Owners of suburban areas with high groundwater levels usually experience difficulties with the arrangement of autonomous sewerage and drains. In wetlands, cesspools quickly fill with sewage, and the cost of sewerage maintenance becomes quite high. But it is possible to install an effective septic tank at a high groundwater level if the owner of the site is ready to increase the volume of construction and incur additional costs for the purchase of a ready-made installation. The investment of additional funds will subsequently pay off in the impeccable operation of the sewerage system and the absence of problems with its maintenance.

How does a high water level affect the operation of a septic tank?

Ignoring the fact of high groundwater causes the following:

- partial flooding of the septic tank, which leads to frequent calls to the sewer truck and results in additional costs;

- complete flooding, which is fraught with the release of contaminated wastewater into the environment;

- waterlogging of the soil around the storage tank, the appearance of a persistent unpleasant odor, the danger of the spread of infections;

- the rise of the septic tank when the water supply system rises, accompanied by damage to sewer pipes, depressurization of the system and leaks.

A flooded or floating septic tank requires complete reconstruction or replacement with a more efficient and reliable design. Alterations involve considerable material and labor costs, so when there is close water, you need to be especially careful when designing and installing treatment facilities.

The area is clayey, the groundwater level is low (water is below 4 m or there is none)

Clay soils are typical for the central zone. Where there is clay, groundwater and perched water are often found. However, hilly terrain may have clayey areas and low groundwater levels. Despite the low drainage capacity of clay, any volumes of pre-treated wastewater can be discharged into the ground.

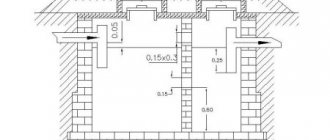

Scheme 1. 3-chamber septic tank and underground filtration field

Description:

- Classic scheme with increased well volume.

- Suitable for any soil with low groundwater level.

- Requires more than 40 m² for the construction of underground drainage fields.

- A 2-level drainage field protects the system from volley discharge of wastewater.

- Pumping out from the first chamber no more than once a year.

In the video below, the author describes in detail the design of the treatment plant, explains the purpose of each of its components: settling tanks, distribution and inspection wells, ventilation, etc. You will learn about recommended tank sizes, the approach to primary settling and treatment in an underground filtration field.

Conclusion:

this simple scheme is applicable in most cases. The exception is high groundwater level. It is easy to maintain and has convenient access to any point in the system. However, you need to be prepared for extensive excavation work, which is needed not so much for installing a septic tank, but for drainage.

When to determine the height of the groundwater level

The level of groundwater lying at a depth of up to 2 m from the surface of the earth is considered high. It may not be constant and may change depending on the season.

Groundwater level is determined during the period of greatest fluid influx into aquifers. This is the time of spring floods and autumn lingering rains.

The level can fluctuate quite significantly. An additional contribution is made by perched water, which is formed due to precipitation and melted snow seeping into the soil, as well as surface water. To protect yourself from them, it is enough to raise the structure above ground level and make a blind area around the perimeter.

If you use sewerage only in the summer, for example, during a summer holiday, then you don’t need to look for the highest water level. It is enough to know where it is located at the very beginning of your stay in the house.

Sand and gravel filters

Filters can include certain elements. Unlike the previous type, filters can be used to serve several cottages at the same time.

In order for the filter to be installed correctly, you need to perform a whole series of works: slag, gravel or, for example, slag is laid out at the very bottom of the pit, the material should have a particle size of about thirty mm, but not less than fifteen mm, the height should be one hundred mm. A drainage network needs to be laid along it, which in turn consists of a central pipe. This includes the collector, and from it the openings of the drainage pipes. Asbestos-cement pipes must be provided with cuts on the side, their depth is twenty mm and width five mm, this must be done at a distance of one hundred mm. The holes, together with the cuts, must also be arranged in a checkerboard pattern.

1 - supply pipeline; 2 - distribution pipeline; 3 - irrigation pipes; 4 - ventilation riser; 5 — drainage pipes; 6 - collection pipeline; 7 - outlet pipeline; 8 — irrigation zone (crushed stone); 9 - drainage zone (crushed stone); 10 - crushed stone base; 11 — ventilation riser; 12 — ventilation riser of the drainage system; 13 — waterproofing (roofing felt); 14 - clay castle; 15 — insulating coating

Fill the drainage network with some material, for example, slag, its size is fifteen to thirty mm, and its height above the top of the pipes is one hundred mm. Then you need to make a layer of the same material again, but only with a size of ten mm and a height of one hundred mm.

The finished filter well is covered with one layer of sand on top; its size should not exceed even two mm.

After the filter layer of the biological treatment station has been laid out, proceed to laying out a layer of gravel, crushed stone, or, for example, slag of fifteen to thirty mm.

The required length for irrigation pipes must be determined based on the load per meter of pipe, approximately one hundred liters per day. The length of the drainage pipe can be determined in exactly the same way. At the very end of the drainage network collector, as well as at the very beginning, you need to install special ventilation risers, their diameter is one hundred mm, and their height is seven hundred mm, all this is measured based on the distance above the ground.

There must be a certain distance from groundwater to the tray; experts say that the minimum value is one meter. If the groundwater is located at too high a level, the filter can be installed in the bedding.

Please note at what distance your installation is located from residential buildings, it is approximately 8 meters; this data must be clarified with a specialist.

How to find the height of the groundwater level

The estimated groundwater level is determined from nearby wells or boreholes. Information can be obtained from neighbors living nearby. The best and most reliable way is to excavate an exploration pit or drill a test well.

To search for ground water using the last method, take a garden drill and make a hole 2-3 m deep. You can line the hole with a sewer pipe so that the walls do not crumble. Based on the established level, it will be clear where the groundwater is located at the moment.

It happens that liquid appears after 0.5-1 m of drilling. This phenomenon is often observed in areas adjacent to reservoirs or near the outlet of interstratal waters. If after a few weeks the level has not dropped, it means that your site is located in a zone of high groundwater level.

Where to install a septic tank

When choosing a location for treatment facilities, pay attention to the installation rules:

- You must retreat at least 15 m from the water well. Moreover, this condition must also be met for the neighboring water intake structure.

- According to the standards, the safe distance to the foundation of the house is 5 m. The maximum gap is not regulated. The main thing is that when connecting the pipe, there remains sufficient usable volume in the septic tank. For the same reason, it is not recommended to bury the pipe leaving the house by more than 0.5 m.

- The septic tank should be located near “wet” rooms, such as the kitchen, bath, toilet, so that the wastewater passes through the shortest possible path.

- It is necessary to leave access to septic tanks and sedimentation tanks for the sewer truck. The length of its hose, as a rule, does not exceed 5 m, but there are models with a hose 15-25 m long. If sediment is removed from the storage chamber with a drainage pump, regular cleaning can be done with your own hands.

- Perhaps in the future there will be additional buildings that require sewerage - a guest house, a bathhouse. Provide a convenient connection option.

- If the septic tank is located next to the entrance or recreation area, the visual component is important. It is advisable to install equipment where it will not spoil the appearance of the site or choose models with a decorative overhead part.

If groundwater is high, it is not recommended to install a septic tank at the lowest point of the terrain, where there is a high risk that the structure will be constantly flooded.

Details

Facilities. Review

For initial use, certain products should be used. These include:

1. Bioforce Septic Shock, which is sold in one liter bottles. Contains enzymes and aerobic bacteria. For a one-cube septic tank, one bottle is used. If the volume of the septic tank is larger, you will have to buy several bottles of the product. One container costs about 900 rudders.

2. Doctor Robik 509 in the form of a liter container. The drug is used to effectively clean the septic tank. First, you need to pump out the old drains and add the product, calculating that one bottle is needed for a septic tank volume of 2 thousand liters. A bottle costs approximately 630 rubles.

To support the fermentation processes, and also for post-cleaning of pits, special preparations are used. These include:

1.Doctor Robik marking 309 is used all year round. The product has the form of a liquid and is sold in a 1 liter bottle. One bottle is used for a septic tank of 2 thousand liters. The product must be injected into the inspection hole. A bottle of the product costs approximately 750 rubles.

2.Doctor Robik marking 409 is used to clean the cesspool all year round. It is better to pour the product into the hole in spring or summer. A bottle of 409 is enough for a septic tank of 2 thousand liters. The product costs 630 rubles. for one bottle.

Solutions for silting a septic tank with a bottom

The bottom part of the septic tank can become silted in septic tanks manufactured at the factory. Such septic tanks have a bottom. The reason for this phenomenon is a small number of bacteria in the container.

