Wedge - for high loads

This is the most common category of anchor bolts, widely used in private and capital construction. In appearance, it is a metal rod, wedged on one side and threaded on the other. There is a spacer sleeve on the conical part; the basic package includes a nut and washer.

Wedge anchors are used for mounting loaded structures on concrete surfaces.

This could be the arrangement of elevator shafts, staircases, installation of utilities. In domestic conditions, such anchor bolts are used for ceiling mounting of large and heavy chandeliers.

| Advantages | Flaws |

|

|

Also, the disadvantages include “non-removability”: the installed anchor cannot be dismantled and reused.

In the table you will find designations and descriptions of anchors from well-known manufacturers.

| Manufacturer | Type | Manufactured diameters and lengths of anchors, (mm) | Examples and explanations of designations (dimensions are indicated in mm) | Peculiarities |

| Fischer (Germany) | FBN | 6…20 (40…421) | FBN 12/100[+120] [GS] 12 – diameter of anchor and thread; 100 – useful length t – standard; 120 – maximum length t (not always specified); GS – equipped with a wide washer DIN 9021 (not specified with a regular washer DIN 125 ). FAZ 12/10[GS] FAN 10/100 FB 16/25 A4 | Fischer Bolzen. Steel 6.8 galvanized or A4 stainless. The most common due to its low cost and high reliability. |

| FB | 6…16 (65…173) | Limited production (mainly from A4 ) | ||

| FAZ | 8…24 (75…234) | Fischer Ankerbolzen Patented special expansion sleeve design allows applications in stretched and fractured areas of concrete | ||

| FAN | 10…12 (90…193) | Limited edition (made of A4 ) | ||

| Hilti (Liechtenstein) | HST | 8…12 (75…235) | HSA-F M16x190/75[/95] 16 – diameter of anchor and thread; 190 – full length of the anchor; 75 – useful length t – standard; 95 – maximum length t (not always specified); HST M12x115/20 | Hilti Stud Anchor. Steel of strength class 6.8 galvanized (5 microns). A4 stainless steel . |

| HSA | 6…20 (50…300) | |||

| Mungo (Switzerland) | MSD | 6…20 (50…270) | m3 12x113 12 – diameter of anchor and thread; 113 – full length of the anchor. MSD 10x120 MSD-C 16×300 – with wide washer DIN 9021 MSDr 10×70 – A2 stainless steel | Stahlbolzen.. Galvanized steel |

| m3 | 6…20 (50…170) | The special design of the spacer sleeve ensures high reliability against rotation of the anchor and maintains load-bearing capacity in cracked concrete. | ||

| Sormat (Finland) | S-KA | 6…20 (40…280) | S-KA 8×50 8 – diameter of anchor and thread; 50 – full length of the anchor. S-KAK D 12/65 12 – diameter of anchor and thread; 65 – useful length t; D – anchor with two spacers | Kiila-ankkuri Made from steel 6.8 according to DIN 1654 or 1651 , electro-galvanized. |

| S-KAK | 6…20 (40…280) | Same as S-KA anchors, but hot-dip galvanized. | ||

| S-KAH | 6…20 (40…220) | The same, but made of stainless acid-resistant steel A4 . | ||

| Tox (Germany) | B.A. | 6…16 (65…315) | BA 12/30/125 12 – diameter of anchor and thread; 30 – useful length; 125 – full length of the anchor. | Bolzenanker galvanized steel |

| Allfa (Germany) | 72000 | 6…12 (40…180) | 72000-10150 10 – diameter of anchor and thread; 150 – full length of the anchor. | Wedge anchor. Galvanized steel yellow passivated. |

| NOBEX (Italy) | TM TMX TMXX | 6…20 (40…220) | TM 8×115 8 – diameter of anchor and thread; 115 – full length of the anchor. | Ancoranti TM – galvanized steel, TMX – stainless steel A2 , TMXX – stainless steel A4 |

| Koelner (Poland) | S.R. | 6…20 (40…250) | SR-12×130 10 – diameter of anchor and thread; 130 – full length of the anchor. | Wedge anchor. Steel 4.6 galvanized, yellow passivated. |

| Technox (Poland) | BZ | 6…16 (75…300) | BZ 10/130 [A4] 10 – diameter of anchor and thread; 130 – full length of the anchor | Kotwa stalowa Galvanized steel (stainless bushing) or all stainless steel A4 |

