What is an abrasive disc and its purpose?

The grinder circle is also called a disk due to its similarity. These consumables are called cut-off because they consist of several layers of a reinforcing base. Why are metal cutting discs made of abrasive materials and not steel? Contact of two steels would lead to their rapid overheating and reduced productivity. Abrasive wheels consist of small grains of electrocorundum and carbide, which are stronger than metals. When cutting metal structures with electrocorundum discs, small particles are burned, and thereby achieve a result in the form of cutting.

Where are they used?

Cutting wheels are classified according to their intended use for metal, concrete and wood. Each type of device under consideration has its own design features, but in the material we will consider consumables for metal. They are intended only for working with the following types of materials:

- Metal

- Steel

- Cast iron

- Stainless steel

- Non-ferrous metals - aluminum, copper

- Galvanization

The abrasive disc is structurally different from attachments for working with concrete and wood. The main difference is the consistency from which the nozzle is made.

Main advantages and disadvantages

- increased geometric cutting accuracy;

- flat surface;

- almost silent operation.

Metal cutting machine: design and manufacture, selection and classification

The cost of work using diamond blades should be calculated for each specific job.

The disadvantages of such a device include its high cost, but the working life of a diamond cutting tool significantly exceeds (almost 70 times) the working life of abrasive discs performing the same work. Equipment downtime is reduced by reducing the frequency of tool replacement. When using active cooling, it is possible to increase rotation speed and productivity. Throughout its service life, the tool retains its geometric characteristics.

What is an abrasive disc for an angle grinder made of?

An angle grinder or angle grinder is a unique tool that can replace many hand-held tools, such as hacksaws for wood and metal. The versatility of the grinder is achieved through the use of consumables - cutting, grinding, polishing, stripping and the like. The most popular are metal cutting discs. Attachments for sawing wood are less popular, since an angle grinder is far from the most suitable tool for working with this material.

The abrasive disk consists of two main components - a reinforcing layer, which is located in the thickness of the nozzle, as well as electrocorundum or silicon carbide. Electrocorundum or silicon carbide is used in the form of grains (small and large), which are connected to the reinforcing layer by sintering. Bakelite or vulcanite is used as a reinforcing layer. What is the difference between bakelite and vulcanite circles for metal, their advantages and disadvantages, we will find out further.

Bakelite vulcanite and ceramic circle which is better to choose

Bakelite and vulcanite are practically the same type of materials that are actively used in the manufacture of reinforcing discs for angle grinders. The reinforcing layer is a fine mesh that is located inside the nozzle. What is the difference between bakelite and vulcanite, and what is the best wheel to choose for metal cutting work, we will find out further.

- Vulcanite wheels have great elasticity, which allows manufacturers to produce nozzles of small thickness from 0.8 mm

. They are based on pre-treated rubber and sulfur. Elasticity has a positive effect on productivity, since large vibrations do not occur during work. The dense structure of the material eliminates the possibility of destruction of the integrity of the device. Vulcanite wheels for metal have found their application in cases where it is necessary to carry out burn-free and fine cutting. The disadvantage of such devices is that they are not resistant to high temperatures, and therefore their destruction is observed already at 160-200 degrees. The thicker and denser the structure of the workpiece being cut, the faster the disc will heat up and its productivity will decrease by 2-3 times. - Bakelite can withstand temperatures up to 250-300 degrees, but during operation they spark strongly.

They are based on a powdery consistency of formaldehyde resins with fillers present. If it is necessary to saw thick and dense metal, for example, rails or I-beams, it is recommended to use bakelite wheels. Bakelite is less elastic, so vibrations occur during operation - Ceramic bond is the most expensive disc, the manufacturing basis of which includes various materials such as talc, fire clay, quartz, feldspar and others.

A distinctive feature of ceramic discs is that they are resistant to water and are also fire-resistant. Their main disadvantage is their sensitivity to shock loads.

For cutting thin and less durable metals, it is recommended to use vulcanite wheels, while bakelite wheels are suitable for long-term cutting of thick-walled materials. However, the reinforcing layer in the design of the nozzle is not the only main factor influencing the performance of the relevant work. You need to pay attention to the material from which the cutting wheel is made.

This is interesting!

The bond (reinforcing elements) may not be present on abrasive wheels, which affects their strength, so for dense metals it is recommended to buy attachments with a reinforcing layer.

