Aluminum ore has gained the most popularity in modern industry. Aluminum is the most common metal of all metals existing on earth today. In addition, it holds third place in the ranking in terms of the number of deposits in the bowels of the Earth. Also, aluminum is the lightest metal. Aluminum ore is a rock that serves as the material from which the metal is obtained. Aluminum has certain chemical and physical properties that make it possible to adapt its use to completely different areas of human activity. Thus, aluminum has found its wide application in such industries as mechanical engineering, automotive, construction, in the production of various containers and packaging, electrical equipment, and other consumer goods. Almost every household appliance used by humans every day contains aluminum in one quantity or another.

Aluminum ore - from mining to metal production. Leading countries in aluminum production

Compared to traditional metals (steel, copper, bronze), aluminum is a young metal.

The modern method of obtaining it was developed only in 1886, and before that it was very rare. The industrial scale of the “winged” metal began only in the 20th century. Today, it is one of the sought-after materials in various industries from electronics to the space and aviation industries.

Aluminum ore was first obtained in the form of a silvery metal in 1825 in a volume of just a few milligrams, and before the advent of mass production, this metal was more expensive than gold. For example, one of the royal crowns of Sweden contained aluminum, and D. I. Mendeleev in 1889 received an expensive gift from the British - scales made of gold and aluminum.

What raw materials are needed to produce aluminum ore? How is one of the most essential materials of our time produced?

Bauxite ore is the basis of global aluminum production

The silver metal itself is directly obtained from alumina. This raw material is aluminum oxide (Al2O3), obtained from ores:

The most common source of starting material is bauxite, which is considered the main aluminum ore.

Despite the more than 130-year history of discovery, it has still not been possible to understand the origin of aluminum ore. It is possible that simply in each region the raw materials were formed under the influence of certain conditions. And this makes it difficult to derive one universal theory about the formation of bauxite. There are three main hypotheses about the origin of aluminum raw materials:

- They were formed due to the dissolution of certain types of limestone as a residual product.

- Bauxite was obtained as a result of weathering of ancient rocks with their further transport and deposition.

- The ore is the result of chemical processes of decomposition of iron, aluminum and titanium salts, and fell as sediment.

However, alunite and nepheline ores were formed under different conditions from bauxite. The former were formed under conditions of active hydrothermal and volcanic activity. The second - at high magma temperatures.

Bauxite

As a result, alunites generally have a crumbly porous structure. They contain up to 40% of various aluminum oxide compounds. But, in addition to the aluminum-bearing ore itself, the deposits, as a rule, contain additives, which affects the profitability of their mining. It is considered profitable to develop a deposit with a 50 percent ratio of alunites to additives.

Nephelines are usually represented by crystalline samples, which, in addition to aluminum oxide, contain additives in the form of various impurities. Depending on the composition, this type of ore is classified into types. The richest contain up to 90% nephelines, second-rate 40-50%; if the minerals are poorer than these indicators, then it is not considered necessary to develop them.

Having an idea of the origin of minerals, geological exploration can quite accurately determine the location of aluminum ore deposits. Also, the formation conditions, which influence the composition and structure of minerals, determine the extraction methods. If the deposit is considered profitable, its development is established.

Chemical properties of aluminum

Under normal conditions, aluminum exhibits an oxidation state of +3, at high temperatures +1, rarely +2.

Aluminum has a high affinity for oxygen, forming the oxide Al2O3; in a powdered state, when heated in a stream of oxygen, it burns, developing a temperature of about 3000°C. This feature of aluminum is used in aluminothermy for the recovery of certain metals from their oxides. At high temperatures, aluminum combines with nitrogen, carbon and sulfur, forming AlN nitride, Al4C3 carbide and Al2S3 sulfide, respectively. Aluminum does not interact with hydrogen; hydride (AlH3)x is obtained indirectly. Aluminum easily dissolves in alkalis with the release of hydrogen and the formation of aluminates. Most aluminum salts are highly soluble in water.

Properties of aluminum ore

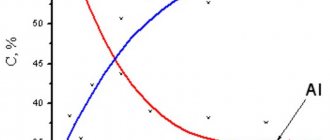

Bauxite is a complex compound of oxides of aluminum, iron and silicon (in the form of various quartz), titanium, as well as with a small admixture of sodium, zirconium, chromium, phosphorus and others.

The most important property in aluminum production is the “breakability” of bauxite. That is, how easy it will be to separate unnecessary silicon additives from it in order to obtain the feedstock for metal smelting.

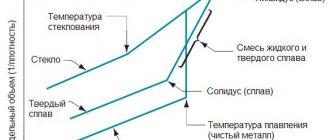

The basis for producing aluminum is alumina. To form it, the ore is ground into a fine powder and heated with steam, separating most of the silicon. And this mass will become the raw material for smelting.

To obtain 1 ton of aluminum, you will need about 4-5 tons of bauxite, from which, after processing, about 2 tons of alumina are formed, and only then you can get the metal.

Aluminum mining

There are a huge number of minerals in which the presence of this metal was once discovered. Scientists have concluded that this metal can be extracted from more than 250 minerals. However, it is not profitable to extract metal from absolutely all ores, therefore, among all the existing variety, there are the most valuable aluminum ores, from which the metal is obtained. These are: bauxite, nepheline, and alunite. Of all aluminum ores, the maximum aluminum content is found in bauxite. They contain about 50% of aluminum oxides. As a rule, bauxite deposits are located directly on the earth's surface in sufficient quantities.

Bauxite is an opaque rock that is red or gray in color. The strongest bauxite samples on the mineralogical scale are rated at 6 points. They come in different densities from 2900 to 3500 kg/m3, which directly depends on the chemical composition.

Bauxite ores are distinguished by their complex chemical composition, which includes aluminum hydroxides, iron and silicon oxides, as well as from 40% to 60% of alumina, which is the main raw material for the production of aluminum. It is worth saying that the equatorial and tropical zones of the earth are the main areas that are famous for deposits of bauxite ore.

For the nucleation of bauxite, the participation of several components is necessary, including monohydrate alumina hydrate, boehmite, diaspore, as well as various iron hydroxide minerals along with iron oxide. The weathering of acidic, alkaline, and in some cases basic rocks, as well as the slow settling of alumina at the bottom of reservoirs, leads to the formation of bauxite ore.

From two tons of alumina, aluminum turns out to be half as much - 1 ton. And for two tons of alumina it is necessary to extract about 4.5 tons of bauxite. Aluminum can also be obtained from nephelines and alunites.

The former, depending on their grade, can contain from 22% to 25% alumina. While alunites are slightly inferior to bauxites, and consist of 40% aluminum oxide.

Technology for the development of aluminum deposits. Aluminum ore mining methods

When the depth of occurrence of aluminum-bearing rocks is insignificant, they are mined using open-pit mining. But the process of cutting off ore layers will depend on its type and structure.

- Crystalline minerals (usually bauxite or nepheline) are removed by milling. Mineral miners are used for this purpose. Depending on the model, such a machine can cut a layer up to 600 mm thick. The rock thickness is developed gradually, forming shelves after passing through one layer.

This is done to ensure the safe position of the operator’s cabin and running gear, which in the event of an unexpected collapse will be at a safe distance.

- Loose aluminum-bearing rocks preclude the use of milling. Since their viscosity clogs the cutting part of the machine. Most often, these types of rocks can be cut using mining excavators, which immediately load the ore onto dump trucks for further transportation.

Leading countries in aluminum ore production

The main deposits of aluminum are concentrated in regions with a tropical climate, and most of the 73% of deposits are found in just 5 countries: Guinea, Brazil, Jamaica, Australia and India. Of these, Guinea has the richest reserves, more than 5 billion tons (28% of the world share).

If we divide reserves and production volumes, we can get the following picture:

- 1st place – Africa (Guinea).

- 2nd place - America.

- 3rd place – Asia.

- 4th place – Australia.

- 5th – Europe.

The top five countries in aluminum ore production are presented in the table

| A country | Production volumes million tons |

| China | 86,5 |

| Australia | 81,7 |

| Brazil | 30,7 |

| Guinea | 19,7 |

| India | 14,9 |

Also, the main producers of aluminum ores include: Jamaica (9.7 million tons), Russia (6.6), Kazakhstan (4.2), Guyana (1.6).