| B | 6…20 (40…350) | B 16/115 16 – diameter of anchor and thread; 115 – full length of the anchor | Steel A45 galvanized | |

| B.L. | 8…16 (75…175) | |||

| Anchor Fasteners (Taiwan) | WAM | 6…20 (40…300) | WAM-10125 10 – diameter of anchor and thread; 125 – full length of the anchor. | Wedge anchor . Galvanized steel, yellow passivated. |

| INKA (Türkiye) | IDKL | 6…16 (75…145) | IDKL12110 12 – diameter of anchor and thread; 110 – full length of the anchor. | Klipsli Dubel Steel 5.6 galvanized |

Expansion anchor: types, parameters, installation, GOST

Main types of metal cutting

The expansion anchor can rightfully be called a new generation fastener.

Using such anchors made of high-strength metals, you can obtain reliable connections between elements of building structures, perform reliable fastening of large and heavy objects on various surfaces, and also solve a number of other problems related to construction, repair, installation and finishing work. Modern industry offers a wide variety of anchor-type bolts, the requirements for the parameters and characteristics of which are specified by the provisions of the relevant GOST.

Driven - for fixing communications

Installation of such products is carried out using the driving method. These are ordinary dowels, only they are made not of plastic, but of high-carbon steel. In appearance, it is a seamless metal sleeve with a conical inner surface and longitudinal slits.

The anchor is driven into a pre-prepared hole with a hammer; during installation, the petals form support arms that have a high load-bearing capacity. After this, a bolt of a suitable diameter is screwed into the anchor, which passes through.

Such anchors are used for installing formwork, cable ducts and utilities, gratings, splinker and ventilation systems, and when installing pipelines.

| Advantages | Flaws |

|

|

Products in this group are conventionally divided into 2 categories: ordinary and special. The second group includes products of the “Zikon” series, which are highly expensive and require special tools for installation.

| Manufacturer | Type | Available thread diameters, mm | Examples and explanations of designations (dimensions in mm) | Peculiarities |

| Fischer (Germany) | E.A. | 6, 8, 10, 12, 16, 20 | EA M 8 8 – M 8 internal thread diameter EA SM 10 | Fischer Einschlanganker Steel 1.4401/1/4571, galvanized yellow-passivated or stainless steel A4 |

| EAS | 6, 8, 10 | Lightweight version of the EA anchor made of sheet steel, with collar | ||

| Hilti | HKD-S | 6, 8, 10, 12, 16, 20 | HKD-S M12/50 12 – M 12 internal thread diameter 50 – anchor length. | Flush Anchor Steel strength class 5.8. |

| HDI | Drop-in Anchor | |||

| Mungo | ESA | 6, 8, 10, 12, 16, 20 | ESA M 8 8 – M 8 thread diameter; | Einschlanganker Galvanized steel, yellow-passivated or stainless steel A4 |

| Sormat (Finland) | LA, LAH | 6, 8, 10, 12, 16, 20 | LA 12 12 – M 12 internal thread diameter. | Ly ö ntiankkuri LA – structural steel, electro-galvanized LAH – made of stainless acid-resistant steel A4. |

| Tox (Germany) | T.E. | 6, 8, 10, 12, 16, 20 | TE M16x65 16 – M 16 internal thread diameter. | Einschlaganker Galvanized steel, yellow passivated. |

| NOBEX (Italy) | DROP | 6, 8, 10, 12, 16 | DROP 12×50 [INOX] 12 – M 12 internal thread diameter 50 – anchor length. | |

| Koelner (Poland) | ST | 6, 8, 10, 12, 16, 20 | ST-08 08 – M 8 internal thread diameter. | Drop in anhor Galvanized steel, yellow passivated. |

| Wkret-met (Poland) | T.S.W. | 6, 8, 10, 12, 16 | TSW 10 10 – M 10 internal thread diameter. | Galvanized steel, yellow passivated. |

| Technox (Poland) | TSR | 5, 6, 8, 10, 12, 16 | TSR 8x30 | Tuleja stalova. Galvanized steel |

| Anchor Fasteners (Taiwan) | DRM | 6, 8, 10, 12, 16, 20 | DRM-12 | Drop in anhor Galvanized steel, yellow passivated. |

| INKA (Türkiye) | IDCA | 6, 8, 10, 12, 16 | IDCA08 | Çakmali Dubel |

Application of expansion anchor: types, advantages and installation

An anchor is a fastening unit made of metal, the main task of which is to fasten individual structures and their parts together. They are used in work related to repair, decoration and construction; they have different types, shapes and sizes. The scope of its application will depend on the type. Produced on modern equipment using the latest technologies, durable and high-quality materials.

