10.16.2020 Author: VT-METALL

Issues discussed in the material:

- Features of argon welding technology

- Metals that can be welded by argon welding

- Main types of argon welding

- Procedure for performing work during argon welding

- Features of argon welding of various metals

What can be cooked using argon welding? Yes, almost everything! And this is good news, because it is sometimes not possible to connect parts from various non-ferrous metals and alloys using conventional methods.

On the other hand, argon welding technology is quite complex and has its own specifics. Therefore, before starting work, you need to study the features of this metalworking method as thoroughly as possible.

Features of argon welding technology

Before talking about argon-arc welding, you should understand what the process of joining workpieces itself is. The metal surfaces of the parts being welded are preheated due to exposure to flame. With this processing method, oxygen in the air reacts with the material, causing it to oxidize. It should be borne in mind that the oxidation of non-ferrous metals and alloy steels takes less time compared to ordinary metals.

Because of this, the quality of the joints decreases: the seams are filled with numerous bubbles, which leads to their loss of strength and destruction. Welding is not suitable for working with aluminum workpieces, since this alloy burns and breaks down when heated.

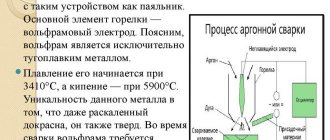

In the argon-arc welding process, a weld pool is used to protect parts from the effects of gases and impurities. The inert gas argon acts as a protective shell.

When welding, other inert gases can be used, for example, helium, which has similar characteristics. However, the disadvantages of helium are its high cost and higher consumption compared to argon.

Argon does not enter into chemical reactions with other elements, including processed metal workpieces. This gas weighs more than air, so it displaces it from the weld pool, preventing exposure to unnecessary gas impurities.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

Argon welding is carried out using consumable or non-consumable (for example, tungsten) electrodes. To determine the type and diameter of electrodes, special tables are used. The choice of one consumable or another depends on the materials being welded.

TIG Welding Equipment

- home

- Equipment

- welding equipment

- Argon arc welding

/

/

/

Argon arc welding (Tungsten Inert Gas welding) - welding with a non-consumable electrode in an inert gas environment (Argon).

The arc burns between the workpiece being welded and an electrode (usually tungsten). The electrode is located in the torch, through the nozzle of which shielding gas enters the welding zone. The filler material is supplied to the arc zone from the side and is not included in the electrical circuit. The main area of application of argon arc welding with a non-consumable electrode is connections made of alloy steels and non-ferrous metals. For small thicknesses, TIG welding can be performed without additives. The welding method ensures good quality and formation of welds, allows you to accurately maintain the depth of metal penetration, which is very important when welding thin metal.

Castolin Eutectic has developed a special line of CastoTig electrodes for wear-resistant surfacing, repair and downtime.

For questions regarding the selection of equipment for manual arc welding, please contact the specialists of our company.

CastoTIG 1611 DC

CastoTIG 1611 DC is a further development of proven Castolin inverter technology. Compact microprocessor-controlled power source designed specifically for DC TIG welding, can also be used for MMA process Details

CastoTIG 1702 AC/DC

CastoTIG 1702 AC/DC - full digital inverter control. The main advantage of digital control: the closed-loop concept in arc control, which controls the stability of the ignition and the entire welding process. Details

CastoTIG 1711 DC

CastoTIG 1611 DC - Full digital inverter control. The main advantage of digital control: the closed-loop concept in arc control, which controls the stability of the ignition and the entire welding process. Details

CastoTIG 2201 DC

CastoTIG 2201 DC - Full digital inverter control. The main advantage of digital control: the closed-loop concept in arc control, which controls the stability of the ignition and the entire welding process. Details

Welding torches for the TIG process

Welding torches for the TIG process for TIG welding Details

CastoTIG 3011 DC and CastoTIG 3012 AC/DC

After many years of close collaboration between the research department and technical specialists, Castolin Eutectic presents a new 300 Amp TIG welding power source, fully digitally controlled and made with the latest technology. Details

CastoTIG 2202 AC/DC

CastoTIG 2202 AC/DC - Full digital inverter control. The main advantage of digital control: the closed-loop concept in arc control, which controls the stability of the ignition and the entire welding process. Weighing just 17 kg, CastoTIG devices are much lighter, more powerful and easier to use than other alternatives. All this makes the CastoTIG model an ideal choice for welding on-site repair work, installation, etc. Details

Cooling units for TIG welding

Call us or send a request by email [email protected] , in the subject line indicate “Cooling 2200 cooling unit / Cooling 3010 cooling unit”, our engineers have welding equipment in stock and will send a commercial proposal indicating the cost and delivery time. Details

CastoTIG 1801 DC and CastoTIG 1802 AC/DC

CastoTIG 1801 DC/1802 AC/DC power sources are designed for mobile use both in field work and in production environments. Details

