What is

Cast iron is an iron-based alloy.

Belongs to the group of ferrous metals. Ferrous metals are iron, alloys based on it (steel, cast iron, ferroalloys), manganese. According to some classifications, chromium is included in the group.

In terms of composition, cast iron is a conglomerate of iron, carbon, plus other metals. The steel formula could contain the same basic components.

The difference between these alloys is the amount of carbon. If it is less than 2.14%, it is steel. More - cast iron.

Other components are alloys and impurities (sulfur, silicon, phosphorus, manganese).

Carbon in the structure of cast iron is represented by inclusions of graphite or cementite (iron carbide, formula – Fe3C).

You can distinguish cast iron from steel visually. Steel is lighter and shiny, cast iron is dark matte.

Advantages and disadvantages

Cast iron, like any material, has positive and negative sides.

The advantages of cast iron include:

- Carbon in cast iron can be in different states. Therefore, this material can be of two types (gray and white).

- Certain types of cast iron have increased strength, so cast iron is sometimes placed on the same line as steel.

- Cast iron can maintain temperature for quite a long time. That is, when heated, the heat is evenly distributed throughout the material and remains in it for a long time.

- In terms of environmental friendliness, cast iron is a clean material. Therefore, it is often used to make dishes in which food is subsequently prepared.

- Cast iron is resistant to acid-base conditions.

- Cast iron has good hygiene.

- The material has a fairly long service life. It has been noticed that the longer cast iron is used, the better its quality.

- Cast iron is a durable material.

- Cast iron is a harmless material. It is not capable of causing even slight harm to the body.

The disadvantages of cast iron include:

- Cast iron will rust if it is exposed to water for a short time.

- Cast iron is an expensive material. However, this minus is justified. Cast iron is very high quality, practical and reliable. Items made from it are also high quality and durable.

- Gray cast iron is characterized by low ductility.

- White cast iron is characterized by brittleness. It is mainly used for smelting.

Presence in iron-carbon alloys

Cast iron

The ledeburite mixture occurs for pure iron-carbon alloys in the range of carbon concentrations from 2.14% to 6.67%, which corresponds to cast iron. The mechanism of ledeburite formation in hypoeutectic (to the left of the eutectic point corresponding to 4.3 carbon on the iron-carbon diagram), eutectic and hypereutectic (to the right of the eutectic point) cast irons differs.

in hypoeutectic cast irons

When the liquid phase of the hypoeutectic cast iron composition is cooled, austenite begins to crystallize first, as a result of which the composition of the liquid phase begins to shift towards increasing carbon concentration (due to the lower solubility of carbon in austenite). Upon reaching the eutectic point (4.3% carbon, 1147 °C), crystallization of the eutectic, ledeburite, begins. During further cooling of cast iron in the temperature range from 1147 °C to 727 °C, austenite is depleted of carbon and secondary cementite is released. Secondary cementite, released along the boundaries of austenite grains, merges with ledeburite cementite and is therefore practically invisible under a microscope. With slight supercooling below 727 °C, austenite transforms into pearlite by a eutectoid reaction (divided into ferrite and cementite). Thus, in hypoeutectic white cast irons, at room temperature, ledeburite, as a structural component, is present along with pearlite and secondary cementite.

in eutectic cast iron

When the liquid phase of the eutectic point composition is cooled to a temperature of 1147 °C, simultaneous crystallization of a mixture of austenite and cementite - ledeburite begins. Subsequently, the austenite decomposes into a ferrite-cementite mixture (pearlite).

in hypereutectic cast irons

In hypereutectic white cast irons, primary cementite crystallizes from the liquid in the form of flat needles, then ledeburite is formed. At room temperature, eutectic white cast iron contains two structural components: primary cementite and ledeburite.

Ledeburite can form in steels if, firstly, their carbon content is high enough (over 0.7% (~1.3%-1.5%), which corresponds to tool steels), and, secondly, at high content of carbide-forming alloying elements (Cr, W, Ti, Mo, etc.). The introduction of these alloying elements, in large quantities, reduces the solubility of carbon in austenite and pearlite, which, in certain cases, leads to the possibility of eutectic precipitation at relatively low carbon contents. Such steels (for example, high-speed steels) are called ledeburite.

Story

The documented history of cast iron starts from the 1st millennium BC:

- Smelting was mastered by the Chinese and their neighbors.

- From the 5th century BC, the period of decorative iron casting began.

- 600 years later, coins appeared in China.

The appearance of the alloy in Europe dates back to the 14th century, in Russia – two hundred years later. Interest increased due to the suitability of cast iron as a material for cannons and cannonballs.

Eglinton Tournament Bridge (completed c. 1845), North Ayrshire, Scotland, built of cast iron

Since the time of Queen Victoria, fireplaces have become the most popular product in the “civil segment” among the British.

Cast iron coal iron

The heyday of the cast iron industry in Russia dates back to the 18th century:

- Bridges and rails appeared.

- Cast iron pots were invented in the Urals - the number one cookware for the Russian stove. Later they were supplemented with frying pans.

- By the end of the century, Russia had become the world leader in the production of cast iron.

The original bridge across the Tey from the north (finished in 1878)

The openwork products of Kasli craftsmen have gained world fame.

The method of molding for casting artistic castings of complex shapes, invented by the Kasli people, is still in demand by machine builders today.

Structure and composition

If we consider cast iron as a structural material, then it is a metal cavity with graphite inclusions. The structure of cast iron is mainly pearlite, ledeburite and ductile graphite. Moreover, for each type of cast iron these elements predominate in different proportions or are absent altogether.

According to the structure of cast iron there are:

- perlite,

- ferritic and

- ferritic-pearlitic.

Graphite is present in this material in one of the forms:

- Globular. Graphite takes on this shape when magnesium is added. The spherical shape of graphite is characteristic of high-strength cast irons.

- Plastic. Graphite is similar to the shape of petals. In this form, graphite is present in ordinary cast iron. This cast iron has increased ductility properties.

- Flaky. Graphite acquires this shape by annealing white cast iron. Graphite is found in flake form in malleable cast iron.

- Vermicular. The named form of graphite is found in gray cast iron. It was developed specifically to improve ductility and other properties.