Areas of use

One of the reliable and high-strength means of fastening is an expansion anchor (anchoring expansion bolt). It can be used to attach various structures or equipment to bases that have solid material.

The bolt allows you to create uniform friction with great force along its entire length, due to this, high retention capacity is ensured, however, the material of the structure must have good density and solidity.

The main material of the bolt is carbon steel, treated with white or yellow zinc to prevent corrosion on its surface. The bolt has a sleeve made of metal, at one end there is a 4-segment spacer part, the other end has a thread on which there is a nut for adjustment and a washer.

The principle of operation of the bolt is quite simple: when the nail located inside the sleeve is driven into the structure, the lower part of the anchor expands and the bolt is attached to the base.

A bolt with spacers is usually used if it is necessary to attach any structural part to the base using a through-hole installation method. You can make facade fasteners. It is good if the base for fastening is made of concrete or stone with a high degree of adhesion. The presence of cracks in the material will affect the load of the bolt; they will reduce it several times.

Chemical - innovative option

Chemical anchors are a metal fastening sleeve or reinforcing rod made of galvanized or stainless steel. The fastener is fixed by injecting a special adhesive composition into the hole, which, after hardening, ensures reliable adhesion of the concrete and the stud.

Chemical anchors are used almost everywhere. They can be used for mounting suspended structures, fences, equipment and any additional elements.

Thanks to the use of an adhesive composition, the anchor easily withstands dynamic loads and vibration, and is not subject to corrosion in an aggressive environment.

| Advantages | Flaws |

|

|

The price of such anchors is noticeably higher than that of other analogues.

| Manufacturer | Type | Dimensions | Peculiarities |

| Fischer (Germany) | R.M. | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M14, M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Reactionsanker An ampoule with resin, inside an ampoule with a hardener. Used with FCR-A anchors or RG studs. |

| FHP | Capsules: 10 (13x90), 12(15x110), 16(18x125), 20(24x180) | Hammerpatrone The ampoules have two cavities: with resin and with hardener. Used when installing fittings. | |

| FIS V 360S | 360 ml composition + 2 mixers | Injections-Mörtel Double cartridge. A special mixing gun is required. | |

| FIS VS 150 C | 150 ml of composition + 2 mixers + adapter | Injections-Mörtel Special cartridge. A standard sealant gun is used. | |

| Hilti (Liechtenstein) | HVU | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(24x170), M24(28x210), M27(30x240), M30(35x270), M33(37x300) , M36(40×330), M39(42×360) | Adhesive Capsule Anchor Ampoule with polyurethane meta-acrylic resin, hardener, quartz sand. |

| HIT- HY150 | 330 ml + 2 mixers | Fast Curing Injection System Two special double tubes (Acrylic resin with additives and hardener). For extrusion, a special Hylti dispensing gun is required. | |

| HIT-HY50 | 330 ml + 2 mixers | ||

| HIT-HY20 | 330 ml + 1 mixer | ||

| Mungo (Switzerland) | MSP | Capsules: M8 (10x80), M10 (12x90), M12(15x95), M16(18x95), M20(25x125), M20(25x175), M24(28x240) | Schlagpatron The ampoules have two cavities: with resin and with hardener. |

| MVA | Capsules: M8 (10x80), M10 (12x90), M12(15x95), M14(16x95), M16(18x95), M20(24x135), M20(25x175), M24(28x210), M30(35x 280) | Verbunanker An ampoule with resin, inside an ampoule with a hardener. | |

| MIT-P | 150 ml + 2 mixers | Injectionstechnik Special cartridge. A standard sealant gun is used. | |

| MIT-P | 235 ml + 2 mixers | Injectionstechnik Double cartridge with parallel arrangement of containers for resin and hardener. A special mixing gun is required. | |

| MIT-SF | 380 ml + 2 mixers | ||

| MIT-EA | 825 ml + 2 mixers | ||

| Sormat (Finland) | KEM | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Kemiallinen ankkuri An ampoule with polyester resin, inside an ampoule with a hardener. Used with KEVA studs. |

