Application

Beginning builders sometimes find themselves in a difficult situation. The drills are new, of a good brand, the drill is in working order, but the resulting hole is not at all as planned, or does not work out at all. Often the reason for failure does not lie in poor work skills or a low-quality tool.

The first thing you should pay attention to is the materials from which the drill is made and the surface where the hole needs to be made. The basic rule is that the cutting tool must be harder than whatever it is going to cut. Proper sharpening of the tip is also important.

If you take a high-quality metal drill and try to make a hole, for example, in concrete, the product will quickly fail. It is not intended for such purposes. Drills with Pobedit tips are suitable for processing the hardest surfaces. Their cutting part is coated with an alloy called “win”, which has increased strength.

On the contrary, such products are often not suitable if processing is required , for example:

- plastic;

- steel;

- tree.

The winner does not cut the material, but rather crumbles it , so the holes are shaggy, ugly and larger than necessary. In the case of plastic, the necessary chip rejection is not ensured. As a result, the hole quickly becomes clogged, which leads to undesirable consequences:

- the load on the drill increases;

- operating time increases and efficiency decreases.

Because of these features, many masters, especially the “old school” ones, advise using pobedit only in suitable cases. However, the classic pobedit drill gradually changed. Now on the shelves there are products with special soldering (inserts), which are used to work with various materials, including “inconvenient” ones. For example, you can find a pobedit metal drill.

Drilling technology for monolith and reinforced concrete

In the case of monolithic structures, it is enough to monitor the degree of heating of the tool. It needs to be cooled periodically. There is an opinion that wetting the drill in water helps to extend working time. But experts have proven that this has no effect. This approach is only relevant for working with diamond drilling rigs.

Diamond drilling using wet technology Source allcorp.ru

If you need to make a hole in a reinforced concrete structure, then drills and drills must be protected. They are not suitable for working with metal despite the high strength of the cutting tip. Therefore, you will have to stock up on equipment for drilling reinforcement. When the obstacle is removed from the hole, it will be possible to continue working with the victorious analogue. The exception is the diamond crown. It handles iron as well as artificial stone.

History will win

The alloy called “Pobedit” was created in the USSR in 1929. Intended primarily for the manufacture of cutting tools. The main goal of the developers was to select the optimal composition and obtain a material of exceptional strength. A solution has been found. The alloy, new at that time, included the following metals:

- tungsten (90%);

- cobalt (10%).

They began to make soldering for drills from pobedit and use it for other purposes. New technology has made it possible to significantly simplify and make more efficient the processing of materials that are particularly durable.

Since its creation, the composition of the alloy has changed many times: a different ratio of tungsten and cobalt was used, additives were added, etc. Now you can find solutions that:

- have different proportions of components;

- cheaper;

- easier to manufacture;

- more durable;

- suitable for working with less hard materials (steel, aluminum, etc.).

Despite the fact that the compositions of such modern alloys differ markedly from the classical ones and from each other, they are still called Pobedit.

Design features and operation

Unlike some other drills, Pobedit drills do not require sharpening. They initially have the required tip structure (angles) for proper operation.

The cutting part is represented by two “shoulders” of approximately the same width. Where they intersect is the future center of the hole . If their widths are different:

- the diameter of the hole will determine the larger “shoulder”;

- as the craftsmen put it, the drill will “break” the hole: it will turn out larger than necessary;

- physical activity will increase;

- the intensity of the drill will increase;

- drills break more often.

If the tip becomes dull , it can be sharpened. In this case, you need to keep in mind:

- The angle depends on the hardness of the material to be processed. The stronger the surface, the smaller it is.

- Pobedit does not tolerate too much heat. At high values, the tip may crack or even separate from the drill. Therefore, you need to prevent overheating and cool it more often when sharpening. For example, plain water will do.

- If overheating does occur, do not cool it suddenly. Otherwise, cracks will appear. It is best to allow it to cool naturally, that is, on its own.

If the diameter of the product is small, then it will most likely fail earlier. This rule applies even to experienced craftsmen. Therefore, it is better to stock up on a certain supply of drills to save time and nerves. Some masters argue that sometimes “courage” is also important. The work spirit can also be lost after going to the store. The extra ones will still come in handy later.