Influence of impurities on material properties

The components that make up cast iron affect the quality of the alloy:

- sulfur helps reduce the refractoriness and fluidity of cast iron;

- phosphorus reduces strength, but makes it possible to vary the shape of finished products;

- silicon reduces the melting point of the metal and enhances its casting properties. In addition, this element makes it possible to obtain alloys of different colors: from pure white to ferritic;

- manganese gives cast iron strength and hardness, but reduces the casting and technological properties of the finished material;

- the introduction of titanium, aluminum, chromium, nickel or copper into the composition allows the production of alloyed alloys. They have high casting qualities and have proven good machinability. Production technology

Cast iron cast in the form of pigs

The source of raw materials for metallurgists is iron ores (rocks with a predominance of iron in the composition).

The ore is sent to processing plants, where part of the “empty” material is removed from the raw material.

The resulting material is transported to the metallurgical plant.

Here they are loaded into blast furnaces:

- Fuel is added - coke (a product of processing coal), limestone, briquetted coal dust.

- Melts at high temperatures.

- During the reduction process, iron with carbon embedded in its structure is obtained from oxides.

As a result of smelting, cast iron and slag are formed (a mixture of fuel ash, unused fluxes, and other products).

Ligatures are added if necessary. They determine the physical and chemical properties of the material.

Production is simple, but environmentally dirty.

Composition of gray cast iron and its structure

The parameters and properties of the alloy directly depend on the cooling mode; the fact is that it is during cooling that the structure of the material is formed.

During the process of slow cooling, considerable iron crystals are formed, and the combination of metal and carbon becomes pearlitic. During such cooling, not only the size of metal crystals increases, but also carbon inclusions. This combination leads to the fact that pearlite material has not only high strength, but also increased fragility.

Assessment of the structure of the MF determines:

- the size of graphite inclusions, measured in micrometers (μM), their distribution, quantity (in%), the type of structure of the metal base and, if pearlite is present, its dispersion.

According to the structure of the metal base, gray cast irons are divided into:

- pearlite - the structure contains pearlite and graphite;

- ferrite-pearlite - ferrite, pearlite and graphite;

- ferritic - the structure consists of ferrite and graphite.

Which base will be depends on the cooling rate after hardening.

To designate parts of the microstructure of cast iron of this type, the terminology defined in GOST 3443-87 is used, for example, flake graphite is designated by the letters PG. Carbon is included in the material in the following forms.

- lamellar rectilinear, it is designated PGF1;

- plate vortex - PGF2;

- needle-shaped - PGF3;

- nest-shaped -PGF4.

Of primary importance for acquiring the required parameters of an iron casting is its structure, which is why when making blanks, careful implementation of the technology of melting and pouring raw materials is required. To obtain the required parameters of gray cast iron and eliminate defects, a modification operation is used.

The composition of SP, depending on its brand, may include the following substances:

The base is Fe (iron), the rest:

- C (carbon) - 2.9-3.7%;

- Si (silicon) -1.2-2.6%;

- Mn (manganese) - 0.5-1.1;

- P (phosphorus) no more than 0.2-0.3%;

- S (sulfur) no more than 0.12-0.15%.

It is permissible to alloy gray cast iron using substances such as Cr, Ni, Cu, and some other elements.

Silicon in the composition increases the graphitization of carbon. Manganese, although it makes graphitization difficult, improves its mechanical properties.

The chemical composition of SP is defined in GOST 1412-85. Gray cast iron is produced in many countries around the world; in the USA, A48-30B is considered an analogue of this material, in Britain BS 200 or 220, in China GB HT 20, in the European Union EN-JL1030 FG20.

Classification

Cast iron is classified on several grounds:

- According to the dimensions and shape of graphite inclusions. Layered, spheroidal, vermicular, flakes.

- By type of carbon. Graphite, cementite.

- According to production technology. Grey, white, reworked.

- Based on the presence of additives. Ordinary and alloyed. Alloyed are alloys of cast iron with metals (molybdenum, nickel, chromium, titanium, etc.). Alloys with such metals give products ductility, resistance to wear, destruction, and corrosion.

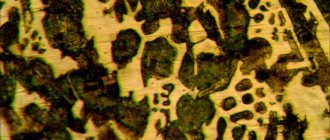

Microstructure of white cast iron

Product characteristics are established at the production stage.

Varieties

There are white and gray cast iron.

- The carbon in white cast iron is in the form of iron carbide. If you break it, you can see a white tint. White cast iron is not used in its pure form. It is added to the process of producing malleable iron.

- At a fracture, gray cast iron has a silvery tint. This type of cast iron has a wide range of uses. It lends itself well to processing with cutters.

In addition, cast irons are high-strength, malleable and with special properties.

- High-strength cast iron is used to increase the strength of the product. The mechanical properties of such cast iron allow this to be done perfectly. High-strength cast iron is obtained from gray cast iron by adding magnesium to the mass.

- Ductile iron is a type of gray iron. The name does not mean that this cast iron is easily forged. It has increased plasticity properties. It is obtained by annealing white cast iron.

- There is also a distinction between half cast iron. Some of the carbon in it is in the form of graphite, and the remaining part is in the form of cementite.

Composition and types of white cast iron

White cast iron consists of the so-called cementite eutectic. In this regard, it is divided into three categories:

- Hypoeutectic. These are alloys in which carbon does not exceed 4.3% of the total composition. It is obtained after complete cooling. As a result, it acquires the characteristic structure of such elements as pearlite, secondary cementite and ledeburite.

- Eutectic. Their carbon content is 4.3%.

- Hypereutectic white cast iron. The content exceeds 4.35% and can reach 6.67%.

In addition to the above classification, it is divided into ordinary, bleached and alloyed.

The internal structure of white cast iron is an alloy of two elements: iron and carbon. Despite high-temperature production, it retains a fine-grained structure. Therefore, if you break a part made of such metal, a characteristic white color will be observed. In addition, in the structure of a hypoeutectic alloy, for example, hard grades, in addition to pearlite and secondary cementite, cementite is always present. Its percentage can approach 100%. This is typical for a eutectic metal. For the third type, the structure is a composition of eutectic (Ep) and primary cementite.

One of the varieties of such alloys is the so-called bleached cast iron. Its basis, that is, the core, is gray or high-strength cast iron. The surface layer contains a high percentage of elements such as ledeburite and perlite. The whitening effect up to 30 mm deep is achieved using the rapid cooling method. As a result, the surface layer is white, and then the casting consists of an ordinary gray alloy.

White cast iron structure

Depending on the percentage of alloyed additives, the following types of metal are distinguished:

- low-alloyed (they contain no more than 2.5% alloying elements);

- moderately alloyed (the percentage of such elements reaches 10%);

- highly alloyed (in them the amount of alloying additives exceeds 10%).