Physical properties of aluminum

Aluminum is a silvery-white light metal. The aluminum lattice is cubic face-centered with parameter a = 0.40413 nm (4.0413 E). High purity aluminum (99.996%) is characterized by the following physical properties: density (at 20°C) 2698.9 kg/m3, melting point 660.24°C, boiling point 2500°C, thermal conductivity (at 190°C) 343 W/ m • K, specific heat capacity (at 100°C) 931.98 J/kg • K, electrical conductivity with respect to copper (at 20°C) 65.5%, coefficient of thermal expansion (from 20 to 100°C) 2, 39 • 10-5 deg-1. Aluminum has low strength (tensile strength 50-60 MPa) and hardness (170 MPa, according to Brinell), but high ductility (up to 50%). Aluminum is highly polished, anodized and highly reflective (90%). Aluminum is resistant to various types of natural waters, nitric and organic acids. When exposed to air, aluminum is coated with a thin, durable film that protects the metal from further oxidation and corrosion.

Development of aluminum ore deposits in Russia

In our country there are several rich deposits of aluminum ores, concentrated in the Urals and in the Leningrad region. But the main method of extracting bauxite in our country is the more labor-intensive closed mine method, which extracts about 80% of the total mass of ores in Russia.

The leaders in deposit development are the joint-stock company Sevuralboxitrude, JSC Baksitogorsk Alumina, and the South Ural Bauxite Mines. However, their reserves are running out. As a result, Russia has to import about 3 million tons of alumina per year.

| Field | Reserves |

| Little Red Riding Hood (Ural) | For 19 years of production |

| Gornostayskoye and Gornostaysko-Krasnooktyabrskoye | For 18 years of production |

| Blinovo-Kamenskoye | 10 years |

| Kurgazskoe | 10 years |

| Radynsky quarry | 7 years |

In total, 44 deposits of various aluminum ores (bauxite, nepheline) have been explored in the country, which, according to estimates, should be enough for 240 years, with such mining intensity as today.

The import of alumina is due to the low quality of the ore in the deposits, for example, bauxite with a 50% alumina composition is mined at the Red Cap deposit, while in Italy rock with 64% aluminum oxide is extracted, and in China 61%.

Aluminum ores of Russia

The Russian Federation is ranked 7th among all countries in the world in terms of the amount of aluminum ore mined. It is worth noting that this raw material is mined in colossal quantities on the territory of the Russian state. However, the country is experiencing a significant shortage of this metal, and is not able to provide it in the volume necessary to absolutely supply the industry. This is the priority reason why Russia has to purchase aluminum ores from other countries, as well as develop deposits with low quality mineral ores.

There are about 50 deposits in the state, the largest number of which are located in the European part of the state.

However, Radynkskoye is the oldest aluminum ore deposit in Russia. Its location is the Leningrad region. It consists of bauxite, which since ancient times has been the main and irreplaceable material from which aluminum is subsequently produced. Table 1. The largest bauxite deposits in Russia

| Name | Content % | Percentage of total reserves | Degree of industrial development | |

| AL2O3 | SiO2 | |||

| "Little Red Riding Hood" Severouralsk | 53.7 | 3.7 | 3.1 | In developing |

| Kalinskoye, Severouralsk | 56.0 | 2.6 | 3.6 | In developing |

| Cheremuzovskoye, Sverdlosk region | 54.2 | 4.0 | 11.0 | In developing |

| Novo-Kalinskoye, Severouralsk | 55.0 | 3.1 | 7.0 | In developing |

| Iksinskoe, st. Navolok | 53.5 | 17.4 | 11.4 | In developing |

| Vezhayu-Vorykvinskoye. Komi Republic | 49.2 | 0.1 | 11.3 | In preparation |

| Vislovskoye, Belgorod | 49.1 | 7.9 | 12.1 | In reserve |

Applications of Aluminum Ore

Basically, up to 60% of ore raw materials are used to produce aluminum. However, the rich composition makes it possible to extract from it other chemical elements: titanium, chromium, vanadium and other non-ferrous metals, which are necessary primarily as alloying additives to improve the quality of steel.

As mentioned above, the technological chain for producing aluminum necessarily passes through the stage of formation of alumina, which is also used as fluxes in ferrous metallurgy.

The rich composition of elements in aluminum ore is also used to produce mineral paint. Also, the smelting method produces alumina cement - a quickly hardening, strong mass.

Application

Due to its lightness, sufficient strength, ability to alloy with many other metals and good electrical conductivity, aluminum is widely used in electrical engineering, as well as as a structural material in mechanical engineering, aircraft manufacturing, construction, etc. Pure and ultra-pure aluminum is used in semiconductor technology and for coating various types of mirrors . Aluminum is used in nuclear reactors due to its relatively low neutron absorption cross section. Aluminum containers and containers transport liquid gases (methane, oxygen, hydrogen), some acids (nitric, acetic), and store food products, water, and oils. Aluminum is used as an alloying additive in alloys of Cu, Mg, Ti, Ni, Zn, Fe. In some cases, aluminum is used to make explosives (aluminal, aluminotol, etc.).

Alternative to aluminum ores

The development of modern production requires increasingly large volumes of aluminum. However, it is not always profitable to develop deposits or import alumina from abroad. Therefore, metal smelting using recycled materials is increasingly being used.

For example, countries such as the USA, Japan, Germany, France, and the UK mainly produce secondary aluminum, amounting to up to 80% of global smelting.

Secondary metal is much cheaper compared to primary metal, the production of which requires 20,000 kW of energy/1 ton.

Today, aluminum, obtained from various ores, is one of the most popular materials for producing durable and lightweight products that are resistant to corrosion. No alternatives to the metal have yet been found, and in the coming decades the volumes of ore mining and smelting will only increase.

Source

Oversupply

Excess microelement is toxic.

An increased aluminum content is dangerous for human health, since immunity is reduced, and sometimes irreversible changes occur in the body, which sharply reduce life expectancy.

Reasons for exceeding the permissible microelement norm

- Work in production where the air is saturated with various aluminum compounds, which leads to acute poisoning by vapors. Aluminosis is an occupational disease of people working in metallurgy.

- Living in places with high levels of substances in the air and environment.

- Using aluminum cookware for cooking and eating from them.

- Taking medications with a high content of microelements. Such medications include: antacids (phosphalugel, Maalox), vaccines (against hepatitis A, B, papillomavirus, Haemophilus influenzae, pneumococcal infection), some antibiotics. With prolonged use of such drugs, aluminum salts accumulate in the body, causing an overdose. To prevent this phenomenon during therapy, it is necessary to simultaneously use choleretic, diuretic drugs and medications with magnesium and silver ions, which remove and inhibit the effect of the element.

- The use of decorative and preventive cosmetics that contain aluminum (antiperspirant deodorants, lipstick, mascara, creams, wet wipes).

- Acute, chronic renal failure. The disease promotes the accumulation and prevents the removal of aluminum salts from the body.

- Oversaturation of the diet with foods rich in this microelement. Remember, any shelf-stable food products packaged in foil or iron cans can accumulate a lot of aluminum. Such products should be abandoned. In addition, today the following food additives are registered, regulated by state standards and approved for use in production: E520, E521, E522/E523. These are aluminum sulfates or salts. Despite the fact that they are absorbed less actively than compounds coming from food or medicine, such substances slowly poison our body. The largest quantity is concentrated in sweets and canned goods.

- Aluminum ions enter the body with drinking water, which is treated at a water treatment plant. In regions subject to heavy acid rain, lake and river water bodies are characterized by tens of times higher AL concentrations than the norm, which leads to the death of mollusks, amphibians, and fish.

Thus, no one is immune from an excess of aluminum in the body.

Characteristic signs of excess microelement:

- decrease in hemoglobin;

- decrease in the number of red blood cells in the blood;

- cough;

- loss of appetite;

- nervousness;

- constipation;

- mental disorders;

- problems with the gastrointestinal tract, kidneys;

- speech disorders, spatial orientation;

- clouding of mind;

- memory lapses;

- convulsions.

Consequences of the toxic effect of a microelement:

- The development of osteomalacia, a disease associated with softening of bone tissue, which disrupts the functioning of the musculoskeletal system, leads to bone fractures and an increase in injuries.

- Brain damage (encephalopathy). As a result, Alzheimer's disease develops. This condition manifests itself in increased nervousness, apathy towards everything around, memory impairment, a tendency to sudden, causeless stress, and depression. In old age, progressive dementia occurs.

- Dysfunction of the gastric tract, intestines, kidneys.

- Trembling of the head, cramps in the limbs, development of arthritis, anemia, rickets.

- Inhibition of the metabolism of calcium, phosphorus, magnesium, copper, iron, zinc in the body.

- Disruption of the central nervous system.

- Inadequate production of salivary enzymes.

- Shortening human life.

Remember, aluminum belongs to the category of immunotoxic microelements, so to maintain health you need to monitor the amount of the compound entering the body daily.

Aluminum ore: silvery, but not silver

Aluminum is one of the most popular and sought-after metals. In every industry it is not added to the composition of certain items. From instrument making to aviation. The properties of this lightweight, flexible and corrosion-resistant metal have appealed to many industries.

Aluminum itself (a fairly active metal) is practically never found in nature in its pure form and is extracted from alumina, the chemical formula of which is Al2O3. But the direct route to obtaining alumina is, in turn, aluminum ore.

Natural sources of aluminum

The trace element is predominantly found in plant foods and baked goods, due to the latter being baked in aluminum pans. In addition, dyes, food additives under the sign E520-523, yeast, and canned food regularly supply humans with this compound. Every year the metal content in ready-made “store-bought” products is rapidly increasing.

Meat, fish, dairy products, eggs are 50–100 times poorer in this microelement than vegetables, fruits, and berries.

Table No. 1 “Sources of aluminum”

| Product name | Amount of aluminum per 100 grams of product, micrograms |

| Cereals | 1970 |

| Rye grains | 1670 |

| Sorghum cereal | 1548 |

| Wheat grains | 1520 |

| Crackers, bagels, baked goods | 1500 |

| Pistachios, nutmeg | 1500 |

| Pasta | 1500 |

| Wheat flour 1st grade | 1400 |

| Wheat flour 2 grades | 1220 |

| Peas | 1180 |

| Premium flour | 1050 |

| Rice cereal | 912 |

| Potato | 860 |

| Kiwi | 815 |

| Jerusalem artichoke | 815 |

| Beet tops | 815 |

| Avocado | 815 |

| Kohlrabi | 815 |

| Artichoke | 815 |

| Viziga | 815 |

| Savoy cabbage | 815 |

| Eggplant | 815 |

| Peach | 650 |

| Beans | 640 |

| Semolina | 570 |

| White cabbage | 570 |

| Corn | 440 |

| cucumbers | 425 |

| Grape | 380 |

| Carrot | 323 |

| Lentils | 170 |

| Apples | 110 |

When consuming foods rich in aluminum, remember that the microelement slows down the absorption of ascorbic acid, pyridoxine, iron, magnesium, calcium, vitamin C and sulfur-containing amino acids. Therefore, it is recommended not to combine these compounds or to increase your mineral intake.

Differences in saturation

Basically, there are only three types of ores worth mentioning that you need to work with if you are mining aluminum. Yes, this chemical element is very, very common, and it can also be found in other compounds (there are about two and a half hundred of them). However, due to the very high concentration, the most profitable extraction will be from bauxite, alunite and nepheline.

Nephelines are an alkaline formation that appeared due to the high temperature of magma. One unit of this ore will yield up to 25% alumina as the main raw material. However, this aluminum ore is considered the poorest for miners. All compounds containing alumina in even smaller quantities than nephelines are obviously recognized as unprofitable.

Alunites were formed during volcanic as well as hydrothermal activities. They contain up to 40% of the essential alumina, being the “golden mean” in our trinity of ores.

And the first place, with a record aluminum oxide content of fifty percent or more, goes to bauxite! They are rightfully considered the main source of alumina. However, regarding their origin, scientists still cannot come to the only correct decision.

Either they migrated from their original place of origin and were deposited after the ancient rocks weathered, or they turned out to be sediment after some limestones dissolved, or they generally became the result of the decomposition of iron, aluminum and titanium salts, falling out as sediment. In general, the origin is still unknown. But the fact that bauxite is the most profitable is already certain.

Aluminum in nature

Aluminum is one of the most common (after oxygen and silicon) elements in the rocks of the earth's crust - 8.8% (by mass). The maximum aluminum content was observed in sedimentary rocks - 10.45% (by mass), the content in medium, basic, acidic and ultrabasic rocks is 8.85%, 8.76%, 7.7%, 0.45% (by mass), respectively. . There are hundreds of minerals in which it is included as a main or fairly common element. The main carriers of aluminum are aluminosilicates. Minerals with the maximum aluminum content are corundum, gibbsite, boehmite, diaspore. The main source of aluminum is bauxite. In addition, aluminum is partially extracted from high-alumina alkaline rocks (urtites, etc.) and alunites.

