A stapler is a compact tool designed to connect various elements using metal staples. There are two types of staplers - stationery and installation. Stationery ones are designed for fastening paper sheets, and mounting ones are for connecting solid materials, the density of which does not interfere with the passage of fasteners.

Stationery stapler

Stationery staplers provide end-to-end fastening of sheets of paper with staples and subsequent bending of their tails. Thanks to this, the reliability of the connection increases significantly. The operating principle of this device is very simple. A plate with staples loaded into the feed tray is subjected to point pressure, as a result of which one of them breaks off. It cuts into paper sheets, piercing them through, after which its tails rest against a special rigid plate that has indentations, which leads to their bending at a given angle.

A standard office-type stapler is designed to work with staples 6 and 8 mm high. Their rigidity is quite sufficient for punching up to 50 sheets. For more serious tasks, large devices are used that work with tall staples made of thick wire. Large staplers are designed for staples up to 26 mm high.

Fasteners for staplers are sold in packages. Each of which contains 20 plates, consisting of 50 brackets connected in a row. Thus, the pack is enough to carry out 1 thousand fixations.

To achieve high-quality joining of sheets of paper, it is not so much the design of the stapler itself that is important, but rather the use of high-quality consumables. A cheap tool that works with good fasteners will be significantly better than an expensive one with cheap consumables installed. Still, it cannot be said that the cost and quality of the instrument itself does not matter.

Cheap ones work well at first, but over time they begin to jam as a result of the reduced efficiency of the spring that feeds the staples. In addition, the extrusion mechanism may become deformed, as a result of which the impact begins not on one bracket, but on several at once. As a result, the tool becomes clogged as a result of several fasteners simultaneous exiting through the narrow feed slot.

With most staplers, the staple is extruded directly by a special plate, which extends when you press on the body of the device with your hand. Expensive and large devices designed for punching cardboard and large quantities of sheets have a more advanced design. They have an additional spring that acts as an amplifier. A special shoulder mechanism increases the force obtained from pressing, resulting in the release of the staple with less strain on the hands.

Additional features of office staplers

At first glance, a stationery stapler seems to be a completely simple design, which is unlikely to have any additional uses. This is wrong. For example, few people know that the plate into which the tails of the staples rest before bending can turn over. It has two installation positions. In the first, the technological recesses for bending the tails are close to each other, and in the second they are wider. In the first position, the staples are bent inward, after which their tails cut tightly into the sheets of paper being connected on the opposite side. In the second position of the plate, when the recesses are widely spaced, the staples bend outward. This type of fastening is used in cases where you need to temporarily attach a stack of paper, but in the future it will have to be disconnected. This fastening method provides reliable fixation, but at the same time, minimal effort is required to remove the bracket.

Also, many models of office staplers can open up, as a result of which their shape turns from an acute angle into a straight line. This technical solution in the design is made for the purpose of driving staples into the surface without bending them, which is necessary when attaching paper sheets to various materials. For example, using a tool in this position, you can attach a notice to a board or tree trunk.

Some varieties of the instrument have a protruding pointed plate at the opposite end. It is necessary to remove previously clogged staples. To do this, you need to drive it under the installed staple and pull the stapler towards you. It is worth noting that this method is quite productive, but not the best. It is much more convenient to use a special tool called an anti-stapler.

Mounting staplers

The mounting stapler is used for nailing various materials with staples. The reliability of such a connection is in no way inferior to small nails, while the nailed material receives a larger pressing area than the head of a nail or screw can provide. This is especially important in cases where fabric or plastic film needs to be fixed.

There are three types of mounting staplers:

- Mechanical.

- Electrical.

- Pneumatic.

Mechanical stapler

Is the most popular. This is facilitated by its low cost, thanks to which everyone can afford it. It can be used anywhere because it does not need to be connected to an electrical outlet or a compressor. Its design is very simple and has much in common with a stationery stapler. The only difference is that the mounting models have a much more powerful spring, the erection of which to strike the staples is carried out by a special mechanism with a handle. When you squeeze the trigger mechanism with your palm, one operation is carried out.

It should be noted that a mechanical stapler quite often fails to cope with the task. The spring used in it wears out over time and becomes softer. As a result, the staple can only penetrate halfway into the material. Often it warps to the side and simply becomes deformed. These problems are especially common in the cheap segment. As for expensive devices, they last much longer. The disadvantage of all mechanical staplers is the need to apply significant effort to hammer each staple. If you need to make several dozen fastenings, then this is not a problem, but when you have to work for a long time, your hand gets very tired.

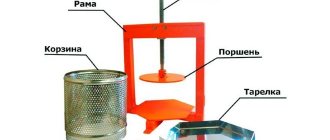

Stapler device

The main elements that ensure the operation of any stapler are the magazine and the impact-return device. The magazine contains a holder with U-shaped guides into which a cassette with consumables (staples, nails) is inserted. The magazine is equipped with a consumable supply mechanism and is made in the form of a spring-loaded pusher, on one side having a thrust plate, on the other - a clamp for fastening in the shop. The impact-return device is a striker made in the form of a plate with dimensions corresponding to the dimensions of the staples or pin used, the diameter and length of which correspond to the length and diameter of the nail head. The firing pin is mounted on a firing pin, which has a shape depending on the design of the stapler and, on the other hand, rests against a spring, the force of which is regulated by a screw. To eliminate shock loads, the device is provided with a buffer (shock absorber), which is made in the form of a polyurethane gasket installed in the device body.

The device is controlled:

- in a mechanical stapler - with a lever hinged on the stapler body and, on the other hand, having a movable rocker arm that fits into the groove of the striker;

- in an electric stapler, the function of the striker is performed by the electromagnet solenoid. When the button is pressed, the contacts close. The current passes through the elements of the control unit, made in the form of a circuit board, to the electromagnet coil, as a result of which the device operates;

— in a pneumatic stapler, the piston of the pneumatic cylinder performs the hammer function. When the trigger is pressed, acting on the pneumatic distributor, compressed air enters the cavity of the pneumatic cylinder, resulting in an impact action.

The sequence of adjusting the stapler

Setting up a staple gun is needed in the following cases:

- after purchasing the tool before starting work;

- if the stapler stops completely driving in the fasteners;

- when starting to work with a material of a different density than the previous one.

If the stapler stops driving in the fasteners completely, this is due to gradual wear of the spring of the impact mechanism or its loosening. For some time, the adjustment will help, but after that you will need to purchase a new stapler.

You should take into account the dimensions of the fasteners for which the tacker is designed: if the size of the staples exceeds what is allowed according to the operating instructions, then adjustment has nothing to do with it, you just need to select the appropriate consumables.

Mechanical staple guns with a coil spring have a screw that regulates the degree of compression. It is shown in the photo below with a red arrow.

If you tighten the adjusting screw clockwise, the spring will compress more strongly and its potential energy will increase. The result will be a blow of greater force. The ejected staple will go deeper into the surface of the material. Turning the adjuster counterclockwise will loosen the spring. The blow will also become weaker. By rotating the screw, you can adjust the stapler to work with material of varying hardness (density).

For mechanical models of staple guns with a spring (leaf) spring of the impact mechanism, the regulator is located under the handle. By rotating it in different directions, the force of the shot is adjusted. It is necessary to reconfigure the impact mechanism every time you start working with a different material. After adjusting the spring compression, it is recommended to test the tool's performance on a workpiece that is no longer needed.

The adjustment process ends when the fastener with the entire length of the legs enters the material without piercing it with the “back”. It is recommended to practice by rotating the adjuster from minimum to maximum spring compression.

Types of faults and repairs

Absence of a fastening element (staple/nail) in the materials being fastened . Most often it occurs when consumables leave the store. The stapler should be rendered inoperative. The cartridge with consumables is removed from the holder. If possible, remove the pusher. The clip tilts to the side, as it is hinged. The jammed part (staple/nail) is removed with tweezers or a narrow flat screwdriver. Next, the stapler is prepared for further work in the reverse order.

The slaughter of fastened materials with two or more elements (staple/nail) . This can happen due to two reasons. The first is due to wear (bevel) in any direction of the end surface of the striker. The impact device cover must be removed. Disconnect and remove the firing pin. Bring the end surface of the striker to the correct shape with a fine file or sandpaper. The main condition is that the end surface should not have a convex appearance. Otherwise, the edges of the staples will protrude when slaughtered. To maintain the action distance of the striker, grind off the supporting surface of the buffer/shock absorber (polyurethane gasket), adjacent to the body of the impact device, to a size corresponding to the size of the striker being ground.

The second is the deformation of the guide surface of the impact device body. For mechanical staplers, this is deformation of the surface of the casing adjacent to the firing pin.

Removed with a hammer or pliers.

The drummer works “idle”.

In mechanical staplers, it occurs as a result of early dismounting of the rocker arm from the supporting surface of the striker groove. In this case, a bevel is produced in this place, which is removed strictly perpendicular to the surface of the striker with a file.

The office stapler is broken: how to fix it

In case of breakdowns, you need to act according to the situation. If we are talking about small devices (pocket or tabletop), it is best to say goodbye to them right away. However, you can carry out simple DIY repairs. Someone will think about how to open and disassemble a paper stapler. Others will act decisively:

- Remove the housing box.

- They will pull the magazine out of the chute.

- Remove consumables stuck at the outlet. A thin screwdriver or tweezers will help them with this.

- The spring mechanism will be returned.

- The housing will be installed.

- Fix the lower and upper parts, connecting them to each other.

Types of staplers

In stores that specialize in selling office supplies, you can find various devices for binding papers. There are so-called pocket options. This category includes any office stapler that can be easily placed in the palm of your hand. The housing of such devices is usually made of plastic. They can sew a small number of sheets at a time. Their main advantage is their low price. But it is worth remembering that they are not suitable for intensive work. With active use, they will very soon have to look for a replacement.

Desktop staplers are most often purchased for offices. It is not advisable to fasten papers by weight with them. The devices are designed to work on a hard, level surface. At the bottom, they usually have a special anti-slip coating that prevents them from moving around the table even under load.

The large stationery stapler differs even in its appearance. It is equipped with a special lever that must be pressed in order to fasten sheets of paper. The most powerful models can staple up to 260 sheets simultaneously. They are often equipped with special devices designed to remove bent staples. Some devices have a special locking bar. It is designed to adjust the bonding depth.

Not just parentheses

Some staplers can work not only with staples, but also with studs of various shapes. The designations of what the stapler works with are indicated on its body or in the instructions.

I tuck the nails into the stapler in the same way as with staples, but you need to be careful after pulling out the spring. A row of nails must be loaded along one of the outer edges of the letter “P”, and not inside this very letter!

If you want it to produce two nails side by side when working with a stapler, load the second row along the second outer edge. Next, the spring is inserted and the stapler is closed.

QUALITY STATIONERY SUPPLIES

AND PAPER FOR CORPORATE

AND WHOLESALE CLIENTS

www.skrepka24.ru - office supplies for wholesale and corporate clients.

UsefulStaplers

Staplers

A stapler (translated from English as “stapler”) is a necessary thing in the office. A stationery stapler is designed for quickly fastening sheets of paper using metal staples.

Types of staplers

Staplers are divided into several types: according to the number of sheets that can be stitched simultaneously.

Mini stapler

Compact model that can be put in your pocket. Staples from 10 to 20 sheets. Staples for mini-staplers come in different sizes: 10, 24/6. The design and color of the case is very interesting: colored, transparent, there are devices that look more like a toy than a stapler itself.

Desk stapler

The stapler is quite compact, does not slip on the table and does not leave scratches on it, as it has a rubber sole. Stitches from 10 to 50 sheets. Standard staples are used: 10, 24/6-8.

Booklet stapler

A specialized stapler with adjustable stitching depth. Equipped with a ruler for ease of use. Sews brochures, catalogs and newspapers along the fold of the pages. Designed for different numbers of sheets, works on different staples.

Printing or typographic stapler

The most powerful stapler. Stitches archives, voluminous stacks of paper. Used in government agencies, libraries, clinics. On average it stitches up to 250 sheets. Designed for both standard staples and specialized ones.

Antistapler (destapler)

Designed to remove staples from paper. The anti-stapler is often built into the stapler itself; it extends from the back of the stapler and uses a pointed tip to pry up and remove the staple. But what looks much more original on the table is a small object resembling a frog, which firmly grips the bracket on both sides. Anti-staplers come in the form of ordinary paper knives with a curved tip.

Stapler-plaer Plier is a special stapler in the form of pliers, it can be used in a canopy. Plyer is used by florists when packing bouquets; it is suitable for attaching labels or labels to fabric.

Read also: VDU 506 muz transcript

Tucker

This is an “installation stapler”, made in the form of tongs. Hammers staples like nails. Used for pinning announcements and posters. Interestingly, many desktop staplers found today perform the function of a tacker.

Staplers also vary in the type of staples that are used with them.

Stapler No. 10

Designed for fastening a small number of sheets, usually up to 15 sheets of standard weight paper.

Stapler No. 23

The most powerful stapler. Works with 23 types of staples. Depending on the length of the leg of the staple used, it fastens up to 260 sheets of paper.

Staplers No. 24

A universal stapler that staples both small quantities (1-2 sheets) and large quantities (20-30 sheets).

What to look for when choosing a stapler

• Staples

There are always two numbers written on the staples, for example, 24/6 - what does this mean?

The first number is the type of bracket. This is a conventional unit, which includes the staple width, cross-sectional dimensions and wire steel grade (caliber) defined for this standard.

The second number is the height of the leg. It is measured in millimeters. The greater the height of the leg, the greater the number of sheets that can be fastened. The thickness of the bracket increases in proportion to its height. To determine the maximum thickness of the sheets to be sewn, subtract 3-4 mm from the length of the legs for their bend.

When choosing the length of the staple leg, remember the main rule - 2/3 of the leg should be in the material being fastened, and 1/3 will hold the material being attached.

A high-quality staple is made from cut wire (equal in diameter on any segment) - then all staples will be equal. A quality staple has pointed ends that allow it to pierce paper easily.

What material should I choose for the bracket? To fasten thick paper and large stacks, we recommend using steel wire staples, as they are stronger than galvanized iron. By the way, all staples with a leg height of 10 mm or more are made of steel.

The quality of the staples is related to the reliability of the stapler, so if you buy a quality stapler, then it is worth purchasing the corresponding staples.

• Internal structure of the stapler

The internal mechanism of the stapler is very important and will affect the operation of the device. The stapler motor system is driven either by a spring or a special metal plate. What's better? The plate is more practical: it lasts longer and provides softer sliding, and the spring has a habit of stretching. The stapler tongue is made of metal (more durable) or plastic (provides smooth feeding of staples).

• Housing and design

Pay attention to the material from which the stapler is made - its durability depends on it. The metal case is more reliable in operation and looks very impressive. But plastic also has advantages: it is lighter, more convenient for transportation, and more pleasant to hold in your hands. Models with combined cases are very convenient: metal + plastic, metal + rubber, metal + plastic + rubber.

The color of the stapler depends on the size and specific application. The more powerful the stapler, and the more functions it performs, the more subdued its color.

• Power and depth

The characteristics of a stapler always indicate the punching power (or volume of fastening) - how many sheets or millimeters of paper the stapler punches. As a rule, office printing paper with a density of 80 g/m2 is taken into account.

The punching depth is the distance from the edge of the paper to the punching point. The depth of firmware in mini-staplers is 35-40 mm, in desktop staplers – from 50 mm or more.

• Package

The packaging will always tell about the quality of office supplies, be it a stapler or staples for it. In addition, the product itself must have markings indicating the country of origin, company and type of bracket used. Sometimes a package of staples is included with the stapler.