What material does a cutting wheel for metal consist of: electrocorundum and carbide?

Metal cutting discs are made from two types of materials, such as electrocorundum and silicon carbide. You can find out what particular cutting wheels are made of by looking at the markings. Marking is the technical characteristics of the nozzles in question. However, knowing what material the cutting wheel is made of is not enough. After all, carbide and electrocorundum nozzles are different, and therefore they must be used depending on what type of metal you plan to cut.

A cutting disc for a grinder, made from grains of electrocorundum, is intended directly for cutting steel products. Electrocorundum grains are soft, so when cutting durable types of steel, these discs are used. Silicon carbide wheels are characterized by high hardness, so they are used for cutting non-ferrous metals, as well as stainless steel, galvanized steel and other soft materials.

These materials differ not only in the degree of hardness, but also in thermal stability. Corundum abrasives are resistant to high temperatures and can withstand loads up to 1900 degrees. Carbide compounds are less resistant to high temperatures, and the least durable are diamond and boron carbide, which can withstand up to 800 degrees.

Classification of discs for grinders

Grinder circles can be divided into several types:

- cutting;

- polishing and grinding;

- sharpening;

- peeling.

What materials are used for processing:

metal;- wooden;

- concrete;

- glass.

Grinder wheels differ in shape, thickness, diameter and material of manufacture. For simple operations, conventional flat abrasive discs are used. When cutting or grinding in hard-to-reach places, use plate-shaped wheels with recessed fasteners.

What kind of discs are there by outer and inner diameter?

It's no secret that grinders differ in power and size. For the corresponding type of tool, discs of standard sizes in outer and inner diameter are used. Manufacturers produce cutting wheels for grinders with the following standards of external dimensions:

- 115 mm - suitable exclusively for low-power household power tools

- 125 mm - suitable for household and semi-professional angle grinders

- 150 mm - for medium-power professional units

- 180 mm - for medium and powerful angle grinders

- 230 mm - for powerful professional angle grinders

Abrasive wheels are also produced for tools with dimensions over 300 mm, but they are used exclusively on special equipment and machines. As for the internal diameters of the holes, which are also called landing holes, the run-up here is much smaller. According to the size of the mounting holes, abrasive wheels for grinders are as follows:

- 22 mm

- 22.23 mm

- 32 mm

The most popular are circles with a dimension of 22.23 mm. They are suitable for angle grinders with seat shaft sizes of 22 and 22.23 mm. Discs with a 32 mm hole are intended for special machines. There are also cutting discs with holes smaller than 22 mm - these are 10 mm, 13 mm and 16 mm. With such small holes, circles are produced whose outer diameter does not exceed 100 mm.

How thick are cutting discs?

One of the most interesting questions is about what thickness a cutting wheel for metal should have. Thick wheels are used for sharpening and thin wheels for cutting. However, not everything is as simple as it might seem. Cutting wheels have a maximum thickness of 4 mm and a minimum of 0.8 mm. Manufacturers produce not only cutting discs, but also sharpening discs made of similar materials, which is important to consider when purchasing. Sharpening wheels are not designed for cutting metal and they are thicker than 3mm.

When choosing a thickness, you should be guided by the following data:

- If the nozzle is thin, then less effort and time is required to achieve the result.

- If a thick disk is used, then it requires spending not only more time, but also more effort.

Many people prefer to use thick discs, justifying this by the fact that a thick nozzle is highly durable and resistant to resolution. In reality, everything is just the same. Reviews and recommendations suggest that working with thin circles is much safer and more reliable, provided that it is chosen correctly. How to choose the right abrasive wheels, taking into account their technical characteristics, is described below. To justify the safety of thin disks, it should be noted that they are more elastic and at the same time are able to bend without deforming, unlike thick-walled nozzles. The thickness of cutting wheels depending on the external dimensions of consumables is indicated in the table below.

Which disc to cut metal with a grinder

Cutting wheels of small thickness (1–1.2 mm) are suitable for working with metal workpieces. They allow you to make straight cuts without applying significant effort. For shaped processing of thin rolled metal, metal grinder wheels of the smallest diameter are used.

Photo No. 5: circles for an angle grinder for metal (125 mm)

Next, when choosing a tool for an angle grinder for cutting sheet metal, they focus on the material that needs to be processed. Cast iron, steel, aluminum and brass require different discs. You will find out information about the purpose of a particular product from the markings on the label.

For stainless steel. Unlike other consumables, discs designed for stainless steel do not damage the protective film on the metal, which protects the material from corrosion.

Photo No. 6: cutting wheel for an angle grinder on stainless steel

For non-ferrous metals. There are separate varieties for cutting cast iron, aluminum, copper, and brass. Anti-caking additives are added to the composition of wheels that work with soft materials. Products for processing cast iron, on the contrary, have solid diamond inclusions.

Photo No. 7: cutting wheel for an aluminum grinder

- For thin profiles and pipes. Sheet metal should be cut with a grinder using circles that are suitable in diameter. Profiled sheets and tin are processed with products with small teeth. Corners and fittings are made with thicker discs.

- Roughing. Used for cleaning burrs and welds. The thickness of the circles is 5–10 mm. The treatment is carried out with the machine tilted at an angle of 30–40 degrees to the surface.

Photo No. 8: grinding wheel for grinder

Brush. Products made from rigid wire effectively remove rust when the grinder is turned in different directions.

Photo No. 9: brush wheel for metal

Petal and abrasive. The former are used for final grinding of smooth surfaces. The second is for removing fairly large protrusions and growths. High-quality grinding involves alternating two types of wheels.

Photo No. 10: petal circle for an angle grinder

What affects the hardness of a cutting wheel?

The devices in question have different hardness, which depends on the material used to make the nozzle. When choosing a disk based on hardness, you need to adhere to the following recommendation - the higher the hardness of the workpiece being processed, the lower this parameter should be for the consumable. To put it simply, to saw or cut metal, steel, cast iron, it is necessary to use electrocorundum wheels.

The softer the workpiece being cut, for example, aluminum, copper, stainless steel, the harder the silicon carbide nozzle should be used. The hardness of the disk also depends on the size of the grains, and this parameter is indicated on the front side of the nozzle in the form of Latin letters from M to T. The hardest are the nozzles, where the letter T is placed.

This is interesting!

In addition to hardness, you also need to take into account the sound hardness index. It is indicated by two numbers that follow the hardness in the marking of the nozzle.

What does the marking of cutting discs for metal mean and how to decipher?

Each cutting disc for an angle grinder has a corresponding marking, which reveals the most important information. Knowing and being able to decipher the markings of cutting wheels, it will not be difficult to choose an attachment. The label contains the following main information:

- Manufacturer - indicated at the very top of the nozzle

- Under the mounting hole, the three most important dimensions are indicated - outer diameter, thickness and seat ring size. An example of the designation is as follows: 180x1x22.23

- Material for which the nozzle can be used. The designation “metal” is indicated on abrasive discs. There are also universal wheels designed for cutting ferrous and non-ferrous metals. If the disc says Steel, then it can cut steel, Inox - stainless steel, Aluminum - for aluminum and copper, Castiron - cast steel and cast iron

- Types of nozzles - this indicator indicates the design of the mounting hole. If the number is 41, then this means that the disk is flat, and if it is 42, it is offset in one direction. Usually the number 42 is present on sharpening wheels

- The binder material is vulcanite, bakelite and ceramic. On domestically produced attachments the type of reinforcing layer is indicated by two Cyrillic letters (for example, BU - reinforced bakelite), and on foreign ones by Latin BF

- The type of material from which the circle is made. If there is a letter A, it is electrocorundum, C is silicon carbide. Before the letter index there is a number indicating the size of the fraction or grain size of the material

- Hardness - indicated immediately after the grain size, for which the Latin letters M and T are used

- Maximum operating speed depends on the type of reinforcing bond. For vulcanite, the maximum speed parameter is from 50 to 80 m/sec, and for bakelite from 80 to 100 m/sec. Rotation speed affects the speed of work

- The expiration date is one of the main parameters that shows whether the nozzle can be used or not. Few people pay attention to the expiration date, which ultimately causes serious consequences in the form of injuries, injuries and even deaths. Before you buy and put the disc into the grinder spindle, you should check the expiration date. It is indicated mainly on the metal part of the seat ring. The indicated values in the form of year and month are the maximum service life, after which the use of consumables is contraindicated

Depending on the manufacturer, other additional information is indicated on the front part of the nozzle, such as the sound index, imbalance class, as well as GOST. The nozzles are not only manufactured to the appropriate standards, but also subjected to testing. What an example of decoding a cutting disc looks like is shown below.

