Story

One of the most famous places where bronze items were found was located in the Kuban River area. In this place, archaeologist Nikolai Veselovsky in 1897 excavated the so-called Maykop culture, which existed in the second half of the 4th millennium BC.

Bronze artifacts found in the Maikop burial mounds were made mainly from an alloy of copper and arsenic, so it is believed that historically these alloys, called arsenic bronzes, .

It was in no way inferior in its properties to alloys of copper with tin or lead, and even surpassed them in a number of characteristics . It was widely used in various areas of human activity of those times, from the manufacture of critical parts to jewelry.

A little history

The oldest find of bronze items was discovered near the Toplica River in the southern part of modern Serbia. It dates back to the 5th century. BC. In our country, the discovery of the oldest bronze artifact occurred in 1897 and belongs to the so-called Maykop culture, which existed in the 4th century. BC. The products are mainly presented in the form of an alloy of bronze and arsenic. Gradually, the existence of soft elastic metal became known in the Middle East, in Egypt.

Finds of bronze preserved over several dozen centuries Source ds02.infourok.ru

The above-mentioned arsenic bronze is considered the first type of this metal. However, the alloy had a wide range of disadvantages associated with the manufacturing process that was harmful to health and the relatively high cost, which was explained by the high cost of arsenic. This became the reason for its gradual displacement from the world market and the use of a more environmentally friendly and cheaper composition - tin bronze (an alloy of tin and copper).

If at the stage of its appearance metal was used for the manufacture of household and work items, then by the 5th century. n. e. in Ancient Greece it began to be used for casting sculptures. Later, the alloy turned into the main source of the monetary industry - coins were cast from it.

Only in the Middle Ages did bronze begin to be used in the production of weapons and church bells.

What is bronze

Bronze is an alloy of copper, where the main alloying component can be various metals and non-metals. The properties of alloys significantly depend on the ratio of components and their qualities, as well as the phase composition of the melt.

Metal has a lot of excellent properties, both user-friendly and decorative. And today we will look at the composition of the alloy, types, grades of bronze and their application, a brief description of the properties of the material and its characteristics, as well as the difference between bronze and brass.

Do you want to melt bronze to make products? Then this video will help you:

Concept and features

The oldest known composition includes copper and tin, as well as other components, the content of which is insignificant. The alloy is marked in accordance with its composition, while the proportion of copper is not indicated, but can be calculated from the content of other components.

Thus, the brand BrAMTS-7-1 means that we are talking about bronze, which contains 7% aluminum and 1% manganese. Accordingly, the alloy contains 92% copper, and no tin at all, that is, this is a grade of tin-free bronze.

Depending on the amount of impurities, the alloy may have a different color. A material where the share of copper is more than 90% has a reddish color, up to 85% is yellow, and an alloy with a copper share of 35% has a steel-gray color.

But, more importantly, the ratio of components determines the properties of the alloy. Thus, red bronze with a tin content of 2% is characterized by very high ductility; it can be forged at normal temperatures. And the material containing 15% tin becomes hard and durable: in ancient times such an alloy was used to make weapons.

These properties - ductility and hardness, depending on the combination of ingredients - determined the two most important historical uses of the alloy - art and war. Edged weapons, cannonballs, and the guns themselves were cast from bronze. But it was also used to create the most beautiful sculptures and jewelry that are the property of the whole world.

Modern alloys have a more complex composition and include the most unusual components. In this way, alloys are obtained that are suitable for a variety of purposes - from electrical engineering to plumbing. Their common property is that the base remains copper.

2 copper alloys, however, have nothing to do with bronze: brass - an alloy of copper and zinc, and cupronickel - with nickel. Brass is noticeably inferior to bronze in terms of corrosion resistance and hardness. This alloy is ductile and retains excellent ductility under a wide range of compositions. And if in art preference is given to bronze, then in jewelry, brass wins.

Advantages and disadvantages

Such a long-standing popularity and long-term use of the material can only be explained by the mass of its excellent qualities. It is also possible to change these qualities by using another component as an alloying additive.

- Diversity is one of the best properties of a material. Tin, aluminum, silver, beryllium bronzes are used extremely widely in the most unexpected areas, since the addition of other metals gives the composition completely different qualities. Thus, most bronze alloys conduct electricity relatively poorly. The same cannot be said about silver bronze: with a fraction of just 0.25% silver, the alloy conducts current no worse than copper.

- Bronze compositions can be cast or deformable. That is, for certain purposes it is possible to obtain an alloy that can be cold forged - deformed at normal temperature - and an alloy that can be cast.

- Bronze castings give minimal shrinkage - from 0.5 to 1.5%. This property explains the popularity of the material not only among sculptors, but also in the field of instrument and machine tool construction.

- Bronze is a material that can be used a second, third, and fourth time. The alloy tolerates repeated melting very well.

- The alloy is safe. While some components during its manufacture may be dangerous - beryllium, for example, then the finished material is completely non-toxic.

- It is characterized by exceptional corrosion resistance: neither urban polluted air nor sea water cause deformation of the material or a decrease in its quality. Bronze is not even susceptible to the action of most acids, so it is often used in the manufacture of acid-resistant equipment.

- Another interesting quality of many alloys is high elasticity. The material is used in the manufacture of a variety of high-precision springs that are characterized by durability.

The disadvantages of the alloy include its cost. Copper, and even more so tin, are relatively common metals, but expensive to obtain. Other types of bronze - aluminum, for example, cost much less, since the alloying component is a more affordable material.

The low thermal conductivity of most alloys can also be considered a disadvantage. However, this quality has also found application - in the manufacture of bathroom accessories or the bathtubs and washbasins themselves.

Varieties

Bronze is distinguished according to several characteristics, indicating its composition and more characteristic properties.

According to the composition they are distinguished:

- tin - alloys can be two- or multi-component. However, tin remains the second largest ingredient here;

- tin-free - all others: aluminum, beryllium, silicon, lead and so on. Each of the components gives bronze some properties. Thus, beryllium provides the material with exceptional elasticity and very high wear resistance, and the addition of silicon provides anti-friction properties.

By application, bronzes are distinguished as follows:

- deformable - alloys are easily forged, they can be rolled, forged, cut;

- molded - products are produced by casting, since it is deformed only at high temperatures. The alloy is used to produce castings of the most complex configurations.

A more specific division of bronzes is related to the structure:

- single-phase - components in a solid solution form one phase;

- two-phase 2 phases appear in the solution, which usually leads to a radical change in properties.

