practical

Practical work

Goal of the work:

study of spring pressure gauges of the OBM type (device, principle of operation, operation).

Spring pressure gauge type OBM

A pressure gauge (from the Greek manos - rare, loose and metreo - measure) is a device for measuring excess pressure (pressure above atmospheric) of vapors, gases or liquids enclosed in a closed space. A type of pressure gauge is a vacuum gauge - a device for measuring pressure close to zero and a pressure-vacuum gauge - a device for measuring vacuum and excess pressure.

The most popular among consumers are pressure gauges with a Bourdon tube or deformation pressure gauges, the design of which was invented by E. Bourdon in 1849.

The Bourdon tube is the main structural element of the pressure gauge, its sensitive element, which is the primary pressure transducer.

The Bourdon tube is usually made of brass or phosphor bronze, has a semicircular shape for low pressures, and a coil shape for medium and high pressures. One end of the tube is connected to the inlet fitting of the pressure gauge, which is the connecting element to the medium being measured, and the other end is sealed and located in a cantilever. By using tubes of a more complex shape (spiral, helical), it is possible to obtain devices with greater sensitivity, but a smaller measurement limit.

Operating principle of deformation pressure gauges.

Under the pressure of the medium, the cantilevered end of the Bourdon tube moves - the tube tries to straighten. The magnitude of this movement is proportional to the magnitude of the pressure.

A simple gear-lever drives a pointer that indicates the pressure value on the instrument scale. Most pressure gauges of the domestic brands MP, MTP, DM TM, M 3/1, OBM, MTI, MPTI, MO, German pressure gauges Wika 111.10, 111.12, 213.53, RCh, RСhg, RChgG and pressure gauges from other manufacturers have such a device.

A general view of the OBM type spring pressure gauge is shown in Fig. 1.

Figure 1 – Spring pressure gauge type OBM

Figure 2 — Diagram of a pressure gauge with a Bourdon tube

1-Bourdon tube, 2-rod transmission mechanism, 3-tooth sector, 4-pointer, 5-fitting

Tubular springs are used as sensitive elements in pressure gauges. As can be seen from Fig. 3, one end of the tubular spring 3 goes into the fitting 7 for receiving the measured pressure. Under the influence of pressure, the free end of the pressure tube 5 will be deformed (bent), and the amount of elastic deformation is proportional to the measured pressure. Due to this relationship, measuring needle 1, due to the movement of the kinematic unit (tribe 2 - sector 4 - driver 6), shows the true value of the measured pressure relative to the instrument scale.

Figure 3 – Kinematic diagram of a pressure gauge with a Bourdon tube

1-arrow, 2-tube, 3-spring, 4-tooth sector, 5-pressure sensor (manometric tube), 6-lead, 7-fitting

Spring indicating and recording pressure gauges are repaired by the repair services of the metrology department. To do this, in a special area, workplaces must be equipped with backup glasses of a standard range with a diameter of 60, 100, 160 and 250 mm, standard scales, and special pullers for removing measuring needles from the instrument axes; clamps for fastening parts of pressure gauges, a set of ladders for restoring clogged threads of fittings M 20X1.4, devices for drawing scales, sets of tweezers and watch magnifiers, sets of small gas burners for soldering sensitive elements (springs).

The most labor-intensive operations are replacing the sensitive element (tube) of the pressure gauge and adjusting the kinematic link “sector - tube” (see Fig. 3).

The sensing element of the device is replaced after it is used to measure pressure exceeding the maximum. As a result, the tube stretches, causing residual deformation that cannot be repaired. To repair such a device, it is completely disassembled, the fitting 7

secure in a vice and, using a gas torch, remove tube

5

from the board. After the solder has melted, the faulty tube is removed with pliers, and in its place, after cleaning the surface, a similar gauge spring is installed (at a given pressure measurement limit). The soldering area is treated with a solvent - rosin with acetone (alcohol) or hydrochloric acid.

Absolute pressure gauges

This type of pressure gauge is designed to measure pressure independent of ambient pressure (independent of atmospheric pressure fluctuations). As a rule, they have a device similar to ordinary pressure gauges with a leaf spring, with the only exception that there is a vacuum on the back side of the membrane.

Pressure range from 0..16mbar to 0..40bar. Accuracy class from 0.6 to 2.5.

Differential pressure gauges

Series G60 For measuring differential pressure.

Series G61 For measuring differential pressure.

Series G62 For measuring differential pressure.

In stock:

4

pcs.

Series G63 Technical parameters

IP class: IP54 temperature: 0°C to 60°C Ambient temperature: up to 100°C Accuracy class: 3.0 Window: Glass Mechanism: 304 stainless steel Housing Housing and bayonet ring: 304 stainless steel Contact Parts: 316 Stainless Steel Bourdon Tube and Fitting

The G63 Series pressure gauges are designed for differential pressure measurement in high operating pressure applications. This piston differential pressure gauge offers special advantages due to its compact, modular design. This makes it possible to replace the measuring system and indicator housing directly on site, as well as subsequent installation and adjustment of electrical contacts.

Series G64 Pressure: up to 200 bar Temperature: up to 80°C Scale diameter: 100mm, 150mm Housing material: Stainless steel Connections: 1/4" NPT female

Series G65 Pressure: up to 200 bar Temperature: up to 80°C Scale diameter: 100mm, 150mm Housing material: Stainless steel Connections: 1/2″ or 1/4″ NPT, M20x1.5 internal

Series G66 Pressure: up to 200 bar Temperature: up to 80°C Scale diameter: 100mm, 150mm Housing material: Stainless steel Connections: 1/2″ or 1/4″ NPT, M20x1.5 internal

Series G67 Pressure: up to 30 bar Temperature: up to 80°C Scale diameter: 100mm, 150mm Housing material: Stainless steel Connections: 1/2″ or 1/4″ NPT, M20x1.5 internal, large size connection available with adapter

Series G68 Pressure: up to 200 bar Temperature: up to 80°C Scale diameter: 100mm Housing material: Aluminum Connections: 1/4" NPT female

Series G69 Pressure: up to 200 bar Temperature: up to 80°C Scale diameter: 100mm, 150mm Housing material: Aluminum, stainless steel Connections: 1/2" or 1/4" NPT, M20x1.5 internal

How does a diaphragm pressure gauge work?

As a sensing element, a diaphragm pressure gauge uses a membrane that acts on a mechanism connected to a pointer. The measured pressure supplied to the pressure gauge deforms the membrane, which in turn causes the needle to move.

The measuring range of a diaphragm pressure gauge depends on the stiffness and area of the membrane.

Diaphragm pressure gauges are suitable for working with aggressive media; they are used to measure pressure in: