The application of the piston pump is very wide. The unit is used for pumping various media - water (technical and drinking), oil, petroleum products, fuel, aggressive liquids prone to explosion. Unable to work with large volumes, they are often used in everyday life - for watering crop areas, gardens, lawns, and maintaining water supply systems. Manufacturers recommend using piston pumps in the chemical and food industries, and mechanical engineering. You can buy them in Russia in a wide range and at a reasonable cost.

Principle of operation

When considering the operating principle of a piston pump, it should be borne in mind that the first design appeared many decades ago. The work scheme has the following features:

- The mechanism has a movable element that performs a reciprocating movement. It is manufactured using modern materials, due to which the insulating qualities are significantly increased.

- The moving element is located in a cylindrical insulating container. When moving, the piston creates rarefied air in the working chamber, due to which liquid is sucked from the pipeline.

- The reverse movement of the moving element leads to the squeezing of liquid into the outlet line. The valve design does not allow liquid to enter the suction line at the time of its ejection.

Operating principle of a piston pump

The simplest operating principle determines long-term and stable operation. It is worth considering that the flow created by such a device can move at different speeds. Too large a volume of the working chamber leads to the fact that the flow will move in jumps. In order to eliminate the occurrence of such an effect, a device with several pistons is installed.

High Pressure Plunger Pump

The operating principle of a high-pressure pump is based on increasing the stroke of the plunger, which, accordingly, increases not only productivity, but also the resulting pressure. The stroke length is increased due to double-sided suction or the presence of several plungers.

Double-acting means that the pumping process occurs on both sides of the cylinder, inside which the rod (plunger) moves. Moving to the right, the rod creates suction pressure on the left side and pumps the medium, pushing it out of the working chamber on the right. When moving to the left, the processes occur in the reverse order. Thus, the volume of pumped liquid or the created gas pressure at the outlet doubles. Double-sided piston pumps have the same principle of operation.

Industrial high-pressure pumps can produce pressures of up to 3.5 mbar with a power of approximately 800 kW.

Device

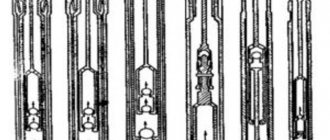

The plunger pump has a relatively simple design. Among the features we note the following points:

- Working chamber. It is represented by a sealed case, which has a mirror surface in the inner part. Due to this, the movement of the moving element is significantly simplified. The working chamber is a part of the cylinder, which is determined by the maximum stroke of the rod. The surface of the cylinder is made using a material that is highly resistant to liquids.

- The pressure and suction tubes are designed to drain and supply liquid. They can have different diameters. In addition, such a structural element may have a valve system, which significantly increases the efficiency of the mechanism.

- The piston creates pressure in the system. The piston pump device has a piston, due to which the liquid is pumped. It is manufactured using several sealing materials. Due to this, the piston can move along the cylinder and at the same time create a vacuum. It is on the surface of the piston that serious pressure is exerted. Some versions are collapsible, allowing for repairs. For example, with prolonged use, seals wear out, which can be replaced if necessary to significantly extend the service life of the mechanism. However, there are also non-separable versions, the repair of which is possible only in special workshops.

- The force is transmitted to the piston through the rod. In the manufacture of this element, high-quality steel with increased rigidity and strength is used. In addition, the materials used are characterized by high corrosion resistance, which significantly extends the service life of the structure. This element is connected to the drive through which force is transmitted. If the load is too high, the rod can become significantly deformed.

Pump device

The reciprocating motion is transmitted from the electric motor through a special mechanism that converts the rotation. Modern versions are compact and can be installed for outdoor or indoor use. In addition, in the manufacture of the case, metal is used, which has high protection from environmental influences.

The device of the double-sided model has quite a large number of features:

- There is a cylinder and a piston, as well as a rod. These elements are slightly different compared to those used to create a one-way mechanism.

- Unlike the previous version, this one has two working chambers.

- The two working chambers have their own discharge and suction valves.

Despite the significant increase in the efficiency of the piston pump, its design is quite simple. In this case, each stroke involves the suction and expulsion of liquid. This significantly increases the efficiency value.

Shaft and bearings

Whatever type of wheel is used, it is mounted on a rotating shaft. The shaft must be secured in the housing with bearings in one of 2 ways:

- Console

- Symmetrical

Cantilever fastening

When the shaft is cantilevered, the impeller is fixed at one end and the bearings at the other.

This design places the suction and discharge ports perpendicular to each other, and the suction port directly in front of the center of the wheel.

Such pumps are called end suction pumps. They are widely used because they are cheap and easy to produce, but they have one drawback related to the path of fluid movement.

During pump operation, a low pressure zone is created in the suction port.

There is a high-pressure zone at the outlet of the wheel, from which the energized fluid enters the spiral casing.

Fluid flows towards the rear plate in open and semi-open wheels, which completely destroys the pressure balance. As a result, an axial force or load occurs - pushing the wheel towards the suction hole.

This can be compensated for by installing stronger bearings or drilling holes in the wheel plate to equalize the pressures. But these are not effective methods.

Symmetrical mounting

A more effective solution is to place the shaft on bearings on both sides. This is called symmetrical design.

Shaft support is improved not only by the placement of bearings on both sides, but also by the ability to use symmetrical closed wheels with double suction.

Since there are the same high and low pressure zones on both sides of the wheel, this successfully eliminates loading forces due to the balance of pressures. This design also has another advantage. The suction and discharge ports are located parallel to each other on opposite sides of the pump, and the housing is axially divided.

By simply unscrewing the bolts and removing the cover, the service technician can access the rotating part of the pump inside without removing the entire pump from the system.

Due to the separate axial design, pumps with a symmetrical bearing arrangement are called split-casing pumps.

All of these, of course, are very good reasons to install such a pump in your mine right now. But there are some disadvantages. Because maintenance operations and sealing requirements are more complex for split casing pumps than for end suction pumps. They are also more expensive.

Varieties

There are a wide variety of piston pump designs available on the market. Classification is carried out according to the following criteria:

- The number of pistons that create pressure in the system.

- The number of discharge and suction cycles in one stroke.

On sale there is a double-acting piston pump, as well as a version with one, three, or several pistons. As previously noted, by increasing the number of moving elements, the possibility of pulsating flow movement is eliminated. As for the number of cycles, there are single-acting and double-acting models, as well as differential models.

Double sided piston pump

Double-acting piston pump design

Classification can also be carried out according to the following criteria:

- Power.

- Throughput or performance.

- Dimensions of the structure.

- Layout features.

A variety of companies produce piston pumps. Quality may depend on the type of materials used, the popularity of the brand and the purpose of a particular model.

Rules for the technical operation of piston pumps

When servicing piston pumps, you must follow the “Rules for servicing and caring for SVMs”, as well as the manufacturer’s instructions.

Before starting the pump it is necessary.

- 1) carry out a thorough external inspection, check for the presence of oils in the lubrication areas;

- 2) make sure that the containers are ready for pumping liquid, open the suction and discharge valves;

- 3) check the tightness of the packing of the oil seals;

- 4) before starting the pump, you must turn it one revolution.

The operation of the pump is monitored using instruments; in the event of non-operational noise and knocking, or increased vibration, the pump must be stopped and the malfunction eliminated.

Literature

Auxiliary mechanisms and ship systems. E. V. Kornilov, P. V. Boyko, E. I. Golofastov (2009)

Similar articles

- Vane pumps – single and double acting

- Marine Fist (Rotary) Pumps

- Rotary pumps - classification and application

- Marine piston pump parts

- Maintenance of marine piston pumps

- Adjusting the steam distribution of direct-acting pumps

- Designs of piston marine pumps

- Marine Pumps - Air Caps

- Main parameters of ship pumps

- Purpose and classification of ship pumps

4.5 Rating 4.50 (1 Vote)

Areas of application

The liquid pump can be used to solve a wide variety of problems. The created design is characterized by high versatility. However, the presence of a moving element and the use of sealing rings when creating a piston makes it impossible to use a piston pump for pumping large volumes of liquids.