Attention! Microorganisms can be killed by alkali, acids or bleach contained in cleaning solutions.

When the septic tank silts up, and if the water in the first compartment of the septic tank looks like sour cream, then a large dose of the bioactivator Doctor Robik marking 509 or Bioforce Septic Shock will help. At the same time, it is necessary to reduce the volume of consumption of chemicals for washing dishes, toilets, laundry, etc.

How to get rid of grease and soap

Fats and soap scum that fall into bottomed sumps cause septic tanks to overflow. Plaques do not allow wastewater to move quickly through the system, causing plugs to form.

Attention! Grease traps will help combat the formation of fat plugs.

Grease and soap plugs can be removed using two methods:

-mechanical,

-chemical.

The chemical method is more effective compared to the first. It is easy to put into practice. You need to pour a special preparation into the sink or toilet. This process should be repeated until the sewer capacity is restored.

To remove soap scum and fat deposits, special preparations should be used. These include:

1.ROETECH K-87 is an effective culture that can cope with paper splitting, soap, and grease. One bottle is enough for a 1 cubic meter septic tank. The product costs 800 rubles.

2.BIOFORCE DRAINAGE COMFORT is a highly effective product, available in sachets that must be dissolved in a 10-liter bucket. One bag is enough to clean 50 meters of sewer pipeline from fat and soap deposits. One package contains ten sachets. The drug costs 2 thousand 770 rubles.

3.Doctor Robik marking 809 is a special product for dissolving soap deposits. Cleans overflow pipes well, the first compartment of the septic tank. One bottle is enough to clean a two cubic meter septic tank of stones and soap deposits. The product is poured into the toilet or introduced through the inspection hatch. The bottle costs 630 rubles.

Attention! When the grease traps are cleaned for the first time, this drug must be administered every year, but there is no longer any need to pump out the container.

How to make a drain for treated wastewater

If the septic tank overflows with water from a large number of residents, then it is necessary to build a well for drainage or a filtration field. If the septic tank does not have sufficient power, the problem will not be solved. If the daily water discharge exceeds more than 1/3 of the total capacity of the tank, it means that it is necessary to build a well or construct a drainage field.

Attention! In this situation, you can dismantle the septic tank and install a new structure of the required size.

Recommended types of septic tanks for high groundwater levels

When underground waters are close, in addition to the lateral pressure of the soil, the tank is affected by the backwater of water, and in winter also by the forces of frost heaving. Therefore, the walls of the structure must be strong and airtight. This can be provided by both factory models and construction-ready septic tanks.

Factory drive

The simplest and most cost-effective option for installing an autonomous sewer system in a country house or house for non-permanent residence is a storage septic tank. It is like a sealed cesspool or drainage pit. Wastewater flows through the supply pipe directly into the tank, from where, after filling, it is pumped out by a sewer truck.

Factory drives are made primarily of plastic. At high groundwater levels, polypropylene or fiberglass septic tanks are preferable, since products made of low-density polyethylene are not rigid enough and can fail due to frosty soil movements.

The containers are installed in the pit manually or using a lifting mechanism. The layout is preferable to a horizontal one, in which there is no need to dig a deep pit. This creates a lower groundwater pressure both during installation and operation.

In addition to ease of manufacture and installation, factory drives have the following advantages:

- complete tightness, no leaks;

- suitable for areas even with very high groundwater level;

- does not depend on power supply;

- meets the requirements of sanitary standards;

- affordable price.

Containers can be used not only temporarily, but also permanently. Free access for sewage disposal must be provided.

Made from reinforced concrete rings

Septic tanks made of reinforced concrete rings are very popular. To assemble the structure, products with a diameter of 1-2 meters and a height of 90 cm are used. Each element is installed on the previous one and secured with brackets. The seams are carefully sealed with waterproofing materials.

Concrete septic tanks can operate in 2 modes:

- gravity;

- with drain pump.

Since concrete is a permeable material, it is recommended to install a prefabricated septic tank when the groundwater level is no higher than 130 cm. In this case, it will operate normally.

The storage tanks are installed in series in the amount of 2-3 pieces and connected by overflow pipes. In the first chamber, sedimentation of solid particles occurs, in the second and third, biological breakdown by bacteria of various types.