Quite common elements are used as alloying additives. The alloyed white cast iron obtained in this way acquires new, predetermined properties.

Properties of white cast iron

Any cast iron alloy, on the one hand, is very strong, but at the same time it is quite brittle. Therefore, the main positive properties of white cast iron include:

- High hardness. This greatly complicates the processing of parts, in particular cutting.

- Very high resistivity.

- Excellent wear resistance.

- Good resistance to increased heat.

- Sufficient corrosion resistance, including to various acids.

White cast irons, with a reduced percentage of carbon, are more resistant to high temperatures. This property is used to reduce the number of cracks in castings.

Appearance of white cast iron

The disadvantages include:

- Low casting properties. It has poor mold filling. During pouring, internal cracks may form.

- Increased fragility.

- Poor machinability of castings and parts made of white cast iron.

- Large shrinkage, which can reach 2%.

- Low impact resistance.

Another disadvantage is poor weldability. Problems in welding parts made of this material are caused by the fact that during welding, cracks form, both during heating and cooling.

Marking of white cast iron

To mark white cast iron, letters of the Russian alphabet and numbers are used. If it contains impurities, then the marking begins with the letter “H”. The composition of the available alloying additives can be determined by the following letters P, PL, PF, PVK. They indicate the presence of silicon. If the resulting metal has increased wear resistance, then its marking will begin with the letter “I”, for example ICHH, ICH. For example, the presence of the designation “Ш” in the marking means that the alloy structure contains spherical graphite.

The numbers indicate the amount of additional substances present in white cast iron.

Brand CHN20D2ХШ is deciphered as follows. This is a heat-resistant high-alloy metal. It contains the following elements: nickel - 20%, copper - 2%, chromium - 1%. The remaining elements are iron, carbon, and spherical graphite.

Types of cast iron

In the generally accepted classification, they are divided according to the form of carbon they contain.

White

It is called so because of the characteristic color of the chip. Carbon C is contained in the form of cementite

(formula Fe3C), formed during cooling of the melt. Hard refractory material.

In hypoeutectic alloys - in the composition of pearlite and ledeburite. In eutectic ones - in ledeburite. In hypereutectic - primary cementite and ledeburite.

In its original form, such cast iron is practically not used. Cannot be processed with high-speed steel tools. Only with carbide nozzles (VC), and even then with difficulty.

It is used as a raw material for producing malleable.

Grey

Also named after the shade on the chip. Contains graphite fractions of various shapes. Carbon precipitation is facilitated by the addition of silicon.

Properties and structure strongly depend on cooling conditions after crystallization.

Rapid cooling will give a predominance of perlite. Alloy of ferrite and carbide. A kind of “hardening” will increase strength and hardness. And fragility, which is not always acceptable.

Gentle cooling determines the increase in ferrite content. An alloy of iron with oxides, mainly Fe2O3. Plasticity will improve. Therefore, modes are selected based on the required parameters.

Gray cast iron is suitable for cast structures.

It has a low curing temperature and good fluidity. Not prone to shell formation.

With all this, carbon inclusions cause low crack resistance. The material confidently withstands compressive forces, but is completely unsuitable for stretching/bending.

The marking indicates the symbols SCh and the ultimate strength in kg/mm2: SCh25. The most common cast irons are those with a C content below 3.7%.

Malleable

To produce white cast iron, it is heated to the required temperature, kept for a sufficient time and cooled slowly (“annealing”). The process provokes the decomposition of Fe3C with the release of graphite and the appearance of ferrite.

The shape of carbon inclusions is not similar to those in gray cast iron. This explains the appearance of some tensile strength and toughness.

Marked “KCh” with the addition of permissible tensile strength in MPa x 10-1 and maximum elongation. Example: CC 35-11.

High strength

A type of gray cast iron, only the graphite formations are shaped like balls. The roundness of the inclusions makes the crystal lattice not prone to cracks.

As a result, the initially valuable properties of cast iron (resistance to compression, ease of casting, etc.) are supplemented by a tensile yield strength comparable to steel, and crack resistance and ductility appear.

They are marked similarly to malleable ones, but with the designation “HF”.

Peredelny

Used as a raw material for steel smelting. Often it does not even leave the enterprise where it was made.

Special

The production of such brands is small, up to 2% of the total volume. May contain significant amounts of alloying elements. Designed for limited purposes and specific conditions. Corrosion and chemically resistant ferroalloys are common.

One of the varieties is anti-friction cast iron. Used for the manufacture of rubbing parts. Alloyed primarily with chromium. Nickel, titanium, copper and others are also added.

It is characterized by high hardness (up to HB 300) and low coefficient of friction (up to 0.8 in the absence of lubricating emulsions).

Base materials: gray, ductile and high-strength cast iron. The markings are respectively AChS, AChK, AChV. The digital components are described above.

How to distinguish cast iron from steel

At scrap metal collection points, cast iron is accepted at a low price, since it is fragile, difficult to process, and removing harmful impurities from it is not an easy task. Experts shared with us tips on how to independently distinguish cast iron from other metals:

- by sound (if you hit steel with any object, the sound comes out very loud);

- by strength;

- on magnetic properties.

Cast iron can be easily distinguished from iron. Iron rusts quickly, it is light silver in color and ductile. But it is more difficult to distinguish cast iron from steel, due to their similar composition; they are externally similar to each other, but the characteristics of the alloys are different from each other.

Steel is easier to process and is not afraid of impacts. There is an opinion that a magnet will help distinguish cast iron from steel. This is correct to some extent, because the magnetic properties of the alloy depend on its composition.

White cast iron

White (pipe) cast iron

– a type of cast iron in which carbon is in a bound state in the form of cementite, when fractured it has a white color and a metallic sheen. There are no visible graphite inclusions in the structure of such cast iron.

White iron castings are wear-resistant, heat-resistant and corrosion-resistant. Strength decreases and hardness increases with increasing carbon and carbide content.

White cast iron with a martensitic structure has the highest hardness. Cast iron containing 0.7-1.8% boron has particularly high hardness HB 800-850.

White cast iron is a very valuable material for parts operating under wear conditions at very high specific pressures and mainly without lubrication.

The characteristic features of alloyed white cast iron have determined the areas of its use as stainless and magnetic cast iron, as well as cast iron with high electrical resistance.

However, predominantly white cast iron is subsequently converted into steel (80%) and other types of cast iron, and therefore is called pig iron.

Differences from aluminum

A magnet can be used to distinguish cast iron not only from steel, but also from aluminum - a silvery-white light metal. This substance is paramagnetic, therefore it has external magnetic susceptibility (in the absence of an external magnetic field, the magnetic moments of atoms are non-zero).

The relative magnetic permeability of the metal is slightly greater than unity, and the magnetic field in it increases insignificantly. Accordingly, aluminum is magnetic, but very weakly. This is not visible visually, so it is generally accepted that it is not magnetic.

In addition to magnetic properties, metals have other differences: color, mass, density, hardness and flexibility. Therefore, you can distinguish them from each other in other ways.

Areas of use

Cast iron is common in many areas.

- It is used for the production of parts in mechanical engineering. Engine blocks and crankshafts are mainly made from cast iron. The latter require advanced cast iron, to which special graphite additives are added. Due to the resistance of cast iron to friction, it is used to make excellent quality brake pads.

- Cast iron can operate smoothly even at extremely low temperatures. Therefore, it is often used in the production of machine parts that will have to work in harsh climatic conditions.

- Cast iron has proven itself well in the metallurgical field. It is valued for its relatively low price and excellent casting properties. Products made from cast iron are characterized by excellent strength and wear resistance.

- A large variety of plumbing products are made from cast iron. These include sinks, radiators, sinks and various pipes. Cast iron bathtubs and heating radiators are especially famous. Some of them still serve in apartments today, although they were purchased many years ago. Cast iron products retain their original appearance and do not require restoration.

- Thanks to its good casting properties, cast iron produces real works of art. It is often used in the manufacture of artistic products. For example, such as beautiful openwork gates or architectural monuments.

White cast iron

Carbon cementite is formed due to instantaneous cooling. Recognized by the whitish color of the fracture, hardness, and fragility. The alloy is unsuitable for machining by cutting. It is used for solid wear-resistant casting (rolling rolls, parts of mill and crushing mechanisms) and as a source of malleable types of cast iron.

Microstructure of white cast iron at 100x magnification

Grey

The basis of the structure is layered graphite, which imparts a grayish tint. It can be machined, but its strength and ductility are low.

Advantages: good anti-friction, damping properties, mini-sensitivity to voltage batteries, fluidity, minimum defects during shrinkage.

It is used as a material for castings of complex configurations with wall thicknesses up to 5 cm.

It is used to make rolling mills, flywheels, columns, frames, and sewer and water supplies (manholes, pipes, fittings).

Cast iron manhole cover

Malleable

The result of heat treatment of white cast iron with flake graphite. This structure ensures strength, ductility, good machinability of castings, and the absence of internal stress.

Thanks to this, the alloy has found application as a material for parts and elements operating under conditions of shock and vibration: pedestals for massive equipment, supports for highways, railway bridges, diesel engine crankshafts.

The Severn Bridge - the world's first cast iron bridge

Half-hearted

An intermediate material between the first two varieties is half-cast iron. The carbon it contains is presented in the form of graphite and carbide in approximately equal proportions. In addition, such an alloy may contain small amounts of lideburite (no more than 3%) and cementite (no more than 1%). The total carbon content of half cast iron ranges from 3.5 to 4.2%. This variety is used for the production of parts that are operated under conditions of constant friction. These include automobile brake pads, as well as rolls for grinding machines. To further increase wear resistance, all sorts of additives are added to the alloy.

High strength

This type of cast iron is obtained due to the formation of spherical graphite inclusions in the metal lattice. Because of this, the metal base of the crystal lattice weakens, and the alloy acquires improved mechanical properties. The formation of spherical graphite occurs due to the introduction of magnesium, yttrium, calcium and cerium into the material. High-strength cast iron is close in its parameters to high-carbon steel. It lends itself well to casting and can completely replace steel parts of mechanisms. Due to its high thermal conductivity, this material can be used for the manufacture of pipelines and heating devices.

Special

Alloys with additional characteristics obtained by alloying, annealing and cooling using special technology.

Divided into:

- ferroalloys;

- corrosion-, wear-, heat-resistant;

- antifriction;

- with electromagnetic properties;

- decorative.

The composition of alloys and technology are regulated by standards.

High-strength grades become the mechanism of turbines, crankshafts, tractor and automobile engines, gears, and rolling rolls.

Anti-friction grades are used for bearings, fuel pump bushings, valves, and piston rings for cars.

Fences, columns, fountains, and small plastic items are forged from decorative ones.

Cast iron fence

Peredelny

A semi-finished product, a source for processing into steel or creating castings. The percentage of phosphorus, silicon, sulfur, manganese components in the alloy is regulated by the industry standard.

Depending on the purpose and percentage of silicon, pig iron for steelmaking, foundry production, phosphorous, and high-strength are distinguished.

The latter type of alloy contains graphite beads and magnesium. Used for the production of parts operating under extreme loads (mechanical and thermal) in aggressive environments.

Application of Ductile Iron

Ductile iron parts have also found their application in the electrical industry. It is made from:

- Terminals;

- Insulator hooks;

- Wire holders.

Such products cope well with force loads; they can bend under mechanical stress.

In textile engineering, ductile iron is used in the manufacture of:

- Gears;

- Forks

- Spokes;

- Parts for paper spinning machines.

In other words, for parts experiencing large static loads, subject to friction and rapid wear. For such products, anti-friction malleable cast iron is used, which is capable of creating minimal friction where there is maximum contact between the parts.

Malleable cast iron is also used in plumbing products. It is made from:

- Water outlets;

- Flange adapters;

- Valves;

- Heating radiators.

These products can work for a long time in an aquatic environment.

Gas systems use ductile iron to make the outlet fittings that connect pipes where all sorts of branches occur.

A variety of grades of malleable cast iron are widely used in landscape design when decorative parts are formed:

- Original hedges;

- Benches;

- Gates;

This alloy is also used in the furniture industry, for elements that can be affected by precipitation:

- Terrace furniture;

- Gazebos.

Parts for household equipment are made from it:

- Vann;

- Washing machines;

- Gas stoves;

- Frying pan;

- Kotelkov.

A lot of car parts are made of ductile iron. These include:

- Drives;

- Wheel hubs

- Gears;

- Carters;

- Engine brackets;

- Skating rinks;

- Brake pads;

- Overlays;

- Balancers

- Cardan shafts;

- Collectors.

Shipbuilding cannot do without malleable cast iron. In the manufacture of equipment for ships, CC is used for the production of:

- Portholes;

- Mast brackets;

- Oarlock;

- Breshtuk;

- Water fittings.