| KEMLA | Capsules: M10 (12x90), M12(14x110), M16(18x140), M20(22x180) | Kemiallinen ly ö ntiampulli Ampoule with polyster resin and hardener. For horizontal and floor mounting only. VSS studs. | |

| ITH | 150 ml, 380 ml | Injektointitekniika Injection mass based on polyester resin. Large cartridges (380 ml) require a special gun. | |

| KEW (Germany) | VAR | Capsules: M8 (10x80), M10 (12x90), M12 (14x110) | Verbundankerpatrone An ampoule with resin, inside an ampoule with a hardener. For use with AS studs. |

| V.M. | 150 ml, mixer SM | Verbundm örtelkartusche Special cartridge with adhesive mass and adapter. A standard pistol is used. | |

| Tox (Germany) | TVA | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Verbund-Anker An ampoule with resin, inside an ampoule with a hardener. Used with TVA-G studs. |

| THP | Capsules: M10 (12x85), M12(14x105), M16(18x135), M20(24x160) | Hammerpatrone The ampoules have two cavities: with resin and with hardener. | |

| TVM-K | 150 ml, 380 ml | Verbundm örtel Injection mass. Large cartridges require a special gun. | |

| NOBEX (Italy) | NCF NCS N.C.E. | Injection formulations NCF and NCE – 380 ml NCS – 150 ml | Fissaggi chimici estremamente efficaci |

| Technox (Poland) | SVA | Capsules: M8 (10x80), M10 (12x85), M12(14x95), M16(18x95), M20(24x175), M24 (28x210) | Ładunek chemicalzny |

| INKA (Türkiye) | IDKIN | Capsules: M12(14x95), M16(18x95), M20(24x170) | Normal Tip Kimyasal Dubel |

Where to buy quality anchor studs?

sells an assortment of anchor studs wholesale and retail at competitive prices for customers in Moscow.

In the hardware catalog, customers will find anchors from well-known brands: FISCHER, FIXator, Hilti, Mkt and other manufacturers. All products are certified and fully meet the requirements for reliability, strength and safety of connections.

We offer wholesalers and retail buyers favorable conditions, consultations and affordable prices. You can order products through the feedback form.

Anchor sizes for concrete

It is impossible to say with certainty, without knowing the nuances of the situation, what size anchor bolt will be needed. This indicator is influenced by the wall material, type of fastening element, expected load and other parameters.

The table will help you roughly navigate the variety of fasteners.

| Type of anchor bolt | Optimal sizes |

| With hook |

|

| With nut |

|

If you are in doubt which bolt you need, measure the thickness of the wall, the expected load and tell them to the salesperson in the store. They will help you choose the best option.

Expansion anchor: choice depending on application

An expansion anchor is a fastening element made of stainless or carbon steel. One end of the mounting bolt has a thread for fixation, and the other is equipped with a special sleeve that expands due to the impact of the fastener. This anchor design allows for maximum connection strength.

Another advantage is the ability to remove fasteners without destroying the surface of the elements being connected. Where expansion anchors are used and how to choose the right device for specific purposes, read on.

Area of use of expansion anchors

The main advantages of an anchor bolt with a spacer sleeve are:

- ease of installation and dismantling. No special tools are required to install/remove the fastener. It is enough to prepare a puncher and a hammer;

- strength. Products are made of steel (carbon or stainless steel) and for additional strength are coated with a layer of zinc, which protects the steel from corrosion;

- resistance to mechanical damage and chemical attack;

- fastening efficiency.

Expansion anchors are used:

- in construction. Using fasteners of this type, you can assemble and install individual elements of large prefabricated structures, for example, electrification poles, scaffolding, road fences, and so on, as well as fasten finished structures to vertical or horizontal bases;

- at home. Using anchors with spacer sleeves, window frames, doors, stairs, lamps and other fixtures are fastened.

How to choose an expansion anchor

The choice of anchor should be made based on the following parameters:

- types of bolt;

- overall dimensions of the fastening element;

- manufacturing company.

Anchor type

Modern manufacturers produce expansion anchors of the following types:

- Bolts and washer are the most common type of fastening anchors. Wide popularity achieved due to ease of fastening and maximum strength. Anchors with washers can be used for concrete, brick and other monolithic bases, as well as bases with slight porosity.

