Are you planning to use a power tool while doing home repairs, but don’t know how to work with an angle grinder correctly so as not to injure yourself? Agree, it would be unwise to unknowingly break a disc in the first minutes or, even worse, injure yourself.

Or have you just decided to acquire a power tool and are studying the rules of its operation in advance? In this case, pay attention to the products of famous manufacturers with a good reputation, who sell really high-quality devices of excellent assembly with a long-term guarantee.

After all, it is safer to work with a reliable tool. One of the excellent options is products from the Bosch, DeWalt, Makita brands, as well as Metabo angle grinders sold in the Moyo network in a wide range. We will look at the operating rules and main mistakes when working with this type of power tool in detail in our article.

The material, in addition to recommendations for using an angle grinder, contains visual photos of working with an angle grinder and useful video tips from experienced users. Having familiarized yourself with the latest and observing the rules of personal safety, you will be able to cope with the chiselling of a concrete wall, cutting tiles or bricks on your own, without involving specialists for these tasks.

Device Features

The simple design of an angle grinder does not prevent it from being one of the most popular and necessary tools in the household. The principle of operation is an electric motor that drives the shaft through an angular gearbox, onto which a special disk is attached.

The main advantage of this technique is its versatility, because when using various discs, cutting, polishing or grinding off excess material is performed. There are discs designed for working with wood, but they cannot be used for metal. Discs with an abrasive base of different grain sizes are used as polishing consumables.

Bulgarians are classified into several types:

- Professional;

- Low, medium and high power;

- Without handles;

- Household;

- With one or two handles.

Low-power equipment is powered from a simple household socket of 220 V, but powerful angle grinders are connected to a network with a voltage of 380 V. Regardless of the power, all machines perform manipulations such as cutting, grinding and polishing wooden, concrete, metal and plastic materials.

The only difference is the operating time. Powerful equipment can work longer without overheating, but household equipment must be given a rest. If necessary, an angle grinder serves as the basis for creating a small machine. To do this, the grinder is fixed permanently and parts, drills, cutters are turned and knives are sharpened.

The grinder is an indispensable equipment for construction and rescue work in auto repair shops and economic activities.

There are several reasons why an angle grinder is classified as a dangerous tool:

- Working with an angle grinder often takes place on an unstable surface, where it is impossible to find support for a stable position.

- Although protected, most of the rotating disk is not protected.

- Abrasive polishing discs often break during operation into medium and small pieces, which fly off in different directions at great speed.

Introductory part. Young fighter course

A grinder, also known as an angle grinder (angle grinder). Brief information for those who hold this capricious instrument in their hands for the first time.

1.1. Grinder device (angle grinder)

- On/off button

- Spindle stop button (spindle rotation is blocked when the tool is turned off when replacing abrasive discs)

- Lever. Rubberized as in the photo. An angle grinder produces noticeable vibrations during operation.

- Protective cover. Removing it is strictly prohibited!

- Air channels. Try not to overlap them with your palms so as not to overheat the angle grinder.

- Abrasive disc. In this case, grinding.

1.2. Actions with an angle grinder. What can you twist and change?

Some models provide the design ability to change

1.2.1. Handle position

1.2.2. Guard position

Very conveniently made by the Japanese (Kawasaki). In a couple of seconds you can rearrange without a key.

The click system also looks interesting, but I personally have not had to use it.

1.2.3. Speed adjustment

There are excellent angle grinders on sale with a speed controller. I use it myself and highly recommend it. Economic considerations are also useful here - the consumption of abrasive wheels will be 2-3 times lower.

1.2.4. Replacing the drive

We change the disk as follows:

- We de-energize the tool (you can simply unplug it from the socket)

- Press the spindle stop (see the grinder device above)

- Use a special wrench to unscrew the lock nut.

This not the most convenient option will be on your grinder by default. When you get tired of turning with a wrench, purchase a modernized nut with a spring-loaded base that clamps the disk. Chinese junk, pay once for AEG, BOSCH or Makita quality.