Malleable cast iron has not been forgotten in the railway industry. During the construction of cars, the following are made from it:

- Spare parts for air brakes;

- Bearings;

- Brackets

- Traction and coupling systems;

- Staples.

For many centuries, humanity has been using cast iron; today almost every person deals with such an alloy. It is highly durable and has a relatively low cost. The only drawback of cast iron parts is their fragility. But, with the correct technology for producing cast iron, this disadvantage is minimized, which is why cast iron parts are so widely used in the industries described above.

https://youtube.com/watch?v=QaZ8bCK4ipE

Manufacturing technologies

As you know, cast iron is produced in special blast furnaces. The main raw material for its production is iron ore. The manufacturing process consists of the reduction of iron ore oxides and the resulting production of another material - cast iron. For its production, fuels such as coke, thermoanthracite, and natural gas are used.

To produce one ton of pig iron, about 550 kilograms of coke and approximately a ton of water are required. The volume of ore loaded into the furnace will depend on the iron content in it. As a rule, ore is used, which contains at least 70% iron. The thing is that it is not economically feasible to use a lower concentration.

The first stage in the production of cast iron is its smelting. Ore is poured into the blast furnace, and then coking coal, which is necessary to pump and maintain the required temperature inside the furnace shaft. During combustion, these components take an active part in the ongoing chemical reactions as iron reducers.

Meanwhile, flux is immersed in the furnace, which acts as a catalyst. By accelerating the melting of rocks, it thereby supports the rapid release of iron. It is important to know that before loading into the furnace, the ore undergoes the necessary pre-treatment. It is crushed in a crushing plant because smaller particles melt faster. It is then washed to remove non-metal particles. Next, the raw material is fired, as a result of which sulfur and other foreign components are extracted from it.

At the second stage of production, natural gas is supplied through special burners into the filled and ready-to-use furnace. Coke is involved in heating the raw materials. Carbon is released, which combines with oxygen to form an oxide. It, in turn, promotes the recovery of iron from ore.

As the volume of gas in the furnace increases, the rate of the chemical reaction decreases. It may even stop completely when a certain gas ratio is reached. Carbon penetrates the alloy and combines with iron to form cast iron. Unmelted elements remain on the surface and are soon removed. Such waste is called slag. It is used to make other materials.

First stage of production

Iron smelting occurs as follows. First of all, ore is poured into the furnace, as well as coking coal grades, which serve to pump and maintain the required temperature inside the furnace shaft. In addition, during the combustion process, these products actively take part in the ongoing chemical reactions as iron reducers.

At the same time, flux is loaded into the furnace, serving as a catalyst. It helps the rocks melt faster, which promotes the rapid release of iron.

It is important to note that the ore undergoes special pre-treatment before loading into the furnace. It is crushed in a crushing plant (small particles melt faster). Afterwards it is washed to remove particles that do not contain metal. After which the raw material is fired, due to this, sulfur and other foreign elements are removed from it.

Second stage of production

Natural gas is supplied to the loaded and ready-to-use furnace through special burners. Coke heats the raw material. This releases carbon, which combines with oxygen to form an oxide. This oxide subsequently takes part in the reduction of iron from the ore. Note that as the amount of gas in the furnace increases, the rate of the chemical reaction decreases, and when a certain ratio is reached, it stops altogether.

Excess carbon penetrates the melt and combines with iron, ultimately forming cast iron. All those elements that have not melted end up on the surface and are eventually removed. This waste is called slag. It can also be used to produce other materials. The types of cast iron obtained in this way are called foundry and conversion.

content .. 11 12 18 ..Cast iron. Iron-graphite phase diagram. Structure, properties, classification and marking of gray cast iron

Classification of cast irons

Cast iron differs from steel: in composition - a higher content of carbon and impurities; in terms of technological properties - higher casting properties, low ability to plastic deformation, almost not used in welded structures.

Depending on the state of carbon in cast iron, there are:

white cast iron - carbon in a bound state in the form of cementite, when fractured it has a white color and a metallic sheen; gray cast iron - all or most of the carbon is in a free state in the form of graphite, and no more than 0.8% of carbon is in a bound state. Due to the large amount of graphite, its fracture has a gray color;

half - part of the carbon is in a free state in the form of graphite, but at least 2% of the carbon is in the form of cementite. Little used in technology.

Iron-graphite phase diagram.

As a result of the transformation, carbon can not only chemically interact with iron, but also be released in the elemental state in the form of graphite. The liquid phase, austenite and ferrite can also be in equilibrium with graphite.

The iron-graphite phase diagram is shown with dashed lines in Fig. 11.1. The lines of the diagram are above the lines of the iron – cementite diagram. The temperatures of eutectic and eutectoid transformations are 1153oC and 738oC, respectively. Points C, E, S are shifted to the left and are located at carbon concentrations of 4.24, 2.11 and 0.7%, respectively.

Fig. 11.1. Iron-carbon phase diagram: solid lines – cementite system; dotted – graphite

At high temperatures, cementite decomposes with the release of graphite, so the iron-cementite phase diagram is metastable, and the iron-graphite phase diagram is stable. The process of formation of graphite in iron-carbon alloys is called graphitization.

Graphitization process.

Graphite is a polymorph of carbon. Since graphite contains 100% carbon, and cementite - 6.67%, the liquid phase and austenite are closer in composition to cementite than to graphite. Consequently, the formation of cementite from the liquid phase and austenite should proceed more easily than graphite.

On the other hand, when heated, cementite decomposes into iron and carbon. Therefore, graphite is a more stable phase than cementite.

There are two possible ways for graphite to form in cast iron.

Under favorable conditions (the presence of ready-made graphite crystallization centers in the liquid phase and very slow cooling), graphite is directly formed from the liquid phase.

During the decomposition of previously formed cementite. At temperatures above 738oC, cementite decomposes into a mixture of austenite and graphite according to the scheme

.

At temperatures below 738oC, cementite decomposition is carried out according to the following scheme:

.

At low cooling rates, the degree of cementite decomposition is greater.

Graphitization from the liquid phase, as well as from the decomposition of primary cementite and cementite included in the eutectic, is called the primary stage of graphitization.

The separation of secondary graphite from austenite is called the intermediate stage of graphitization.

The formation of eutectoid graphite, as well as graphite resulting from cementite, which is part of pearlite, is called the secondary stage of graphitization.

The structure of cast iron depends on the degree of graphitization, i.e. on how much carbon is in a bound state.

