Main characteristics

The main characteristics that determine the properties of steels and their purpose include:

- percentage value of the chemical elements included in the composition (determined in accordance with GOST);

- physical and mechanical properties (permissible bending strength, hardness, density, thermal conductivity parameters, corrosion resistance, heat resistance);

- manufacturing technology (cast or sintered compositions).

The carbides used in production are not subject to dissolution and destruction at excessive temperatures. But they are fragile, therefore, to form the required level of hardness of the product, they are bonded with other metals.

Compound,%

si, MPa

Density r, g/cm3

HRA, not less than WC TiC Co Т30К4 66 30 4 980 9.5-9.8 92.0 Т15К6

79 15 6 1176 11.1-11.6 90.0 T14K8 78 14 8 1274 11.2-11.6 89.5 T5K10 85 6 9 1421 12.4-13.1 88.5Just like the VK alloys, the tensile strength in bending and compression, as well as the impact strength of the TK alloys increase with increasing cobalt content.

With increasing carbon content within the three-phase region, flexural strength increases, while hardness and wear resistance decrease.

The presence of structurally free carbon simultaneously leads to a decrease in strength, hardness and wear resistance during cutting. Presence in alloy h

-phase reduces the bending strength, but increases hardness and wear resistance when cutting.

For alloys with the same cobalt content and the same size of carbide phases, the flexural and compressive strength, impact strength, plastic deformation and elastic modulus decrease with increasing titanium carbide content.

In accordance with the above laws, the cutting properties of the alloys also change: an increase in the cobalt content leads to a decrease in the wear resistance of the alloys during cutting, and with an increase in the titanium carbide content (at a constant volumetric cobalt content), wear resistance increases, but at the same time the operational strength decreases. Therefore, grades of alloys such as T30K4 and T15K6, which have a maximum margin of plastic strength, are used in finishing and semi-finishing conditions of steel with high cutting speeds, low and moderate loads on the tool. Alloys T5K10, T5K12 with the highest cobalt content and a margin of brittle strength are designed to work under severe conditions of shock loads with reduced cutting speed.

Titanium tantalum tungsten hard alloys.

Industrial titanium-tantalum tungsten hard alloys (TTK alloys) consist of three main phases: (Ti, W, Ta)C solid solution, tungsten carbide and cobalt-based solid solution.

The introduction of tantalum carbide into alloys improves their physical, mechanical and operational properties, which is expressed in an increase in bending strength and hardness at room and elevated temperatures, and an increase in the work of deformation at elevated temperatures.

Tantalum carbide in alloys reduces creep, significantly increases the fatigue limit of three-phase alloys under cyclic loading, and also increases heat resistance and resistance to oxidation in air.

The standard (GOST 3882-74) contains five grades of alloys of this group - TT8K6, TT10K8-B, TT7K12, TT20K9 and T8K7, in which the tantalum carbide content ranges from 2 to 12% (Table 11.8).

A study of the cutting properties of TTK alloys showed that an increase in the tantalum carbide content in the alloy increases its wear resistance during cutting, especially due to a lower tendency to crater formation and destruction under the influence of thermal cyclic and fatigue loads.

Taking into account the noted properties, TTK alloys are recommended for heavy machining, cutting difficult-to-cut materials with significant thermomechanical loading of the tool, as well as intermittent cutting operations, especially milling, characterized by a variable cut section and cyclic thermomechanical loads on the cutting part of the tool.

The TT7K12 alloy has the greatest brittle strength among the alloys of the TTK group, which is recommended for processing steel under particularly unfavorable conditions (intermittent turning, planing, rough milling).

The use of tools made of TT7K12 alloy instead of high-speed tools allows you to increase the cutting speed by 1.5-2 times.

For milling operations, alloys TT20K9 (for processing steel) and TT8K7 (for processing cast iron) are recommended. For fine and semi-finish turning, boring and milling of gray and malleable cast iron, non-ferrous metals, continuous turning of high-strength, stainless steels, including heat-treated ones, as well as titanium alloys, the TT8K6 alloy is intended.

Rough, semi-rough turning and milling of high-alloy, stainless and heat-resistant steels and some alloys are successfully carried out with tools made from TT10K8-B alloy.