• Paper

The thickness of a standard sheet of office paper is 80g/sq.m. It is worth considering that depending on the thickness of the sheets being stapled, the power of the stapler will also vary.

How to charge a stapler

Before you load your stapler, determine the size of staples that will fit it. The number of the staple used in a particular stapler is written on the packaging.

Bend the cover of the stapler. It is connected by a spring to a plastic element that presses the staples against the opposite edge of the metal groove in which the staples are placed. Opening the cover will pull the spring, followed by a plastic element, thus freeing up space for new staples.

Take one section of staples and place them in the metal groove, ends facing down. Close the lid and click the stapler once to test. If a staple with concave ends falls out of it, it means everything is working, but if this does not happen, or the staple is bent incorrectly, repeat the procedure or change the stapler.

Stapling Types

There is also an open type. In this case, the staples are bent outward. This method is preferable to use in cases where only temporary stitching of sheets is necessary. Papers fastened in this way can be easily separated, and the marks are practically invisible.

Sometimes in offices they use a special stationery stapler with straight staples. It is necessary in situations where it is necessary to attach paper (some kind of announcement or document) to a special board with a soft surface. It can be made, for example, from cork.

Important nuances

It is also important to note that staplers vary in power. This indicator determines how many sheets your device can fasten at a time. By the way, it is also important to choose the right staples for a stationery stapler. It is advisable to know not only their size, but also the manufacturer. It should be taken into account that thicker brackets are required for more powerful devices. Otherwise, they will bend and break when you try to sew them through a stack of papers.

In addition, you need to know that there are devices that only work when resting on a table or other flat surface. If you try to fasten papers by weight with such a stapler, the staples will fall out or become deformed.

Tips for extending service life

To maximize its service life, it is necessary to store the construction stapler under the following conditions:

- relative air humidity not exceeding 70%;

- the temperature must be above +5 degrees Celsius;

- The air in the storage area should not contain alkali or acid vapors, as well as dust and abrasive inclusions.

In order to repair a stapler, in many cases you only need to correctly adjust the depth of the shots, adjusting it to a specific material, and also use high-quality fasteners that are suitable in size . When a staple gun doesn't work at all, more extensive repairs will need to be made, often involving replacing broken or worn parts. When performing repair operations, be sure to remember about personal safety: remove consumables, put the device on fuse and turn off the power for electric and pneumatic models.

Today, many jobs that were previously done with just a hammer and nails can be done with a stapler. This tool is needed to connect some soft materials together or attach them to a hard surface. Moreover, if, for example, a stationery stapler is intended only for paper and thin cardboard, then a construction stapler has a wider application, as well as a furniture stapler. The stapler is used not only in the home, but also in production. Naturally, household models of tools cannot be compared with professional ones. However, they are cheaper, and they cope with their direct responsibilities very well.

Additional options

It seems to many that a stationery stapler is a fairly simple device that cannot be improved in any way. But manufacturers are making it more convenient to use. So, when purchasing, pay attention to the fact that there is a plastic footrest or rubberized inserts at the bottom. They will protect your table from scratches.

Another important and convenient addition is the presence of a built-in destapler. This is a special device with which you can quickly straighten the staples. It will come in handy in situations where you need to separate previously fastened sheets. It is inconvenient to pick out staples with scissors, much less with fingernails, and it looks unsightly.

Principle of operation

If you are serious about choosing a tool for stapling papers, then you will be interested in the device of a stationery stapler. Staples are inserted into a special metal trench. They move forward using a spring or a special plate.

It is worth noting that the second option is considered more practical. This is due to the fact that springs tend to stretch over time; they can slip off the hooks on which they are attached. The plate can ensure smoother operation of the moving tongue. It ensures that the clip of staples is always fixed at the edge. The push rod can be made of metal or plastic. In the first case it will be more reliable.

Classification of staples used

To use a staple gun, you need staples. They are divided into separate types according to the following criteria:

- according to the material from which they are made;

- by degree of hardness;

- by the presence of coverage;

- by size;

- according to form.