Basic designations

A thorough approach to the selection of abrasive wheels depends on the following criteria:

- Overall circle diameter;

- Thickness of the disk plate;

- Bore diameter (rarely differs from 22.2).

In addition, the basic information usually includes an expiration date.

According to standards, the thickness of a plate with a diameter of 125 mm is from 2.3 mm to 2.5 mm. Discs of 1-1.2 mm are considered thin with the same diameter .

The main information should be looked for on the front surface: the specialization of the wheel will be indicated there - whether it is intended for cutting only steel or is also suitable for non-ferrous metals. There are also universal options. The size of the cutting disc, expiration date and the maximum number of revolutions allowed during use are also indicated there.

Best before date

Usually these numbers, stamped around the mounting hole of the plate, are given little significance. However, cutting disc insist on using the product within the time period they specify: for example, V 01/2018 would mean an expiration date before the beginning of the first quarter of 2018.

External diameter

This most important parameter, in fact, means the class of angle grinder for which the cutting wheel is designed. The following options are common: 115, 125, 150, 180 or 230 mm. It is unacceptable to install a wheel of a larger diameter than it should on the grinder. This is expressly prohibited by safety precautions coupled with common sense. Firstly, the protective casing will interfere, and secondly, the rotation speed of the cutting edge will go far beyond the limits provided by the manufacturer of the power tool, which is highly likely to result in serious injuries and failure of the equipment.

Plate thickness

The thinner the cutting disc, the easier it is to cut through the material: the smaller blade area reduces its resistance. In general, thin plates have many advantages:

- Get the job done faster;

- They heat up less;

- The cut turns out smoother.

At the same time, the disadvantage of this kind of circles is no less obvious: rapid grinding. However, for low-power, battery-powered angle grinders that are not intended for long-term operation without interruption, this type of disc is ideal.

It is worth noting that, subject to safety standards and operational requirements for power tools, neither thin nor thick disks are too dangerous: the reinforcing mesh holds the structure of the plate, regardless of its thickness.

Specification parameters

A specification is a four-character code that encrypts information about the fraction of abrasive grain and the substances that bind it. For example, AS is marked with highly purified white electrocorundum, intended for cutting stainless steel workpieces. The code numbers indicate the grit per unit of disk surface: to work with steel, you will need a coarse-grained cutting wheel marked 30 or 24.

For non-ferrous metals you will need a circle with code 40, or even 60 if the metal is soft. Further, the letter of the Latin alphabet indicates the hardness of the binder component. The closer the letter is to the end, the harder the bond. However, there is an inverse relationship with the hardness of the material being processed, since it is not the bond that cuts, but the abrasive grain.

The last two symbols rarely change and indicate the binding component, which uses the viscous thermosetting plastic Bakelite.

How to choose a cutting wheel for an angle grinder: main criteria and recommendations

Why do you need an appropriate approach to choosing a cutting disc for metal? After all, this type of nozzle is one of the most dangerous. Its danger is that during the work the consumable material may collapse, which causes serious consequences. Everyone understands what consequences may arise, therefore, to eliminate such cases, in addition to working in equipment and protective equipment, you need to learn how to choose the right abrasive wheels for an angle grinder.

- Type of tool for which consumables are needed. This can be not only an angle grinder, but also stationary equipment, machines, special equipment

- Life time. It is this indicator that you need to pay attention to first.

- Grit size or fraction size of abrasive particles - the lower the grain number, the larger the fraction, as on emery wheels. The larger the fraction, the rougher the processing, but at the same time less time is spent on cutting

- Disc outer diameter and seat ring size

- Disc thickness - the smaller the value, the higher the safety and the faster the result is achieved

- Number of revolutions - the value indicated on the disk should not exceed the value indicated in the technical specifications of the angle grinder. Typically angle grinders have a maximum rotation speed of 9 to 11 thousand rpm

- Type of reinforcing layer - bakelite or vulcanite

- The material for which the nozzle is intended is metal, aluminum, stainless steel or universal

It is important to pay attention to the presence of GOST, as well as quality marks that confirm that the nozzle is not a fake. The current standard according to which cutting wheels for metal are produced is GOST 21963-2002. You should not buy the cheapest consumables along with the expensive ones, since often it is the price that plays a decisive role, affecting quality and safety.

This is interesting!