Read below about the basic properties, mechanical characteristics of bronze and the difference in the chemical composition of this metal from brass.

Tin

Tin bronze is an alloy with a predominant amount of copper mixed with tin. It has been historically proven that this composition is one of the first to be mastered by Homo sapiens. It is characterized by greater (compared to ordinary copper) hardness, strength, and melts better and easier.

The disadvantage of bronze is that it practically does not change when exposed to pressure. This condition does not allow it to be used in other popular types of metalworking: forging, stamping, rolling, cutting, sharpening.

This feature places it directly in the group of cast metals. In addition, in terms of these characteristics, it is in no way inferior to others. For example, bronze has a minimum percentage of shrinkage (1%), for brass and cast iron this figure is 1.5%, steel shows an even higher value - 2%.

Based on these criteria, regardless of the tendency to segregation and relatively low fluidity, bronze is in demand in the production of complex-shaped castings, including those related to artistic casting.

Healthy! Liquation is a heterogeneous composition of chemical elements resulting from the transformation of the latter into crystals with a certain structure (crystallization).

Tin-free

The term “bronze” may refer to other copper alloys that do not contain tin. These are brass, constantan and aluminum bronze. The latter is the leader in terms of mechanical properties and is more resistant to chemical influences.

Healthy! When silicon is added to copper, an alloy is formed that has excellent fluidity.

Popularization of bronze alloy for modern manSource epilot.ru

The best elasticity characteristics are characteristic of beryllium bronze. This alloy is also characterized by high hardness. It is easy to process (cut) and is often used for the manufacture of springs, membranes, and spring contacts.

Excerpt characterizing Bronze

The count looked around and to the right he saw Mitka, who was looking at the count with rolling eyes and, raising his hat, pointed him forward, to the other side. - Take care! - he shouted in such a voice that it was clear that this word had been painfully asking him to come out for a long time. And he galloped, releasing the dogs, towards the count. The Count and Semyon jumped out of the edge of the forest and to their left they saw a wolf, which, softly waddling, quietly jumped up to their left to the very edge at which they were standing. The evil dogs squealed and, breaking away from the pack, rushed towards the wolf past the legs of the horses. The wolf stopped running, awkwardly, like a sick toad, turned his big forehead to the dogs, and also softly waddling, jumped once, twice and, shaking a log (tail), disappeared into the edge of the forest. At that same moment, from the opposite edge of the forest, with a roar similar to crying, one, another, a third hound jumped out in confusion, and the whole pack rushed across the field, through the very place where the wolf had crawled (ran) through. Following the hounds, the hazel bushes parted and Danila’s brown horse, blackened with sweat, appeared. On her long back, in a lump, lolling forward, sat Danila, without a hat, with gray, tousled hair over a red, sweaty face. “Whoop, whoop!” he shouted. When he saw the count, lightning flashed in his eyes. “F...” he shouted, threatening the count with his raised arapnik. -About...the wolf!...hunters! - And as if not deigning to deign the embarrassed, frightened count with further conversation, he, with all the anger he had prepared for the count, hit the sunken wet sides of the brown gelding and rushed after the hounds. The Count, as if punished, stood looking around and trying with a smile to make Semyon regret his situation. But Semyon was no longer there: he, taking a detour through the bushes, jumped the wolf from the abatis. Greyhounds also jumped over the beast from both sides. But the wolf walked through the bushes and not a single hunter intercepted him. Nikolai Rostov, meanwhile, stood in his place, waiting for the beast. By the approach and distance of the rut, by the sounds of the voices of dogs known to him, by the approach, distance and elevation of the voices of those arriving, he felt what was happening on the island. He knew that there were arrived (young) and seasoned (old) wolves on the island; he knew that the hounds had split into two packs, that they were poisoning somewhere, and that something untoward had happened. Every second he waited for the beast to come to his side. He made thousands of different assumptions about how and from which side the animal would run and how it would poison it. Hope gave way to despair. Several times he turned to God with a prayer that the wolf would come out to him; he prayed with that passionate and conscientious feeling with which people pray in moments of great excitement, depending on an insignificant reason. “Well, what does it cost you,” he said to God, “to do this for me! I know that You are great, and that it is a sin to ask You for this; but for the sake of God, make sure that the seasoned one comes out on me, and that Karai, in front of the “uncle” who is watching from there, slams into his throat with a death grip.” A thousand times during these half-hours, with a persistent, tense and restless gaze, Rostov looked around the edge of the forest with two sparse oak trees over an aspen underhang, and the ravine with a worn edge, and the uncle’s hat, barely visible from behind a bush to the right. “No, this happiness will not happen,” thought Rostov, but what would it cost? Will not be! I always have misfortune, both in cards and in war, in everything.” Austerlitz and Dolokhov flashed brightly, but quickly changing, in his imagination. “Only once in my life would I hunt down a seasoned wolf, I don’t want to do it again!” he thought, straining his hearing and vision, looking to the left and again to the right and listening to the slightest shades of the sounds of the rut. He looked again to the right and saw something running towards him across the deserted field. “No, this can’t be!” thought Rostov, sighing heavily, like a man sighs when he accomplishes something that has been long awaited by him. The greatest happiness happened - and so simply, without noise, without glitter, without commemoration. Rostov could not believe his eyes and this doubt lasted more than a second. The wolf ran forward and jumped heavily over the pothole that was on his road. It was an old beast, with a gray back and a full, reddish belly. He ran slowly, apparently convinced that no one could see him. Without breathing, Rostov looked back at the dogs. They lay and stood, not seeing the wolf and not understanding anything. Old Karai, turning his head and baring his yellow teeth, angrily looking for a flea, clicked them on his hind thighs. - Hoot! – Rostov said in a whisper, his lips protruding. The dogs, trembling their glands, jumped up, ears pricked. Karai scratched his thigh and stood up, pricking his ears and slightly shaking his tail, on which felts of fur hung. – Let in or not let in? - Nikolai said to himself while the wolf moved towards him, separating from the forest. Suddenly the whole face of the wolf changed; he shuddered, seeing human eyes that he had probably never seen before, fixed on him, and turning his head slightly towards the hunter, he stopped - back or forward? Eh! anyway, forward!... obviously,” he seemed to say to himself, and set off forward, no longer looking back, with a soft, rare, free, but decisive leap. “Whoops!...” Nikolai shouted in a voice that was not his own, and of its own accord his good horse rushed headlong down the hill, jumping over water holes and across the wolf; and the dogs rushed even faster, overtaking her. Nikolai did not hear his cry, did not feel that he was galloping, did not see either the dogs or the place where he was galloping; he saw only the wolf, who, intensifying his run, galloped, without changing direction, along the ravine. The first to appear near the beast was the black-spotted, wide-bottomed Milka and began to approach the beast. Closer, closer... now she came to him. But the wolf glanced slightly sideways at her, and instead of attacking her, as she always did, Milka suddenly raised her tail and began to rest on her front legs. - Whoop! - Nikolai shouted. Red Lyubim jumped out from behind Milka, quickly rushed at the wolf and grabbed him by the hachi (hips of his hind legs), but at that very second he jumped in fear to the other side. The wolf sat down, clicked his teeth and got up again and galloped forward, escorted a yard away by all the dogs that did not approach him. - He will go away! No, It is Immpossible! – Nikolai thought, continuing to scream in a hoarse voice. - Karai! Hoot!...” he shouted, looking with the eyes of the old dog, his only hope. Karai, with all his old strength, stretched out as much as he could, looking at the wolf, galloped heavily away from the beast, across it. But from the speed of the wolf’s leap and the slowness of the dog’s leap, it was clear that Karai’s calculation was wrong. Nikolai could no longer see the forest far ahead of him, which, having reached it, the wolf would probably leave. Dogs and a hunter appeared ahead, galloping almost towards them. There was still hope. Unknown to Nikolai, a dark, young, long male from someone else's pack quickly flew up to the wolf in front and almost knocked him over. The wolf quickly, as could not have been expected from him, stood up and rushed towards the dark dog, snapped his teeth - and the bloody dog, with a torn side, shrieked shrilly and stuck his head into the ground. - Karayushka! Father!.. - Nikolai cried... The old dog, with his tufts dangling on his thighs, thanks to the stop that had taken place, cutting off the wolf’s path, was already five steps away from him. As if sensing danger, the wolf glanced sideways at Karai, hid the log (tail) even further between his legs and increased his gallop. But here - Nikolai only saw that something had happened to Karai - he instantly found himself on the wolf and together with him fell head over heels into the waterhole that was in front of them. The moment when Nikolai saw the dogs swarming with the wolf in the pond, from under which one could see the wolf’s gray fur, his outstretched back leg, and his frightened and choking head with his ears pressed back (Karai was holding him by the throat), the minute when Nikolai saw this was the happiest moment of his life. He had already taken hold of the pommel of the saddle to dismount and stab the wolf, when suddenly the animal’s head poked up from this mass of dogs, then its front legs stood on the edge of the waterhole. The wolf flashed his teeth (Karai was no longer holding him by the throat), jumped out of the pond with his hind legs and, tucking his tail, again separated from the dogs, moved forward. Karai with bristling fur, probably bruised or wounded, had difficulty crawling out of the waterhole. - My God! For what?...” Nikolai shouted in despair. The uncle's hunter, on the other side, galloped to cut off the wolf, and his dogs again stopped the beast. They surrounded him again. Nikolai, his stirrup, his uncle and his hunter hovered over the beast, hooting, screaming, every minute getting ready to get down when the wolf sat on its backside and every time starting forward when the wolf shook itself and moved towards the notch that was supposed to save it. Even at the beginning of this persecution, Danila, hearing hooting, jumped out to the edge of the forest. He saw Karai take the wolf and stop the horse, believing that the matter was over. But when the hunters did not get down, the wolf shook himself and ran away again. Danila released his brown one not towards the wolf, but in a straight line towards the notch in the same way as Karai - to cut off the beast. Thanks to this direction, he jumped up to the wolf while the second time he was stopped by his uncle's dogs.

Properties and characteristics

Tin bronzes are more common in the national economy.

As a rule, when describing the properties, the parameters of cast tin are indicated, since a larger number of products are produced using this method. The main technical characteristics of the alloy include the following qualities:

- density – determined by the mass fraction of tin. So, with its content from 8 to 4%, the density varies from 8.6 to 9.1 kg/cu. cm;

- depending on the composition of the alloy, its melting point varies from 880 to 1060 C;

- tin bronze conducts heat poorly - from 0.098 to 0.2 cal/(cm*s*C);

- heat capacity averages 0.385 kJ / (kg*K);

- the electrical conductivity of most bronzes is also not too high and is significantly less than that of copper: the electrical resistivity value is 0.087–0.176 μOhm*m;

- the material corrodes very slowly both in air and in contact with water. Thus, the corrosion rate in air is 0.002 mm/year, and in sea water – 0.04 mm/year.

About what metals and what else is included in the composition of bronze, what is its formula and chemical. Contents, find out below.

This video will tell you how to paint metal “bronze”:

Physicochemical characteristics

In terms of appearance, bronze, brass, copper and aluminum products have many similar features. Compared to brass, bronze products are characterized by greater resistance to abrasive wear. Copper metal has higher thermal and electrical conductivity, and if you compare bronze with aluminum, it will have a higher density.

The properties of a product are directly influenced by its chemical composition. The introduction of even a small amount of alloying substances changes the physical characteristics of the metal.

Influence of alloying components:

- tin, phosphorus and iron - increase corrosion resistance, strength and hardness;

- lead - increases the flexibility of the material for cutting and cutting;

- zinc and chromium - responsible for casting qualities and heat resistance;

- nickel, silicon, manganese and zirconium - increase elasticity and ability to undergo plastic deformation;

- beryllium - forms a protective film on the surface of products that prevents oxidation.

Properties of bronze

If we compare it with brass, bronze is characterized by higher corrosion resistance, strength and anti-friction properties. It is quite stable in air, salt water, carbon dioxide solutions and solutions of many organic acids. Most types of bronze can be welded and soldered with hard and soft solders.

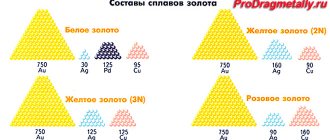

Depending on the amount of additives, the color of bronze can be from red to white. Let's look at how alloying elements affect the properties of bronze. Tin, nickel, silicon and aluminum increase the strength, corrosion resistance, and elastic properties of bronzes. In combination with lead, zinc and phosphorus, anti-friction properties also increase. Nickel and iron significantly refine the grain and increase the recrystallization temperature. Silicon and manganese increase heat resistance. Chromium, zirconium and beryllium increase the heat resistance of alloys and slightly reduce electrical conductivity.

Let's take a quick look at the most commonly used types of bronze.

- Beryllium bronze is the leader in hardness among other copper alloys. In the hardened state it has good ductility and manufacturability, and in the aged state it has high mechanical properties. The level of mechanical properties can be further increased by plastic deformation before aging. Beryllium bronze is used to make springs, membranes and tools.

- Aluminum bronze is characterized by high density, resistance to aggressive environmental factors and chemical elements, and good resistance to sea water. This type of bronze can be processed with cutting tools. Tapes and strips of pipes are made from it.

- Silica-zinc bronze makes it possible to produce products of complex shapes due to its increased fluidity in the molten state. Such bronze has a high degree of compression resistance and does not spark under mechanical stress.

- Lead bronze has excellent anti-friction properties, resists shock loads well, and is also characterized by high strength and refractoriness. It is used for heavily loaded bearings.

- Tin bronze has all the above properties and is the most widely used in modern industry.

Bronze classification

According to their chemical composition they are distinguished:

Tin bronzes are alloys with the main alloying component tin. In addition to tin, lead, phosphorus and zinc may be present as additional components. With the addition of tin, copper acquires greater fusibility, elasticity, and hardness. Consequently, the alloy is more amenable to polishing. Additional components improve mechanical, casting, and anti-friction properties.

Tin-free (special) bronzes are alloys that do not contain tin as an alloying element. They are not inferior in properties to tin bronzes, and in some they even surpass them.

According to technological characteristics, bronzes are divided into:

- Deformable – well amenable to mechanical processing: stamping, corrugation, forging. The tin content in them is no more than 6%, which ensures the necessary ductility. Sheets, bronze wire, bronze rod, and bronze tape are made from deformable tin bronzes.

- Foundry - intended for shaped castings. Various parts for machines operating in salt sea water, bearing shells, and gears are made from cast tin bronzes.

Main alloying components

The main component that determines most of the technical characteristics of bronzes is copper. To give the alloy the necessary parameters, special additives are used - alloying components. One of the common alloying components contained in bronze is tin. It was from tin bronze that bells were cast and called “bell” bronze.

Also the following can be used as an alloying element:

- Be – beryllium. Increases the strength of bronze.

- Si – silicon and Zn, zinc to increase the surface abrasion resistance. These same elements increase the fluidity of bronzes, which has a positive effect on the quality of casting.

- Pb – lead. Increases the anti-corrosion properties of metal.

- Al – aluminum. Increases corrosion resistance, oxidation resistance at high temperatures and reduces metal reaction with sulfur compounds and engine exhaust products.

Percentage of bronze components

The percentage of elements, as well as the chemical composition, is included in the abbreviation of the alloy grade. It does not indicate the percentage of the main element - copper, but indicates the content of all alloying elements in percentage terms.

For example, in the BrO3Ts12S5 brand the content of components is as follows:

- tin – 3%;

- zinc – 12%;

- lead – 5%;

- the remaining 80% comes from copper.

The percentage of copper in the alloy affects its color. The more copper, the brighter the golden color the bronze has. With a copper content of 50%, the color of the alloy will become white, close to the color of silver. In accordance with the tasks set, it is possible to obtain different colors of the metal by varying the percentage of alloying elements and copper.

By chemical composition

Based directly on the chemical composition of bronze, the following varieties are distinguished.

- Tin . The material of this subspecies contains 3.5-7% tin. The alloy boasts high strength, reliability and elasticity after pre-pressure treatment. The material has excellent casting qualities. Shrinkage can reach 1% (as is the case with cast iron).

The main disadvantage of this material lies in the appearance of microscopic pores during the crystallization of the casting.

- Tinless . This category includes varieties of alloys whose chemical composition does not contain expensive tin. Instead, more accessible and inexpensive materials are included.

- Aluminum . The most flexible material. Its casting properties turn out to be lower than those of expensive tin bronze, but there are no micropores in the composition. The composition contains nickel, phosphorus and iron - components that improve the properties of the aluminum alloy.

- Silicon . A high-strength subtype of material, resistant to corrosion, and electrically conductive. The material is not afraid of low or high temperatures or alkaline environments. In order for the metal to have higher strength characteristics, the chemical composition is additionally alloyed with manganese and processed by cold deformation.

- Beryl alloy is allowed to be subjected to heat treatment using hardening and artificial aging . The main disadvantage of this type can be considered the high cost of beryllium.

Because of this, silicon bronze alloy is used exclusively in the production of special components, which must be highly wear-resistant and durable.

By processing

Bronze alloys are divided based on types of processing.

- Deformable . In the production of bronze parts, such popular technologies as forging, broaching, cutting, and milling are used.

- Foundry . A separate type of bronze alloy. Parts that consist of this metal are made by metallurgy.

By structure

Different types of bronze alloys are also divided according to their structure. The following options are available.

- Single-phase . The components present in such a metal form only one specific phase in a solid solution.

- Two-phase . Products are produced using casting, because they are deformed exclusively under the influence of high temperatures. From a two-phase alloy it is possible to obtain castings of the most complex and intricate configurations.

Varieties

Experts distinguish the following types of bronze:

- Lead - a composition in which the main alloying additive is lead. The finished material is resistant to high pressure. Used in the manufacture of moving elements in industrial equipment.

- Silica-zinc - in addition to the main component, this composition contains tin and silicon. The mixture has good plasticity and fluidity. It is easy to work with the material and make products of complex shapes from it. It welds well and is resistant to low temperatures.

- Beryllium bronze is a hard material. Resistant to high temperatures and corrosion. The composition includes cobalt, nickel and iron.

- Aluminum - the mixture contains 95% copper and 5% aluminum. The material has a golden hue and shines in the light. Resistant to alkalis and acids. Does not change characteristics when exposed to low temperatures, has high strength.

If it is necessary to strengthen the structure of the material, nickel is added to it. Electrical conductivity is reduced with chromium.

Bronze composition

Bronze is a double or multi-component alloy consisting of copper and other elements that improve the basic properties of the metal, except zinc. Such elements are called alloying elements. Bronze contains more than 2.5% by weight. Manganese, tin, beryllium, lead, silicon, chromium, phosphorus, iron, aluminum and other elements are used as alloying components. Alloys are marked with the combination “Br”, letters that indicate the main alloying components and numbers indicating their content. For example: BrO5 - tin bronze, BrA5 - aluminum bronze. The chemical composition of bronze alloys and their grades are determined by the corresponding GOSTs. You can buy bronze on our website.