Due to the insufficient degree of purification, clarified wastewater cannot be discharged onto the terrain. Further processing is carried out by filter fields, trenches, wells or infiltrators.

Advantages of septic tanks made of concrete rings:

- high strength, allowing to withstand lateral soil pressure and frost heaving without any deformation;

- no or very low power consumption;

- long service life.

Deep biological treatment station

A more technologically advanced method of wastewater clarification is SGBO, in which water is purified up to 98%. For areas with high groundwater level with permanent family residence, this is a convenient option that eliminates the labor-intensive installation of filtration fields.

The station is a multi-chamber (3 to 5) container with compartments designed for a specific type of cleaning:

- mechanical clarification zone, where solid particles precipitate, grease and films are retained;

- anaerobic fermentation chamber, in which biological processes take place without access to oxygen;

- zone of aerobic oxidation in the presence of oxygen and bioenzymes.

Biotreatment stations are equipped with drainage pumps, compressors, valves, airlifts and other devices that consume energy. The water obtained after purification can be used for technical purposes. The equipment is operated for a long time without pumping, maintenance is required once every 3 years.

Instructions for selection and installation of VOCs

Its production and maintenance will cost less in comparison with factory analogues: a 3-section septic tank with a volume of 6 cubic meters with delivery of rings costs up to 40 thousand rubles, while its plastic counterpart costs from 80 thousand rubles without taking into account the delivery of the container and its installation.

In this article we will look at 5 typical designs for septic tanks made of reinforced concrete rings, which have proven themselves to be functional and durable.

Purpose of the article:

introduce the reader to the 5 main options for constructing wastewater treatment plants made of concrete rings. Describe in detail the schemes and technological solutions used.

Filtration facilities at high groundwater level

Recessed filter fields and trenches, when water is located close to each other, serve more as a receiver of seasonal precipitation than for soil purification. In order for the septic tank to function fully, special raised structures are used to prevent untreated wastewater from coming into contact with the ground and contaminating the soil.

Prefabricated filter well

If the level rise is not observed often and for a period of time from 4 to 7 weeks, a completely workable option is to install a filter well from reinforced concrete rings. It should be located no closer than 2 m from the septic tank, and pump liquid from the last chamber using a drainage pump.

At high groundwater levels, the drainage well is installed at ground level. A cushion of gravel and crushed stone materials 20-40 cm high is placed under the structure, depending on the type of soil: thinner for sandy soil, thicker for clayey soil. Holes are made in the side surfaces through which liquid will penetrate into the filter layer.

The well is sprinkled with crushed stone, geotextiles are laid, and a layer of soil is placed on top. It is imperative to install a supply ventilation riser.

Infiltrators or drainage tunnels

Outwardly, they resemble inverted trays made of thick plastic, inside of which drainage materials are placed - crushed stone, gravel, sand.

Wastewater is supplied from the septic tank through the inlet pipe by a drainage pump. After passing through the filter layer, they seep into the ground.

For tunnel construction:

- Prepare a pit with a crushed stone-gravel cushion 30 cm high.

- Install plastic drainage infiltrators with horizontal slots.

- Lay geotextiles to avoid rapid siltation of the drainage material

- Sprinkle the top with soil 0.5-0.8 m thick.

The design of infiltrators requires mandatory ventilation. With access to oxygen, the breakdown of organic matter occurs much faster.

Filter structures should not be located next to wells or boreholes. To calculate the number of infiltrators, soil permeability is taken into account. The lower it is, the more products need to be installed.

The links are connected to each other by overflow pipes. At very high groundwater levels, infiltrators are placed on the ground surface. The structure can be insulated with expanded polystyrene or other material that is resistant to moisture and rot, and then covered with soil on top.

Filter embankments

The close occurrence of groundwater is a big problem when installing septic tanks. It happens that they come to the surface, and the soil in the area becomes swampy.

But even in critical conditions it is possible to construct a full-fledged filter structure. For this purpose, the method of laying a dissipating pipe on an embankment 1 m high is used. The thickness of the crushed stone cushion is 30 cm. The filter is covered with geotextile on top and covered with earth to avoid freezing. For ventilation, the top of the pipe must be raised above the surface of the sprinkler.