Terms of use

The main danger when working with technology lies in the principle of its use. To cut, the disc must be in contact with the surface of the material , while the master holds the grinder suspended , relying only on his own experience and attentiveness. One awkward movement and the disk breaks or the machine jerks when it comes into strong contact with the work surface. That is why when working with powerful units it is better to already have basic skills . For beginners, a household grinder with low power and a disc diameter of 115-125 mm is more suitable.

If you thoroughly understand the instructions for the safe use of angle grinders, then you don’t have to worry about your health. In terms of safety when working with an angle grinder, there are several important notes:

- During cutting, the grinder is held firmly with both hands, but not pressed into the surface of the working area;

- The master must stand firmly on his feet or knees. This will protect him from injury when jerking the tool;

- The power cable must be located at a safe distance from the cutting disc and the area where hot sparks reach;

- Movements around the work area are carried out with the device turned off;

- If the power goes out, the grinder should be de-energized;

- The thickness of the blank should not exceed the diameter of the cutting disc. Here it is important to calculate the grinding of the circle during operation.

Backlash

The most common and dangerous moment of working with an angle grinder is the occurrence of a kickback , which is characterized by an instant and very sharp throw of the tool towards the operator. The force of the impact can be so great that it is simply impossible to hold the grinder in your hands - this is especially dangerous if work is carried out at head level. Kickback injuries can be so severe that they are sometimes fatal.

The cause of kickback may be the use of a non-working (deformed or damaged) working disk and/or its jamming in the material. Very often, a kickback occurs at the final stage of cutting, when all that remains is to modify the last layer of material connecting the parts being cut. In this case, it is recommended not to complete the cut on the same side, but to complete it on the other.

Safety precautions for preventing the occurrence of a kickback or at least minimizing its consequences for humans contain several simple rules:

- It is unacceptable to use equipment not intended for an angle grinder:

- circle of larger diameter , since to install it you will have to remove the protective casing and during use the linear speed of the cutting edge will exceed;

- a saw blade that is completely unadapted to the speed of rotation of the angle grinder - a carbide tip flying off from its tooth at cosmic speed can become a fatal bullet for a careless craftsman.

- The operator must stand firmly with both feet on a firm, level surface to withstand the impact energy.

- Extreme care should be taken when handling sharp edges, edges of material and any corners . You must be prepared for the possible kickback of the angle grinder and move your body away from the intended location of the impact as a result of a reverse strike.

- If the working disc is jammed, the grinder should be turned off and the cutting disc should be removed from the cut..

Safety precautions and understanding of the principles of working with an angle grinder guarantee high-quality performance of assigned tasks without causing any injuries or harm to human health.

Precautionary measures

An angle grinder is a dangerous tool. When working with it, a number of conditions must be observed:

- Do not use the tool without safety glasses;

- Before starting cutting or polishing, check the suitability of the disc at idle speed;

- Clothing should cover your hands and protect from hot sparks;

- Do not remove the protective cover from the angle grinder;

- When cutting on a plane, the master and assistant should be on the side of the tool;

- The unit cuts material under its own weight, and excess load will lead to deformation or jerking;

- Working without a break leads to overheating of the equipment and fatigue of the master, who must hold the grinder firmly in his hands, observing the cutting angle;

- The workpiece to be processed must be firmly secured;

- You cannot grind parts with the side of a cutting disc, because there are specialized wheels for such work;

- Within the work area there is a master and his assistant. All other people move to a safe distance;

- The radius of the cutting wheel should correspond to 1/6 of the thickness of the workpiece.

Working with defective discs

A health hazard often comes from a deformed cutting disc. Even a minor defect at high speed reveals itself in unexpected ways. Chips, cracks, or the absence of a small piece of the disc lead to its loosening, which is why the grinder often simply flies out of your hands . Therefore, before starting cutting, it is better to pre-check the consumables for defects , and do this immediately before starting work, because damage could appear after a fall or external influence on the disk. Sometimes the plate can be stepped on, and the master simply will not notice it.

Despite numerous warnings that it is impossible to work with defective disks, situations arise when the technician simply did not visually see the defects. Such situations occur all the time and therefore it is necessary to follow a number of rules in order to protect your health as much as possible:

- Before each installation or start of cutting, it is necessary to check the consumables for defects;

- Work exclusively in personal protective equipment: gloves, goggles or a protective mask.

The grinder is most often suspended in the hands of the master and does not have a fulcrum, so the cutting or polishing process should be approached with extreme concentration and sobriety. People with an unbalanced psyche or poor health are prohibited from starting to work with an angle grinder.

Safety precautions when working with an angle grinder. How to work with an angle grinder correctly!!!

Twenty-five again, again I see how builders and finishers who have been working with construction tools for many years cannot handle them correctly: drill, cut with an angle grinder correctly, and even the safety precautions for working with an angle grinder are in distant echoes of the past, and besides, all the work It’s worth doing with glasses, no one knows anything!

I have already had the honor to present you with an article on how to properly drill and install grooves without dust using a grinder

, as well as equally interesting information about what could go wrong when working with an angle grinder. An important article on how to work with a hammer drill. And so let's get started:

How to work with an angle grinder correctly?

Before you start working with an angle grinder, you should initially assemble and equip it correctly. First of all, let's deal with the protection against the grinder. If you are left-handed, then the protection should be rearranged. When purchasing an angle grinder, all the protection is for the right hand, but the protection for the left hand is simply twisted:

– it’s worth unscrewing the clamping nut and twisting the protection so that when you start working with the grinder, holding it with your left hand, you can see the entire grinder disk, and not vice versa. We also attach protection under the right arm.

An important point when attaching the protection: – on the grinder it should be slightly inclined towards you so that the chips fly away from you and do not hit your hands! This rule for working with an angle grinder specifically relates to safety precautions when working with an angle grinder.

The second important nuance when assembling an angle grinder is to attach a key for clamping the disc to the electric cord for the angle grinder. The key for clamping the disc onto the grinder, for convenience and for safety, needs to be wrapped with electrical tape on the fourth part of the electric cord of the grinder, on the plug side. This will ensure convenient operation when changing grinder discs and the key will not get in the way. Now you can start working with the grinder.

The very first rule when working with an angle grinder, or with any tool, is to let the tool make the cut on its own, and in no case do not put any force on it. Your task is simply to adjust the stroke of the tool and sometimes lightly press on it, if there is a need for it. This nuance will preserve your instrument, even if it is the cheapest

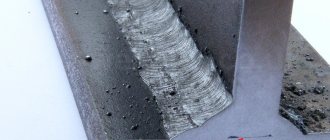

Bulgarian, safe and sound, and she will serve you well and for a long time. But in the photo on the right side of the article, you can clearly see how not to work with an angle grinder. The photo shows how shavings from cutting with an angle grinder fly onto the clothes and in the face of the person working with the angle grinder. When cutting sideways with an angle grinder, you need to hold the angle grinder with its protection towards you, and the visible cutting side away from you.

Safety precautions when working with an angle grinder.

Safety precautions when working with power tools

, and especially

with an angle grinder,

you must always observe!!! The first and indisputable safety rule when working with an angle grinder:

1) Protect your eyes by wearing safety glasses;

Safety precautions when working with an angle grinder include one more nuance:

2) Carry the cut away from you with the grinder, which will allow, in the event of a clamp on the disc, the grinder to fly out in front, and if you were pulling towards yourself, it will fly at your feet, especially if these are medium or large grinders.

3) It is also worth knowing that the grinder mode is no more than a meter and we do not stretch forward and do not climb under ourselves, trying to cut off more, after which we must 4) turn it off and start moving around, adjust the cord of the grinder there. It is this point in safety precautions when working with an angle grinder that is important because the worker will begin, at a reflex level, to correct or tighten or fold back the cord from the angle grinder, and the angle grinder itself will continue to work at this moment. And this is fraught with consequences:

– There were cases when the wire, with such a throw back, fell under a working grinder disk and cut their legs, maimed those standing nearby, and damaged the meter, which costs from 1500, due to a short circuit.

Just above we discussed the clamping key from the grinder, which needs to be tied near the fork of the grinder. Let me clarify this point. This is due to the fact that when you cut with an angle grinder on the floor, the key, wound in the middle or close to the handle of the angle grinder, clings to your leg during work and you, again, frantically begin to correct it, etc., etc., since he simply gets in the way.

