Application of pipeline elements for various types of sewerage

Fittings for internal sewerage

The internal sewerage system is laid before the water supply is installed. When laying internal sewerage, it should be taken into account that hot water from a dishwasher or sink can be discharged into the system.

Shaped parts must withstand temperatures up to 75°C (up to 95°C is allowed for a short time). Polypropylene has these properties.

Fittings made of polypropylene are resistant not only to high, but also to low temperatures (cracking does not occur when freezing). When assembling all pipeline elements, it is necessary to take into account the expansion of the material when discharging hot water, so the parts are not connected “all the way”. The smooth inner surface prevents deposits from sticking to the walls, which prevents blockages.

Polypropylene fittings for internal sewerage

The internal sewerage system also uses compression fittings, which are usually included with the equipment (for example, a water heater).

The use of compression fittings allows you to connect pipeline elements without soldering, welding or gluing. Only two keys are used for connection, and dismantling is carried out using only one key.

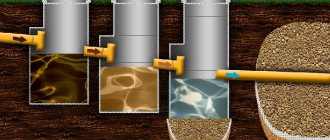

Shaped parts for external sewerage

PVC pipes and fittings are used for laying the external sewerage system. Due to their high annular rigidity, the shaped parts of PVC sewer pipes withstand soil pressure and are not susceptible to destruction from the inside or outside under the influence of wastewater and groundwater. O-rings located in the sockets give the system a tight seal. The system is easy to install and dismantle if necessary.

By using pipes and fittings for PVC sewer pipes to lay the pipeline, you save not only during construction, but also in the future, since the system will not require maintenance and repair costs over many years of operation.

Classification of fittings

Shaped parts are divided depending on their purpose.

Bends (corners) change the direction of the structure by an angle - 45o, 90o, 120o. The pipeline route can change both vertically and horizontally. A socket with a sealing ring on one side.

The flexible outlet is used in the internal sewerage system. It is used in cases where it is impossible to use standard parts, since the pipeline has a slight bend. The socket with gasket is located on one side.

Plastic bends for sewer pipes

The tee allows for a branch from the main pipeline and comes in the following types:

- Straight tee (angle 90°C) with sockets on both sides, into the grooves of which o-rings are inserted. A pipe of smaller diameter is inserted into the branch socket. The straight part of the tee is inserted into the socket of the pipe being connected.

- Oblique tee (angle 45°C) with sockets on the outlet and on one side of the element. Oblique tees for sewer pipes are used in cases where it is necessary to make a branch at an angle.

Tees: straight and oblique

The cross provides drainage in two directions:

- A single-plane cross is used when it is necessary to install two branches in the same plane.

- A two-plane sewer pipe cross connects pipelines located in two planes.

Crosspieces: one- and two-plane

A coupling connects pipes of the same diameter in a straight span. On both sides there are sockets with grooves into which o-rings are inserted. Connects two straight pieces of pipe. They are used when repairing part of a pipeline, when the damaged part of the pipe is removed, a new section is installed, and then connected with a coupling. A corrugated coupling (flexible outlet) is used to connect to a bend in an internal sewerage system.

A sewer pipe plug covers the end. Used for repairs and replacement of pipeline parts. Closing the end of the pipe prevents wastewater and odors from entering the room where the system is being disassembled and assembled.

Coupling (left) and plug (right)

The adapter is used to connect pipes of different diameters:

- The eccentric is put straight onto a pipe of larger diameter, and a pipe of smaller diameter is inserted into the socket with a sealing ring.

- The transition from a plastic pipe to a cast iron one is carried out using adapters for sewer pipes.

Eccentric (left) and cast iron-plastic adapter (right)

The inspection provides access to the pipeline from the inside. The lid is easy to remove and is airtight. Installed for prevention and maintenance of the system in easily accessible places. The bell is on one side, the other side is straight.

A non-return valve on a sewer pipe protects against sewage leaks. Overfilling the system leads to pressure on the membrane, which closes the damper. The valve prevents wastewater from moving up the pipeline. There is a possibility of emergency shutdown of the system. The sealed cover is removable and allows the valve to be cleaned.

Inspection and check valve

The anti-vacuum air valve (sewer aerator) is designed to prevent the ingress of gases from the sewerage system. Installed at the highest point of the vertical riser. If there is a vacuum in the pipeline, it is released through the valve. Thanks to the installation of the valve, the hydraulic seals do not break.

The ventilation hood serves to protect the system from debris and other contaminants and is installed in the upper riser (exited to the roof).

Air valve (left) and ventilation hood (right)

Types of fittings for installing external sewer systems

To avoid confusion, PVC connecting elements for external sewerage are made in orange (brown) color. They are also distinguished by their strength, thickened walls, high rigidity class and large dimensions. The main types of fittings are the same in both sewer systems, only the diameter changes. There are components specially manufactured for the external system, these include:

- three-socket tee - ensures the merging of three gadflies of a smaller diameter into a main drain pipe of a larger circumference;

- adapter between different pipe diameters and materials;

- non-return valve - prevents waste from circulating in the opposite direction due to clogging or overfilling of the system. One valve is enough for the external sewage system of a small private house, but not for a high-rise building, where it can only be installed on a separate apartment;

- siphon with two elbows - a water seal connection included in the pipeline in front of the wastewater receiver;

- saddle - a part designed like a saddle with an inlet hole in the middle, serves as a connection for an additional outlet to an already working system. The saddle is glued, wrapping around the main pipe, and its socket is connected to the outlet.

Some types of fittings allow you to make a branch from an existing pipeline

A pressure sewer network with a pressure of 6-11 atm requires the use of flange connections, that is, special fittings (mainly couplings) equipped with a rubber layer and a bolt tie. The connection is particularly durable, leak-proof, and can be quickly replaced.

What are pipeline fittings

Not a single building where a person carries out his life activities can do without organizing a water supply system. Delivery of vital moisture to the consumer is carried out through a pipeline.

Naturally, when organizing a pipeline system, you cannot get by with just a straight pipe. In order to distribute the water supply system to all floors of the building and connect each consumer to it, it is necessary to provide it with shaped parts.

Pipeline components

Pipeline fittings are auxiliary parts that complete the water supply system. They provide reliable pipe connections, bends and branches, as well as many other functions.

From this we can conclude that the fittings are designed to assemble the entire pipeline system together and give it the necessary angles of rotation and outlets for each individual user. Even if your pipeline is a straight pipe, you cannot do without connecting elements at its ends.

What types are there

The main purpose of pipeline fittings is to ensure reliable connection of all its elements.

According to their purpose, shaped products are divided into the following types:

- transitional, which provide connection of pipes of different diameters;

- crosses, which allow you to organize several branches in the pipeline;

- tees, with the help of which branches are connected;

- branch pipes, which provide a 90-degree rotation of the pipeline system;

- branch pipes, which are designed for installation of special fittings.

Shaped products can be manufactured with different working wall thicknesses. These dimensions depend on the conditions for which and for what period of operation a particular pipeline system is intended.

Which material is better

Pipeline fittings are made of steel, cast iron and plastic. Depending on the material and design features of the product, various methods of connecting them to pipeline elements are used.

When organizing a pipeline system in residential buildings, fittings made of plastic have recently become especially popular. They have a lower price and are not subject to corrosion.

Couplings and bushings for connections

The use of couplings and bushings for connections has a number of main features:

• a part such as a coupling is used to connect sections of pipes of sewer and water supply systems with equal diameters; • The bushing is used to reduce the diameter to a specified size that fits the connection. Pulls onto the pipe socket; • in order to avoid increasing the likelihood of leaks and blockages, it is necessary to minimize the number of couplings used in the sewer system design, since one coupling in the pipe additionally forms two butt resistances; • the use of couplings for connection is necessary only in case of overcoming obstacles in the way of laying the frame strut and other communications.

We recommend: How to cover pipes with blinds in the bathroom and toilet

To ensure reliable connection of pipes when overcoming obstacles, you must do the following:

1. Cut a hole in the rack with a diameter slightly larger than necessary. 2. Cut off a part of the pipe approximately the same length as the distance between the posts. 3. Insert part of it into the cut hole at a slight angle. When the end of the pipe passes beyond the stand, it is necessary to connect this stand to the pipeline system using various fittings.

Fittings for pipelines

The specification you were given is incorrect. The designers didn’t want to count the fittings, so they wrote them complete with fittings,

Since most of the time is spent on counting them. You won’t do the math yourself, but if you start, it will take a lot of time, and also what a responsibility. Therefore, the only solution I propose is that there are no problems with a steel pipe: you take the cost and laying of the pipeline.

With polypropylene pipes, the installation is as indicated, and the cost is taken according to the price list of the pipes with an increase of 10 percent.

And then, when the work is carried out, you will get better

Category: Types of water pipes

Fittings&pipes

Shaped parts with anti-corrosion protection are used when making turns, transitions from one pipe diameter to another, and branches. They are used when connecting various types of pipes:

— steel electric-welded pipes with a spiral seam with a diameter of 254 mm, with anti-corrosion ethinol coating;

— steel thin-walled spiral-seam pipes with a diameter of 254 mm with double-sided zinc coating;

— steel pipes with a wall thickness of 168–1220 mm;

— steel thin-walled electric-welded pipes with a diameter of 168-426 mm with a spiral seam;

— thin-walled steel pipes with a diameter of 200-400 mm with varnish ethinol coating;

— asbestos-cement pipes with a diameter of 150-500 mm;

— polyethylene pipes with a diameter of 160-300 mm;

— cast iron pipes with a diameter of 150-400 mm.

To connect pipes, reducers, tees, bends, crosses and pipes are used.

Transitions are used in pipelines to arrange transitions from one pipe diameter to another.

Tees are used to install branches on pipelines. They come in equal passage and transitional types.

Bends are used to make pipeline turns at an angle of 90°.

Rice. 1. Transition: 1 - sleeve-2 - transition; 3 - bell

The content of the work

5. PIPELINE FITTINGS

5.1. RELEASES

Bends are used as inserts in places where pipelines turn at a certain angle. The most common types of bends are three types: steeply curved seamless, bent and sectional. They are designed for pressure up to 10 MPa and are made of steel grades 20, 10G2 and 09G2S.

Steeply curved seamless bends are made from sections of steel pipes at various angles of rotation.

Rice. 5.1. Steeply curved seamless bends.

Bent bends

are made on cold and hot bending pipe bending machines, including those with HFC heating; bends with a radius of less than 2Dn are bent only with heating. Carbon steel bends are standardized.

It is allowed to use bends with other α and R in accordance with the instructions of the design documentation. The bending radius is taken from the Rα10 series according to GOST 6636-69, and l and lР are determined by the formulas:

l=R tg.; lр = 0.0175 Rα.

Rice. 5.2. The bends are bent.

The mass of the outlet, kg, is determined by the formula

where q is the linear density of the billet pipe, kg/m;

l1 and l2 - are established in the design documentation, taking into account the conditions of manufacture, transportation and installation, but not less than 100 mm.

The conditional pressure Ru is accepted, as for billet pipes, if the wall thickness in the curved section corresponds to that calculated by the formula

where s is the minimum wall thickness of billet pipes, mm.

Sectional bends

manufactured by welding sectors and half-sectors cut from seamless or electric-welded pipes. Sectional bends made of carbon steel are manufactured according to OST 36-43-81 with Dу. up to 400 mm and according to OST 36-21-77 with Dу = 500 – 1400 mm.