Table 11.8

Composition and characteristics of physical and mechanical properties of titanium tantalum tungsten grades of hard alloys for cutting (GOST 3882-74)

| Alloy grade | Composition/o | sAnd , MPa | Density r , g/cm3 | HRA, no less | |||

| W.C. | TiC | TaC | Co | ||||

| TT7K12 | 81 | 4 | 3 | 12 | 1666 | 13,0-13,8 | 87,0 |

| TT8K6 | 84 | 8 | 2 | 6 | 1323 | 12,8-13,3 | 90,5 |

| TT10K8-B | 82 | 3 | 7 | 8 | 1617 | 13,5-13,8 | 89,0 |

| TT20K9 | 67 | 9,4 | 14,1 | 9,5 | 1470 | 12,0-13,0 | 91,0 |

| T8K7 | 85 | 7,5 | 0,5 | 7 | 1519 | 12,8-13,1 | 90,5 |

The group of tantalum-containing alloys also includes the so-called MS alloys,

the production of which was mastered under a license purchased from (Sweden) (Table 11.9).

Alloys of grades MC101, MC111, MC121, MC131 and MC146 are intended for processing steel and steel castings in various conditions, alloys MC211, MC221 and MC241 are for cutting difficult-to-cut materials, and alloys of grades MC301, MC306, MC312, MC313 and MC321 are for processing cast iron and non-ferrous metals. MS137 and MS318 grade alloys are intended for milling steel and cast iron, respectively.

Studies of the cutting properties of MS alloys have shown their high reliability compared to standard alloys, which is associated with the increased stability of the physical and mechanical properties of MS alloys. Therefore, the higher cost (by 40-60%) of MS alloys compared to standard alloys is fully justified by the high stability of cutting properties and operational reliability of tools equipped with MS inserts.

Basic properties of alloys of the “MS” group (TU 48-19308-80)

| Alloy grade | Analogue alloy (GOST 3882-74) | Properties | |||

| sAnd , MPa | r , G/CM3 | Hardness, HV30 | Coercive force, kA/m | ||

| MS111 | T15K6 | 1150 | 10,22-10,38 | 1525-1675 | 8,7-11,9 |

| MS121 | T14K8 | 1200 | 11,6-11,79 | 1475-1625 | 7,2-9,5 |

| MS131 | T5K10 | 1400 | 11,35-11,51 | 1430-1570 | 8-10,4 |

| MS137 | T14K8 TT20K9 | 1400 1800 | 11,68-11,84 | 1485-1635 | 13,5-15,2 10,2-15,2 |

| MS146 | TT7K12 | 1500 | 13,04-13,2 | 1320-1460 | 15,9-23,6 |

| MS211 | VK6M-TT10K8B | 1400 | 14,7-14,86 | 1590-1680 | 10,3-13,3 |

| MS241 | VK8 | 2000 | 13,81-13,97 | 1530-1630 | 9,4-11,2 |

| MS301 | VKZM | 1150 | 14,15-14,25 | 1175-1295 | 20,6-23,6 |

| MS306 | VK60M | 1150 | 14,95-15,11 | 1760-1940 | 19,8-23,2 |

| MS312 | VK6M, | 12,79-12,95 | 1700-1940 | 15,9-23,2 | |

| MS318 | VK6,T8K7 | 1500 | 12,8-12,96 | 1575-1725 | 15,2-20,6 |

| MS321 | VK6 | 1350 | 14.64-14,86 | 1450-1600 | 13,4-15,2 |

| MS313 | VK6M | 1300 | 14,74-14,94 | 1505-1655 | 13,4-17,3 |

Tungsten-free hard alloys (TBHS).

Due to the high scarcity of the main components of the hard alloy, and primarily W and Co, extensive research has been launched in the CIS countries to develop economically alloyed tungsten-free hard alloys.

A promising direction in the development of tungsten-free hard alloys (TBF) turned out to be the creation of alloys based on titanium carbonitride and carbide with a nickel-molybdenum binder.

