Calcination of electrodes

Calcination of filler materials is considered one of the stages of heat treatment, which is carried out to reduce the liquid content in their outer coating.

Excessive moisture content can cause poor ignition of the electrode, sticking, or shedding of the layer. Because of this, the quality of the welding process deteriorates. Therefore, before welding, it is necessary to check the available filler materials with their preliminary preparation. Basically, the processes of calcination and drying of welded electrodes are similar, but during drying, not such high temperatures are used, and the procedure is performed with increasing heating. In some cases, the electrode is dried before calcination (in accordance with technological requirements).

It should be noted the main cases when calcination is needed:

- when placing electrodes in high humidity conditions;

- after long storage;

- if liquid gets on them or is detected during the welding process;

- after opening a new package.

It should be noted that calcination of filler materials must be carried out before welding; it helps to achieve high results.

However, you should not carry out this procedure often (more than 2 times), as there is a danger that the coating will lag behind the main rod.

It is necessary to calculate the required volume of electrodes for welding and send them for drying so that after completing the procedure there is a minimum number of them left. The next time you weld, use re-dried electrodes first.

Drying electrodes

The need to dry the filler material may arise to increase the temperature of the electrodes before welding. Not all brands can be used without preheating. The reason for this is the large difference between temperatures, which can be harmful to the weld pool and the formation of a poor-quality seam. Drying is also necessary to create a tight connection under pressure. Then the electrodes are gradually heated so that the moisture evaporates from them or it does not boil when limescale appears.

Electrode drying oven

Calcination and drying of welded electrodes can be carried out in several options, based on the desired mode and the equipment used. Specialized devices are used in production:

1. electric calcination furnaces

with additional drying options. Modern modifications have a microprocessor controller that facilitates programming of the entire welding process. The maximum temperature limit is 400°C. Taking into account gradual regulation, the load level is up to 160 kg, and the maximum power level is 8.5 kW (for some models it is 3 kW when connected to a 3-phase 380 V network). These furnaces provide stationary operation and a high level of thermal insulation. Thanks to the presence of thermal screens, uniform heating of the electrodes occurs;

2. electric oven with thermometer

with an average operating range of 100-400°C. Such electric furnaces are compact in size, so they can be transported independently. The operation of the devices is based on the use of heating elements with automatic control. The stoves can be connected to a 220 Volt network. Their power depends on the chosen model, varies between 1-3 kW, the maximum number of loaded electrodes can be 50 kg;

3. thermal canisters for drying

. The equipment is a sealed container with thermal insulation, which is used for storing additive raw materials. The compact parameters of thermal canisters allow the welder to easily install them at the workplace. The main difference between the equipment is the ability to heat filler materials from transformer energy or from a 220 Volt network. Their maximum load level is 10 kg;

4. thermos pencil cases are similar to thermopencil cases

, but they are able to maintain internal temperature without heating. The equipment typically takes a long time to cool down.

Temperature and calcination mode of welding electrodes

To obtain high-quality results, you need to know about the process of calcining electrodes. According to experts, the duration of the procedure should not exceed 2 hours. When performing welding work, you need to use dry material, so the electrodes are first placed in a pencil case, where the specified temperature conditions are maintained.

Preparing metal equipment and electrodes for welding

The importance of calcining materials before performing welding work has been proven by many professionals. The lack of heat treatment affects the quality both during welding and after.

Poor ignition and sticking of the rod, shedding of the coating, unreliability and defectiveness of the welded joint, unsatisfactory appearance of the finished product (in the photo on the right: bubbly slag from the wet coating) - and these are just the main problems.

Heat or dry - what's the difference?

The calcination and drying procedures are similar in almost all respects. However, there are some minor differences. Calcination is carried out strictly according to the instructions presented on the packaging (as in the photo above). The purpose of drying is to remove moisture. Therefore, for this procedure it is not so important to strictly and seriously follow the recommendations.

Thus, in some cases, “folk” remedies can be used to carry out heat treatment. But to do this, you need to have information on how to dry electrodes at home. Information should be obtained from reliable sources and rely only on the opinions of experts. Basic explanations on how to dry electrodes at home are given below.

Features of the process implementation

All the secrets of preparing electrodes for welding lie in the correct calcination procedure. Typically the process is performed in several steps:

- Consumables are placed inside the device or in special cases. The machine or oven closes.

