What is a sewer air valve, how does it work and what is it needed for?

The unpleasant smell of sewerage is not just an irritating factor, it is much more dangerous than is commonly believed.

Sewage gas is harmful to human health, flammable, and in some cases can even explode. The problem is serious, so to solve it, ventilation of the entire drainage system is used. To implement it, various devices are used, but most of them are intended for outdoor installation. The only element that is used indoors is the air valve for the sewer, which should be discussed in more detail.

Application of ventilation valves

In the construction industry, situations often arise when it is simply not possible to vent the riser to the roof. Without this, the operation of the system is impossible, and something needs to be done in this situation, because a system in which water hammers constantly occur and odors enter living quarters cannot be considered high-quality and reliable.

In such cases, a sewer ventilation valve comes to the rescue, which is installed on the top of the riser. Ventilation valves owe their invention to the inhabitants of Scandinavian countries.

In constant frost conditions, the outlet channels of the risers froze, and there was no contact with the atmosphere. The result was disastrous: the entire building was literally saturated with unpleasant odors, and the lack of air in the system during rarefaction was not compensated for by anything.

Ventilation valves for sewerage can solve such problems without any problems. A typical valve is designed with a movable diaphragm that can control the pressure in the pipeline. These devices allow you to forget about the need to bring the riser to the roof. Not only can the riser be led into the attic using valves, but it can even be placed in separate rooms where plumbing is installed (read: “Ventilation of the sewer riser, design rules”).

Where and how to properly install a vacuum valve on the sewer?

Let me break this question into two parts.

Where The device is installed at any point in the upper part of the sewer system as close as possible to the riser. It is desirable that the distance from the riser to the vacuum valve be less than the distance from the riser to any device with a water seal.

Note! This requirement is not always necessary. The valve shutter operating threshold is normally much lower than the water shutter threshold.

In addition, the valve can be installed on a long horizontal sewer branch near the outermost plumbing fixture.

Most often, a vacuum sewer valve is installed directly on the riser, in the socket of the upper outlet of the tee or cross behind the toilet.

The only requirement is to ensure complete tightness of the connection between the valve and the socket and all other connections of the comb (internal sewage system of the apartment) with plumbing fixtures. Let me make this recommendation a little more specific:

- The valve is inserted into the socket of a plastic pipe (PVC, polypropylene) without additional equipment. Tightness is ensured by the standard o-ring seal of the socket. In order to simplify installation, it can be lubricated with liquid soap;

- For a cast iron pipe you will have to purchase a rubber cuff - an adapter.

When using it, the installation instructions are a little more complicated:

Connections of plumbing fittings (elbows and corrugated siphons of washbasins, sinks and bathtubs) are made with mandatory sealing with rubber cuffs.

Principles of sewer system ventilation

The riser output channel is vital for the system so that all devices connected to it work properly.

It is much easier to explain the need for a good ventilation system if we consider the basic principles of its operation:

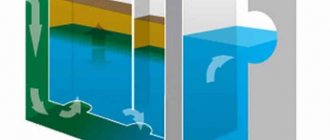

- Discharged water from plumbing fixtures enters the riser.

- Once in the riser, the water begins to draw in air, creating a vacuum or negative pressure difference. This is especially important when draining large volumes of water, since in this case there will not be enough air in the system to stabilize the pressure. The magnitude of the rarefaction will be so great that its value can safely be called critical.

- The appearance of negative pressure causes water to enter the pipe from the weakest water seal. This process is called breaking the water seal, because in order to equalize the pressures, air must appear in the system - but there is nowhere for it to come from. The only place is the sink, since the resistance in these areas is always less. As a result, air is drawn into the system from the siphon, thereby destroying the water barrier.

- Then everything is clear: the water sucked out of the siphon valve allows sewer odors to enter the living space. Of course, they take this opportunity and enter the house, thereby disturbing the peace of the residents. Given the fact that some sewer gases can be toxic or explosive, it becomes clear that their occurrence must be avoided.

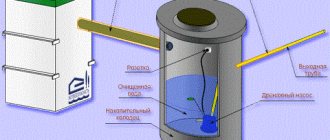

Ventilation valve device for sewerage

The design of the ventilation valves assumes the presence of a side window equipped with a mesh that prevents small insects from getting inside. The thermally insulated housing contains the main working element of the device - the diaphragm. In addition, the device may include a gasket cuff and an adapter, which allows the valve to be mounted on a riser of any diameter (or a limited range of diameters). The cuff makes it possible to increase the tightness of the device.

To make a ventilation valve for sewerage, a certain amount of synthetic materials is required. There is a membrane on the inside of the housing that does not react in any way to positive or neutral pressure.

The operation of the valve begins at the moment when negative pressure arises in the system: the vacuum acts on the membrane, opening it, and air enters the system. When the pressure on both sides of the valve is equal, the diaphragm closes itself.

As long as the pressure in the system is stable, the diaphragm is in the closed position and prevents odors from entering the room. That is, the valve not only equalizes pressure in critical cases, but also monitors its changes in the background. The sewer vent valve also plays a certain role in matters of pipeline clogging. If the system is clogged, then after draining the air leaves the riser, which creates positive pressure. Naturally, the membrane remains closed, so air begins to escape through the sink, pushing water and dirt out. After the system has stabilized, the water will go back into the siphon and the water seal will be restored, but the dirt from the sink will not go away, and this is a direct confirmation that it is time to clean the pipeline.

Operating principle

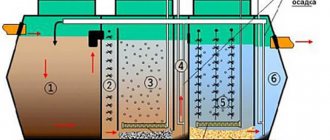

Let's look at the operating principle of the most common design. An example would be a 110 mm vacuum sewer valve, one of the most popular models. Such devices are installed on sewer pipelines with a diameter of 110 mm. There are other sizes, for example, for a 160 mm pipe, or a device for horizontal lines with a diameter of 50 mm. All products of the same model range operate according to the same scheme, so there is no fundamental difference in their design.