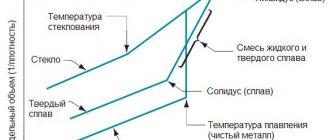

The alloys are distinguished by high hardness, scale resistance, have a low coefficient of friction on steel and a reduced tendency to adhesive interaction with the material being processed, which reduces tool wear on the rake surface when processing steel and makes it possible to obtain low roughness of the machined surface and high dimensional accuracy when processing steel. At the same time, tungsten-free alloys have a lower elastic modulus, and therefore resistance to elastic and plastic deformations, than tungsten-containing alloys, lower thermal conductivity and impact strength, so they are less resistant to impact and thermal loads, and also have lower heat resistance, i.e. intensively soften at lower temperatures than alloys of the TK type.

These properties also determined the areas of rational use of alloys when processing materials by cutting: mainly finishing and semi-finishing when turning and milling carbon and alloy steels with high cutting speeds and a relatively small cut section instead of titanium-tungsten alloys.

It is effective to use tungsten-free alloys in the form of replaceable multifaceted plates, since during soldering and sharpening, due to low thermal conductivity, internal stresses may appear and, as a consequence, cracks on the plates, as well as a decrease in their operational durability.

Table 11.10

Composition and main properties of industrial grades of BVTS

| Alloy grade | Content of main components in% (by weight) | Physical and mechanical properties of alloys | |||||

| TiС | TiCN | Ni | Mo | r , g/cm3 | sAnd , MPa | HRA, no less | |

| TN20 KNT16 | 79 — | — 74 | 15,0 19,5 | 6,0 6,5 | 5,5-6,0 5,5-6,0 | 1050 1200 | 90,0 89,0 |

The country's industry produces two standard grades of tungsten-free alloys in accordance with GOST 26530-85 (Table 11.10). Taking into account the relatively low values of heat resistance and plastic strength of BVTS, research work has been carried out to improve their properties by strengthening the binder or carbonitride phase. The result of such developments was the emergence of new grades of BVTS with improved properties in terms of brittle and plastic strength.

An example of improving BVTS can be the LTSK20 alloys, the carbon-nitride phase of which is alloyed with zirconium, the TV4, TsTU and NTN30 alloys, the binders of which have noticeably higher strength and heat resistance due to alloying, respectively, with tungsten carbide, tungsten and titanium and niobium carbides. A new group of alloys of this type has increased operational reliability and an expanded scope of application. In particular, alloys TV4, NTN30 are recommended for roughing steel during milling and turning (areas of application P20-P30).

The composition and some properties of high-strength BVTS are shown in Table. 11.11.

Table 11.11

Classification

- By composition

- Tungsten-cobalt (VK) – brands VK3M, VK3, VK8, VK6M, etc. Within the group, brands differ in different percentages of cobalt, type of production, and grain size of tungsten carbide (fine-grained and coarse-grained structure). Grades with a cobalt percentage of up to 12% are suitable for cutting tools. As the percentage of cobalt increases, the stability of the composition during cutting decreases, but its operational strength increases. Tools made from steels of this group are used to work with cast iron, structural steels, and brittle materials during impact processing, intermittent technological cycles, during which the temperature in the cutting zone does not rise to significant levels.

- Titanium-tungsten-cobalt (TK) – grades T14K8, T5K10, etc. The chemical composition of this type of hard alloy includes the following components: titanium carbide, tungsten and cobalt as a connecting link. If we compare these alloys with the VK grades, we can note that they have high levels of hardness and heat resistance, resistance to oxidation, but they are less elastic, and the electrical and thermal conductivity of the materials is lower. Designed for working with metals that are operated at more intense cutting speeds.

- Titanium-tantalum-tungsten-cobalt (TTK) - TT8K6, TT7K12, TT10K8B, etc. The addition of tantalum to the structure significantly improves the performance capabilities of the resulting alloys, increasing their resistance to high temperature influences and increasing strength. They are used for cutting difficult-to-cut materials when the tool is subjected to severe stress during operation.

- Tungsten-free (BVTS) - KNT16, TN20, etc. They are manufactured without the use of tungsten and cobalt, based on titanium compounds, with the addition of nickel and molybdenum as binding elements. In terms of hardness, these compositions are similar to brands of the tungsten group; they almost do not oxidize, and in terms of elasticity and strength they are inferior to them. Suitable for equipment that operates in intermittent cutting.

- According to production technology

- Cast steels are manufactured using classical casting technology, followed by mechanical and heat treatment.

- Sintered compositions (one-carbide, two-carbide, three-carbide) are produced using powder metallurgy methods, with further grinding, laser, ultrasonic, and chemical treatment.

- Instrumental - used for cutting, stamping, pressure, drilling of processed materials.

- Structural – used for the production of parts that have high requirements for wear resistance and resistance to heavy loads.

- Heat-resistant and heat-resistant - suitable for instruments exposed to temperature influences during operation.

- Group P – for materials that form drain chips.

- Group K – for cutting cast iron, non-ferrous metals, hard materials that form elemental and fracture chips.

- Group M – for processing stainless steel, heat-resistant and titanium materials that form drain and fracture chips.

§3. Tungsten wire

Production

Tungsten wire is one of the most common types of products made from this refractory metal. The starting material for its manufacture is forged tungsten rods with a diameter of 2.75 mm.

Wire drawing is carried out at a temperature of 1000 °C at the beginning of the process and 400-600 °C at the end. In this case, not only the wire, but also the die is heated. Heating is carried out by a gas burner flame or an electric heater.

Drawing of wire with a diameter of up to 1.26 mm is carried out on a straight chain drawing mill, within a diameter of 1.25-0.5 mm - on a block mill with a coil diameter of ~1000 mm, with a diameter of 0.5-0.25 - on single drawing machines .

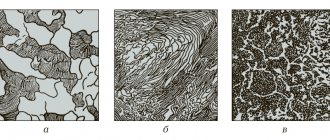

As a result of forging and drawing, the structure of the workpiece turns into a fibrous one, which consists of crystal fragments elongated along the processing axis. This structure leads to a sharp increase in the strength of tungsten wire.

After drawing, the tungsten wire is coated with graphite lubricant. The surface of the wire must be cleaned. Cleaning is carried out using annealing, chemical or electrolytic etching, and electrolytic polishing. Polishing can increase the mechanical strength of tungsten wire by 20-25%.

Application

Tungsten wire is used for the manufacture of resistance elements in heating furnaces operating in an atmosphere of hydrogen, neutral gas or vacuum at temperatures up to 3000 °C.

Tungsten wire is also used for the production of thermocouples. For this purpose, tungsten-rhenium alloy with 5% rhenium and tungsten-rhenium alloy with 20% rhenium ( BP 5/20 ) are used.

In GOST 18903-73 “Tungsten wire. Assortment” indicates the areas of application of wire grades VA, VM, VRN, VT-7, VT-10, VT-15. Tungsten wire VA, depending on the group, surface and metal condition, diameter, is used for the manufacture of spirals of incandescent lamps and other light sources, spiral cathodes and heaters of electronic devices, springs of semiconductor devices, loop heaters, non-spiral cathodes, grids, springs of electronic devices. VRN brand wire is used to produce bushings, traverses and other parts of devices that do not require the use of tungsten with special additives.

Areas of application of hard alloys

Hard metal alloys are actively used in the production of equipment and tools for finishing difficult-to-process materials, parts of machine tools and machines subject to intense loads.

Main areas of use:

- production of tools for metal cutting: milling cutters, broaches, drills, cutters;

- equipment for mining and logging equipment: drills, working surfaces of equipment, devices for cutting;

- production of durable bearings: cages, balls, rollers, spraying on housings;

- tools and machine parts for drawing, stamping, calibrating, rolling, pressing, branding: equipment for the working surface, dies and dies, etc.;

- equipping measuring equipment: tool parts, working surfaces;

- surface spraying on parts made of other materials to give them better wear resistance, heat resistance, hardness, and anti-corrosion properties;

- production of elements for household and industrial devices: resistors, rheostats, electric heaters, parts for laboratory and industrial furnaces.

Hard alloy products

The main type of product offered by manufacturers and metalworking companies is cutting tools. Drills, cutters, plates, rods are the most popular products in the carbide metal segment. Equipping production with tools and equipment made of high-hard alloys significantly increases the productivity and efficiency of technological processes and allows the use of modern metal processing technologies. This has a positive effect on the quality and speed of metal products produced.