Wooden furniture is incredibly popular among users. It is made from environmentally friendly, natural material, smells pleasant, and lasts a long time. No less practical, but inexpensive are products made from chipboard, laminate, MDF and other combined bases.

Despite its strength, any furniture deteriorates over time, wears out, and loses its attractiveness. To update its appearance and extend its service life, furniture wax has been developed - a universal composition that hides minor defects and protects surfaces from moisture.

Application of wax

Furniture wax is understood as a professional product based on natural waxes, resins and other components, intended for processing wood and lumber, as well as finished products and structures made from them. Most often, wax is used for furniture restoration: this is its direct purpose, which is stated in the instructions.

It is perfect for processing cabinet furniture and its wooden elements, providing the following effects:

- hiding damage, chips,

- sealing cracks of any depth,

- giving a beautiful shine,

- enhancing natural shade or tinting furniture,

- filling voids,

- improving the quality characteristics of wood.

The scope of application of the material is not limited to furniture repair. Its composition is perfect for working with other types of products and coatings.

The product can be used for the following purposes:

- Floor treatment. If there are cracks in the wooden surface, it is worth purchasing furniture wax to fill them. It is also suitable for rubbing into damaged parquet or laminate, because any floor covering wears out during use, especially under increased load.

- Repair of decorative items. Using wax, you can update the “appearance” of picture frames, boxes, tea houses, various wooden boxes and drawers, figurines and jewelry. For small-sized products, it is most convenient to use the product in the form of a pencil. It will quickly remove a network of cracks, small scratches, and return things to their shine and presentability.

- Restoration of windows and doors. Cracked, old windows and door panels can be repaired using furniture wax, as well as giving them a richer tone or changing their natural shade.

Wax for furniture repair: where to buy, how to use

Hi all! I think not all of you know such a brand as Edding, as well as what products it produces. Edding has many competitors, but the essence of them all is the same. They produce wax for furniture repair.

This is exactly what I want to talk about today. This is a special composition that allows you to independently restore old or damaged furniture.

It will be relevant to recall one of our previous materials, where we discussed the restoration of lacquered furniture. Today I’ll tell you what it is, how to use it and when it can come in handy.

Types of compositions

Furniture wax can be colored (pigmented) or colorless. Also, such products differ in the form of release, although they are all approximately the same in composition - they contain carnauba and beeswax, tree resin, linseed, olive oil, drying oil and essential oils.

Soft

Wax, which has a texture similar to regular Vaseline, is best used to remove chips, scratches, cracks and large dents on horizontal surfaces. It is suitable for both wood and laminated bases, perfectly seals marks from fasteners and fittings, and masks knocked-down corners on tabletops and other products.

The soft material is sold in finished form, packaged in jars, buckets, and tubes. It is squeezed onto the base or spread with a spatula, the excess is removed with a cloth or felt.

Most soft compounds have poor resistance to ultraviolet radiation and atmospheric factors, and are therefore not suitable for outdoor use. You can change their color yourself by diluting with transparent wax or mixing several shades.

Solid

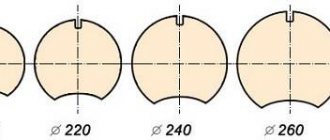

Compositions in the form of pencils of different thicknesses, as well as in the form of crayons and pens, are usually used to quickly and conveniently eliminate chips, scratches, cracks on vertical, inclined and horizontal substrates. They are great for frames, doors, furniture, and interior items. The dense texture and resistance to adverse events and temperature changes make the products suitable even for outdoor use. Some of them have to be melted before use, others are applied like crayons without preparation.

Liquid

In addition to natural resins, such products may contain synthetic components that allow them to maintain fluidity. The material can be applied using a brush or brush; it easily penetrates into any cracks, scratches, chips, or holes. The wax does not dry for long, is absorbed well, and does not leave marks on the skin after drying. Outwardly, it resembles drying oil or wax stain. Due to its structure, it is best to use it only on horizontal or slightly inclined bases.

GTV furniture fittings: product descriptions, customer reviews

- Working with furniture structures. Yes, this is the main purpose that a pencil or restoration wax, presented in a different form, has. Hides defects, fills voids, improves the characteristics of wood;

- Floor covering treatment. Suitable for working with wood-based materials. It can restore not only parquet, but also laminate;

- Restoration of decorative elements. These are paintings, restoration of mirrors, caskets, boxes, figurines, etc.;

- Restoration of doorways, doors, window frames. Scratches and other damage are well camouflaged and the wood is protected.

As you can see, wax has a wide range of applications, as evidenced by user reviews.

It won’t be difficult to purchase similar products in Moscow or St. Petersburg by visiting stores like Leroy Merlin. Plus you can always order online.

Choice of product

When purchasing wax, you need to follow a number of rules. First of all, the specific problem is taken into account: if a small scratch appears on the furniture, it is easier to remove it with a wax pencil; if there is a large chip, you should buy a paste-like (soft) material. Also, when selecting, carefully consider the shade of the product - it must match well the color of the product itself, otherwise it will stand out on it in the form of a spot.

Waxes for outdoor use must have powerful water-repellent properties and contain components that prevent them from fading from ultraviolet radiation. To restore a large surface or to completely renew furniture, it is worth buying wax in large containers, which is much more profitable.

Types of wax for furniture and features of its use

The house, furnished with wooden furniture, feels warm and cozy. The only pity is that over time, an expensive cabinet or shelf can dry out and become covered with a web of cracks. Furniture wax will breathe new life into wood and return furniture to its original shine and beauty. This professional product can be used not only on clean, but also on varnished surfaces.

Instructions for use

To work with a soft composition, you will need a rubber spatula, felt, and to open the package - a sharp knife. First, prepare the surface so that it is clean and the pores of the wood are open.

The defective area is cleaned of varnish (if it was previously applied) using a solvent, washed to remove dirt, and completely dried. To improve the absorbency of the composition, go over the base with sandpaper (in the direction of the fibers of the material).

Then proceed like this:

- open the wax package,

- scoop up the product with a small spatula,

- apply the composition to the damaged area, sealing the crack, scratch,

- rub the material with felt,

- the excess is carefully cleaned off with the same spatula or knife,

- leave the product to dry for an hour,

- polish the surface again to give it a glossy finish.

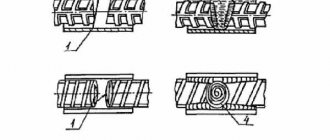

As a rule, a scratch is treated with hard wax in the form of a pencil without prior preparation. Some products involve preliminary melting and subsequent infusion into a crack or other defect. In this case, you will need a soldering iron or a hair dryer to work. If you don’t have such tools, you can use a gas torch or lighter. The heated material is applied to the problem area, leveled with a spatula, and after drying, polished with a soft cloth. Excess composition is removed with a blunt knife.

Stages of work

The wood polishing process consists of several stages. In order for the surface to look perfect after polishing, it must first be sanded, then covered with a layer of primer and only then thoroughly polished.

Surface grinding

This procedure does not cause any particular difficulties, but it takes a lot of time to give the tree a perfect look.

The surface must be free of chips, burrs, cracks and other defects. First, the wood is treated with sandpaper No. 46-60, then with abrasive material No. 80-100 and finally sanded with sandpaper No. 140-170.

After sanding, the wood becomes clean, smooth, without protruding fibers or lint .

Padding

At this stage, the prepared wood is primed using shellac polish and a linen swab . It is not recommended to use cotton or wool fabrics for these purposes; they leave behind small fibers and lint, which are clearly visible on the polished product.

To apply the primer, put a small amount of polish on a swab and begin rubbing in different directions. With this approach, small cracks and pores are most effectively filled, and impregnation occurs better.

Note! First, make a smear on a test surface. The polish should dry quickly and not form bubbles. If there is a lot of it, then the excess is removed by wiping the test surface.

The primed product is left to dry for 2-3 days . After the varnish has dried well, it is necessary to sand the wood with a fine-grained abrasive material. The resulting dust is removed with a rag.

Polishing

After priming, the so-called polishing is performed. A couple of drops of vegetable oil are applied to a tampon made of linen fabric (this facilitates easier sliding) and a little liquid shellac polish is poured . For work, you can further dilute the shellac-based composition (usually an 8% solution is used).

Place the tampon from the side and make smooth circular movements . Polishing is carried out in three passes , where each layer must dry, sand with fine-grained sandpaper and be cleaned of dust. A slight gloss can only be seen after applying the third layer of the product.

Pros and cons of using wax

Furniture wax does not remain on the surface, but penetrates into the structure of wood or other wood-based materials. It does not spoil the texture, but at the same time it saturates the pores of the wood, repelling moisture and reducing the rate of destruction of the material. Other benefits of using wax:

- pleasant to the touch velvety coating after the product dries,

- enhancing color and expressiveness of the design,

- the presence of different shades, the ability to change the natural tone of the item,

- Reliable filling of all defects - chips, cracks, scratches.

There are few downsides to such funds. Compared to varnishes, waxes have less protective power, and their layer will have to be renewed more often. Some species deteriorate from ultraviolet radiation and fade, so restoration work will need to be carried out regularly.

Do-it-yourself furniture restoration using wax

Wooden furniture is incredibly popular among users.

It is made from environmentally friendly, natural material, smells pleasant, and lasts a long time. No less practical, but inexpensive are products made from chipboard, laminate, MDF and other combined bases. Despite its strength, any furniture deteriorates over time, wears out, and loses its attractiveness. To update its appearance and extend its service life, furniture wax has been developed - a universal composition that hides minor defects and protects surfaces from moisture.

Self-production

There is a simple recipe for making furniture wax with your own hands. You need to take 100 g of beeswax, grind it and melt it in a water bath. Add 50 g of turpentine and continue heating the mixture until smooth. Add 25 g of rosin and an arbitrary amount of propolis there (to give the product a pleasant smell). After the mixture has cooled, you can lubricate the furniture and polish it well with a rag.

Homemade wax is not inferior in quality to store-bought wax. With its help, you can easily restore the appearance of old, damaged furniture, seriously saving on the services of craftsmen!

How to use wax when restoring furniture

They begin work by preparing the surface that is decided to be updated. In order for the wax to penetrate into the inner layers of the wood, it is necessary to remove the varnish or paint coating, if any. To do this, the furniture is treated with a solvent and then cleaned with sandpaper.

Grease stains or other contaminants should be thoroughly cleaned before waxing. If desired, you can use sandpaper or a sander to whiten the entire wooden surface.

If the furniture is made of pure wood, without coating, it is enough to free it from dust and small debris using a vacuum cleaner and a soft cloth - and you can begin processing.

To eliminate serious flaws, it is advisable to use hard wax. This product has a very thick viscous consistency, so it must be melted before starting work.

To update furniture using a solid mixture, you need to do the following:

- Using a soldering iron, gas torch or regular lighter, melt part of the wax pencil and apply it to the surface to be treated. You must act as quickly as possible, as the product sets within a few seconds.

- Excess material is removed with a blunt knife or spatula.

- The waxed area is polished with a piece of coarse cloth.

To give the furniture a natural shine, you need to apply wax again as soon as the first layer has completely dried.

Without some work experience, it is not easy to cope with the application of a solid composition. Therefore, it is better to first experiment on an old stool or other unnecessary thing and only then begin to restore the central setting.

Soft furniture wax is much easier to handle. This product is sold ready-made, there is no need to melt it, and the soft mixture hardens within an hour. So if something didn’t work out the first time, there is always time to correct small flaws.

Conditions for storing and using the wax product

Like any substance, wax impregnation made from natural organic components has a limited shelf life. For proper use and storage of wax polish, the following conditions must be observed:

- The shelf life of herbal impregnations in sealed containers is usually no more than 2 years.

- Store the wax product in a dark, cool place.

- The heated product is used to create a moisture-resistant, durable layer of wood finishing.

- The hardened mastic is used for polishing and glossing floors and furniture.

- A little solvent is added to the solid composition. The liquefied substance is applied with a brush, roller, then rubbed with a cloth or velvet rag.

- Before processing wooden products, remove the old wax coating. To do this, use solvents and zero-grade sandpaper.

- When working with a brush, you need to direct the fleecy bristles along the fibers of the wood structure.

- In order to give the treated area a certain shade, the appropriate color is added to the impregnation.

- If the impregnating agent dries slowly, a substance such as a drier is added to it. It can be purchased at art stores. The liquid acts as an accelerator for the polymerization of mastic and an antifungal agent.

Why do you need to wax wood?

The bee product has the priority right to be called wax. The rest of the products are artificial products of the chemical industry. Furniture and any wooden surfaces are subject to various physical impacts. This can cause minor damage (scratches, cracks) and lead to loss of presentation. Wood tends to release vapors from the internal structure of the material into the atmosphere, which causes cracks and drying out.

Since ancient times, people have polished floors and furniture with beeswax. A layer of greasy product masked small cracks and prevented the depletion of the wood mass due to evaporation. The process of treating surfaces with wax is called waxing. For many decades there has been an increase in the need for bee products, which have become scarce. As a result, new compositions were invented that were superior in properties to natural wax.