Staples according to material are:

- aluminum, used when working with non-solid materials;

- copper (expensive), also intended for soft parts;

- steel, suitable for both non-hard and soft materials, but will rust over time;

- made of stainless steel (stainless steel) is a reliable option in a wide variety of conditions, but has a high price.

By hardness

Based on hardness, fasteners are divided into the following types:

- simple;

- very hard;

- hardened.

The ends of the fastener can also be sharpened differently, making it easier to drive in under certain conditions.

By shape

Based on the shape of the staples, the following types are distinguished:

- U-shaped;

- U-shaped;

- T-shaped (pins).

Most often in practice, fasteners in the form of the letter U are used, and U-shaped ones are used mainly when laying cable lines. Pins are almost invisible fasteners. They are used when fasteners must be as invisible as possible.

Loading the stapler

Staples are inserted into the internal mechanism, which, when pressed sharply on the device, shoot and fasten the sheets. When the clip runs out, it simply needs to be replaced with a new one.

If you have a full-load stapler model, then you need to insert 1 new plate of compressed staples into it. But there are other options - they put ½ of the clip. The usual pocket and office options are easy to figure out. To change the staple plate, you don’t need to look for what the schematic of a stationery stapler looks like. Simply lift the top cover and insert the clip into the groove.

There are special models with front loading. They have a button on the body, pressing which you release the spring of the mechanism. At the same time, the gutter moves forward.

It's a little more difficult to deal with professional devices. Some of them can even load 7 types of staples. At the same time, users have the opportunity to adjust the mounting depth.

How to insert staples into the receiver

The design of all mechanical hammers is almost the same. There is a handle-lever, due to which pressing occurs, and at the bottom of the stapler there is a metal plate that opens the receiver. This is where we have to load the staples.

Read also: Nickel cadmium batteries device

Before you buy brackets at a hardware store, you need to find out what size will fit your device. As a rule, the size and type of suitable staples are indicated on its body.

For example, the body of our stapler indicates a width of 12 mm and a depth of 6-14 mm. This means that you will only be able to charge staples in this range.

Smaller or larger brackets will not fit into the receiver. The size of the staples in millimeters is also indicated on their packaging.

To insert projectiles into the stapler, you need to open the metal plate on the back surface.

To do this, you need to take it with your thumb and forefinger on both sides, then pull it towards you and slightly down. Thus, we press the metal tab on the back surface of the plate, and pull out a metal spring, similar to the one found in a regular office stapler.

If there are any staples left in your stapler, they will fall out once the spring is pulled out. If they are not there, then it’s time to install new ones for further work.

The staples are inserted into the receiver (the hole is in the “P” position). Next, insert the spring back, closing the metal tab. That's all, the tool is loaded and ready to go!

Stapler device

The main elements that ensure the operation of any stapler are the magazine and the impact-return device. The magazine contains a holder with U-shaped guides into which a cassette with consumables (staples, nails) is inserted. The magazine is equipped with a consumable supply mechanism and is made in the form of a spring-loaded pusher, on one side having a thrust plate, on the other - a clamp for fastening in the shop. The impact-return device is a striker made in the form of a plate with dimensions corresponding to the dimensions of the staples or pin used, the diameter and length of which correspond to the length and diameter of the nail head. The firing pin is mounted on a firing pin, which has a shape depending on the design of the stapler and, on the other hand, rests against a spring, the force of which is regulated by a screw. To eliminate shock loads, the device is provided with a buffer (shock absorber), which is made in the form of a polyurethane gasket installed in the device body.

The device is controlled:

- in a mechanical stapler - with a lever hinged on the stapler body and, on the other hand, having a movable rocker arm that fits into the groove of the striker;

- in an electric stapler, the function of the striker is performed by the electromagnet solenoid. When the button is pressed, the contacts close. The current passes through the elements of the control unit, made in the form of a circuit board, to the electromagnet coil, as a result of which the device operates;

— in a pneumatic stapler, the piston of the pneumatic cylinder performs the hammer function. When the trigger is pressed, acting on the pneumatic distributor, compressed air enters the cavity of the pneumatic cylinder, resulting in an impact action.