Tool design

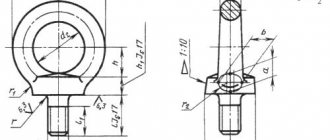

A pobedite drill consists of several elements:

- The working part is designed to remove stone chips and dust from the channels. It is equipped with spiral grooves, which contributes to more efficient removal of production waste. Unlike other similar equipment, such products do not have cutting edges.

- Pobedit head - made from a solid plate or equipped with several carbide tips.

- Shank - can be in the shape of a cone, cylinder or polyhedron. It serves to secure the drill in machine tools.

The Pobedit drill for a hammer drill has a slightly different design. Its distinctive feature is the shank configuration. It is not rigidly fixed in the cartridge, but implies free fastening. Thanks to this, the tail part can perform translational oscillatory movements.

The drill shank is equipped with two guide grooves. The function of one of them is to provide quick-release fixation. For more efficient operation, it is recommended to periodically treat this element with lubricant.

The carbide tip is fixed on the Pobedit drill using copper solder. Thanks to this feature, the connection's resistance to overheating is significantly increased. In addition, this design virtually eliminates the risk of chipping along the edges of the drilled hole.

Main types

There are many types of drills made from Pobedite. They differ in manufacturer, quality, and price. Depending on the shape of the shank, there are:

- hexagonal: regular or recessed for quick installation;

- cylindrical - chambered for a standard drill;

- SDS - can be fixed in most rotary hammers;

- triangular - they are held especially securely and do not rotate.

The diameters are also different. Values start from 3 mm. Pobedit drills are:

- for working with stone, brick, concrete;

- for gas and foam concrete;

- for ceramics, glass, tiles.

Drill bits for the hardest surfaces

Pobedit drills for stone, brick, and concrete are the most popular. Most of them can be used in shock mode. The sharpening angle is usually 130°. Some companies make the tip shape more complex:

- the angle is greater;

- the tip is centering.

If the hammer drill mode is selected, the tool crushes the surface like a chisel. The removed material is removed thanks to special grooves on the steel body of the drill. The usual number of these devices is from 2 to 4. They also have another purpose. The grooves prevent the drill from getting stuck while rotating.

Some manufacturers, on the contrary, prohibit the use of their products in shock mode. It depends on the characteristics of the alloy and the sharpening angle.

Typically, winning products in this category are considered disposable. At least that's what sellers do. However, craftsmen often sharpen them themselves and use them again. This requires an electric sharpener and a little practice.

Sometimes you need to get a large hole. If the diameter is from 65 to 120 mm, special crowns are used. Their design also includes a similar drill.

Drills for porous concrete

Today, building products made from porous concrete are very popular:

- foam concrete;

- aerated concrete;

- silicate

If a small hole is required, a regular metal drill bit may work. Its disadvantage is that it is short-lived. It is better to choose a standard victorious one. In this case, you don’t have to worry about the plaster.

If a hole of 30−120 mm is required , Pobedit drills with special brazing are used for the following materials:

- externally similar to feather drills for wood;

- shank - up to 450 mm, piercing through a standard block;

- the strength of the alloy is lower than for stone;

- for waste disposal there is a spiral of 1-1.5 turns;

- Any drill or hammer drill will do, the only condition is to use the non-impact mode.

Can be used for surfaces with external or internal finishing. The main thing is that there is plaster - without a reinforcing mesh of metal.

Drill bits for tiles, ceramics, glass

On sale you can find products designed for other types of material:

- glass;

- tiles;

- ceramics.

They are distinguished by the following features:

- the pobedit tip in such cases is made in the shape of a cone;

- the shank is round, sometimes in the form of a hexagon;

- used in shockless mode;

- diameter: 3−12 mm.

Sometimes the design of this type of drill is strengthened:

- pobedite plates - two;

- cutting edges - four;

This results in smoother edges and increased accuracy. It is usually recommended to use a rotation speed of about 400-800 rpm during operation. Products with a diameter of 10 mm are most often in demand.

There are other nuances when working:

- If you need a hole of 20-94 mm, “ballerinas” are used - circular drills. With their help you can change the diameter of the hole. Consist of two pobedit plates. Sometimes a mesh is included to protect against splinters.

- If small holes are required, then drills of this type are quite suitable for concrete. Moreover, there may be plaster on it.

Many manufacturers recommend using water cooling during operation. This will help:

- extend service life;

- increase efficiency.

