What is a manual hoist and where is it used?

Electrical diagram of a VAZ 2115 car

A manual hoist is used to lift and lower all kinds of loads when performing loading and unloading, installation, repair and construction work.

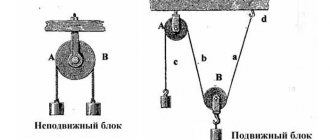

The unit can be operated at temperatures from -20 to +40 degrees. You can use a manual hoist to move loads in a horizontal plane if the mechanism is equipped with a cat. The design of a manual hoist includes a body with a mechanism for lifting loads, as well as a hook suspension from which the load is suspended. When lifting a load, a gear-gear transmission operates, which is manually activated by a chain thrown over a sprocket. The drive and movable sprockets of the hook suspension are wrapped around a welded or plate load chain. The manual hoist has a brake that prevents the spontaneous lowering of a lifted load.

The manual hoist has a wide range of lifting capacities and lifting heights. Structurally, a manual hoist is designed to be used by one person. Manual hoists are commercially produced with the following parameters: load capacity from 500 to 5000 kg, lifting height from 3 to 12 m. A manual hoist is a very useful and, in some cases, necessary device, which is installed in small car repair shops, used in small construction and other facilities. In case of failures in the supply of electrical energy in production, manual hoists turn out to be indispensable devices.

However, manual hoists have some disadvantages. For example, mechanisms require physical effort from workers, and are also inferior to electric models in terms of speed. Based on the type of suspension, manual hoists can be divided into the following categories:

- Mobile. They are suspended from trolleys that move on I-beams fixed to the object.

- Stationary. They are attached to the structure using the top hook.

Manual gear hoists are lifting mechanisms that consist of a gearbox and chain hoist, drive and brake mechanisms, load and traction round-link chains, and a movable block suspension with a hook.

The gearbox of the device is a two-stage, two-flow coaxial cylindrical gearbox with a load-bearing disc brake on the input shaft. This is required for smooth lowering and automatic stopping of the load when operating a manual hoist.

These hand-held devices can be hung permanently on a special hook or equipped with a mobile cat cart.

Category: Interesting » Industrial equipment

Technical characteristics of gear hoist

A device consisting of only a few nodes, by definition, must be extremely reliable. However, the strength declared by the manufacturer does not always correspond to reality. That is why it is desirable that the description of the hoist indicate the alloy from which the gears are made. The best option for gear material is alloy steel containing from 0.1 to 0.6 percent carbon. It is better to choose blued or galvanized chains, that is, those that are sufficiently protected from corrosion. The mechanism is usually protected from impacts by a reliable casing.

All hoists, including gear ones, come in different models, each of which has a certain load capacity. The latter usually corresponds to other parameters, such as the diameter of the chains, their number in the block and weight per meter, as well as the weight of the hoist itself and its dimensions. The last two characteristics are taken into account together with the chains, that is, from the upper hook (hook) to the lower hook (traction) at its highest point. As for the height for which the lifting devices are designed, it varies from 3 to 12 meters for different models. All of the above indicators can be seen and compared in the table:

Elektrotal

Wheels for VAZ 14

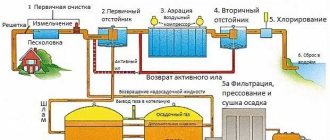

Electric hoists can be stationary, portable and mobile. The former are used only for lifting loads; they are attached to the beams or floors of the workshop. Portable electric hoists are suspended from the top hook, similar to manual hoists.

The electric hoist consists of a drum for winding rope, a pulley and a trolley moving on a monorail.

Electric hoists, unlike manually driven hoists, have a more complex design and are driven by an electric motor.

Electric hoists are used for servicing machines when installing heavy parts and devices for processing, as stationary lifting devices during installation and disassembly of equipment, etc.

Electric hoists mounted on trolleys are called hoists. Carts can be manually or electrically driven for movement.

An electric hoist (telpher) is an electric winch (Fig. It consists of a trolley, an electric lifting motor, a gearbox, an electromagnetic brake, a drum for winding the cable ST) and a clip with a hook.

Electric hoists can be installed on crane beams, rotary cantilever beams, cantilever cranes moving along rail tracks.

