You live in a private house or apartment in a city high-rise building, where the water supply system is connected to public pipelines. During peak hours, the pressure drops sharply, as a result the instantaneous water heater and washing machine do not turn on. – It’s impossible to take a shower. You have decided correctly: you need to buy a pump to increase water pressure. Which? By far the best. We bring to your attention the best booster pumps. Choose.

In what cases is a water pressure booster pump used?

It is known that water main systems contain a large number of taps and branches, as well as pipe bends. Because of this, a pressure drop occurs that is significantly lower than the values established in the regulatory documentation for urban networks. Low water pressure in most cases can also be due to wear and tear on the pumping equipment.

So, the pressure power must be at least 4 atmospheres. In practice, this figure is much lower. The table shows some values of the pressure standards of the water supply system for the operation of household appliances and other equipment.

Table 1. Minimum operating water pressure indicators for household appliances

| Pressure indicator (in atmospheres) | Equipment |

| 2−2,5 | Washing machines and dishwashers |

| 3 | Fire extinguishing system equipment |

| 4 | Jacuzzi, hydromassage boxes |

The problem of lack of pressure can be solved by installing a water circulation pump in your home. Such equipment is often used by residents of the upper floors of apartment buildings. Peaks of high water consumption are observed in the morning and evening hours, so residents of high-rise buildings experience difficulties in obtaining it. This entails the inability to use water heating equipment, as well as failures in the operation of autonomous heating systems.

Pump installation in a home plumbing system

Boosting water pressure equipment is also installed in cases where the pressure at different points of consumption within the same apartment differs, or there are completely no comfortable living conditions (water flows in a thin stream constantly, there is no way to turn on the washing machine, heating, etc.).

Advice! Not in all cases, the problem with the pressure of cold and hot water can be solved using pumping equipment. Very often it is too low due to a clogged water supply system or a breakdown. Before you buy a pump to increase water pressure, you need to make sure that there is no emergency, and if necessary, eliminate it or replace the damaged section of the line.

Rules for selecting unit power

The power of the device must be commensurate with the needs of the system. Not enough pressure is bad, but you don't want too much pressure either.

If a pump that is too efficient is selected for the water supply system, the pressure in the system will increase and all its elements will be subjected to unnecessary additional load. This leads to rapid wear and frequent breakdowns.

Stable water pressure in the system must be no less than two atmospheres. This is enough for comfortable water procedures, as well as for starting an automatic washing machine.

Although some models are more demanding in terms of operating conditions. For example, if the house has a shower, hydromassage, jacuzzi or other similar devices, the pressure should be higher.

In this case, it is better to increase the pressure in the water supply system to 5-6 atmospheres. Certain types of equipment require even higher performance.

Therefore, the first step before installing a pressure booster pump should be to study the documentation of household appliances. If you plan to purchase any devices in the future, their characteristics also need to be taken into account.

To create a constant high pressure in the system, special pumping stations are used, including a pump and a hydraulic tank. Their operation is controlled using a pressure switch

A specialist can make accurate calculations, but usually preliminary data made “by eye” is sufficient. To determine how much pressure actually exists in the system, you can use a regular liter jar. They open the water and measure how many liters of water pour out of the tap within a minute.

Then you need to deal with your current needs. If the inconvenience is due to the fact that when the tap in the kitchen is open it is difficult to take a shower due to low pressure, it is enough to use a regular pump, which will increase the pressure by a couple of atmospheres.

But if the house has an automatic washing machine, shower cabin or other equipment of this kind, you should study the technical documentation.

Each such consumer requires a certain water pressure. Lack of sufficient pressure can lead to expensive equipment running idle.

Household appliances, especially foreign ones, are not designed for such operating conditions. A breakdown caused by a lack of normal pressure may be considered a case that does not comply with the warranty conditions.

You can focus on the maximum pressure indicators in the water supply system indicated in the device data sheets. If you have a large number of such equipment, you should seek advice from an engineer.

When choosing a water pump model suitable for power to increase pressure, you should also take into account the needs of equipment that you plan to purchase in the future.

Lack of pressure in the plumbing system can lead to premature wear and failure of expensive water heating and plumbing equipment

Classification of high pressure water pumps

By type of control

Many people do not know how to increase water pressure in an apartment and choose the right booster equipment for these purposes. First of all, you should know that devices for providing the necessary pressure differ in the type of control.

They can work in automatic and manual mode. In the first case, a water flow pressure sensor is installed in the pump, which regulates its operation. As soon as the tap opens, the pumping unit turns on. You should know that such equipment is much more reliable than manual analogues, since it has protection against switching on in dry mode (in the absence of water pressure).