Rice. 11.2. Scheme of formation of structures during graphitization

Exposure at temperatures above 738oC leads to graphitization of excess undissolved cementite. If the process is completed completely, then at high temperatures the structure will consist of austenite and graphite, and after cooling - of pearlite and graphite.

When the primary graphitization process is incomplete, above a temperature of 738oC the structure consists of austenite, graphite and cementite, and below this temperature - of pearlite, graphite and cementite.

When passing through the critical point of transformation of austenite into pearlite, and holding at a temperature below the critical point, it will lead to the decomposition of cementite, which is part of the pearlite (secondary graphitization). If the process is completely completed, then the structure consists of ferrite and graphite; if the process is incomplete, it consists of pearlite, ferrite and graphite.

Structure, properties, classification and marking of gray cast iron

From an examination of the structures of cast iron, we can conclude that their metal base is similar to the structure of eutectoid or hypoeutectoid steel or technical iron. They differ from steel only in the presence of graphite inclusions, which determine the special properties of cast iron.

Depending on the form of graphite and the conditions of its formation, the following groups of cast iron are distinguished: gray - with lamellar graphite; high-strength – with spherical graphite; malleable - with flake graphite.

Schemes of cast iron microstructures depending on the metal base and the shape of graphite inclusions are presented in Fig. 11.3

Rice. 11.3. Diagrams of cast iron microstructures depending on the metal base and the shape of graphite inclusions

The most widely used cast irons are those with a carbon content of 2.4…3.8%. The higher the carbon content, the more graphite is formed and the lower its mechanical properties, therefore, the amount of carbon should not exceed 3.8%. At the same time, to ensure high casting properties (good fluidity), carbon must be at least 2.4%.

The influence of cast iron composition on the graphitization process.

Carbon and silicon promote graphitization, manganese impedes graphitization and promotes bleaching of cast iron. Sulfur promotes bleaching of cast iron and worsens casting properties; its content is limited - 0.08...0.12%. Phosphorus does not affect the graphitization process, but improves fluidity. Phosphorus is a useful impurity in cast iron, its content is 0.3...0.8%.

The influence of graphite on the mechanical properties of castings.

Graphite inclusions can be considered as a corresponding form of void in the structure of cast iron. Near such defects, during loading, stresses are concentrated, the greater the value of which, the sharper the defect. It follows that plate-shaped graphite inclusions soften the metal to the maximum extent. The flake-like form is more favorable, and the spherical form of graphite is optimal. Plasticity depends on shape in the same way. The relative elongation () for gray cast iron is 0.5%, for malleable cast iron - up to 10%, for high-strength cast iron - up to 15%.

The presence of graphite most dramatically reduces resistance under severe loading methods: impact; gap The compression resistance decreases little.

Positive aspects of having graphite.

graphite improves machinability due to the formation of brittle chips;

cast iron has better anti-friction properties compared to steel, since the presence of graphite provides additional lubrication of friction surfaces;

due to microvoids filled with graphite, cast iron dampens vibrations well and has increased cyclic viscosity;

cast iron parts are not sensitive to external stress concentrators (grooves, holes, transitions in sections);

cast iron is much cheaper than steel;

The production of products from cast iron by casting is cheaper than the production of products from steel blanks by cutting, as well as casting and pressure treatment followed by machining.

Gray cast iron.

The structure does not affect the ductility; it remains extremely low. But it does affect hardness. Mechanical strength is mainly determined by the number, shape and size of graphite inclusions. Small, swirl-shaped graphite flakes reduce strength less. This form is achieved through modification. Aluminum, silicocalcium, and ferrosilicon are used as modifiers.

Gray cast iron is widely used in mechanical engineering, as it is easy to process and has good properties.

Depending on the strength, gray cast iron is divided into 10 grades (GOST 1412).

Gray cast irons, with low tensile strength, have fairly high compressive strength.

Gray cast iron contains carbon – 3.2…3.5%; silicon – 1.9…2.5%; manganese –0.5…0.8%; phosphorus – 0.1…0.3%; sulfur – <0.12%.

The structure of the metal base depends on the amount of carbon and silicon. With increasing carbon and silicon content, the degree of graphitization and the tendency to form a ferrite structure of the metal base increase. This leads to softening of cast iron without increasing ductility. Pearlitic gray cast iron has the best strength properties and wear resistance.

Given the low resistance of gray cast iron castings to tensile and impact loads, this material should be used for parts that are subject to compressive or bending loads. In machine tool building these are basic, body parts, brackets, gears, guides; in the automotive industry - cylinder blocks, piston rings, camshafts, clutch discs. Gray cast iron castings are also used in electrical engineering and for the manufacture of consumer goods.

They are designated by the index SCh (gray cast iron) and a number that shows the value of the tensile strength multiplied by SCh 15.

High-strength nodular cast iron.

High-strength cast irons (GOST 7293) can have a ferritic (VCh 35), ferrite-pearlite (VCh 45) and pearlitic (VCh 80) metal base. These cast irons are obtained from gray cast irons as a result of modification with magnesium or cerium (0.03...0.07% of the casting weight is added). Compared to gray cast irons, the mechanical properties are increased, this is caused by the lack of unevenness in stress distribution due to the spherical shape of graphite.

Cast irons with a pearlitic metal base have high strength values with a lower ductility value. The ratio of ductility and strength of ferritic cast iron is the opposite.

High-strength cast irons have a high yield strength,

,

which is higher than the yield strength of steel castings. Also characterized by fairly high impact strength and fatigue strength,

,

with pearlite base.

High-strength cast irons contain: carbon - 3.2...3.8%, silicon - 1.9...2.6%, manganese - 0.6...0.8%, phosphorus - up to 0.12%, sulfur - up to 0. 3%.

These cast irons have high fluidity, linear shrinkage is about 1%. Casting stresses in castings are slightly higher than for gray cast iron. Due to the high modulus of elasticity, the machinability is quite high. They have satisfactory weldability.

High-strength cast iron is used to make thin-walled castings (piston rings), forging hammers, beds and frames of presses and rolling mills, molds, tool holders, and faceplates.

Casting crankshafts weighing up to 2..3 tons, instead of forged steel shafts, have higher cyclic toughness, are insensitive to external stress concentrators, have better anti-friction properties and are much cheaper.

They are designated by the index HF (high-strength cast iron) and a number that shows the value of the tensile strength multiplied by HF 100.

Malleable iron

Produced by annealing white hypoeutectic cast iron.

Good properties of castings are ensured if graphitization does not occur during the process of crystallization and cooling of the castings in the mold. To prevent graphitization, cast irons must have a reduced carbon and silicon content.