- The temperature is being adjusted . Usually the characteristic is written directly on the packaging, set by the manufacturer;

- Start the oven and wait for the required interval. The consumable must cool down, after which it can be taken out for direct use.

Carrying out the procedure obliges the specialist to comply with safety requirements. The task must be completed in a special uniform and with the use of other personal protective equipment.

Ways to dry and calcinate electrodes at home

The ingenuity of some welding specialists has led to the emergence of several effective methods for processing materials without the use of special equipment. We also recommend that you familiarize yourself with this material on how to calcinate.

The most popular and simple method is to improve welding rods by calcination in the oven .

This procedure includes several steps, after familiarization with which any novice welder will know how to calcinate electrodes in the oven:

- An electric is more suitable for drying than a gas oven. The gas contains a small amount of water , and heating cannot be done over an open fire ;

- you should preheat the oven to 200-250 degrees (or to the temperature written on the package);

- place the welding rods inside;

- close the door tightly;

- wait 1.5-2 hours;

- Turn off the device and allow it and the materials to cool gradually.

If a master needs to know how to dry electrodes at home, then he needs to familiarize himself with another “folk” method - heating the materials with a hair dryer .

To carry out this procedure, the welder will need a tool capable of producing temperatures up to 150 degrees, and a container (pipe) for loading materials. The electrodes are loaded into a pipe, the diameter of which must match the diameter of the device.

Hot air is directed into the container and the process continues as long as necessary for specific materials. On some hair dryer models, you can set the desired temperature.

If desired, you can install both a thermometer and a timer on the pipe to turn the hair dryer on and off.

True, this way we are already approaching the creation of a homemade stove.

Some skilled craftsmen build a furnace for calcining electrodes with their own hands:

- To do this, it is necessary to weld a frame from a profile pipe;

- the frame is “ sheathed ” on the outside with galvanized steel sheet, on the inside – with glass-magnesium sheet;

- Seal seams and joints with sealant;

- fill the space between the outer and inner layers with mineral wool, which will serve as a thermal insulation material;

- cover the LSU layer with mirror stainless steel;

- To prevent heat loss, it is necessary to place a silicone seal ;

- To load materials, you need to screw the corners inside the device and weld the grates .

- the oven for drying electrodes must also be equipped with a temperature sensor .

Self-built furnace for calcining electrodes

This scheme may allow some changes.

Find out more about calcining electrodes

If a novice specialist has the desire and opportunity to continue to improve his skills and seriously engage in welding work, then he needs to think about purchasing professional equipment for calcining, drying and storing electrical conductors: an oven or a thermal pencil case.

Equipment for calcining electrodes

There are several types of equipment designed for heat treatment of electrodes and preparing them for work. Let's start with the basics - the oven.

The calcination oven is a metal box with trays for rods. To maintain a constant temperature in it, the walls are lined with special materials that retain heat. Thanks to this, the electrodes will be heated evenly during the entire calcination time. Depending on your needs, ovens can reach different temperatures. The most popular values are from 50°C to 650°C.

You can see what such a stove looks like in this video:

Another “gadget” that is useful for welders is a pencil case. It does not heat the electrodes, but only maintains them in a dry and heated state. Its peculiarity is that it is completely insulated and sealed. Using a pencil case, you can be completely sure that the electrodes will not become damp while you work.

There is another type of such device - a thermal pencil case. It allows you not only to maintain the temperature of the rods, but can also warm them up. Thermostat and built-in heating allow you to prepare consumables right on the job site.

Thermal cases look like small boxes with a door. They weigh about 3 kg and can produce temperatures up to 120°C.

Another type of equipment is cabinets. They have functions similar to thermal cases. The cabinet body is insulated and retains heat. Depending on the model, cabinets are equipped with a thermostat and thermometer.

Cabinets are used in large industries where it is necessary to simultaneously prepare a large number of rods.

Rods for welding can be subjected to heat treatment, either using special industrial equipment or in a home workshop.

For example, ovens are used for calcination. Manufacturers offer a wide range of such equipment. When choosing a specific one, you should take into account the technical characteristics of the device:

- furnace power;

- the weight of the rods that can be loaded into the oven at one time;

- the maximum voltage required for the operation of the equipment;

- oven weight;

- its dimensions;

- availability of additional functions.

The possibility of using it for calcination of cabinets is also possible. Their peculiarity is that the rods in them can not only be subjected to heat treatment, but also dried, and also stored for a long time. When purchasing such cabinets, you must first familiarize yourself with the availability of additional functions.

There are several variants of canisters for heat treatment of welding rods (drying). For example:

- Thermal cases.

- Thermoses.

Types of equipment

Drying and calcination of welding electrodes can be done in several ways, depending on the required mode and available equipment. For the industrial sector, specialized types of equipment are used, such as:

- An electric oven equipped with a thermometer. The average operating range of such equipment is 100-400 degrees Celsius. These are fairly compact types of equipment, so you can even carry them yourself. The operating principle is based on heating elements that are controlled automatically. Such a stove can be connected to a standard 220 V network. The power depends on the model and ranges from 1 to 3 kW. The maximum electrode load is up to 50 kg.

- Electric ovens for calcination, which have additional drying functions. Modern models have a microprocessor controller that helps program the entire process. The equipment has high thermal insulation and operates in stationary mode. Within the working volume, the electrodes are heated evenly due to the presence of heat shields. The maximum temperature reaches 400 degrees Celsius, taking into account smooth adjustment, the load goes up to 160 kg, and the maximum power is 8.5 kW, although on some models this figure is 3 kW. Here you will already need a three-phase 380 V network for connection.

- Thermal cases - this equipment is used for drying. This is a heat-insulated, sealed container that can be used to store consumables. Due to its compactness, it can be located at the welder’s workplace. Its main feature is the ability to heat the electrodes directly from the energy of the transformer, or with a standard connection to a 220 V network. The maximum load of thermal cases is 10 kg.

- Thermos cases are in many ways reminiscent of thermal cases, but they can maintain the temperature inside without heating. They are characterized by long cooling, so the temperature from 150 degrees Celsius to 80 will drop within 4 hours, and to 18 degrees – 10 hours.

Electric furnace for calcining welding electrodes

Features of drying electrodes at home

If you decide to dry the electrodes, most likely you suspect moisture ingress. Therefore, the main purpose of drying is to reduce the percentage of moisture on the electrode surface. You don't have to be an expert to dry a conductor. Pay attention to the information written on the packaging. The manufacturer must indicate the drying conditions for the product.

If you do not have a special thermal case designed for drying the electrode, use a heating object that you have at home. For example, an electric oven will do. It must be closed. Drying the electrode over an open fire is prohibited by safety regulations.

If you ignore calcination in cases where it is absolutely necessary, this can lead to poor quality work, the creation of an incorrect seam, increased conductor consumption, and unsatisfactory results.

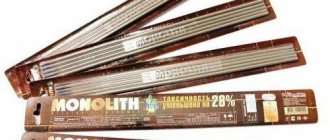

MEZ electrodes

All technological parameters of heat treatment of electrode products: temperature conditions, holding time, etc., are indicated by the manufacturer on the packaging and in the accompanying documentation. The products of the Magnitogorsk Electrode Plant are no exception. You will find this and other data on the MEZ branded packaging, as well as in the documents.

The high quality of electrodes of this brand is confirmed by certificates of the Russian river and sea registers, as well as GOST and NAKS certificates.

Design and functionality

The case for calcining electrodes has a rectangular shape. The dimensions depend on the volume of the electrodes to be accommodated; for household devices it is approximately 150x170x600 mm. The pencil case consists of:

- frame,

- camera,

- a heating element,

- electrical insulation,

- thermal insulation,

- front cover for loading the camera,

- back cover and heating control unit,

- wires.

Before drying the calcined electrodes, they are placed in the chamber and tightly closed with a lid. Then, on the reverse side, the wires are connected to the power source. The heating element is turned on - a spiral wrapping around the outside of the chamber.

The chamber is first covered with insulation, only then the spiral is laid so that the current does not flow when touching the electrodes and the inner surface of the thermal canister.

The heating element raises the temperature inside the device to 110⁰C. This is enough for the moisture to evaporate. After 2 hours you can start working.

In a home workshop, with a small amount of welding work, they use covers for electrodes that have a plastic sealed housing . They retain the heat of hot objects placed inside and do not let air through. The coated rods cool for several hours, remaining hermetically sealed.

Features of flux calcination, equipment for its implementation

Liquid can be removed from the flux by calcination at 260-400 °C. The entire volume of flux must reach the specified temperature.

This procedure should last at least 2 hours.