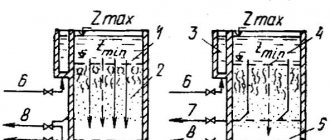

Electric hoist 9 moves along the lower flanges of the supporting I-beam. The drive is connected to the second drive wheel by a transmission shaft 8 without intermediate supports.

An electric hoist (telpher) is an electric hoist (Fig. I, a), which not only lifts the load, but also moves it along a single-rail track located near the ceiling of the workshop. It consists of a trolley, a lifting electric motor, a leedductor, an electromagnetic brake, a reel for winding - J & HH cable and a clip with a hook. The hoist control buttons are located at the level of the worker’s chest.

Electric hoist 9 moves along the lower flanges of the supporting I-beam. The drive is connected to the second drive wheel by a transmission shaft 8 without intermediate supports.

The electric hoist consists of a drum for winding rope, a pulley and a trolley moving on a monorail.

Electric hoists are supplied with a manufacturer's passport, which contains their technical characteristics. A nameplate indicating the load capacity, lifting height, year of manufacture and serial number is attached to the electric hoist.

The electric hoist consists of two structurally related mechanisms: lifting and moving, each of which is driven by its own engine. The electric hoist moves along an I-beam on running wheels, which are driven by engine 5 through a spur gearbox. In the simplest electric hoists, braking devices are not installed on the movement mechanisms. Mechanical stops limit the movement of the hoist R on both sides.

Electric hoists (Fig. 3) are used for lifting and horizontal movement of loads. They are equipped with two electric motors to lift and move loads. The hoists are hung on I-beams.

Electric hoists can operate as stationary ones, being attached to floor beams or to specially laid beams. In cases where, in addition to lifting the load, it is also required to move it horizontally, electric hoists are attached to trolleys (cats) with a manual movement mechanism or to trolleys with an electric drive. Current supply is carried out by a flexible cable (with a short travel distance) or using trolleys located on brackets parallel to the monorail track. Electric hoists suspended from electrically driven trolleys are called hoists.

Tips and tricks when choosing chain hoists

Lifting equipment is purchased with long-term use in mind. To avoid mistakes, it is advisable to pay attention to a number of points before purchasing.

- Load capacity. You should not limit yourself to the maximum weight of current cargo. It is quite possible that tomorrow more powerful lifting mechanisms may be required. Therefore, it is better to purchase a model with a carrying capacity reserve of 20-30%.

- Lifting height. As a rule, manual hoists are produced for lifting loads to a height of 1.5-9 m. There are models that lift the hook to 18 meters or more. It is worth choosing the model that will most accurately match the parameters of the working site in terms of lifting height.

- Presence of anti-corrosion coating on metal surfaces. The body of the hoist side, as well as the chain, must have a protective coating of powder paint or galvanization. This will allow you to operate the equipment outdoors.

- Safety certificates. Their presence will confirm the safety of the device for personnel.

In addition, the availability of service centers is important. Like any mechanism, a manual hoist requires regular maintenance and sometimes repair. A nearby service station will speed up service and reduce losses from equipment downtime.

Video - Manual chain hoist, choice, tricks of the job

Electric hoist, telpher, electric hoist

Electric hoists are designed for lifting and horizontal movement of cargo along a monorail track indoors and under a canopy at ambient temperatures from -40 to +40° C. They are used as an independent mechanism, as well as as part of suspended and support crane beams, cantilever, gantry and other cranes. They differ in load capacity, height, design, as well as operating conditions. Hoists are widely used in both small warehouses and large industrial enterprises. They are in many ways superior to their manual counterparts, have greater functionality and are faster.

- Electric hoists Bulgarian

Telphers and electric motors ELMOT AD - Chinese electric hoists

- Russian electric hoists

- Ukrainian electric hoists

In the CIS countries, electric rope hoists with one lifting mechanism with a load capacity from 0.25 to 12.5 tons are manufactured, which use double, quadruple and double pulley blocks, as well as hoists with two lifting mechanisms with double single, double and triple pulley blocks.

Electric hoists are manufactured in various designs: A - the electric motor is located inside the drum; B - electric motor is built into the drum; B - the electric motor is built into the drum, an additional load-bearing brake is provided; G - electric motor outside the drum.