Septic tank type “Filter trench”

Trench septic tanks with a horizontal irrigation pipe are identical in principle to sand and gravel filters. For pipe lengths up to 30 meters:

- the operational loading height of the filtration trench is 800 mm;

- width 500 mm;

- daily productivity of one meter of pipe is up to 70 liters;

- sanitary protection zone – within 8 meters.

1 - coarse sand; 2 - irrigation pipe; 3 - backfill; 4 - ventilation risers; 5 - intermediate layer of sand; 6 - distribution layer of sand; 7 - lower drain; 8 - gravel backfill

Features of installation with close underground waters

To prevent the infiltration of contaminated wastewater both inside and outside, the storage tank must be absolutely sealed. The best choice for waterlogged soils is a septic tank made of polymers - polypropylene, polyethylene or fiberglass. The walls must be thick enough, and the structures must have stiffening ribs to withstand heavy loads.

Installation stages

Installing a septic tank under standard conditions includes the following steps:

- Digging a pit.

- Sand cushion installation.

- Immersion and leveling of the container.

- Laying sewer pipes.

- Filling the structure with water.

- Condition check, commissioning.

- Backfill with layer-by-layer compaction.

Features of installation in close water

At high groundwater levels, work differs from usual in a number of nuances:

- Groundwater can flow in large quantities. You need to stock up on a drainage pump for pumping.

- It is advisable to choose a horizontal layout of the septic tank in order to raise the bottom of the pit as high as possible.

- If the slopes crumble, install retaining walls made of boards or panels.

- To secure the container, a reinforced concrete slab with outlets is placed in the pit or a reinforced concrete cushion is installed with anchors made of reinforcement. After immersing the septic tank, it must be secured with steel slings so that the installation does not float when lifting the water supply system. This is especially true for lightweight plastic structures and metal caissons.

- Sewer and overflow pipes, connecting elements, and drainage field must be raised as high as possible. If they are even periodically under water, the system will overflow and will not work.

- The neck of the structure is raised to a height of up to 30 cm above ground level, and an insulated blind area is installed around it.

- The joints in a prefabricated septic tank made of reinforced concrete rings are carefully sealed with waterproofing mixtures.

Common mistakes

Before installing a septic tank, you need to draw up at least a simple project. Thanks to this, it is possible to avoid many mistakes, including the most common:

- The outlet of the house sewer pipe is too deep. At a high groundwater level, this can lead to groundwater being thrown into the sewerage system, preventing flow. You will also have to bury the septic tank, which is very undesirable. It is optimal to make the exit at around -50…-60 cm, and insulate the communication itself.

- Incorrect pipe slope. With a diameter of 110 mm it is 2-3 cm per linear meter. Reducing or increasing the angle of inclination contributes to the formation of blockages. The flow rate must be optimal so that the solid part of the waste moves along with the liquid.

- Backfilling the pipe with soil. To protect communications from various types of deformations, it is recommended to use drainage materials - sand, crushed stone. The soil, especially clayey soil, is unsuitable for this, since it increases in volume when moistened and frozen.

- Narrow pit. If the pit size is too small, it is difficult to install the septic tank correctly. In addition, on clay soils, sand must be used for backfilling to protect the walls from frost in the soil.

- Incorrect installation order. Backfilling is carried out only after filling the septic tank with water, so that the soil does not compress the empty body, and also to prevent subsidence of the 2-3 ton installation during operation. Otherwise, this risks failure of the pipe connections.

Filter cassette

After the distribution well is installed, load the filter well into it. Subsequently, it is used so that wastewater can be pumped into the cassette. In order to install this cassette, the top layer of fertile soil is first removed. The site is carefully prepared, and it should be fifty cm larger than the cassette.

The depth of the pit should be about fifty cm, then it is filled with sand and thoroughly compacted. After this, concrete blocks must be placed along the entire perimeter of the site, they must be secured to each other. You will end up with a kind of box that needs to be filled with gravel (take small gravel), then a cassette is placed on it - infiltrates that have no bottom.

1 - wastewater supply pipeline; 2 - filter base; 3 - supporting blocks made of concrete or reinforced concrete; 4 - reinforced concrete floor slab; 5 - filtration wells; 6 — ventilation riser; 7 - wooden cover; 8 - drainage tray; 9 — hatch; 10 - waterproofing; 11 - stone blind area; 12 - stone paving; 13 — cast iron hatch; 14 — jet barrier wall

You need to connect a pipe or hose to the installed cassette; it is through this that the drains will then flow; install a pipe for ventilation. Foam plastic is laid on top of the installed cassette (it serves as insulation), add soil about twenty cm, maybe a little more, but not less.