The operation of the device is based on the principle of operation of a reverse-action vacuum valve. When negative pressure occurs, the lid is forced to open and let in outside air. The peculiarity is the direction of influence - the tube has a chamber of a specific shape that communicates with the internal cavity of the sewer pipes. An area of reduced pressure interacts with the top of the lid, lifting it and letting outside air in. When the pressure normalizes, the lid is lowered under its own weight and placed in its original place. The operation speed of the mechanism is high, so it is impossible for gases from the sewer to enter the apartment or house.

Application

An air valve for sewage 110 mm (or another size) is used in the following cases:

- when there is no drain pipe in the sewerage system and the system is not ventilated;

- if it is not possible to bring the vent pipe to the outside of the roof;

- in apartments of multi-storey buildings, where pressure drops often occur when large quantities of water pass through a long vertical pipeline.

There are other valve designs, but they are typically used in large industrial or public service applications.

Design and principle of operation of the air valve

Terms of use

There are basic rules, the implementation of which will enable the valve to perform all the functions assigned to it:

- The air valve must be tight even at low pressures. If the building contains no more than 4 residential premises or 3 floors, then an additional valve is not needed. Of course, in order to remove the rated volume of drainage, the riser pipe must be thicker than the thickest horizontal pipe so that there is enough air in the system to compensate for the vacuum.

- In order for the ventilation valve to work properly, its performance must be higher than the established standards. Valves are used in cases where there is no riser outlet to the roof, so they must be as powerful as possible in order to maintain the required pressure in the system at all times. Typically, air drain valves allow about 32-47 liters of air per second to flow when the negative pressure reaches 250 Pa. Of course, the more valve power exceeds design, the better for the entire system.

- The operating conditions in multi-storey buildings are quite difficult, and in this case the valve performance must be even higher. The same is said in all construction regulations. If we reduce this information to one rule, it turns out that the valve capacity must be at least five times greater than that of the riser. In addition, when installing ventilation in the toilet of a private house, the height of which is more than four floors, special rules for creating a ventilation system are used.

- The use of ventilation valves is determined by a large number of regulations. For example, in design modeling, the capacity of air valves is a parameter that must be included in the calculations. The valve parameters are directly related to the volumes of wastewater that the sewer system will have to process: the larger they are, the greater the power the device should have.

Design and principle of operation

Before you go to the store to make a purchase, you need to understand how the mechanism works and become familiar with the design.

There is nothing complicated in the design of a vacuum valve.

Do you know how to choose and buy a fecal pump for a cesspool? This useful article contains advice from simple plumbers. Find out what to look for when inspecting the device.

Read everything you need to know before buying cross-linked polyethylene pipes for heating here.

On the page: it is written how you can make a tabletop fountain with lighting and fog with your own hands.

The unit is very simple and consists of the following elements:

- Fixture frame.

- A small special opening that is designed to allow air to enter the body of the mechanism.

- Rod . This component responds to the pressure difference that occurs inside the sewer system.

- Gasket made of especially durable rubber . With its help, smooth movement of the rod is ensured, and it also limits the movement of the rod.

- Cap designed to protect the elements located inside the valve from dirt and dust.

Air Valve Installation

The ventilation valve for sewerage can be installed:

- horizontally;

- vertical;

- under a roof or indoors.

A lot depends on the design of the unit and the chosen installation method. As a rule, the list of recommendations for installing a damper in the attic includes insulating the room. The valve is not insulated, the main thing is that the cold does not enter the room where it is installed, and then proper insulation will be created by the space between the roof and the device itself.

To protect the membrane from external factors such as dirt and moisture, the valve must be mounted at least 30 cm above the topmost pipe to which the plumbing is connected. The distance to the nearest siphon should not be less than 20 cm. All this allows you to protect the air valve for unventilated sewer risers from breaking the tightness, since the problems arising from this can be extremely unpleasant.

When installing a valve in a bathroom or toilet, you should use the following recommendation and provide the room with the maximum amount of air.

Experts advise carefully monitoring this point, since water has the unpleasant property of capturing a volume of air that is 25 times greater than the volume of water itself. You can look at the design of the air valve in more detail in the photo, and then most of the questions will disappear by themselves, since the visual image allows you to immediately understand how this device works.

Conclusion

A properly installed ventilation valve on a sewer improves its operation and prevents various gases from entering living spaces, thereby disturbing comfortable living conditions. Experts agree that a ventilation valve makes it possible to solve the problem of ventilation of the sewer system in the simplest way. In addition, this device is the optimal solution for ventilation of houses with no more than three floors, but it can also be used in large houses: it is enough to connect several risers that have a common ventilation outlet and mount a sewer ventilation valve on it.

Installation

The installation method depends on the design and type of valve. There are two common options:

- installation of a vertical (common) riser into the gap.

- separate installation for each device - sink, bathtub, toilet, etc.

In the first case, a 110 mm sewer valve is usually used, corresponding to the standard size of a plastic riser. It is inserted into the riser assembly in the same way as any elbow or tee.

The second option requires installing an outlet with an inlet pipe where the device is connected.

There are some general rules that must be followed during installation work:

- the installation point of the device must be in a heated room;

- it is necessary to organize access to the device for inspection, replacement or repair;

- the height of the valve should not exceed the highest drain point;

- installation into the socket must be carried out only with an o-ring.

Knowing these little tricks, you can do the installation work yourself.

Overview of the air valve - how it works and what it is needed for