Electric hoists are manufactured for general use and special ones (high-lifting, explosion-proof) for moving along curved routes and along straight paths. Some hoists can be equipped with a two-speed motor, microdrive, brake on the movement mechanism, etc.

Operating mode group for electric hoists - 3M according to GOST 28835 (explosion-proof hoists - 2M). Type of current - three-phase 380 V, frequency 50 Hz. The hoists are powered via a flexible cable. The hoists are controlled using a pendant four-button remote control. Electric hoists are equipped with electromagnetic shoe or disc brakes.

We can also offer you a wide range of components and spare parts for this type of equipment.

If you need to buy an electric hoist or other lifting equipment, contact our specialists and get more detailed information. Our managers will always be able to advise and select you a hoist that will meet all the necessary requirements for the upcoming operation.

| Catalog of lifting equipment (PDF file): |

Advantages of electric hoists

Compared to other load lifters, electric hoists have a number of advantages:

- high productivity - they have a fairly high speed of moving weights;

- efficiency - fast movement reduces the time required for work; also, fewer workers are needed to service electric hoists, which together reduces overall costs and pays off the cost of paying for electricity;

- high degree of safety - the mechanism is controlled remotely using a remote control, which protects the operator from possible traumatic situations;

- compactness makes it possible to use in small spaces;

- simple loading/unloading process, even for large cargo;

- long service life, reliable operation;

- simple, convenient repair thanks to the design of separate working units and blocks.

Special rules for operating electric hoists:

- transporting people using hoists is strictly prohibited;

- you need to carefully monitor and prevent contact of electric hoists with aggressive substances to avoid damage to the insulation;

- It is not recommended to use hoists in dusty rooms, this accelerates wear of the mechanism;

- It is not recommended to install hoists on unstable, swinging surfaces.

Special drive shaft. Drive chain and drive wheel

The hoist itself is suspended above the load itself, which must be lifted using a special trick. The lifting chain will be independently attached to the load. At the moment when we pull the drive chain, the drive wheel itself begins to rotate and rotates along the drive shaft, which begins to drive the gears, and at this time they turn the wheel of the lifting chain itself, which lifts the load itself.

It is worth taking a closer look at how gears produce the greatest concentration of lifting force in themselves, which is transmitted to the lifting chain. This drive chain is attached to a specialized segment on the drive wheel itself. The moment we pull, it begins to turn. The drive wheel is attached to a special friction plate, which is screwed to the ratchet.

At the moment when the plate and the ratchet begin to rotate together, the lock will fall into the teeth of the ratchet, preventing the wheel from unscrewing in the other direction under the influence of the weight of the load itself. With each process of transferring forces from one wheel to another, the force received from the drive chain increases several times.

The drive wheel is also mounted on the transfer shaft. As soon as the wheel begins to turn, it begins to drive the entire shaft. At the other end of this shaft there is a small and toothed gear, on which there are about 5 teeth at once. At the moment when it begins to make turns, the force transmitted by the action of the chain through a special drive wheel begins to increase rapidly. In this way, it increases in a special ratio of 7 to 5. A small toothed gear begins to drive the other two gears from the remaining wheels simultaneously.

Thus, the driving force of a small gear begins to be evenly transmitted by two wheels at once instead of one. A small gear immediately begins to drive 18 teeth, which are located on the remaining wheels. In turn, either of the two wheels has a small wheel at the back, which includes four teeth at once, increasing the total impact force by 18 to four.

These small wheels begin to drive a second wheel with 19 teeth in it, which begins to concentrate all the force on several links in the lifting chain attached to the last drive wheel. With the help of all these large and small wheels, the force from the drive traction can increase as much as thirty times.

A manual hoist is a fairly simple mechanism. It consists of a number of gears and two chains. A chain hoist makes an increase in total force as a result of the process of transforming a small number of forces that are applied over an overall length into a larger force that is applied over a smaller length.

Features of manual hoist

It is worth carefully familiarizing yourself with what a manual hoist consists of, as well as what principle of operation it can perform.

A manual chain hoist looks like a mechanical device that is used when lifting particularly heavy loads, equipment and various objects to various heights. It includes several circuits at once. One is the one for which the traction process is carried out, and the second is the one that carries out the lifting of the load. The force that can be generated while you pull the chain is 30 links at once, and also increases their lifting force by as much as thirty times.