To calcinate ceramic fluxes, the temperature should be 300°± 25°C, fused - 200°± 50°C.

You cannot calcinate flux that is in a package or barrel. If after the procedure the flux is not used immediately, it must be stored at a temperature of 130°± 25°C.

For stationary piercing of fluxes, a large container with a digital thermostat SDF 50 Stationary Drying Flux (50 kg), SDF 50 Stationary Drying Flux (250 kg) is used. Each of them has a hatch at the bottom for unloading flux. The calcination temperature is 0-400°C.

SDF 50 Stationary Drying Flux (50 kg)

SDF are large containers for calcination and storage of flux.

- Digital thermostat with a wide range of storage temperature adjustments.

- Capacity – 50 kg

- Calcination temperature range 0-400°C

- After calcination, the temperature automatically drops to the recommended preset storage temperature of 130°C

- There is a hatch at the bottom for unloading flux

SDF 50 Stationary Drying Flux (250 kg)

SDF are large containers for calcination and storage of flux.

- Digital thermostat with a wide range of storage temperature adjustments.

- Capacity – 250 kg

- Calcination temperature range 0-400°C

- After calcination, the temperature automatically drops to the recommended preset storage temperature of 130°C

- There is a hatch at the bottom for unloading flux

Calcination of electrodes and fluxes is a mandatory procedure necessary to obtain a quality product.

Electrode calcination log

The calcination log is an official regulatory document that records all processes of preparing welding materials.

The information is presented in the form of a table, which includes several sections: calcination date; serial number of calcination; type of electrodes; mass of calcined material, kg; calcination temperature; time of processing; responsible for calcination; person performing control. The journal is kept in one copy, laced, numbered, sealed and certified by the signature of the person responsible for office work at the facility.

The magazine can be purchased at a printing house for a fee or you can view a sample document on the Internet.

Calcination instructions

Different electrodes require different temperatures and calcination times. These parameters are indicated on the packages. Therefore, before starting work, you must read the manufacturer's instructions. Foreign factories do not always write how to warm up the rods. You'll have to go to the official website and find this information.

Not all electrodes need to be calcined. Thus, cellulose-coated rods are produced in metal cans and there is no need to warm them up before use.

In practice, calcination looks very simple. You need to heat the oven to the desired temperature and place the electrodes in it for a certain time, after which they will be ready for use. You can cook them right away, or you can move them into a thermal case to take with you to the site.

For example, Uoni 13/55 electrodes are calcined at a temperature of about 270°C for 1 hour.

Drying instructions

Before drying electrodes for welding, they need to be weighed. After all, the oven load, on average, is a minimum of 10 kg, and a maximum of 40 kg. After this, the following operations should be carried out:

- Load the electrodes inside;

- Close the lid tightly;

- Adjust the temperature according to the parameters specified for drying;

- Detect or set the time that this process should last;

- Withstand the entire period;

- Turn off and let the oven cool down so that there is no sudden temperature change.

"Note! It’s enough for everything to cool down to 100-150 degrees Celsius.”

Calcination of flux

Before using welding fluxes, they must contain the least amount of moisture. If the package is opened or damaged, the moisture content of the flux may increase. The reason for this is condensation. Taking into account the degree of increased humidity of the flux, the quality of the weld seams will deteriorate with the following consequences:

- Cracks will begin to appear.

- Internal porosity will appear.

- The fluidity of the flux will increase.

- The appearance of the weld seam will deteriorate, and the process of slag separation will deteriorate.

Calcination of electrodes

furnace for calcining electrodes

The most popular and in demand are Uoni 13/55 electrodes. As an example, we will consider the technology of their calcination. Calcination of welding electrodes Uoni 13 55 must be carried out before their use. This way you can ensure stable combustion of the welding arc and high quality of the seam formed. The temperature at which the procedure is performed should be 250-300°C, time – 1 hour. It is best to calcinate the electrodes in a special oven, placing them in special boxes.

Summarizing all of the above, it is clear that drying electrodes for welding is not a complicated procedure, but it is mandatory. It is best to use a furnace for calcining electrodes. Knowing how to dry electrodes at home will make welding work much easier.

How to properly store electrodes?

If welding electrodes are stored incorrectly, then the work will be impossible. The arc will become unstable and the connections will be poor. To avoid such problems, you must follow some rules.