So you and I have completed a course for young fighters in such a necessary topic as safety precautions when working with an angle grinder.

The principle of woodworking

The angle grinder was originally designed for polishing and sanding surfaces, and therefore it can easily cope with operations on wooden workpieces. At the same time, there are some nuances and rules of work that will not only protect the craftsman, but will also help him better cope with wood processing.

First, you should dwell on the types of nozzles, among which are:

- Sanding pads are a multi-layer compound disc where rubber and plastic alternate with foam rubber, sandpaper or wool flannel. The structure helps to extend the life of the wheel and polish the surface.

- Flap discs are designed for rough processing of wood at the initial stage. Sandpaper petals of different grain sizes are attached to the surface of the circle, which polish the surface, removing all imperfections.

- A wire brush is used to remove old paint from a wooden surface.

Operations involving polishing or sanding wood are considered relatively safe. During operation, the disc does not get stuck in the cut, there are no jerks, short circuits or deformations of the wheel.

Wood cutting

Only one type of cutting wheel is used to cut wood material. With its side teeth it resembles a circular saw blade, but they are not so long. The teeth help cut deeper into the material, but you need to cut the boards carefully, as the grinder may jerk. Boards about 40 mm thick are sawn off.

The use of circular discs instead of cutting wheels is strictly prohibited, because they are designed to operate at 3 thousand rpm. The grinder does not produce even half this speed. Accordingly, circular circles are deformed at best. The use of circular wheels can cause serious injury.

Polishing ceramic tiles

In the construction industry, the grinder occupies a leading place among tools. Using special discs and attachments, ceramic products are cut and polished, preparing them for installation. A diamond-coated grinder requires special consumables, because cutting ceramics with a regular cutting wheel will lead to breakage or cracks in the tiles.

Dry cutting discs for tiles are divided into segmented and solid . Both types do not require constant cooling - which is why they got their name.

Solid discs are cooled only after 1-2 minutes of operation by lowering the circle into cold water . The segmented type cools itself due to the slots , but they are not always suitable for cutting ceramic tiles due to the formation of chips on the surface of the material. A segmented or solid disc processes ceramic material and any natural stone . Sometimes, with high-quality work, it is possible to cut paving slabs with a household grinder without deformation or process the edge part of the cut.

Straight line cutting

Unlike cutting wood, ceramic is a brittle and demanding material that easily deforms under high loads. Therefore, the discs are pre-selected depending on the density of the stone. The speed must be higher than when processing low density materials.

It is most effective to cut ceramic tiles using circles with a diameter of 115 mm at a speed of about 6-8 thousand revolutions per minute. Not every household grinder produces such power, so you will have to find a tool with the necessary characteristics.

The procedure for working with the material is divided into several stages:

- The tiles are laid on a flat surface with a clamp attached and marked in the cutting area.

- Cutting begins gradually along the surface of the entire tile. First you need to make a rut with a depth of 1-1.5 mm, gradually increasing it.

- Move the grinder evenly and slowly while cutting. You cannot put pressure on the unit, because it itself goes deeper into the tile under its own weight.

- There is no point in completely cutting the material. Most often, they place a nail under the tile and simply press it to break it.

Processing metal with a grinder

Processing metal with a grinder is the most difficult. This is mainly due to the large number of hot sparks that appear when cutting this material. Manipulations are carried out only in fireproof protection. In addition, the work area should be cleared of objects that could ignite if struck by a spark.

Cutting metal products requires care, patience and basic skills. This will help keep the grinder suspended, which will prevent jerking and sucking of the disc into the hole.

When cutting metal products, a number of rules should be followed:

- All workpieces are securely fixed and free of rust.

- It is better to cool the metal before cutting.

- The disc can be pinched by the workpiece, so it is better to gradually increase the depth of the slot.

- There is no need to press on the grinder, as it calmly cuts under its own weight.

The grinder is an indispensable assistant in any household or in large construction works. It helps to process any material with minimal effort and time. Initial experience and advice will be enough for successful manipulations with this tool. The main thing is to follow safety precautions while working, which will help avoid serious injuries.