The hoist will qualitatively increase the force, as a result of which the process of changing a small level of effort will be developed to the maximum applied to a large drive chain, which is attached to a shorter length of the load chain.

The manual chain hoist will include:

- Toothed gears.

- Load chain.

- Wheel made from a lifting chain.

Classification of manual hoists by drive type

According to the type of manual drive, hoists are divided into lever and chain.

Lever

In lever hoists, the operator controls the process of raising and lowering using a lever mounted on the equipment body. This design feature requires close proximity of the operator to the unit. Lever manual hoists are suitable for use in confined spaces - in wells, manifolds, pipelines, inspection pits. With their help, you can move loads in a horizontal direction, that is, use them as an analogue of a winch.

Using lever models, they work with loads whose mass does not exceed 5 tons. The maximum lifting height is the height of a person (the height of a raised arm). Lever hoists cannot provide high productivity.

The main areas of application of lever manual hoists:

- in public utilities to perform single operations - tensioning cables, installing hatches and laying pipes in a trench;

- during landscaping and in forestry - for uprooting stumps;

- for placing heavy equipment in industrial premises;

- when carrying out repair work in auto repair shops.

Chain

Manual chain hoists are load-lifting devices that lift, secure and lower loads by rotating a chain that drives the gear shaft of the gearbox. With their help, the load can be lifted to a height of up to 10-12 m. This equipment is designed quite simply. Its design includes: a drum with a chain wound on it, a transmission mechanism and a manual drive. The hoists can be mounted on a hook, which can be moved horizontally if necessary, or permanently on a beam.

Chain hoists use round link chains, the main characteristics of which are the diameter of the bar and the pitch. When choosing a chain for a chain manual hoist, take into account: the load capacity of the mechanism stated in the technical data sheet and the operating conditions of the equipment. Chains have standard and increased strength levels. For manual models, endless traction chains with a lifting capacity of up to 8 tons can be used.

Chains must be certified. If there is no certificate, then before carrying out work with loads, the sample is tested for withstanding loads and a conclusion is drawn up based on their results.

Electric hoist operating principle and application

Wednesday, December 23, 2015

Modern lifting mechanisms - hoists - can be manual or electric. Electric hoists are divided into mobile and stationary.

Unlike manual hoists, electric hoists can lift heavier loads. They have a higher rate of ascent. They are usually installed on monorail beams on special trolleys. Electric hoists are also called telphers and electric hoists.

The domestic market today offers predominantly electric hoists of Russian and Bulgarian production. Electric hoists have different dimensions and technical characteristics. Any customer chooses the mechanisms that are needed for the work he carries out.

Design features of electric hoists

Any electric hoist consists of the following elements:

- gearbox;

- hook suspension;

- coupling;

- lifting drum;

- running trolley;

- cargo rope;

- electrical equipment.

Such hoists are intended for lifting, lowering and moving loads in a horizontal plane. The mechanism moves along a monorail or stationary channel.

Terms of Use

Electric hoists can be used under a canopy at temperatures from minus 20 to plus 40 degrees Celsius. If the electric hoist is equipped with a protective motor and special equipment, then it can work indoors. These mechanisms cannot be used:

- for transporting people;

- in a room with vapors of acids and alkalis, which have a negative effect on electrical wiring;

- in a room with explosive and flammable vapors and gases;

- on sea and river vessels in conditions of roll and pitching.

Production managers and shop managers can look at the catalog of electric hoists on the Internet on specialized websites to make an informed choice. Depending on which traction element is used, electric hoists can be chain or rope. Such mechanisms are stationary and mobile.

Application of electric hoists

Electric hoists are widely used in many industries. These can be small warehouses or workshops of large enterprises. Telphers have proven themselves well in the market. Both domestic and Bulgarian mechanisms meet European standards. They are available in a wide range of models and options. They can be used everywhere.

The use of these mechanisms depends on the specific production in which they are involved. It can be:

- construction sites,

- factory floors,

- store warehouses and similar places.

If the mechanism is made in a moisture- or dust-proof, explosion-proof design, it can be used in aggressive environments.

The hoist acts as an independent device for lifting loads, and in beam cranes, jib cranes and others, as a lifting mechanism.