Malleable cast iron contains: carbon - 2.4...3.0%, silicon - 0.8...1.4%, manganese - 0.3...1.0%, phosphorus - up to 0.2%, sulfur - up to 0, 1 %.

The formation of the final structure and properties of castings occurs during the annealing process, the diagram of which is presented in Fig. 11.4.

Rice. 11.4. Annealing of malleable cast iron.

The castings are kept in an oven at a temperature of 950...1000C for 15...20 hours. Cementite decomposes: .

The structure after exposure consists of austenite and graphite (annealing carbon). With slow cooling in the range of 760...720oC, decomposition of cementite, which is part of pearlite, occurs, and the structure after annealing consists of ferrite and annealing carbon (ferritic malleable cast iron is obtained).

With relatively rapid cooling (mode b, Fig. 11.3), the second stage is completely eliminated, and pearlitic malleable cast iron is obtained.

The structure of cast iron, annealed according to mode B, consists of pearlite, ferrite and annealing graphite (ferrite-pearlite malleable cast iron is obtained)

Annealing is a long 70...80 hours and expensive operation. Recently, as a result of improvements, the duration has been reduced to 40 hours.

There are 7 grades of malleable cast iron: three with a ferritic (CN 30 - 6) and four with a pearlitic (CN 65 - 3) base (GOST 1215).

In terms of mechanical and technological properties, malleable cast iron occupies an intermediate position between gray cast iron and steel. The disadvantage of malleable cast iron compared to high-strength cast iron is the limited wall thickness for casting and the need for annealing.

Ductile iron castings are used for parts operating under shock and vibration loads.

Gearbox housings, hubs, hooks, brackets, clamps, couplings, and flanges are made from ferritic cast iron.

Pearlitic cast iron, characterized by high strength and sufficient ductility, is used to make driveshaft forks, links and rollers of conveyor chains, and brake pads.

They are designated by the index KCh (high-strength cast iron) and two numbers, the first of which shows the value of the tensile strength multiplied by , and the second - the relative elongation - KCh 30 - 6.

Bleached and other cast irons

Bleached – castings, the surface of which consists of white cast iron, and the inside is gray or high-strength cast iron.

Cast iron contains 2.8...3.6% carbon and a low silicon content of 0.5...0.8%.

They have high surface hardness (950...1000 HB) and very high wear resistance. Used for the manufacture of rolling shafts, carriage wheels with bleached rims, and balls for ball mills.

For the manufacture of parts operating under abrasive wear conditions, white cast iron alloyed with chromium, chromium and manganese, chromium and nickel is used. Castings made from such cast iron are characterized by high hardness and wear resistance.

For parts operating under wear conditions at high temperatures, high-chromium and chromium-nickel cast irons are used. Heat resistance is achieved by alloying cast iron with silicon (5...6%) and aluminum (1...2%). Corrosion resistance is increased by alloying with chromium, nickel, and silicon.

For cast iron, heat treatment can be used.

content .. 11 12 18 ..

Industry challenges

Today, cast iron casting has dubious prospects. The fact is that due to high costs and large amounts of waste, industrialists are increasingly abandoning cast iron in favor of cheap substitutes. Thanks to the rapid development of science, it has long been possible to obtain higher quality materials at lower costs. Environmental protection plays a major role in this issue and does not accept the use of blast furnaces. It will take years, if not decades, to completely convert iron smelting to electric furnaces. Why so long? Because it is very expensive, and not every state can afford it. Therefore, all that remains is to wait until mass production of new alloys is established. Of course, it will not be possible to completely stop the industrial use of cast iron in the near future. But it is obvious that the scale of its production will fall every year. This trend began 5-7 years ago.

Gray cast iron

Gray (cast) cast iron

- an alloy of iron and graphite, which is present in the form of plates or fibers.

Gray cast iron is characterized by high casting properties (low crystallization temperature, high fluidity, low shrinkage) and serves as the main material for casting. Widely used in mechanical engineering for casting machine beds and mechanisms, pistons, cylinders.

In addition to carbon, gray cast iron contains other elements. The most important of them are silicon and manganese. In most grades of gray cast iron, the carbon content is in the range of 2.4-3.8%, silicon 1.0-4.0% and manganese up to 1.4%.

Methods of welding cast iron products

To weld the material, specialists resort to the use of coated or carbon electrodes. In addition, flux-cored wire is used, as well as equipment for gas welding. If we consider the process of welding high-density cast iron products from a technological point of view, then we need to highlight three main areas:

- Obtaining a high-quality weld in the material.

- Producing a low-carbon weld.

- Preparation of a weld consisting of alloys of non-ferrous metals.

When welding high-density cast iron products, an important task is to prevent the occurrence of hardened areas. To avoid this, preheat the parts that will be welded. Depending on the degree of heating, the following types of welding are distinguished:

- hot - with this welding mode, the products are preheated to a temperature of 600–650 degrees Celsius;

- semi-hot - a high-density product prepared for welding is heated to a temperature of 450 degrees Celsius;

- cold welding - performed without preheating.

The use of the first two modes of welding high-density cast iron should be resorted to in cases where the task is to obtain a high-density alloy in the weld material, which is close to the base material.

Hot welding. When this mode is performed, the cold part prepared for welding is heated to 650 degrees Celsius. This allows you to create conditions for uniform heating and slow cooling of parts after completion of work.

Semi-hot welding. When the connection of cast iron products is made by semi-hot welding, then to solve the problem of increasing graphitization, they resort to using the method of introducing graphitizing substances. They are aluminum, titanium or silicon. They are introduced into the welding area, and the parts themselves are heated to a temperature lower than during hot welding.

Proper preparation of cast iron for welding

Preparation of cast iron for welding must be carried out without fail; the quality of the finished seam, its strength, and wear resistance depend on it. If this process is performed correctly, it will prevent fragility and porosity of the material structure, as well as eliminate possible defects.