The main feature of the geochemical behavior of aluminum in endogenous processes is its fairly uniform distribution in crystallizing aluminosilicates - feldspars, micas, amphiboles and pyroxenes. It is not typical for post-magmatic and hydrothermal formations. The only unique but rather rare aluminum mineral associated with pegmatites is Na3AlF6 cryolite. In exogenous processes, aluminum is a very weak migrant due to the high hydrolyzability of its salts with the precipitation of poorly soluble hydroxide Al(OH)3, the low solubility of its other compounds, and the high crystallochemical stability of aluminum-silicon-oxygen radicals in aluminosilicates. The main concentrator of aluminum in exogenous processes is kaolin, which is formed as a residual product during the weathering of acidic, intermediate and basic rocks. Subsequently, during the erosion and redeposition of kaolinite weathering crusts, aluminum enters sedimentary rocks, mainly clays. Under particularly contrasting weathering conditions (humid tropics, high ambient temperatures), decomposition in rocks reaches the stage of formation of residual (eluvial) bauxites. There is little aluminum in living organisms and the hydrosphere, although individual organisms are known to be aluminum concentrators (moss mosses, some types of mollusks). At the same time, in soils and some waters rich in organic matter, a certain migration mobility of aluminum in the form of organomineral compounds is noted. A special mobility of aluminum is established in some volcanogenic-hydrothermal ultra-acidic and acidic solutions. For the main genetic types of deposits and enrichment schemes, see Art. Aluminum ores, bauxites.

Aluminum mining methods

The necessary ores are mined in two ways.

In terms of the open method of mining the treasured Al2O3 in aluminum deposits, the three main ores are divided into two groups.

Bauxite and nepheline, as higher density structures, are cut by milling using a surface miner. Of course, it all depends on the manufacturer and model of the machine, but, on average, it is capable of removing up to 60 centimeters of rock at a time. After a complete passage of one layer, a so-called shelf is created. This method ensures that the combine operator remains safe in his position. In the event of a collapse, both the chassis and the operator's cab will be safe.

The second group contains alunites, which, due to their friability, are mined by quarry excavators and then unloaded onto dump trucks.

A radically different method is to punch a shaft. Here the mining principle is the same as in coal mining. By the way, the deepest aluminum mine in Russia is the one located in the Urals. The depth of the mine is 1550m!

Processing the resulting ore

Next, regardless of the chosen extraction method, the resulting minerals are sent to processing workshops, where special crushing devices break the minerals into fractions approximately 110 millimeters in size.

The next step is to obtain additional chemicals. additives and transportation to the further stage, which is sintering the rock in furnaces.

Having gone through decomposition and received an aluminate pulp at the exit, we will send the pulp to be separated and drained from the liquid.

At the final stage, what is obtained is cleaned from alkalis and sent back to the oven. This time - for calcination. The finale of all actions will be the same dry alumina that is needed to obtain aluminum through hydrolysis.

Even though opening a shaft is considered a more difficult method, it is less harmful to the environment than the open method. If you are for the environment, you know what to choose.

Aluminum mining in the world

At this point we can say that indicators for interactions with aluminum around the world are divided into two lists. The first list will include countries that own the largest natural reserves of aluminum, but perhaps not all of these riches have time to process. And the second list contains the world leaders in the direct extraction of aluminum ore.

So, in terms of natural (although not realized everywhere, yet) wealth, the situation is like this:

These countries can be said to have the vast majority of Al2O3 in the world. They account for 73 percent in total. The remaining reserves are scattered around the globe in less generous quantities. Guinea, located in Africa, is, in a global sense, the largest deposit of aluminum ores in the world. It “grabbed” 28%, which is even more than a quarter of the global deposits of this mineral.

And this is how things stand with the processes of mining aluminum ore:

- China is in first place and produces 86.5 million tons;

- Australia is a country of strange animals with its 81.7 million. tons in second place;

- Brazil - 30.7 million tons;

- Guinea, being the leader in reserves, is only in fourth place in terms of production - 19.7 million tons;

- India – 14.9 million tons.

You can also add to this list Jamaica, capable of producing 9.7 million tons, and Russia, with its figure of 6.6 million tons.

Aluminum production in Russia

At the beginning of the twentieth century, the emergence of the aluminum industry took place in Russia. It was in 1932 that the first aluminum production plant appeared in Volkhov. And already on May 14 of the same year, the company managed to receive a batch of metal for the first time. Every year, new aluminum ore deposits were developed on the territory of the state and new capacities were put into operation, which were significantly expanded during the Second World War. The post-war period for the country was marked by the opening of new enterprises, the main activity of which was the production of manufactured goods, the main material for which was aluminum alloys. At the same time, the Pikalevsky alumina plant was put into operation.

Russia is famous for its variety of factories, thanks to which the country produces aluminum. Of these, UC Rusal is considered the largest, not only within the Russian state, but throughout the world. He managed to produce about 3.603 million tons of aluminum in 2015, and in 2012 the company reached 4.173 million tons of metal.

Aluminum in Russia

Regarding aluminum mining in Russia, only the Leningrad region and, of course, the Urals, as a true storehouse of mineral resources, can boast of certain indicators. The main method of extraction is mining. They mine four-fifths of all ore in the country. In total, on the territory of the Federation there are more than four dozen deposits of nepheline and bauxite, the resources of which will definitely be enough even for our great-great-grandchildren.

However, Russia also imports alumina from other countries. This is because local substances (for example, the Red Cap deposit in the Sverdlovsk region) contain only half of alumina. Whereas Chinese or Italian rocks are saturated with Al2O3 by sixty percent or more.

Looking at some of the difficulties with aluminum mining in Russia, it makes sense to think about the production of secondary aluminum, as the UK, Germany, USA, France and Japan have done.

Aluminum shortage

Microelement deficiency in the body is such a rare phenomenon that the likelihood of its development is reduced to zero.

Every year the amount of aluminum in the human diet is rapidly increasing.

The compound comes in food, water, food additives (sulfates), medications, and sometimes in the air. In medical practice throughout history, several isolated cases of deficiency of the substance in the human body have been recorded. Thus, the pressing problem of the 21st century is the oversaturation of the daily menu with an element rather than the development of its insufficiency.

Despite this, let’s look at the consequences of aluminum deficiency in the body.

- General weakness, loss of strength in the limbs.

- Slowing growth and development of children and adolescents.

- Impaired coordination of movements.

- Destruction of cells, tissues and loss of their functionality.

These deviations occur if a person regularly does not receive the daily requirement of aluminum (30-50 micrograms). The poorer the diet and the lower the intake of the compound, the more intense the symptoms and consequences of deficiency.

Application of aluminum

As we already stated at the beginning of the article, the range of applications of aluminum and its compounds is extremely wide. Even at the stages of extraction from the rock, it is extremely useful. The ore itself, for example, contains small quantities of other metals, such as vanadium, titanium and chromium, useful for steel alloying processes. There is also a benefit at the alumina stage, because alumina is used in ferrous metallurgy as a flux.

The metal itself is used in the production of thermal equipment, cryogenic technology, participates in the creation of a number of alloys in metallurgy, and is present in the glass industry, rocketry, aviation, and even in the food industry as an E173 additive.

So, only one thing is certain. For many more years, humanity's need for aluminum, as well as its compounds, will not fade away. Which, accordingly, speaks exclusively of an increase in its production volumes.

Source

Beneficial features

This element of the periodic table belongs to the category of compounds that play a primary role in the human body.

Aluminum Features:

- Regulates and accelerates cell regeneration, thereby prolonging health and youth.

- Participates in the formation of cartilage, ligaments, skeleton, muscle, bone and connective tissue, promotes epithelization of the skin.

- Increases the activity of digestive enzymes and the digestive ability of gastric juice.

- Needed for the production and improvement of the body's perception of phosphate and protein complexes.

- Activates the thyroid gland.

- Strengthens bone tissue.

In addition, aluminum is contained in biomolecules, creating a strong bond with nitrogen and oxygen atoms. The microelement is indicated for people with bone fractures and people suffering from acute, chronic hyperacid gastritis, gastric ulcers, and osteoporosis.