What are drill bits with pobedit used for?

For proper use, you need to know exactly what the Pobedit drills are intended for. After all, if you use them to drill inappropriate material, you will not only not achieve your goal, but also destroy a very expensive tool.

The basic rule for using a drill with a winch is the fact that it can only process material that has less hardness.

The main area of application of such drills is the processing of concrete, brick, artificial and natural stone, marble, granite, and ceramic products. All these materials have high hardness and cannot be processed using conventional drills. Pobedit concrete drills are designed for installation on a hammer drill, and therefore work well in conditions of not only cutting, but also impact.

Concrete and stone are hard but fragile materials, so after work, a lot of stuck waste remains on the drill, which must be removed.

When drilling deep holes in durable material, it is advisable to cool the Pobedit concrete drill. If operated at high speed for a long period of time, the weld bead may be damaged or even separated from the drill body.

Periodic cooling can be done with ordinary water, but it should be taken into account that if the cooling is too rapid, the solder may burst.

The operating principle of a Pobedit drill is based on chipping the material being removed rather than cutting it. Therefore, it is not suitable for working with all types of materials. But special pobedit drills for metal are produced. They are similar in design to other Pobedit drills, but may differ in the sharpening angle of the cutting edge and have additional coating. When working with such a tool, intense heating occurs when metal rubs against metal, so Pobedit metal drills require very active cooling.

Selecting a Victory Drill

The stores now have a large selection of drills made from Pobedit. You can always choose something suitable for a specific case, given working conditions and material. They are sold individually or in sets.

Product prices may vary greatly. It depends:

- from the manufacturer, brand recognition;

- from the country of manufacture;

- from the seller.

As a rule, popular European brands are more expensive . They are usually worth it, as they are distinguished by:

- good quality, including sharpening;

- mandatory guarantee;

- The tips are difficult to distinguish against the general background, since the soldering is very neat.

There are mid-level products. The cheapest products include products from unknown companies. Their common disadvantages include:

- strength - low;

- do not always correspond to the stated characteristics.

Drills from Bosch

Bosch products are well known to everyone. The company also produces drills with pobedit tips. Their diameter ranges from 3 to 25 mm.

Blue Granite series products are designed for stone processing. They are distinguished by:

- reliability;

- quality;

- They drill concrete better than ordinary pobedit ones;

- U-shaped groove for good waste removal;

- used with impact drills.

You can also highlight:

- Silver Percussion - also for stone and concrete of special strength.

- Impact - for processing natural and artificial stone.

- Karat - designed for drilling any surface except concrete and artificial stone. The cutting part is sharpened in a special way and sharper, so the edges of holes in various materials are smooth.

- Black Quartz - for roof tiles and tiles. Can withstand heavy loads.

DeWalt drills

Among the manufacturers, DeWalt stands out . The products of the Extreme SDS-Plus series are especially famous. Its features include:

- diameters - from 4 to 16 mm;

- shank - round or hexagonal;

- the cutting part is serrated, even takes concrete with reinforcement;

- the groove is in the shape of a jug, it removes debris well;

- the tip is attached to the drill using a special technology; special solder with copper is used;

- due to the design, such products can better withstand overheating;

- the holes are very smooth.

When choosing pobedit drills from any manufacturer, it is better to give preference to those that are designed for a specific material. If the tool is used infrequently, you can get by with “wide-spectrum” products. In any case, it is important to feel the characteristics of each type in work and practice.

Design features of a drill with pobedit

A pobedite drill does not differ significantly in appearance from a standard twist drill. It also consists of a shank, a working part and a cutting edge and has a cylindrical shape. The shank can be cylindrical, hexagonal, or have an SDS profile if it needs to be installed in a hammer drill. The working part of the drill is made of tool steel and has a number of helical grooves on the surface designed to remove chips from the drilling zone. But the drill tip is made of hard alloy - pobeda.

Drills with a Pobedit tip do not require pre-sharpening immediately after purchase. They are ready for use, and their cutting profile angle is 130 degrees. The pobedite tip usually has a flat shape. Its width is identical to the diameter of the hole that needs to be made in the workpiece. This tip is fused to the working part of the tool. The tip of the drill is the center of the tip. The tip divides it strictly into two equal parts. If they are not equal, then such a tool will not work.