Bronze, based on copper and tin, is one of the oldest alloys produced by man. In the 3rd millennium BC, bronze products appeared in Mesopotamia and Southern Iran. Everything necessary for human life was made from this alloy in ancient times. Archaeologists discovered weapons (daggers, axes, arrowheads, swords), furniture and interior items (mirrors), as well as dishes (jugs, vases, plates). In addition, coins and all kinds of jewelry were made from bronze. Around the 5th-4th centuries BC, ancient Greek sculptors learned to cast large bronze statues; by the way, this technology is still relevant today. In the Middle Ages, bronze was used to make cannons and artillery shells. Bells have long been cast from this alloy. By changing the composition and size of the casting, craftsmen created bells with an amazing sound.

Types of bronze

The main component of bronze is copper, to which other metals (usually tin) are added. At the same time, the share of other substances is no more than 2.5%, which makes it possible to improve the performance of the resulting alloy. If copper is combined with zinc, brass is obtained; when zinc is replaced with nickel, a cupronickel composition is obtained. There are other options. For example, BrA5 is a type of bronze obtained by adding aluminum. We work with the BrO5 brand, made on the basis of tin, since this material fully complies with state requirements.

Receipt

Bronze is produced by fusing copper and alloying components. The process takes place in electric induction furnaces or crucible furnaces. The smelting charge can consist of fresh metals, as well as production waste and secondary metals. Melting is carried out under a layer of flux or charcoal.

The required amount of coal or flux is placed in a heated furnace, and then copper is loaded. After melting and heating the copper to the appropriate temperature, the melt is deoxidized with copper phosphate. Next, heated alloying elements are introduced into the melt. Refractory alloying elements are introduced in the form of alloys. The melt is stirred until the components dissolve and heated to the required temperature. Before casting, the melt is again deoxidized with phosphorous copper to eliminate its oxides.

Bronze melts well and fills ingot molds evenly. The alloys are produced in the form of flat and round ingots. Ingots are processed by rolling or pressing.

The result is a wide range of rolled metal:

- bronze ribbon;

- bronze wire;

- bronze pipe;

- bronze bushings;

- bronze circle;

- bronze rod.

Decorate the walls with bronze panels

The high plasticity of bronze allows you to make three-dimensional panels of any complexity and decorate walls with them. And decorators take full advantage of this. The style of wall decor varies from abstract forms to strict classical lines and vintage paraphernalia. Sometimes a bronze panel is given the functions of a sconce.

Photo: renoguide.com.au

Photo: lushome.com

Photo: jerusalemhouseministries.net

Production of material

Bronze is obtained from pure metals or alloys in ingots. The second is more common, as it is cheaper and allows you to get any cast bronze.

- The first stage is the extraction of copper and tin from the deposits. Tin is found in cassiterites, stannines, and so on. Copper is more common: it is mined from native copper and many minerals - chalcopyrite, bornite, chalcocite. The metal is isolated in several different ways, of which pyrometallurgical, that is, oxidative annealing and fire refining, is the most common.

- Then the composition of the charge is calculated: it depends on the composition of the future product and on the production method - from secondary alloys, from metal and secondary alloys, and so on.

- Melting itself, for example from pigs, includes several stages:

- loading - the material is loaded into dried and heated graphite-carboride or graphite-chamotte crucibles. Electric and electric arc furnaces are best suited as they allow melting to be carried out as quickly as possible. This is important because when melting metals, there is a high probability of gases being absorbed into the melt;

- melting - first of all, copper is melted, and then various components are added that improve the mechanical properties of the alloy, and basic alloying additives;

- overheating - the melt is heated to 1200 C under a layer of charcoal. If the source metals are contaminated, liquid salt fluxes are used;

- degassing - the melt is cleaned of gas impurities by blowing with argon or nitrogen.

- Castings are obtained from the finished alloy. Most often, gating systems are used for this. Casting is done in clay or metal molds. It is possible to produce castings using centrifugal casting.

In 2021, there was an increase in prices for copper - up to 4%, and tin - up to 10.3%. Accordingly, the cost of products made from bronze and bronze scrap increases. The latter in October had a cost from 190 to 210 rubles. per kg.

The price of products - rod, casting, sheet - depends on the composition of the alloy. So, a rod of different brands can be purchased for both 308 and 803 rubles. per kg.

Next we touch on the marking and use of bronze.

How to easily distinguish brass from bronze with a magnet

Many professionals claim that the difference can be immediately felt if you compare different products by weight. Since lead and tin are quite heavy metals, bronze ones are slightly heavier than brass ones.

There are several more ways, we will provide them to you, and make the choice yourself:

- Take two objects and try to identify them by eye. Choose a room with good lighting. You will notice that one figure is lighter than the other. The dark one will be bronzed.

- If identical figurines do not have a high cost, you do not mind them for conducting an experiment, then try them for strength. Bronze is not so easy to deform; you will have to put in some effort using cutting equipment. If you succeed, and on the fracture you will see a smooth-to-the-touch area with a fine-grained structure, then this is a brass figurine. It will also produce light loose shavings if the surface is scraped with a knife or other sharp objects.

- Due to the high content of tin, iron and nickel in the composition, some bronze subspecies have magnetic properties. To get a reliable and tangible result, you will have to use a powerful neodymium magnet. As a rule, not everyone has one of these in their home. Otherwise, it is not possible to identify the fusion. After all, brass contains only 1–3 percent of materials that can be magnetized. It is very difficult to obtain an accurate answer using this method, since there are different grades of alloys. But you can try.

Marking

To help buyers and manufacturers understand bronze alloys, special markings for bronze were created. It is a set of numbers and letters that indicate the name of the components and their percentage in the composition:

- At the beginning of the marking the letters “Br” are indicated, which indicate the name of the material.

- After the main designation there is a letter indicating alloying additives.

- The marking closes with a number indicating the percentage of the alloying component.

An example of a bronze grade is BrO5. The alloy contains 5% tin. The markings of all compounds with a copper base are indicated in tables that can be found on the Internet.

Decoding the markings of bronze alloys

In the marking code of each grade of bronze, information is encrypted using letters and numbers that characterizes the type of alloy, designations of alloying components and impurities in descending order. The letters indicate the type of alloying component, and the numbers indicate its average percentage content.