The wastewater that will enter the space formed between the filter media and the filter will spread, and then be filtered and go into the ground. In order for the filtration surface to be increased to the required size, you can consider the option of a well.

The size of the loading fragment for the filter base should be calculated at approximately 2-10 mm - this is fine crushed stone, slag or other material. Make the paving from stone, its size should be 60-100mm.

A brief overview of models of ready-made septic tanks for high groundwater

If there is not enough space on your site to construct filter trenches or wells, a guaranteed result can be obtained by installing ready-made biotreatment stations. Domestic and foreign manufacturers produce models of various performance and price categories that purify wastewater up to 80-98%.

Septic tanks "Topas"

In these installations, the effective decomposition of organic matter is facilitated by stepwise processing using colonies of aerobic and anaerobic bacteria. The station body is waterproof, so groundwater does not have any influence on the wastewater treatment process.

The device is energy-dependent, since the operation of the pumps, aerator and airlifts requires power. The performance of septic tanks of different models provides comfortable living for a family of 4 to 10 people, and a two-body station - up to 20.

Septic tank "Tank"

Non-volatile installations TANK, TANK UNIVERSAL, MICROB are made of thick durable plastic. The design has stiffening ribs that protect the septic tank from being compressed by the soil. Waste processing is carried out in 3 chambers. After clarification, wastewater requires additional soil treatment.

The BioTANK series of septic tanks is equipped with electrical equipment. An aerator is installed in the additional chamber, enriching the wastewater with oxygen. The breakdown of organic matter occurs quickly, and the output is clean water without any odors. The remaining sludge can be used as fertilizer.

Unilos Astra installations

The model range of this equipment is very wide - from Astra 3 with a capacity of 3 m³ to Astra 250 MEGA, where the volume amounts to hundreds of cubic meters. The devices are equipped with a sewage pumping station, a frame-fill filter, and an ultraviolet disinfectant.

The system is controlled by a remote control; in case of an emergency, an alarm is triggered. Consumers note that the station operates very quietly, and there are completely no unpleasant odors nearby.

Septic tank "Tver"

The Tver septic tank is perhaps one of the best solutions for areas with high groundwater level. Thanks to the horizontal layout, the station does not need to be too deep, and its internal structure is so simple that maintenance will not be a problem.

The manufacturer produces equipment with a capacity of 350 l/day, which is enough for a small family or temporary residence in the country. For 4-5 people, models with a volume of at least 3 cubic meters are recommended. This ensures deep processing of the entire amount of wastewater with the release of technically pure water, which can be used to wash a car or water trees.

The area is sandy, the groundwater level is low (water is below 4 m or there is none)

The combination of low groundwater level and well-draining soil are ideal conditions for constructing a septic tank made of reinforced concrete rings. Moreover, in this case, you can do without a filtration field, so the capabilities of a filter well are sufficient. There may be several design options; we have identified the simplest and most effective.

Scheme 4. 3-chamber septic tank with one hatch

Description:

- Compact 3-section septic tank with filter well.

- 1 hatch for servicing the entire system.

- Saving on additional rings - they are needed only for one well.

- Filter layer throughout the entire volume around the wells and between them.

- The bottom of 2 wells is concreted. There are no holes in the filter well, there are holes in the walls of the lower ring.

The following video shows the construction process without unnecessary comments. The main part of the work is carried out in 1 day. For increase

Conclusion:

This scheme saves space for installing external sewerage; there is no need to buy additional rings and hatches for 3 wells.

Scheme 5. 2-chamber septic tank with a filter well

Description:

- A simple diagram of a 2-chamber septic tank with a filter well.

- Can be installed and put into operation in 1 day.

- You can get by with wells made of two rings.

- The bottom of the first well is necessarily solid.

The simplified wastewater treatment scheme is due to the excellent drainage properties of the soil. In the video below, the author explains in detail the role of each structural element of the treatment plant. The video also contains a lot of food for thought, which will make you feel more confident when installing a septic tank.

Conclusion:

scheme for permanent or seasonal use. Takes up little space on the site, copes with volley discharges of wastewater. Large drainage layer resource. Pumping sludge from the first chamber no more than once a year.