First of all, you need to understand the structure of welding electrodes. It consists of a rod and a covering. Regardless of the type of coating, it is important to protect them from moisture.

The rod is made of a special alloy with which nothing can happen. In this regard, the essence of storing electrodes comes down to protecting the coating.

Design of a pencil case for drying electrodes.

It is better to store materials for welding in a dry, well-ventilated area. Any possibility of moisture or water getting on the surface of the rod must be completely eliminated. Otherwise, the coating will degrade and ultimately it will not be possible to work with such an electrode.

Storage should be carried out in a room where the temperature does not drop below 15°C. Of course, any mechanical damage and contamination will also render the electrodes unusable.

They must be packaged in boxes, which can be made of metal, plastic or cardboard. In the latter case, for greater reliability, the box should be additionally wrapped with plastic film, for example, cling film.

In case of long-term storage or presence of moisture, it is necessary to calcinate the electrodes. In this case, do not forget that the heat treatment parameters for each type of rod are different.

During transportation, the same requirements apply to packages as for storage. However, during transportation, care should be taken to mitigate possible impacts that could damage the electrode coating.

Welding materials

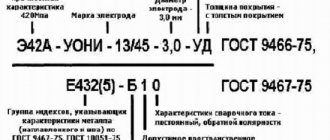

Replacing electrodes that provide higher strength of the weld metal with electrodes that guarantee lower strength of this metal is not allowed without agreement with the design organization. However, in all cases, it is impossible to replace electrodes with calcium fluoride coatings (basic type) E42A-F—E55-F with electrodes with acidic ore or rutile coatings (acid type) E42-T—E46-T. Electrodes with calcium fluoride coatings of types E42A-F—E55-F can only be used for welding with an extremely short arc. During long-term (more than 3 months) storage in a warehouse or storage for more than 5 days at the work site, the electrodes should be calcined in an electrical cabinet even in the absence of visually noticeable moisture in the coating. Calcination of electrodes in fiery furnaces is not allowed.

Laying electrodes of type E42-T should be done at a temperature of 180°C for 1 hour, and electrodes of type E42A-F—E55-F at a temperature of 400-450°C - for 1-2 hours.

If moisture in the coating or high porosity of the seams is detected, such calcination of the electrodes is mandatory, regardless of the shelf life of the electrodes.

When stored at the work site, electrodes must be kept in waterproof, lockable boxes, which should not remain at the workplace after the end of the work shift.

The electrodes should be calcined in an electric oven. It is recommended to manufacture electric furnaces with a power of about 10 kW for a voltage of up to 36 V.

Electrodes with a diameter of up to 4 mm are recommended for use for welding in a ceiling position, and with a diameter of up to 5 mm for welding in a vertical position.

For semi-automatic submerged arc welding, steel welding wire should be used in accordance with GOST:

for connecting vertical rods with diameters of 36 and 40 mm from class A-II steel - wire Sv-08 and Sv-08A with a diameter of 2.5 mm or wire Sv-08GA with a diameter of 2 mm;

for connecting horizontal rods with diameters of 36 and 40 mm made of class A-III steel - Sv-08GA wire with a diameter of 2 mm;

in other cases not specified above - wire Sv-08 or Sv-08A with a diameter of 2 and 2.5 mm (when using graphite molds, the use of welding wire with a diameter of 2.5 mm is not allowed).

Note. In the absence of wire grades Sv-08 and Sv-08A, it is allowed to use welding wire Sv-08GA with a diameter of 2 mm when welding rods made of steel classes A-II and A-III.

For semi-automatic arc welding with multilayer seams on a steel clamp-overlay of butt joints of reinforcing bars of classes AI and A-III, bare wire of the EP-245 grade should be used.

The surface of the welding wire must be free from burrs, and the wire itself must be free from sharp fractures or kinks; a thin layer of oxide film that has not turned into rust is allowed.

The wire should be wound on spools; It is recommended to perform such winding and mechanical cleaning of the wire on special winding machines.

Coils of wire with a clean surface can be used without rewinding onto spools. In this case, you should use an unwinding drum and install felt on the feed mechanism to remove lubricant from the wire.

For semi-automatic bath arc welding of connections of reinforcing bars made of steel of classes AI-A-III, fluxes of grades AN-8, AN-14, AN-22, FN-7 or AN-348A should be used.

For automatic welding of T-joints of embedded parts elements, AN-348A flux should be used.