Pumping unit with automatic control

As for manual installations, they operate in continuous mode. This requires periodically monitoring the equipment and, if necessary, turning it off to avoid overheating. A significant disadvantage of such stations is the high energy consumption and short service life of the mechanisms.

Hand pumps are usually cut into a pipeline and connected to the household electrical outlet. If you open the valve, the relay contacts are activated, which turn on power to the pumping device. In turn, this leads to an increase in pressure in the main line. There are also flow-through installations that are installed directly at the point of water intake or in front of various types of equipment to enhance their operation.

Installation for increasing water pressure

According to the permissible water temperature in the pipes

Almost every pumping station for increasing pressure in the main line is designed for a certain operating water temperature. It cannot exceed 60°C. The pump is connected to the apartment wiring, increases the pressure in the system, after which the water is heated, if necessary, using boilers, water heaters, boilers and other installations. Among the pump models, there is equipment that operates from a cold or hot water supply line. There are also universal station designs that operate regardless of the type of connection and liquid temperature.

By type of engine cooling

Since electric motors are used to change the force of water pressure in the lines, this requires the use of cooling systems. Pumping units come with a “wet” as well as a “dry” armature. In the first case, the equipment is small in size and is installed directly on the main pipe.

“Wet” pumps, unlike their “dry” counterparts, operate almost silently, since during pumping water the rotating parts of the mechanism are lubricated. If the injection compressor has a “dry” armature, its shaft is equipped with an impeller, thanks to which the housing is cooled by air. Such pumps are characterized by increased productivity, and they are used if it is necessary to provide normal pressure simultaneously for several water intake points (consumers). It is important to know that the design of “dry” pumps is fundamentally different from other types. The rotor of the device is located outside the structure of the unit, and it also has a separate air cooling system. In this case, the interaction of the electric motor armature with the aquatic environment is completely eliminated.

Pump with dry cooling system

Pump installation

The installation location of booster pumps is very important and determines the efficiency of their operation. The flow sensor can only be activated if water flows through the pump, therefore, to supply water to the first or second floor, the device should be installed in the basement. At the same time, full-fledged operation is only possible in a complex installation with another pump, which will ensure the lifting of liquid through the pipes.

The operating diagram of the booster pump is easy to understand and will help you install the unit correctly. The injection device must be mounted on a pipe in front of the water intake points so that with low pressure it can turn on and supply water to all consumers. When you start one of them (turn on the washing machine or open the tap), the water moves, and the flow sensor instantly reacts to this movement, turning on the pump (usually it takes no more than a second). If you live on the 4th-5th floor and install a pump in the basement, then its power will not be enough to raise the water to the required height.

Booster pump connection diagram:

- On the pipe to which the pump will be connected, make markings in accordance with the length of the pump and adapters.

- Turn off the water in the apartment.

- Cut the pipe according to the markings.

- Make external threads on both ends of the pipe.

- Screw adapters with internal threads onto the pipes.

- Screw the fittings that should come with the pump into the adapters. During the installation process, check the instructions for the device and look at the arrows drawn on the body (they indicate the direction of flow).

- Run a three-wire cable to the pump from the electrical panel. It is recommended to organize an additional outlet near the installation site, and connect the pump itself through a separate RCD.

- Carry out a test test of the pump, paying special attention to all joints - there should not be a hint of leakage. For high-quality sealing, wrap FUM tape or tow around the threads.

Useful tips

As you can see, the installation diagram for a booster pump is not that complicated, but to do everything correctly, you need to have minimal plumbing skills - be able to cut pipes and make threads.

To ensure that the pump serves you for many years, follow these rules when installing:

- To make the pump work longer, it is advisable to install a mechanical filter at the inlet. In the city, the water is quite dirty, and the pipes are mostly old with many years of deposits on the inner walls, so it would be a shame if a piece of hard plaque accidentally came off the pipe and got into the new pump and ruined it.

- Install the pump in a dry, heated room. If the temperature drops below zero, the water inside will freeze and the device will fail.

- The installation of a shut-off valve must take place up to the point where the pump is installed, so that, if necessary, preventive work can be carried out by blocking the access of water.

- Any pump, even the quietest one, vibrates during operation, and this vibration over time can disrupt the stability of the device - weaken it. So get used to checking the strength of the fasteners from time to time and tightening them if necessary.

A pump that pressurizes water can significantly improve the quality of life in a city apartment or private house. You may have to invest a little money and spend a little time for this, but in the very first winter you will feel dramatic changes - the rooms will become warmer, and hot water will flow from the tap immediately, and not after 5 minutes of waiting.

How to increase water pressure in an apartment

When to choose a water pressure booster pumping station

A pumping station may be required if water does not flow to the top floors of high-rise buildings. This equipment is also used for installing a water supply system in a private home. The station is a centrifugal equipment designed to increase and stabilize water pressure in pipelines. The tank has a reservoir of a certain volume, which is filled by means of a pump. As soon as the water supply in it runs out, the relay is activated and the liquid enters the accumulator. In practice, it has been established that the larger the volume of the tank, the more reliable the equipment operates, since the installation is turned on and off infrequently.

Pump with hydraulic accumulator

Related article:

Pumping station for a private house. Why do you need a pumping station, its advantages and disadvantages, operating principles, selection criteria, popular models and manufacturers, prices, details of do-it-yourself installation - read in our publication.

Why should you choose a water-cooled pump for your apartment?

Many people prefer to install water-type cooling units in their apartment. This is due to the fact that pumps that increase water pressure in a water supply system with a “wet” anchor have compact dimensions, have a low noise level and are easy to maintain.

Compact water-cooled unit

In addition, connecting this equipment is not particularly difficult. First, a piece of pipe of a certain length is cut out of the supply line, after which a unit is installed, which operates on the principle of flow-through pumping equipment. The installation is carried out directly in front of the point of water intake or equipment (boiler, washing machine, etc.) to ensure the required pressure for its operation.

How to install a self-priming pump

Installing a pump of this type is not particularly difficult. To do this, you will need approximately the same skills and tools that are needed to install other types of pumping equipment. Schematically, the installation of a booster pump can be represented in the following steps:

- Choosing a location for the accumulator and pump.

- Installation of a hydraulic accumulator.

- Installation of pipes for connecting equipment to the water supply.

- Hanging the pump from the wall.

- Pump and accumulator piping.

- Checking the operation of equipment in automatic mode.

In fact, a pump and accumulator with a pressure switch is a variation of a pumping station. To implement the installation of such a system of devices, you first need to find a place to place the tank. Some craftsmen replace the hydraulic accumulator with a membrane with an ordinary large capacity, for example, a 200-liter plastic tank.

Instead of a pressure switch, the tank is equipped with a float switch to ensure that it automatically fills as needed. Such a tank is installed as high as possible: in the attic or on the top floor. You should immediately think not only about the size, but also about the configuration of the container.

The flat and narrow tank will take up less space than a traditional cylindrical model. Although there are no special requirements for the configuration of the container. When choosing a location for a container, you should provide access to the tank/hydraulic accumulator or the ability to easily dismantle this element. This is necessary to perform maintenance, repair or replacement of the device.

The photo shows the installation of check valves when installing a plastic tank, as well as the procedure for connecting the inlet and outlet pipes to the water pipe

Hydraulic accumulators are supplied ready for installation, but the tank should be prepared. There are holes in it for water inflow and intake. You can also make a separate shut-off valve to drain the water in an emergency. The pipes for supplying water to the tank and taking it into the water supply system are mounted to one water pipe.

In modern conditions, it is more logical to use easy-to-install and reliable plastic pipes for installing water supply systems. To prevent air from being sucked into the tank from the pump, and also to prevent water from entering there when the equipment is turned off, check valves should be installed on both pipes. After this, pipes are installed to connect the tank to the water supply system.

Circulation pumps take up minimal space and do not interfere with the maintenance of household appliances

Once the tank or accumulator has been installed and the necessary water pipes have been laid, you can begin installing the suction pump. Typically, such a device is supplied disassembled. It is first assembled and then installation begins.

If you decide to mount the pump on the wall, you should first make markings for the fasteners. The pump is then suspended and connected to the water supply pipes. Overall, this is not a very complicated operation. An important point is the direction of the fluid in the pump. It is indicated on the body with special marks.

The pump should be installed in such a way that the water flows from the tank to the water collection points. Thus, the installation and connection diagram for the pressure booster pump is as follows: hydraulic accumulator-pump-consumer. Then the pump is connected.

This is a detailed diagram of connecting the pressure booster pump to the water supply system. For installation, the pipes are usually disconnected at the beginning of the system and the pump is connected to them using fittings

All connections must be carefully sealed. If threaded connections are used to connect the booster pump, a suitable sealant should be used: FUM tape, flax thread, etc. The amount of sealant should be sufficient, but not excessive. The device is connected to plastic pipes using special fittings.

After this, you should check the operation of the entire system. If a tank with a float sensor was used, fill it with water. They check not only the operation of the sensor. The container that serves as a storage tank should be checked for leaks. If everything is in order, you can proceed to testing the operation of the pump itself.

The pump must be connected to the electrical network. It is recommended to move the pump switch lever to the position corresponding to automatic mode. All that remains is to open the nearest water tap and observe the operation of the device. If the installation is done correctly, the pump should automatically turn on and the water pressure will increase noticeably.

Pressure boosting circulation pumps are installed in a similar manner. A suitable place in the water supply is chosen for them, and they are inserted there. In this case, it is also extremely important to connect the pump correctly, taking into account the direction of fluid flow. If the position of the device is incorrect, the pump will still allow a flow of water.

Connection diagram of the circulation pump to the water supply system. Installation of such a device is very simple, but it is important not to confuse the direction of water flow

But its work will be extremely ineffective, since the device simply will not function. The instructions and the housing indicate in detail the correct position of the pump. After installation, the pump is connected to the electrical network and its operation is checked. If the water pressure at the nearest water intake point has increased, it means that the installation was completed correctly.

A small pump to increase pressure is simply cut into the system. Usually, to do this, it is enough to remove a piece of pipe of the appropriate length at the beginning of the water supply

Installing a system with a hydraulic accumulator looks a little more complicated. First you need to understand the structure of the entire structure. The pump is connected to the hydraulic accumulator using special hoses. Then a pressure switch is connected, with which the equipment will be turned on and off.

This figure shows in detail the principle of operation of a pump with a hydraulic accumulator and the procedure for connecting it. The pump fills the tank and then turns off

The configuration of such a relay deserves special attention. Before starting work, it is recommended to carefully study the instructions and recommendations of the manufacturer. If the knowledge and skills for high-quality installation and configuration of equipment are not enough, it is better to contact a specialist for advice or completely entrust him with all the work.

The best models of water pumps for increasing pressure in an apartment

Wilo booster pump

If you need to install a reliable pump to increase water pressure in your apartment, you should pay attention to Wilo products. In particular, the PB201EA model has a water cooling type, and the shaft is made of stainless steel.

Wilo PB201EA pump with wet rotor

The unit body is made of cast iron and treated with a special anti-corrosion coating. Bronze connecting pipes ensure long service life. It is also worth noting that the PB201EA unit has silent operation, automatic overheating protection and a long service life. The equipment is easy to install, however, it should be remembered that only horizontal installation of this device is possible. Wilo PB201EA is also designed for pumping hot water.

Grundfos water booster pump

Among the models of pumping equipment, products from Grundfos should be highlighted. All units have a long service life, withstand quite large loads well, and also ensure long-term uninterrupted operation of water supply systems.

Grundfos self-priming pumping station

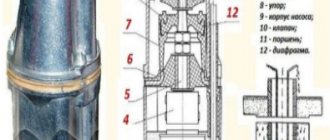

Model MQ3-35 is a pumping station that can be used to solve problems with water pressure in pipes. The installation is controlled automatically and does not require additional control. The design of the unit includes:

Popular models and manufacturers

Let's look at the most famous and common models of booster pumps:

Wilo Star-RS 25/4

A German pump, which is considered the best of the circulation devices. The wet rotor design ensures minimal noise levels and long life of the pump. It has a durable cast iron body, the impeller is made of polypropylene. Productivity is 3.5 m3/h, head is 4 m. Temperature range of the transported liquid is from -10° to + 110°. Pump weight is only 2.4 kg;

Grundfos UPA 15-90

The brainchild of Danish manufacturers. A classic booster pump capable of developing a head of up to 8 m with a productivity of 1.5 m3/hour. Can be started manually or in automatic mode (when the tap is opened, the flow sensor is triggered). The power of the unit is 120 W. Initial (input) pressure - 0.2 Atm. The temperature range is from +2 to +60°, which allows you to work only with the cold water circuit. The service life declared by the manufacturer is 10 years;

Jemix W15GR15-A

A product of a joint Russian-Chinese company. It has a cast iron body and an aluminum motor casing. Equipped with a flow level controller that allows operation in automatic or manual mode. With a productivity of 1.5 m3/hour, the pump demonstrates a head of 15 m, which far exceeds the performance of many European designs. Autostart of the unit occurs at 0.09-0.12 m3/hour;

Comfort X15GR 15

Domestic booster pump. It has a stainless steel body, a capacity of 1.8 m3/hour and a head of 15 m. Designed only for working with clean water. A specific requirement is horizontal installation of the unit. Power - 120 W. Users note the high performance and reliability of the pump, but criticize the too high noise level;