For example, the BrOTsS4-4-2.5 brand is bronze (Br) alloyed with tin (O), zinc (C) and lead (C). Tin and zinc in the alloy are 4% each, lead is 2.5%. Accordingly, the percentage of copper in this alloy will be 100 – (4 + 4 + 2.5) = 89.5%.

For deformable bronzes, first there is a letter designation in a row, and then numbers are put down, for example, like the alloy BrOF2-0.25. For casting grades, after the designation of each alloying element, its volume is indicated as a percentage. An example is the casting alloy BrA10Zh3Mts2, where:

- Br is bronze;

- A10 - 10% aluminum;

- Zh3 - 3% iron;

- Mts2 - 2% manganese.

How to find out whether it is bronze or not using laboratory methods

The above methods are suitable only in cases where the alloys are pure and have a maximum content of tin and zinc. And since we already know that various additives are used in various industries, verification can only be done using chemical reagents or spectral analysis. The latter method is more convenient and effective.

Careful not to damage the base metal, remove some shavings or dust using a hacksaw. In a glass container, mix nitric acid and water in equal proportions. Place the sample in a heat-resistant container and fill it with the resulting solution. Wait for complete dissolution and place the vessel on the fire. Bring the liquid to a boil and keep it there for about 30 minutes. If you find a white precipitate, it is bronze.

If you don’t have acid on hand, you can use a highly concentrated saline solution. Bronze shavings will not change their appearance, but brass shavings will darken.

During experiments, be as careful as possible, remember that you are working with dangerous chemicals. Try to use protective clothing and a respirator. If the outcome is unfavorable, you risk severe burns!

However, these methods do not work 100 percent at home. After all, you don’t know what impurities are used. To determine the chemical composition, only spectral equipment used in specialized laboratories is suitable.

Differences between bronze alloys

Each type of bronze has a set of unique characteristics that are determined by the content of chemical elements.

- BrB2. Valuable properties include flexibility in welding and soldering with silver solders, high electrical and thermal conductivity, and lack of sparking. This allows it to be used for the manufacture of tools used to work in explosive enterprises - in mines, mines, oil and gas processing plants.

- BrAZH9-4. Aluminum-iron bronzes are improved by heat treatment, quenching and tempering, resulting in increased ductility, hardness and abrasion resistance.

- BrAZHN10-4-4. Metal alloyed with aluminum, nickel, and iron is characterized by heat resistance, tensile strength, weather resistance, low electrical conductivity, and resistance to erosion.

- BrOF. It is used in the industrial production of metal products by pressing, drawing, and cold rolling under pressure. The main feature of BrOF grades is corrosion resistance.

- BrOTs4-3

. An indisputable advantage of tin-zinc bronzes is excellent deformability. They lend themselves well to processing both cold and hot. - BrOTsS4-4-2.5

. The advantages of wrought alloys are excellent anti-corrosion, anti-friction and spring properties, flexibility in turning and milling. - BrOTsS5-5-5. Casting bronzes, which have universal operational parameters, are perfectly cut, are not afraid of friction and thermal effects, and are easy to melt, evenly filling molds of any configuration.

- BrAZHMts. Copper with additives of aluminum, iron and manganese retains the original level of strength when heated, prolonged exposure to aggressive environments, including sea water, solutions of most acids and alkalis, petroleum products, and organic substances.

What difference does a visual inspection make?

Before moving on to solving the problem, let’s figure out where these materials are used and what they look like.

Before the advent of iron throughout the world, copper played a special role in the manufacture of weapons, money, household dishes and various utensils, works of art and even jewelry. Already in the nineteenth century they knew how to use metals to counterfeit money.

Today, the bronze alloy has lost its position, but is still actively used in various spheres of the national economy:

- Decorative. Thanks to its resistance, ductility, durability, anti-corrosion and excellent malleability, small figurines and huge sculptures, interior parts (forged or cast railings of stairs, cornices, covered courtyards, etc.) are made from it. Household items with decorative elements look great - lamps, sconces, writing sets, jewelry boxes, picture frames and mirrors.

- Industrial. In the automotive industry, it is used to make bearings, bushings, gears, O-rings and gaskets that operate under high pressure.

- In electronics, it is indispensable in the production of parts of the smallest sizes, integrated circuits, and fiber-optic equipment.

- With the addition of aluminum, this material is perfect for equipment operating in aggressive environments (sea water, chemical laboratories, water supply machines, units used in explosive conditions).

- Construction The cost is quite high, so it is used only for the manufacture of decorative plumbing fixtures (faucets, fittings, all kinds of components and wiring in hot and cold water supply systems, bathtub feet, handles, etc.).

Let's look at what bronze looks like.

Copper and tin alloy can come in a variety of shades of brown. It depends on what other element is added to the bulk during production (silicon, aluminum, nickel, zinc, lead, beryllium and others). It has a structure with large grains, which immediately catches the eye upon first inspection.

Let's talk about brass. It is basically a two-component copper-based alloy with a large or minimal amount of zinc added. It has a lower price, because the cost of Zn itself is two times cheaper than Cu. Therefore, this material is most widely used in various fields of industry. Since it is perfectly weldable to steel, has high anti-corrosion properties, strength, and ductility, bimetal (tompak) is made from it. Due to the fact that elements can be made using cold forging or using low temperature, this element is used in jewelry. Today, brass jewelry successfully competes with gold jewelry.

The scope of application is not limited to this. The two-component alloy is used to make various mechanisms for vehicles, chemical equipment and heating equipment for the manufacture of profile parts used in marine and river shipbuilding. In the construction field, brass is used only in water supply in order to resist corrosion in components subject to friction.

The alloy is of much greater importance for the production of special-purpose pipes that are used in the gas field. Seamless pipes allow gas to be transported under high pressure.

In everyday life you can often find brass fittings used in all engineering and water-bearing systems. These include adapters, couplings, plumbing nipples and tees. In addition, various bathroom accessories are manufactured: taps, heated towel rails, holders for things, shelves for hygiene products, hardware, faucets and even washbasins.

How to distinguish at home?

Bronze has quite a few differences from other similar metals. There is nothing complicated in the art of “calculating” this material. Let's look at how you can easily and simply distinguish bronze at home.

- Bronze differs from many other alloys in its high strength and rigidity. Thus, the metal can be easily distinguished from copper or brass. It is enough to literally test the material “to the teeth” - there should be no traces left on the surface of the bronze alloy, as is the case with pressure.