- Anchors with fixing nuts are mainly used for fastening heavy and large-sized objects, since a pre-installed nut allows you to reduce the time for fixing and, accordingly, holding the object “in weight”.

- Expansion anchor with ring or hook. This fastening element is used when it is necessary to hang individual objects, for example, a ceiling lamp. The fastening element is pre-installed into the base (ceiling) and after that any structure is hung.

- A stud anchor is used for through fastening of structures or individual parts. Studs are usually equipped with washers and fixing nuts.

Fastener dimensions

For strong fixation, it is necessary not only to choose the right type of anchor bolt, but also to first determine the dimensions of the fastening element.

Currently, bolts are produced in different lengths and diameters. The selection of overall dimensions is made depending on the weight of the structure being fixed. The greater the weight of the object being fixed, the larger the expansion anchor must be used.

Popular manufacturers and their features

Many parameters of the anchor bolt (dimensions, safety factor, etc.) depend on the manufacturer of the fastener. The main manufacturers of expansion anchor bolts at present are:

- Hilti company (Liechtenstein). Fastening elements are made of zinc coated steel. The diversity of the line of spacer bolts allows you to fix structures with different dimensions (HSA or HSV for small shapes and HSL 3 or 3G for large objects), as well as use bolts in seismic zones (HST marking).

- Fischer company (Germany). Anchors are characterized by increased strength, which allows the use of fastening bolts in various climatic conditions.

- (Russia). A wide range, reasonable price range, as well as high quality allow you to select expansion anchors for both industry, construction, and domestic needs.

Thus, expansion anchors are the most common types of anchor fasteners, as they can be used in almost any conditions and are capable of holding even objects that are heavy and large in size.

Mechanical anchors

There are many varieties and designs of them, which are mainly the own development of manufacturing companies. According to the principle of operation, they can be divided into spacer and driven ones. Expansion anchors expand when installed when torque is applied. These include classic anchor bolts and studs, as well as anchor sleeves. The second group includes the so-called driven-in anchors with controlled deformation, which are wedged when the internal spacer wedge is driven in.

Although the mechanical anchor is a very effective and economical fastener, however, it has some limitations in its use. Expansion at the sides of the hole causes high compressive stresses in the base material. This means that there must be enough solid material around the fastener to support these loads without damage. This requires large edge distances. Expansion anchors are often not suitable for use in weak base materials, hollow blocks and bricks with voids.

Ground anchor installation

The technical term "anchor" translated from German means anchor. The first mention of ground anchors appeared 30 years ago, when the famous American company Foresight Products LLC received an order to secure floating oil production platforms. To solve this problem, engineers developed a system of special anchors that reliably hold the massive hull of the platform on the ocean floor. The result was so successful that the idea of an anchor was transferred from the ocean to land, as a result of which the ground anchor appeared.

A ground anchor is a fastener fixed in a solid load-bearing foundation (soil), which ensures the transfer of tensile forces from the fastened structural elements directly to a solid soil foundation.

Components of a ground anchor:

- Header . In the anchor design, this part performs the function of transferring the load forces of the structure being secured or another element directly to the anchor rod - the anchor rod.

- Anchor rod . The main technical purpose of the element is the intermediate transfer of pulling forces from the head to the root part of the anchor.

- The root part is the embedment left in the ground.

More detailed information about other earth anchor devices is contained in the technical document of departmental standards VSN 506-88 “Design and installation of earth anchors”.

Disadvantages of chemical anchoring

Thus, we have established that chemical fastenings are not inferior in strength to mechanical ones, can be placed at a short distance from the edge and from each other, and work well in porous, weak and hollow building materials. Obviously, the main disadvantage of chimankers is related to their installation.

Anchor ampoules (capsules)

- First, they are much more sensitive to poor hole cleaning than mechanical anchors.

- Secondly, before they are tightened or loaded, the composition must be allowed to completely harden, and this takes time.

Capsule systems are less susceptible to poor hole cleaning than injection systems because as the pin rotates, the resin along with the coarse aggregate tends to draw some of the dust remaining on the sides of the hole into the mixture. However, best practice until recently dictated that the openings of all chimankers should always be thoroughly cleaned, using both a blower (or vacuum cleaner) and a brush and blower.