Application of piston pump in gardening

Application of a pump for pumping water

Considering the scope of application, we note the following points:

- The materials used in manufacturing can withstand the effects of various chemicals. That is why piston pumps are used to work with various types of fuel, explosive mixtures and chemically aggressive environments.

- There are quite a large number of models on sale that can be used for work at home.

- In the food industry, the design is also used extremely often. This is due to the delicate effect on the pumped medium.

Piston pump in the oil industry

In the manufacture of a structure, a variety of materials can be used, which determine the scope of application.

Liquid pump

Purpose and design of the coolant pump

The liquid pump, or pump as it is called, creates forced circulation of liquid in the cooling system.

As a rule, single-stage centrifugal pumps are used in engine cooling systems. The liquid pump is usually driven from the crankshaft using a V-belt, toothed belt or spur gear.

The liquid pump consists of a housing, which is a volute, a drive shaft placed in the housing on bearings, an impeller, which is often integral with the drive shaft, as well as sealing elements - cuffs, seals, etc.

Advantages and disadvantages

A piston liquid pump is characterized by a fairly large number of advantages and disadvantages. The advantages include:

- Simplicity of design. As previously noted, similar piston pumps were manufactured several decades ago and their design has changed insignificantly.

- High reliability, which can be associated with the simplicity of the mechanism and the use of high-quality materials. Wear-resistant materials can withstand prolonged mechanical stress.

- Ability to work with various media. The wide range of applications is determined by the fact that the materials used do not react to the effects of various chemicals.

There are also several serious drawbacks. An example is low productivity. Such models are less suitable for pumping large amounts of liquid. In addition, the design is not suitable for long-term operation, since the active elements quickly wear out and lose their performance characteristics.

Design features and principle of operation

If we consider the design of a centrifugal pump in cross-section, then the following elements can be distinguished in the design of such equipment.

- The electric motor in the centrifugal pump device plays the role of a driving element. That part of the internal structure of the centrifugal pump where its drive motor is located is carefully sealed, which is necessary to protect the power unit from contact with the pumped liquid medium.

- The pump shaft transmits rotation from the electric motor to the impeller.

- The design of a centrifugal pump necessarily includes an impeller, on the outer cylindrical surface of which there are blades that move the pumped liquid medium through the internal chamber of the device.

- Bearing units ensure easy rotation of the shaft with the impeller fixed on it.

- Sealing elements protect the components of the internal structure of the hydraulic machine from contact with the pumped liquid medium.

- The pump body, as a rule, is made in the shape of a snail and is equipped with two pipes - suction and pressure.

Main parts of a centrifugal pump

The design diagram of a centrifugal pump, in addition to the above parts, may include a number of additional elements:

- a hose through which the pumped liquid medium enters the pressure line;

- a hose through which liquid enters the internal chamber of the device;

- a check valve that prevents the movement of an already pumped liquid medium in the opposite direction;

- a coarse filter that prevents solid inclusions contained in the liquid medium from entering the inside of the pump;

- a vacuum gauge, with the help of which the degree of rarefaction of air in the working chamber is monitored;

- a pressure gauge, through which you can control the pressure of the liquid flow created by pumping equipment;

- elements of shut-off valves that allow you to regulate the parameters of the flow of liquid medium entering and exiting the pump.

Design of the pumping part of centrifugal type equipment

The design and principle of operation of any centrifugal pumps are simple. So, the principle of operation of a centrifugal pump is as follows.

- The liquid medium entering the internal working chamber is captured by the impeller blades and begins to move with them.

- Under the influence of centrifugal force, the liquid medium is thrown towards the walls of the working chamber, where excess pressure is created.

- Being under excess pressure, the liquid medium is pushed out through the pressure pipe.

- At the moment when the liquid medium from the central part of the working chamber is thrown towards the walls, an air vacuum is created, which ensures the suction of a new portion of liquid through the inlet pipe.

Operating principle of a centrifugal pump

The principle of operation of the centrifugal pump described above applies to both surface and submersible models. The main function of centrifugal pumping equipment is performed by an impeller with blades. In accordance with the principle of operation of centrifugal pumps described above, such devices ensure the suction of the pumped liquid medium and its expulsion into the pressure line in a constant mode, which guarantees the stability of the parameters of the created flow.