CastoTIG 2301 DC and CastoTIG 2302 AC/DC

CastoTIG 2301 DC/ 2302 AC/DC power sources are designed for mobile use both in field work and in production environments. Details

CastoTIG 2801 DC

CastoTIG 2801 current sources from Castolin Eutectic offer qualitatively new solutions in TIG welding of ferrous and stainless steels, nickel-based alloys, titanium, copper and other metals. Details

CastoTIG 2802 AC/DC – 4502 AC/DC

CastoTIG 2802/4502 AC/DC power sources from Castolin Eutectic offer qualitatively new solutions in TIG welding of ferrous and stainless steels, nickel-based alloys, titanium, copper and other metals. Details

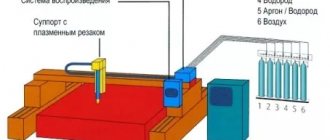

"Plasmacenter" offers

- services for size restoration and application of functional coatings;

- supply of equipment and materials for the processes of welding, soldering, surfacing, spraying, deposition, additive technologies (for example, flame, plasma, high-speed and detonation spraying, plasma surfacing, electric spark alloying, powder dispensers, control devices);

- conducting R&D in the field of surface engineering, coating tribology, plasma processing methods, selection of optimal coatings and methods of their application;

- training, consulting in the field of surfacing, sputtering, hardening, modification, hardening.

Contact us by phone: +7 (812) 679-46-74, +7 (921) 973-46-74, or write to us by email.

Our managers will tell you in detail about the technologies we have for coating, hardening, restoring, imparting surface properties, as well as the cost of the company’s services.

Metals that can be welded by argon welding

So, what can be cooked using argon welding? Most often it is used to work with materials that contain aluminum or stainless steel. This technology is preferred by employees of car service stations. The use of argon welding allows you to extend the life of car parts.

Argon welding can be used to weld individual transmission elements, radiators, air conditioning pipes and other parts made of aluminum alloys.

The technical features of automotive parts do not allow the use of other processing methods, for example, plasma spraying or soldering.

You can use argon welding to weld parts made of duralumin, titanium, cast iron, copper, silumin, and other non-ferrous and ferrous metals. Since materials have their own characteristics, the professionalism and experience of a welder familiar with the chemical reactions of metals when heated helps to perform high-quality work and obtain a reliable welded joint.

Also, using argon-arc welding, they create unique forged products (gates, fences, furniture, chandeliers, etc.). Due to the large number of small elements of the finished product, its finishing grinding is difficult. The technology used optimizes the manufacturing process, and finished parts do not require further processing.

To obtain high-quality welded joints, in addition to argon, it is necessary to use additives. Thanks to their experience, welders can select the optimal consumables for faster and more professional work.

Main types of argon welding

The choice of welding type depends on the metal being processed. Manual argon welding using stick electrodes has the following features:

- obtaining a thin, neat weld;

- high speed metal processing;

- relatively low operating temperature;

- no need for additives.

Manual or automatic argon arc welding using piece tungsten electrodes and filler wire is widely used in industry. This technology is more complex and time-consuming, but it has a number of advantages:

- the use of automatic equipment significantly increases labor productivity compared to manual methods;

- can be used for argon welding of alloy and carbon steel workpieces;

- The welding seam is of high quality.

The choice of one or another welding technology depends not only on the available equipment, but also on the material from which the workpieces are made. In most cases, manual and automatic or semi-automatic welding can be used to weld similar metals.

For argon welding, it is preferable to use equipment with direct and alternating current. The high cost of the equipment is compensated by the possibility of using it to work with almost any metal.

Filler material supply

During TIG welding, special attention should be paid to melting the edges and creating the weld seam. This problem can be solved in several ways:

- due to the heat provided by the welding arc;

- through the use of filler rods.

The nuances of working with the additive

In this case, an important role is played by the technique of supplying filler material to the welding zone, since this directly affects how wide the seam will be and how accurately it will be created.

- When applying the additive, it is necessary to do this without sudden movements, as otherwise this may lead to the formation of splashes. To avoid such unpleasant phenomena, it is desirable that the filler material is introduced evenly in the form of smooth and slow movements obliquely relative to the surface being welded along the entire length of the weld.

- The additive must be fed in such a way that it comes from the front of the welding torch.

- Particular attention must be paid to ensuring that the filler wire is always in the gas protection zone.

Naturally, novice welders do not always succeed the first time. Therefore, it will take a lot of practice to achieve the desired result the first time. Considerable benefit in welding with this method can come from familiarizing yourself with the relevant video materials, from which you can learn how to properly perform argon welding, so that you can then use the acquired knowledge in practice, following the recommendations received while watching such video instructions.

Procedure for performing work during argon welding

Argon welding with non-consumable tungsten electrodes can be used to weld parts made of stainless steel and non-ferrous metals (aluminium, titanium, magnesium).

The electrode is placed in the current supply collet of the torch with a ceramic nozzle that directs inert gas into the area to be welded. The device has a water cooling system. When choosing the diameter of the electrode, it is necessary to be guided by the required current strength, depending on the thickness of the workpiece. Since no splashes are generated during the welding process, the torch is closed with a mesh filter, which evenly distributes the argon flow.

Features of argon welding of various metals

So, using argon welding you can weld various metals, the main thing is to know and take into account their characteristics, since without this it is impossible to obtain a high-quality welded joint.

- Stainless steel.

Stainless steel products are quite difficult to process. A common problem is cracking and diverging welds. To avoid this, argon arc welding is used to connect parts. When working with stainless steel, you need to remember some nuances:

- the additive and non-consumable electrode move exclusively along and not across the weld;

- will improve the quality of the connection, but at the same time increase gas consumption by blowing the welding area from the front and back sides;

- the additive must be located in the zone of action of the protective gas;

- the tungsten rod should not touch the surface of the workpieces being connected, including when the arc is activated (this is done using special plates).

After finishing work on stainless steel products, the gas supply is stopped after 10-15 seconds to allow the seam to cool and prevent oxidation.

You can weld stainless steel pipes using argon welding. The processing itself is similar to working with sheet products, but the welding joint must be blown with gas from the outside and inside.

Airflow from the outside does not raise any questions, but in order to supply gas from the inside, you should:

- close one of the pipes to be welded with a plug;

- hide the joint with electrical tape;

- slowly let argon into the second pipe and close it;

- remove the electrical tape and continue welding in the same way as when working with other sheet products.

- Aluminum.

What can be cooked using argon welding? It is this technology that allows you to connect aluminum products without any problems. The problematic nature of welding this metal is due to its properties: upon contact with air, it enters into a chemical reaction with oxygen, as a result of which the surface is immediately covered with an oxide film. After mechanical removal of the film, it reappears after a short time.

Aluminum oxide formed on the surface of the part is refractory; it can be destroyed by alternating current or current with reverse polarity.

In addition to creating a protective environment, the use of argon in this case destroys the oxide film. When welding parts made of thin sheet steel, about 6 l/min of inert gas is consumed, and when welding parts made of thick sheet steel, about 15 l/min.

Regardless of the welding technology used, it is important to thoroughly clean the workpiece beforehand. The cleaning sequence will be as follows:

- degrease the surfaces of the parts to be joined using a solvent;

- remove the oxide film mechanically or chemically;

- dry the clean surface.

After such preparation, the quality of the weld will be much higher.

When using helium for welding, constant current equipment is required. The disadvantages of the technology include:

- higher cost of helium compared to argon;

- increased consumption of inert gas;

- Technically, working with helium is more difficult than working with argon.

- Copper.

The difference between copper and other non-ferrous metals lies in its chemical properties - the metal is more resistant to aggressive environments. When working with it, professional welders use a mixture of argon and helium, consumable or non-consumable tungsten electrodes, as well as direct current equipment.

Technology

A durable ceramic nozzle is inserted into the burner body. It contains a clamping collet for fixing a non-consumable tungsten electrode (diameter from 0.5 to 8.0 mm). The contact end is sharpened to make it easier to work with. The part of the electrode protruding from the other side is covered with a rear cap.

The electrical circuit is simple. When welding with direct current, straight polarity is usually used. (Variable is used for aluminum). The minus is connected to the electrode, the plus to the sheet of metal. This is due to the fact that it is necessary to heat the tungsten rod less, and the material being joined as much as possible, since heat is distributed approximately in the proportion of 3: 7. The voltage range is from 10 to 30V, the current is from 5 to 600A.

Since the electrode and the material being welded are energized, an electric arc is formed between them, sufficient to melt the edges of the metal and filler wire and form a weld pool. The essence of the process is precisely this - after cooling, the edges with the additive form a continuous seam, firmly connecting the parts of the material.

With manual technology, the welder holds the torch with one hand, tilting it back 10-15 degrees to the vertical, and with the other feeds the wire into the work area. The end of the electrode should be close to the metal (1.5-3.0 mm), but not touching it. To start working, press the button on the burner - the electricity will turn on and gas will flow.

During operation, an inert gas is supplied to the weld pool, usually argon (flow rate from 5 to 20 l/min). Since it is heavier than air, it immediately displaces oxygen from the working area, as a result of which the metal being joined does not burn, but only melts. In addition, the formation of oxides that reduce the quality of the seam is eliminated.

Since argon has a high ionization potential, the arc does not ignite well. Plus, the moment you touch the sheet, the sharpened end of the electrode melts and becomes dirty. To simplify ignition, an oscillator is connected in parallel to the circuit. It delivers a stream of RF pulses to the electrode. Thanks to them, the degree of ionization in the contact zone increases significantly, and the arc ignites much easier.

To improve the quality of the seam, make it more monolithic and less porous, 3-5% oxygen is added to argon. This is no longer possible, otherwise the metal will start to burn. And in this case, the harmful impurities that got into the weld pool only burn out.