DAB DIVERTRON 1200

A submersible pump that is appreciated by owners of private houses. Provides water supply from wells. The power is 1.1 kW; at a immersion depth of 10 m, the pump is capable of lifting liquid to a height of 48 m. It demonstrates high productivity - 5.7 m3/hour. There is an electronic control unit, idle protection (shutdown). Needs power supply stabilization;

GILEX "Vodojet" PROF 55/75 House

Borehole pump of domestic production. The productivity is 3.3 m3/hour, and the pressure is up to 75 m, which allows you to work in deep wells. At the same time, the power of the unit is only 900 W. The permissible immersion depth is 30 m, the operating condition is vertical installation. Used for clean water only;

Patriot F 900

Recognized as the best submersible drainage pump. It has a plastic body, a float switch, and a vertical pipe. Able to work with dirty water. It operates according to the scheme - 2 hours of work, followed by a 15-minute break. The unit's productivity is 14 m3/hour, power - 0.9 kW, pressure - 10 m. There is a limitation on liquid temperature - up to + 40°.

This is not an exhaustive list of popular models. Their number is very large; the user can choose a pump for any conditions and tasks.

How to connect

When thinking over the connection diagram, you must be guided by the following recommendations:

- In order for household appliances to function properly, the booster unit should be located directly in front of them;

- if there is a water storage tank located in the attic area, it is better to place the pump at its outlet;

- in case of an unexpected failure, it is necessary to organize the installation of an emergency route (bypass), which will ensure stable operation of the device;

- when installing a hydraulic pump in an apartment building, it is important to understand that when it is turned on, the remaining residents may be left without H2O (in such a situation, storage tanks will come in handy, which can be used instead of units that increase the pressure);

- To get the desired result, you should not only put the device in the water supply, but also change the pipes to products of larger diameter.

Calculation example

Basic necessary data for choosing the appropriate surface pump model for water supply at home:

- Maximum fluid flow rate in l/min or m³/h.

- Suction height is the difference between the levels of the pump inlet pipe and the surface of the water in the source.

- Discharge height is the difference in levels between the highest point of the pipeline and the pump outlet pipe.

- The initial pressure for a free-flow well or well is equal to atmospheric pressure.

- Final - the required pressure in the home plumbing system.

- Pressure losses in pipelines depend on the fluid flow and the quality of the surfaces of the internal walls of the pipelines, which create friction for its movement.

The suction height of surface-type hydraulic pumps cannot exceed 10.33 m - the height of the water column creating equal atmospheric pressure.

To simplify calculations , it is rounded to 10 m , and the pressure created is equated to one technical atmosphere, 1 at = 1 kG/cm², or approximately 1 bar ~ 0.98 at.

The discharge height, or pressure, is determined by the technical parameters and power of the unit .

Often the value of pressure is confused with pressure, calling one another. These quantities are equivalent, but not exactly equal to each other. The pressure at the outlet of the pump depends only on its technical characteristics, and the pressure depends on the totality of external conditions : flow rate and liquid consumption, its temperature, altitude above sea level, etc.

When calculating, all system pressure values in pascals, bars, atmospheres and other units lead to equivalent pressure values in meters .

Let's give an example, taking the geodetic level of the pumping station location as zero:

- The fluid flow provided by the hydraulic pump is 40 m³/h. This is quite sufficient consumption for household needs.

- The water level in the well is 4 m below zero.

- The highest point of water rise is 15 m above it.

- The total losses in the inlet and outlet pipelines can be found in the tables for a specific type of pipe, but they are usually calculated based on the fact that for every 10 m of the pipeline 1 m of pressure is lost, therefore we will take them equal to (15 m + 4 m) / 10 = 1 .9 m.

- Let us take the final pressure at the top point to be 1 bar ~ 9.87 m.

The total pressure of the hydraulic pump will be equal to: 4 m + 15 m + 1.9 + 9.87 = 30.77 m.

If the water pumping station is installed not in a caisson located next to the well, but in a house, the pressure loss along the length of the supply pipeline should also be taken into account .

For each pump there is an operational characteristic that shows the pressure drop depending on the flow rate and has something like this :

When choosing a specific pump model, you should compare the calculated parameter values with the nameplate values for the selected unit at the required operating point.

The hydraulic power of the pump can be found using the empirical formula: P (W) = 2.725 x Flow (m³/h) x Pressure (m).

For our example we get : 2.725 x 40 x 30.77 = 3.354 kW.

For more information on calculating and selecting a pump for water supply to a country house, watch this video: