Loading…

Loading…

The Malysh vibration pump is produced in Russia by several factories. The inexpensive device is used in water supply farms, as a drainage or irrigation device. A characteristic feature of the tool is easy maintenance, light weight and the lowest cost in the segment.

Scope of application of the pump

The Malyshok pump can be used to solve a wide range of problems; this equipment is used in garden plots, subsidiary plots, farmland and dachas. Given the versatility of the pump, it can be used for the following purposes:

- installation of an irrigation and watering system in a garden plot, watering fields and irrigating plantings; in addition, the equipment can be effectively used for pumping water from an artificial reservoir or, conversely, filling it;

- pumping water from a well or well into a water supply system or special containers; using this pump, you can easily provide water to all intake points on a medium-sized summer cottage;

- pumping water from basements and utility rooms in case of flooding. Compact dimensions, ease of connection and operation of the equipment are excellent for these purposes.

The Baby submersible vibration pump is in great demand on the market - it is one of the best price-quality ratios

Depending on the specifics of use, you can choose the Malysh pump with a lower water intake or with an upper one. The option with a lower intake is most effective when used in wells or boreholes with a diameter of more than 100 mm. Also, such equipment is well suited for pumping water from small reservoirs, that is, it is useful when flooding premises or pumping water from lowlands. The disadvantage of a lower intake is a high risk of dirt and various small particles getting in, so it is recommended to install a filter at the inlet of equipment with a lower intake.

A pump with an upper intake not only prevents debris from getting inside, but is also characterized by more efficient cooling and is practically not afraid of overheating. Such a pump can be safely left running unattended, which allows it to be used to ensure the continuous operation of an autonomous water supply system. This type of equipment is also used to lift water from wells and wells.

The principle of operation of the Baby pump with an upper water intake in a reservoir: 1 - pump, 2 - protective ring, 3 - clamp, 4 - nylon cable (cord), 5 - bundle, 6 - hose, 7 - power cord, 8 - spring suspension, 9 — crossbar

Operating principle of the Baby pump

Like any other vibration pump, the Malysh works on an inert principle - this means that it has a vibrator in its body that gives the liquid oscillatory movements. The vibrator is an anchor to which a rod is attached. When the pump is turned on, the armature is attracted to the magnet, then the magnet is turned off, and a special spring returns the armature with the rod to its original position. Such oscillations occur approximately 50 times per second.

Judging by the characteristics of the Malysh pump, it is clear that such a simple design can nevertheless provide a sufficiently high liquid pressure in the water supply system.

The operating principle of the “Baby”

The not too complicated and reliable design, as well as the good characteristics of the Malysh pump, make it an excellent option for simple and economical use. It consists of a sealed housing, protected from liquid penetration, and an electric drive located in it. The drive contains a core, an electrical wire, a vibrator and two coils.

Options with top water injection are equipped with a valve to close the inlet in the absence of water pressure in the top part of the body. In a model with a lower intake, such a valve is located at the bottom.

What parameters to consider when choosing

At a relatively low price, the technical characteristics of the Malysh submersible pump fully satisfy the needs of the modern user:

- operating voltage – 220W;

- productivity – 432 l/s;

- the presence of upper and lower holes for water intake;

- working depth – up to 40 m;

- power – 245 W.

Varieties of Baby pump models

The price of the Malysh water pump varies from 1000 to 2000 rubles, but it has good performance characteristics that allowed it to gain trust among users. In modern modifications, a built-in automatic protection system is additionally installed. Automation protects the pump from overheating as a result of dry running, and also allows the engine to quickly respond to power surges in the network. This is very important for suburban areas, which cannot always boast of a stable power supply.

Automatic water pump Baby turns off the power to the mechanism when the water level in the tank is low. The level is determined using a float system. When the water rises to a certain level, the pump motor starts again. The protection system operates from the same power source as the pump itself.

You should also understand that there are several modifications of this unit on the modern pumping equipment market.

Examples of immersing a Malysh pump with upper and lower water intake into a well or well

Classic pump Baby

The peculiarity of this model is that it is designed to supply water over long distances. The Classic Malysh effectively pumps water over 100-150 m, so it is often used for watering large summer cottages. The diameter of the hose for the Malysh pump is 18-22 mm.

This model is not intended for use in polluted environments; the permissible concentration of impurities should not exceed 0.01%. There are also requirements for the temperature of the pumped water - no higher than 35? C.

The basic model is not equipped with overheating protection, a filter and a pressure switch. And if the filter can still be installed on your own, then you will have to do without other modifications. Of course, all this directly affects the price of the unit, because it is much lower than other models. The basic model can be submerged to a maximum of 5 m, and water is drawn through the bottom valve.

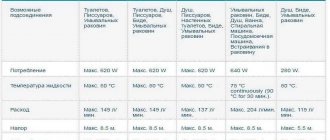

Table of technical characteristics of Malysh pumps

Pump Malysh-M

In terms of its technical characteristics, this model is practically no different from the classic one, except that water is drawn through the top valve. Therefore, this modification of the Malysh well pump is recommended for use where lower intake is impossible due to high contamination of the bottom.

Baby-K

It has the same characteristics as the base model, but boasts built-in overheating protection. This model can be effectively used for long-term continuous operation without supervision.

Installation of pumps "Malysh-M" and "Malysh-K" with upper water intake

Malysh-Z

The submersible pump for the Malysh-3 well is most relevant for use in small wells. It is not much more expensive than the base model, but at the same time boasts significant design differences:

- The pump itself and the electric motor are enclosed in a monolithic sealed unit, which completely prevents water from getting inside.

- The rated operating power is lower than that of the base model and is only 165 W. This is quite enough for working in a small well.

- The unit produces 0.432 m?/hour at a pressure of 20 m.

- The weight of the device does not exceed 3 kg.

Also, the pump of this model has a compact size, and it comes with a water-protected cable. A water filter is not included in the basic package, but you can easily purchase and install it yourself.

The power of the Baby vibration pump, depending on the model, ranges from 185 to 240 kW

Pump operating rules

It is logical that most pumping equipment is operated in difficult conditions. Because of this, the risk of breakdowns significantly increases, which can be reduced if you follow a number of basic operating rules and carry out preventive repair work in a timely manner.

Most often, equipment fails due to debris that gets into the mechanism. Also, over time, clogging of pipes, abrasion of parts, and the formation of silt deposits on the walls of the inlet and outlet can occur. The best method of dealing with pump clogging is to install special filters for the Malysh pump. They trap solid particles and prevent them from penetrating the mechanism. The best option is the EFVP-St-38-125 filter. Not only does it prevent particles up to 150 microns in size from entering the pump mechanism, but it is also very easy to install.

Pump device "Baby" with bottom water intake

The financial cost of purchasing and installing a filter will be about 100 rubles. Such measures will significantly extend the life of the equipment and increase the efficiency of use, and you will be provided with clean water from any body of water.

Installation and connection of equipment

Before you begin installing pumping equipment, you should take into account the specifics of different models:

In order to reduce the amount of vibration of the operating mechanism, you need to secure one end of a durable nylon cord in a special hole on the pump body, and attach a special elastic suspension to the other end, which can be a medical tourniquet or an elastic rubber hose.

Malysh pumps are available with aluminum or plastic housings

When operating in a confined space, such as a well or borehole, the pump may hit the walls of the tank, leading to premature failure. To prevent this from happening, it is recommended to put a wide thick rubber ring on the body, which will serve as a shock absorber during impacts.

Remember that the equipment must be installed in a vertical position; horizontal installation can lead to premature failure. The immersion depth of the unit must be greater than the lower dynamic water level. Before installing a submersible pump for the Malysh well, you should carry out preparatory work, that is, determine the depth of the pump in the tank and purchase a hose of the appropriate diameter. It is very important that the diameter of the hose matches the device so that it can work as efficiently as possible.

A mismatch between the sections of the hose and the pump inlet can lead to overloads and premature wear of components. Under no circumstances should you connect the device to the electrical network during the installation process; this can only be done after all installation work has been completed. If the electrical cable is too short, it can be extended, but the connection point must be located outside the well.

The pump is connected to the electrical network only after all installation work has been completed.

Maintenance Features

So, in order for your Baby pump to last as long as possible, be sure to follow the conditions of its storage and use recommended by the manufacturer. Only in this case will the normal operation of the unit be guaranteed for the required 2 years. What is typical is that the pump does not require any special care or complex equipment, therefore, proper maintenance should not be difficult.

After you install the device in the well for the first time, wait and let it work for several hours, then remove it and carefully examine it - look for possible malfunctions. And if everything is normal with this, then the equipment can be loaded back and continued operation, allowing for prolonged immersion.

From time to time (approximately every three months, although if possible it is recommended to do this after every hundred hours of use), still inspect the device. If traces of friction are found on the casing, we can safely say that the pump was installed incorrectly - during operation it interacts with the walls of the well. To avoid all this, try to position the unit very level, not forgetting about the previously mentioned rubber ring on the body.

If the inlets are clogged, clean them carefully, being careful not to damage the rubber valve. It is recommended to clean with a tool that has a blunt end. If you do not intend to use the equipment for the winter, remove it, wash it thoroughly and dry it. The pump should be stored as far as possible from any heating equipment; moreover, you should protect it from direct sunlight.

Note! If you followed all the manufacturer’s recommendations, but a breakdown still occurred due to reasons beyond your control, we recommend contacting your nearest service center.

The video below will tell you about a possible way to improve the unit.

Video - How to lengthen the Baby's water intake

Features of repairing the Baby pump with your own hands

The need to repair the Malysh pump most often arises due to the fact that small debris gets into the mechanism from the water, and silty deposits also form. Therefore, to extend the life of the equipment, it must be disassembled and cleaned regularly. A video of repairing the Baby pump with your own hands can be easily found on the Internet. It clearly demonstrates that repairs are carried out in the following sequence:

Built-in automatic protection system helps the pump cope with voltage surges

Once the pump is disassembled, you can begin cleaning and repairing it. In addition to blockages, one of the common causes of unit breakdowns can be peeling of the epoxy compound as a result of expansion of the housing due to temperature changes. Repairing the Malysh water pump with your own hands in the event of such a breakdown is quite simple. First, you should tap the body with a small hammer to determine where the compound is peeling off. Where it has moved away, the sound will be thinner. Then you need to remove the assembly with the compound, and use a grinder to apply notches to the body. The same notches in the form of a mesh must be applied to the knot.

Then a sealant is applied to the assembly and to the inner surface of the case; glass glue or another similar composition is best. The unit with the applied sealant is inserted into the housing, and a force of about 300 kg is applied to it. After the sealant has hardened, the pump must be reassembled in the reverse order.

The Malysh pump repair kit may include sealant, but sometimes it is safer to use additional products.

One of the important points when assembling the pump is the alignment of the holes that are located in the central and upper parts of the rubber gasket of the device. These nodes are symmetrical, so their relative positions can be confused. The functionality of the device can be easily checked by lowering it into a bucket of water. The height of the water jet from the outlet pipe without a hose should be approximately 30 cm.

Overall dimensions of electric pumps “Malysh”

Common problems and solutions to them

One of the common problems with the operation of this device is that it works, but does not pump water. There may be several reasons for this:

You can repair the pump yourself, the main thing is to understand the principle of its operation.

If the water pressure switch for Malysh pumps or other complex equipment fails, then it is better not to risk it and seek qualified help. Despite the simplicity of the unit, improper repairs can lead to complete failure of all parts.

Advantages and disadvantages

A pump with an aluminum casing will last longer

The main advantages of the pump include:

- low noise level during operation;

- moderate depth of water intake (up to 40 meters);

- compact dimensions;

- long continuous operation;

- multitasking;

- long service life (for devices with an aluminum flask);

- maintainability;

- profitable price.

A significant disadvantage is the sensitivity of the pump to sand and clay impurities in the water.