Application area

The choice of anchor piles and the scope of application largely depends on the load forces acting on the anchor and on the category of soil to which the entire load will be transferred. It is clear that subsidence, highly compressible soils, as well as silty and peaty soils are not suitable for installing anchor ties. Clay soil with increased plasticity is also at risk.

In construction, anchor piles are used to secure the walls of underground structures, earthen slopes and vertical walls of deep pits.

The use of ground anchor ties under conditions of low load forces :

- In individual construction: strengthening fences and fences, poles and masts of street lighting, fixing supporting elements of sports and children's playgrounds, installation of construction scaffolding.

- In gardening: for securing small architectural forms, strengthening the root system and crowns of large trees and vineyards.

medium force areas :

- Fastening power transmission line support structures.

- Strengthening engineering elements for the protection of embankments and slopes.

- Fastening load-bearing walls from prefabricated reinforced concrete blocks.

- Fixation of gabions.

- Preventing sagging of underground pipeline communications.

- Fixing floating buoys, pontoons, berths and docks.

Scope of application of ground anchors under conditions of strong overturning forces and loads:

- Fastening the walls of deep pits.

- Strengthening the support masts of high-voltage lines.

- Strengthening television and radio towers.

Installing a soil anchor micropile into a solid soil foundation removes all the risks of developing destructive deformations in the structures being fixed and their being pulled out of the soil.

Which anchor has a higher load-bearing capacity?

When comparing the load characteristics of chemical and mechanical fasteners, it is impossible to say unambiguously which of them can withstand the greater load. Both versions are available in a wide range of load ratings.

In the case of mechanical anchors, each size (diameter, length) has certain working load limits. The strength of any chemical attachment point is determined by many factors.

The main ones are:

- diameter of the rod or reinforcement;

- hole depth (embedding);

- condition of the base material (wet or dry) during installation.

These three factors influence bond strength and are critical when calculating the load capacity of any chimanker.

Chemical studs have virtually unlimited embedment depth, so you can insert any length of stud into the hole to increase the load. That is, the GREATER THE INSTALLATION DEPTH, THE HIGHER THE LOAD CAPACITY.

And if you decide to use a larger diameter hole with a thicker rod, you can again increase the load.

And finally, if the tightening torque of the expansion anchor is not observed, its load-bearing capacity is reduced, whereas for chemical studs, the tightening torque does not affect the load-bearing capacity of the fastening.

Chemical anchors

Chemical anchor is a general term referring to steel studs, bolts and rods that are attached to a substrate, usually masonry and concrete, using a synthetic resin adhesive system. They are very effective for heavy loads, as they form a very strong bond between the metal element and the base material. This connection is often stronger than the foundation itself.

When you need to secure something close to the edge of concrete or brickwork (gates, railings, brackets), the only way to keep the base intact is to use a chimanker, the nature of the anchorage of which does not cause internal stresses. The chemically retained rod eliminates the possibility of cracking of the surrounding concrete. It can also be used in concrete of unknown quality or low compressive strength.

Anchor bolt with nut - how to fasten

Essentially, it is a stud with a nut and washer that is screwed into a coupling (threaded sleeve). Therefore, it can be called an anchor bolt with a nut or a stud anchor. We study in detail how to fasten anchor bolts with a nut ourselves and use them.

On one side, a nut and washer are screwed onto the stud, and on the other, there is a “wedge” in the form of a cone. In the wide part the wedge corresponds to the diameter of the coupling, in the narrow part it corresponds to the pin. The coupling on the wedge side has a notch and longitudinal slots.

Installation is quite simple, even a beginner can understand how to attach anchor bolts with a nut.

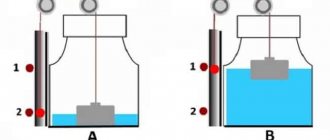

Mounting diagram

A hole for the coupling is drilled in the base and cleaned of dust. The part is hung on the anchor, inserted into the hole and hammered in with gentle blows of a hammer until it stops. Then tighten the nut a few turns.

Screwing onto the stud, the nut “unscrews” it from the coupling; as a result, the wedge expands the coupling along its entire length with slots.

Anchor bolts are made from galvanized steel. Used for concrete, stone, solid brick.

There is an “improved version” of such an anchor - a double-spacer one.

It has two movable couplings with slots, one of which fits into the other with a cone. When the nut is screwed in, the shank pushes one sleeve onto the other. The first one expands with a wedge cone and itself expands the middle coupling, forming two fastening belts.