- You can conduct an experiment with a saline solution (200 g per 1 liter of water). After 10-15 minutes, a copper product will acquire a richer and more striking shade than a bronze piece.

- They resort to heating the metal to approximately 600 degrees Celsius (a similar temperature can be obtained using a special gasoline burner). If you bring the device, for example, to brass, a dark film of zinc oxide will appear on the material. It will not be visible on a bronze product.

- If you heat brass, it will bend. If such an operation is carried out on bronze, it will not change its properties and shape. If you have the opportunity and a sample of the metal, you can try to melt it. The same brass will burn with a white flame, scattering snow-white flakes - this is how the zinc burns out.

- You can distinguish bronze from brass in another reliable way : place several shavings of each metal in separate containers, and then pour diluted nitric acid into it (1 part acid and 1 part water). Wait a little until most of the components have time to dissolve. Next, you need to heat the beakers and bring the solutions to a boil. Keep them on low heat for 30 minutes. The liquid containing pieces of brass will be transparent, but in a vessel with bronze shavings a snow-white precipitate of tin will form.

How is bronze made?

Over the long period of existence of bronze production technology, only the tools and equipment have changed, but the essence has remained the same. As in ancient times, the raw material for producing this copper alloy can be a charge or bronze waste, and the flux, which prevents too intense oxidation of the metal in the molten state, is charcoal.

This centrifugal casting installation will allow the production of bronze blanks weighing up to 50 kg

The smelting process itself, as a result of which bronze is obtained, is performed in the following sequence.

- The crucible with the feedstock is placed in a furnace preheated to the required temperature.

- To prevent the metal from oxidizing too much after melting, crushed charcoal - flux - is added to it.

- After the metal has completely melted and warmed up well, phosphorous copper is introduced into its composition, which plays the role of an acid catalyst.

- After some exposure in a heated state, alloying and binding elements (ligatures) are added to the molten metal, after which the resulting alloy is thoroughly mixed.

- Before casting the molten metal, phosphorous copper is again added to it, which in this case is necessary to reduce the activity of oxidative processes.

At all stages of production, it is necessary to carefully monitor compliance with the correct temperature conditions in the furnace and the alloy itself. The amount of alloying and binding components added to the molten metal should also be controlled.

Application area

Bronze alloys, due to the diversity of their properties, find a wide variety of applications.

- The most famous is the material for sculptures and many decorative items: figurines, ashtrays, lamps, grilles, railing decorations and more. Casting bronze allows you to obtain the most complex castings that literally depict the pores of the skin.

- In jewelry, the material is used much less frequently, although it used to be almost the basis of women's jewelry.

- Bronze fittings - overhead hinges, locks, handles, taps, mixers and even plumbing fixtures. The alloy provides not only exceptional durability and corrosion resistance of objects, but also allows you to turn them into an elegant decorative element.

- Many parts are made from cast bronze of different compositions - gears, bushings, seals, parts of equipment designed to work under water.

- Deformable bronzes are used in high-precision technology.

- Other types of alloys are used in areas where the usual tin bronze is not used. For example, beryllium bronze has much higher thermal and electrical conductivity, and therefore is actively used in electrical engineering.

The alloy performs excellently under conditions of variable dynamic loads. Therefore, parts of aircraft navigation instruments, car circuits, etc. are made from beryllium bronze.

- Another well-known application is fittings of various kinds. For more active use in water supply, bronze is too expensive a material, however, the most critical components, as well as numerous fasteners, are made from a copper alloy, since it is extremely resistant to corrosion and inhibits bacterial activity.

Bronze is the oldest and most famous alloy in human history. The diversity of its composition and properties ensures that it is widely used today.

This video will show you how to clean bronze items:

Industry

As already mentioned, due to its low shrinkage ability, tin bronze is widely used for the manufacture of springs, bearings, and pressure contacts.

Aluminum bronze is cheaper than tin bronze, but it is the first alloy that has excellent anti-corrosion qualities. This makes it popular in the manufacture of chemical equipment and those that often come into contact with salty sea water.

Alloys with high ductility and elasticity are used in the production of automotive gaskets, components of measuring instruments, and gears.

Materials that are resistant to corrosion and have good electrical conductivity are successfully used in the electrical industry. For example, beryllium bronze is used to make parts, spring contacts and integrated circuits for mobile phones, smartphones and other gadgets. For the same reason, metal is used in the production of fittings for the installation of pipelines: taps, valves, tees, adapters.

Hardware

- Anchors

- Nails

- Dowel

- Self-tapping screws

- Screws

Non-ferrous metals

- Aluminum

- Bronze

- Brass

- Copper

- Nickel

- Tin

- Lead

- Titanium

- Chromium

- Zinc

Ferrous metals and substances

- Excipients

- Iron

- Cast iron

Household use

Durability, hardness, strength, resistance to adverse conditions and environmental influences make bronze in demand for the manufacture of outdoor decorative elements. You can find alloy products on almost any street: lanterns, benches, gazebos, sculptures and statues.

The popularization of bronze kitchen utensils was observed at the beginning of the Bronze Age, and this tradition continues today.

Application of bronze

Impeccable performance qualities have made bronze one of the most common materials in mechanical engineering, aviation, shipbuilding and large industry. This metal is not susceptible to moisture, does not wear out, and is almost impossible to deform. Therefore, bronze is used in the production of rolled products intended for use in aggressive chemical environments, as well as for the production of parts and pipes of various profiles.

Reliability and long service life are additional characteristics due to which bronze has become widely known in the field of sculpture and art. Interior parts are made from it - candlesticks, chandelier bodies, decor. Therefore, the specialists of the Bronzamania workshop can guarantee the long service life of all products available for sale - our products retain their beautiful appearance and functionality for decades, without reacting to weather conditions and other adverse factors.

Ready product.

Bronze alloy price

The cost of bronze alloys depends on several factors:

- What alloying additives are included in the alloy and in what percentage.

- In what form is the product sold? The more complex the design, the more expensive it will cost.

- Appearance and condition. If the surface of a bronze item has cracks, scratches, scale or dents, its value will decrease.

Bronze is considered the oldest alloy. It is used in different areas of industry due to the variety of materials based on it. The characteristics of this metal make it possible to use it under the influence of acids and alkalis, as well as install bronze parts in industrial equipment.

Sources

- https://tokar.guru/metally/splavy/bronza-sostav-splava-svoystva-i-primenenie.html

- https://stroyres.net/metallicheskie/vidyi/tsvetnyie/bronza/osobennosti-splava.html

- https://m-strana.ru/articles/bronza-eto/

- https://cuprum-metall.ru/informatsiya/bronza/

- https://cu-prum.ru/bronza.html

- https://proflasermet.ru/article/bronza-sostav-splava/

- https://vplate.ru/metally-i-splavy/iz-chego-sostoit-bronza-i-gde-primenyaetsya/

- https://metalloy.ru/splavy/bronza

Advantages and disadvantages

To evaluate a bronze alloy, you need to talk about its strengths and weaknesses.

Pros:

- The presence of mixtures with different types of metals and additional components allows their use in various areas of industry.

- Creation of alloys with different characteristics. You can vary the ratio and percentage of alloying components.

- The material can be recycled again.

- High elasticity.

- Resistant to corrosion, acids and alkalis.

The disadvantage is the high cost of bronze alloys. Because of this, buyers often prefer other materials.

Comparative characteristics and differences between metals

In the metallurgical industry, there are clear criteria for distinguishing between bronze and brass. However, if a person is not associated with this field of activity, he will not be able to determine by eye what material is in front of him. Combining copper with tin or zinc produces alloys that have different properties and are used in specific areas.

Bronze and brass have different properties and belong to completely different categories. The first alloy can be tin or tin-free, while the second can be two- or multi-component.

Bronze alloy consists of tin to which lead may be added. The color of the metal will depend on the percentage of one element or another. The main additive element in brass is zinc.

Bronze is resistant to chemical and aggressive compounds. In addition, its negative reaction to salty sea water made it possible to use the alloy in shipbuilding and navigation. Brass cannot boast of this, so to give it improved qualities, additional elements must be introduced into the alloy. In addition, bronze has better strength and anti-friction characteristics than brass. This allows you to significantly expand the scope of application of the alloy.

The high zinc content in brass gives the alloy a variety of colors from pink-red to golden yellow. This is what makes it similar to noble gold.

What does brass look like?

The silvery-white color of bronze is achieved by adding more than 35% Sn to its composition. An alloy containing at least 85% copper is brownish-red in color. Since compounds with high levels of impurities are rare, it can be argued that basically brass is a metal of golden yellow color, and bronze is closer to red, sometimes dark brown. The same colors of brass and bronze will appear on the broken objects. This allows you to easily distinguish brass products from bronze ones.

From a metal such as brass, not only decorative elements are made, such as furniture fittings or artistic objects for interior decoration, but also main parts used in various industrial fields.

Bronze and brass have a lower melting point than pure copper. This makes it possible to make various products from them for home use. Artistic casting made of bronze and brass looks very beautiful. However, for this you need to have the appropriate equipment and know the technology and rules for performing such a procedure.

Structure and color

To determine whether brass or bronze was used to make a product, you can look at the alloys and their fracture. Brass is lighter in color and fine-grained in cut. Bronze, on the other hand, has a coarse-grained structure and is distinguished by a dark brown tint.

Materials differ in a number of characteristics. These include the following features:

- The use of tin as an alloying element in bronze, and zinc in brass. The basic component of both metals is copper.

- Bronze, including those with a traditional chemical composition, copes well with aggressive components, including salty sea water.

- To impart maximum corrosion resistance, additional alloying elements are introduced into the brass composition.

Give preference to bronze sinks

Adding a bronze sink to your bathroom or kitchen is a smart decision, and not just for aesthetic purposes. Bronze has one of the lowest rates of corrosion in water among metals. It also has poor electrical conductivity. Some people consider this a disadvantage, but for rooms with a large number of electrical appliances this is a definite plus. And the variety of shapes and colors will allow you to choose exactly the sink that will become the main decoration of the bathroom or kitchen.

Photo: endlesssummerbrooklyn.com

Photo: polkadothomee.com

Photo: klaverweiden.com

Install a bronze hood

A bronze hood is an unexpected decorative move. The kitchen immediately looks good and respectable. The shape of the hood is matched to the interior style; the color scheme of the kitchen does not play a big role - bronze will suit both a light background and a mixed one.

Photo: splendidhabitat.com

Photo: allarchitecturedesigns.com

What is stronger, brass or bronze?

When comparing maximum permissible loads, wear resistance and other parameters, it is important to consider that the characteristics are affected by the composition of the alloys. For comparison, it is worth taking the highest grade metals. This will help you find out how brass differs from bronze in terms of physical and chemical parameters. Having studied the data, you can note:

- Bronze is heavier. The reason is the presence of tin. Its mass is greater than that of zinc.

- The corrosion resistance of brass is lower. Bronze can come into contact with salt water with little or no effect, but brass alloys must be alloyed to reduce the effects of corrosion.

- The wear resistance of bronze products is higher, since the metal has a lower coefficient of friction.

This is interesting: How to decipher the grade of steel

Based on these properties, it can be noted that bronze is stronger than brass when considering equally high-quality alloys.

Install bronze furniture

Bronze furniture, like forged furniture, is not as rare as it might seem at first glance. Most often it is made of dark bronze, and these are chairs, armchairs, headboards of beds and benches, table legs. Bronze is often combined with other materials, such as glass and natural stone. A rare option is bronze cabinet fronts. But very effective.

Photo: apartmenttherapy.com

Photo: aisyahome.com

Photo: homedesignersuite.co

Attach bronze curtain hooks

Do you think that few people will pay attention to such little things as curtain holders? Well, no. They will see it and definitely appreciate it if it is an unusual figured holder made of bronze. As well as bronze window and door fittings. It is tiny decorative details that create what is called a “stylish interior”.

Photo: inspiredme.co

Photo: thecollectionaire.blogspot.com

Methods for chemical determination of alloys

Chemistry is a fairly effective way to identify brass and bronze. However, accurate results can only be obtained by reactions that destroy the metal, which will negatively affect the product. The chemical method includes the following steps:

- chips are removed from the copper alloy (so as not to damage the entire metal);

- mix a solution of nitric acid and water (in a ratio of 1:1);

- Next, you should place the chips in an acidic reagent;

- the solution is heated to boiling point after the chips are dissolved;

- The boiling temperature is maintained over low heat for half an hour.

If the shavings were brass, the solution in the container will remain transparent. When bronze dissolves, a tin precipitate (white) precipitates. Taking this into account, the method only works for bronze containing tin.