Modern electric hoists of domestic and foreign production

The domestic lifting industry produces electric rope hoists of the TE type. Their design was developed back in the fifties of the last century. Despite such a considerable age, such hoists are produced and find consumers.

Along with products from Korean and Polish manufacturers, Bulgarian-made electric hoists in chain design are in particular demand in our country. Such hoists are low noise and compact, light weight and low height. Bulgarian produced a series of electric hoists called “Shipka” especially for Russia. Bulgarian factories Yantra, Balkanskoe Ekho, Skladova Tekhnika and others also operate for the Russian market of lifting equipment.

Differences between the telpher and other devices

This mechanism has a number of differences from other lifting units. These differences determine its scope. There are restrictions on the movement of certain types of cargo.

Telpher and hoist

One of the closest to such a unit in terms of the tasks it can solve can be considered a lifting system called a hoist. They are manufactured with three types of drives: electric, mechanical and manual. An electric hoist is considered the most convenient to use. It is a compact mechanism with an electric motor, a system of suspensions and load securing. The electric hoist is designed for lifting loads whose weight does not exceed 12 tons.

The electric hoist device includes the following units:

- Electrical engine;

- control unit (can be manufactured as a portable remote control or mounted in a stationary cabinet);

- a lifting system consisting of a drum, a gear coupling with a wheel;

- load brake.

The difference between a manual hoist and an electric one is the absence of an electric drive. For manual hoists, lever or worm lifting systems are used.

It is used in warehouses, construction sites, and auto repair shops. Regardless of the design, the hoist has a limited range of action. This is what distinguishes a hoist from a hoist. In addition, the hoist has larger dimensions, which means greater load capacity.

Crane beam and hoist

Often, when solving practical problems, it becomes necessary to choose a crane beam or a hoist. Each of these lifting units has its own advantages that allow it to solve specific problems.

This is how it differs from a standard hoist. Beam cranes come in two types: support or suspended.

Models of the first type have a load-bearing beam located below the plane of the load-bearing structures. In the second type, these elements are arranged in reverse. The main elements of a typical beam crane are:

- two beams (span and end);

- a lifting mechanism (usually an electric motor with a gearbox, like a hoist);

- end supports;

- Remote Control;

- braking system;

- fixation devices (e.g. hook).

The main difference of the crane beam is the presence of four degrees of freedom, which significantly expands the possibilities for lifting and transporting secured cargo.

Using hoists in life

In suburban farming you can find a considerable number of jobs where special lifting devices will act as a good assistant. First of all, when considering such a mechanism, a special thought arises about lifting such a heavy load to the attic window. These could be simple bags of pet food, agricultural blocks of hay, or even building materials to re-cover the entire roof.

And during the construction of a house, a manual type of hoist can be used well, especially during the construction of a frame structure. It is enough that you simply purchase a small crane, which will include a special mobile cantilever boom, or put together the same product from hand lumber, in which case you will have your own construction equipment. It and special reinforced concrete blocks under a strip foundation near a fence or building can be lowered in a special trench, as well as heavy types of pillars can be built vertically, and the bricks can be raised to the second level of the cottage under construction.

It is strictly forbidden to use a hoist to lift animals or people to great heights, as this would be a gross violation of safety rules.

In a garage, such a device is also quite useful in most cases, for example, in order to lift the body or remove the engine from the hood of a vehicle. Even in a modern apartment it is not difficult to find a use for such a useful device, especially if the house has high ceilings. In particular, the owner of both a scooter and a moped is able to lift his two-wheeled mobility device onto balconies located on the second floors.

With the help of an external boom, you can quite easily lift furniture to the upper platform in the house, either directly into the premises of a low-rise building, or, conversely, lower it to the lowest floor in the entrance. It is very easy to find the use of a hoist; the main thing is to choose the right device so that it can efficiently withstand the entire load that falls on it.

Purpose and design of manual hoist

The choice of mechanisms for vertical movement of cargo is quite diverse. Even for manual lifting, there are different types of hoists available to handle even the most demanding tasks. Depending on the purpose, you can choose a device capable of lifting significant weight or moving it in the desired direction. The ease of handling the load, its maximum weight and dimensions will influence the design of the hoist, which should ensure maximum productivity in work. Each of the mechanisms used has certain advantages and it is worth considering all their possible variations.