Preparation should consist of the following:

- sawing cracks. Often cracks in cast iron have a thin and deep structure. If the thickness of the workpiece is 4 mm, then the seam applied on top will not significantly melt the surface of the crack. This will leave a fragmented structure within the alloy base. In this case, the degree of resistance to tearing and fracture will be weak. In order for there to be good brewing in these places, it is necessary to saw the crack with a grinder using a thin disk. At the same time, the greater the thickness of the material, the deeper the sawing should be;

- drilling the edges. When visually inspecting a cast iron part, it is impossible to see the exact end of the crack depth. For this reason, before you start welding a crack, it is worth drilling small holes along its edges. A distance of 5 mm is required from the visible end of the fault. If you drill through the edges, this will ensure that the internal space is well filled with metal, as well as protect against continued splitting;

- performing edge cutting. The degree of weldability of cast iron may differ due to overheating in the area of the connecting seam, which can lead to increased fragility of this area. To prevent this process, uniform heating is required over the entire length of the connection. The area of the connecting seam is diluted with metal, for this purpose the correct cutting of the edges is used. When connecting thick plates, the edges are beveled at an angle of 45 degrees, while a small bluntness of 3-4 mm should be left at the base. This separation will ensure good filling of the separation area, and it will also increase the strength and wear resistance of this area;

- carrying out preforming. When welding a thin cast iron alloy product, the likelihood of liquid metal leakage increases. For this reason, in these cases it is necessary to place a graphite lining under the product; this will support the heated area and preserve the original shape of the element.

Gas welding

Gas welding of cast iron is mainly used in cases where it is required to obtain a high-strength weld, but subject to a small penetration of the surface of the base metal. At the same time, the technology of gas welding of cast iron is accompanied by the use of several welding modes, on which the quality of the final joint will depend.

The quality indicator of a welded joint is influenced by the following components:

- types of supply voltage modes;

- type of technique of the superimposed welded joint;

- current indicator;

- passing speed.

How to weld cast iron and steel using gas arc welding in order to ultimately obtain a connection with high strength without cracks, pores and other defects? To do this, you need to comply with some requirements during the workflow:

- the arc voltage indicator should be from 18 to 21 V;

- current strength - 100-120 A;

- travel speed no more than 12 m per hour;

- Welding work must be carried out using special welding wires 09G2SA or PANCH 11 with a diameter of 1 mm.

Argon welding

Welding cast iron with argon is used by many novice welders on the advice of experienced comrades, and they often resort to semi-automatic welding in an argon environment. This method is not justified for products made of cast iron alloys. The connection is obtained as in heated air, but the costs increase greatly.

The technology for welding cast iron and steel with argon usually requires the presence of a neutral environment. Of course, a seam can be obtained in an atmospheric environment, but its quality will greatly deteriorate. When welding in this environment, microcracks may form in the joint, and uneven hardening will also be observed.

If, in addition to welding, the inert gas argon is supplied, the chemical composition in the weld pool will not change in any way. If argon is used, the welding method does not matter at all. The quality of the welds is equally good for any connection of parts - butt, overlap, patch.

TIG welding of cast iron using argon is considered the most optimal option, which allows you to make a strong seam. Using gas you can cook almost any combination. If there are some difficulties in purchasing argon, then it is better to leave it for joining cast iron and steel.

Production Features

An alloy of iron and carbon, which takes the form of graphite flakes in the metal structure, is called malleable cast iron. It is obtained by long-term heat treatment of white cast iron blanks. Under the influence of annealing, the structure of the metal changes, cementite in it turns into graphite. This process is called graphitization. After heat treatment, the alloy changes its mechanical characteristics - strength and hardness decrease, and the material becomes plastic.

Annealing technology includes 5 stages:

- Slow heating of the workpiece for 20–25 hours to a temperature of 950–1000 ºС.

- The first stage of graphitization. Exposure at a temperature of 950–1000 ºС for 15–20 hours.

- Slow cooling to a temperature of 740–720 ºС, operation time 6–12 hours.

- The second stage of graphitization is a long exposure of the workpiece at a temperature of 720 ºС or a gradual decrease in temperature from 760 to 720 ºС. The duration of this operation is about 30 hours.

- Complete cooling of the part.

There are four annealing methods to impart the required properties to an iron casting. They differ in stage No. 4 (temperature range from 760–720 ºС). The remaining annealing stages are the same.

- Rapid cooling to a temperature below critical - 720 ºС and holding at this temperature for 30 hours.

- Slow cooling over 30 hours, in the critical temperature range from 760–720 ºС.

- Step cooling in the temperature range from 760 to 720 ºС.

- Technology of alternate heating above 760 ºС and cooling below 720 ºС.

Features of caring for cast iron cookware

After any type of cleaning, measures must be taken to create a protective layer on the cast iron to prevent corrosion in the future:

- turn on the oven at 180 degrees, warm it up;

- grease the frying pan with oil (any oil except olive oil), applying a thin layer;

- place the product in the oven, bottom up, leave for 60 minutes;

- turn off the cabinet, do not take out utensils for another hour;

- Remove the pan, rinse, wipe dry, and put away for storage.

Cast iron should always remain a little greasy - this will allow it to maintain protection against corrosion for a long time. In the future, you should follow these care tips:

- Always wait for the product to cool down and only then start washing it;

- after each wash, lubricate the item with vegetable oil and heat for 1-2 minutes;

- do not leave the pan with ready-made liquid food for a long time - after cooking, pour it into another container;

- do not use aggressive detergents, brushes, or abrasives on a regular basis, they wash off the protective layer and the cast iron rusts faster;

- to remove burnt food, soak the dishes in warm water, then easily remove the remains with a washcloth;

- do not forget to use the dishes regularly so that they do not stand idle;

- do not wash in the dishwasher;

- Do not cook acidic food, which corrodes the protective layer.

High-quality care of cast iron will keep the product in excellent condition, eliminate the appearance of rust, while maintaining its non-stick properties and ability to retain heat.

Sources

- https://jgems.ru/metally/chugun

- https://stroyres.net/metallicheskie/vidyi/chyornyie/chugun/ponyatie-osobennosti.html

- https://metallicheckiy-portal.ru/articles/chermet/raznoe/chto-takoe-chugun-sostav-i-soderzhanie-ugleroda-v-splave/

- https://elton-zoloto.ru/raznoe/skolko-procentov-ugleroda-imeetsja-v-sostave-chuguna.html

- https://lux-stahl.ru/metally-i-splavy/izbytok-alyuminiya-v-chugunah-vyglyadit-kak.html

- https://ometalledo.ru/soderzhanie-ugleroda-v-chugune-i-stali.html

- https://www.syl.ru/article/304510/chto-takoe-chugun-svoystva-sostav-poluchenie-i-primenenie

- https://sakhkor.ru/materialy/vidy-chuguna.html

- https://morflot.su/procentnoe-soderzhanie-ugleroda-v-chugune/

- https://metallvsegda.ru/poleznoe/chto-takoe-chugun-sostav-i-soderzhanie-ugleroda-v.html