You need to pay attention to the manufacturer. Today, nozzles from different companies are produced - Hilti, Bosch, Makita, Metabo, Hitachi, Expert, Luga, Zubr and others. By the way, Luga brand nozzles (they are also called “meadows”) are recognized as the most reliable, efficient and productive.

Features of installation/removal of cutting wheels

Before you start cutting a metal object, you need to know how to handle the grinder. We are talking, first of all, about the correct installation/disassembly of the cutting disc. Failure to comply with the rules for their implementation can lead to serious troubles.

Installing the cutting wheel

The first step is to check the position of the locking nut located below, on which the circle is placed. It is necessary to ensure that the spline on the nut itself matches the spline on the drive shaft of the grinder. Then a cutting disc is put on this shaft so that its marked side is on top.

Then the upper lock nut is tightened, after which, holding it with your hand, you should turn the circle in the direction of its rotation. When cutting metal, a self-tightening effect occurs on the joint. This phenomenon is caused by the difference in the direction of movement of the consumable element and the nut. It simplifies the installation procedure. There is no need to tighten the top nut with a wrench.

Removing the cutting disc

Removing the cutting wheel involves the following steps:

- after the disk completely stops rotating, the grinder is disconnected from the power supply network;

- the cylindrical protrusions of the key, which has a special configuration, are inserted into the sockets of the upper lock nut while simultaneously pressing the stop button;

- the key turns counterclockwise. The breaking of the nut from the supporting surface provides the primary rotational force. Its subsequent unscrewing can be done manually;

Which cutting wheel is better to buy and its parameters

Often you don’t want to study and read a lot of information, so especially for those who do not want to understand the technical features of consumables for an angle grinder, a description of the ideal cutting wheel has been compiled. The ideal abrasive wheel model has the following parameters:

- Bakelite bond with two reinforcing layers

- Electrocorundum, designated by the letter A, is used for cutting ferrous metals.

- Thickness 1 to 2 mm

- The outer diameter depends on the type of grinder available. The easiest way to cut metal is with a grinder with a disc size of 125 and 150 mm

- For cutting hard metals, it is better to use nozzles with a fine fraction.

- Rotation speed 80 m/s

As you can see, choosing a circle for cutting metal is not difficult if you know the main features about it. When choosing, trust and rely only on yourself, since most sellers can only distinguish discs by purpose for metal, wood and concrete. This information is exaggerated, but if you ask the seller what type of harness is used in a particular model of consumable, it is unlikely that he will understand what we are talking about.

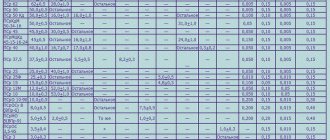

Consumption rates for cutting discs for metal formulas

What determines the consumption of a cutting wheel for metal? Of course, 80% of users will answer on quality. However, everything is not so simple, since the consumption of the disk depends on the correct choice of the nozzle and its application. Before using an accessory to cut different types of metals, make sure it is designed for that purpose. There are no standards for the consumption rate of abrasive wheels, but there is a formula by which calculations can be made. The formula for calculation with notations is presented below.

To summarize, it should be noted that it is strictly contraindicated to use attachments that have defects and have expired. This is unsafe, so you should think carefully before using a faulty attachment. Unlike steel discs for sawing wood and cutting concrete, abrasive wheels have the lowest cost. That is why it is not recommended to save money, and when working with an angle grinder, always use a minimum set of protective equipment.

Comparison of consumables from popular manufacturers

| № | Trademark | Bore hole diameter (mm) | Average price (RUB) | Country of Origin |

| 1 | "Bison" | 22,2 | 25 | China |

| 2 | "Luga-Abraziv" | 22, 22,2 | 30 | Russia |

| 3 | Gigant | 22 | 30 | China |

| 4 | Sturm | 22,2 | 32 | China |

| 5 | Stayer | 22 | 36 | China |

| 6 | Fit | 22 | 42 | China |

| 7 | Hitachi | 22,2 | 45 | Russia, "Luga-Abraziv" |

| 8 | Bosch | 22,2 | 85 | EU |

| 9 | Metabo | 22,2 | 90 | EU |

In addition to abrasive metal cutting wheels for grinders, you can find similar products on sale intended for other power tools. These are cutting discs with a diameter of 350÷400 mm for Husqvarna rail cutters and the like, as well as mini-discs Ø32 of the “Dremel” type for mounting on equipment with a cylindrical shank.