- home

- Sewerage

- biotank

The autonomous sewage system "Biotank" from, characterized by its compact size and reliable design, will provide you with comfort for many years! This is a non-energy-independent biological wastewater treatment plant, which is perfect not only for a summer house intended for seasonal living, but also for houses where people live permanently.

In the manufacturer’s line, everyone will be able to choose a suitable model, based on the number of people living in the house. In addition to volumes, Biotank septic tanks can differ in several other parameters. For example, if you need to place an autonomous sewer system in a small area, a vertical septic tank that is installed in a deep pit is suitable for you. If there are no space restrictions, you can choose horizontal models.

Both vertical and horizontal models can have a forced discharge of purified water onto the terrain or be gravity-fed. These series are marked with letter designations - “PR” and “SM”, respectively.

Design features of Biotank septic tanks

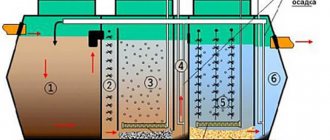

The Biotank installation has a rectangular cast body, divided into four chambers. In each of them, one of the stages of wastewater treatment occurs:

- The first chamber is the primary settling tank, in which solid particles settle.

- The second chamber includes an aerator with a floating load and biofilm. Here the process of oxidation of contaminants to nitrites and nitrates occurs.

- The third chamber is a secondary settling tank, where clean water is separated from the biofilm. The sediment accumulated at the bottom is transported from the third chamber to the first by means of an airlift for further continuous cleaning.

- The fourth chamber is a biofilter operating on the principle of a hydrocyclone. It gravity-fed or forcibly directs purified water to be discharged onto the ground.

At the exit, the degree of wastewater purification reaches indicators corresponding to sanitary standards - 95-98%.

Main characteristics

The modern septic tank Biotank is an energy-dependent installation that provides a high degree of purification of domestic sewage waste.

Energy consumption

Electricity is necessary for the normal functioning of the Biotank septic tank. However, short power outages do not have a significant impact on the quality of cleaning. Of course, the aeration process cannot be carried out without power supply, so the level of water contamination in the containers gradually increases.

Advice! According to the manufacturer, a power outage for no more than 24 hours will not have a significant impact on the quality of operation of the treatment plant. In the absence of power supply, the installation uses a cleaning principle based on mechanical settling. If there is no electricity for more than a day, the septic tank will continue to function, but the quality of cleaning will decrease.

Electricity consumption depends on the performance of the model, but, in any case, the installation is economical, so the amount in the electricity bill after installing the septic tank will increase slightly.

Degree of purification

If the Biotank septic tank operates normally, the degree of purification reaches 98%, so the discharged water can be discharged without additional treatment. When there is a power outage for more than a day, the degree of purification decreases and does not reach 80%. In this case, soil purification is required.

Advice! If a septic tank is installed in a holiday village, where electricity is often cut off for long periods, it is necessary to install a treatment facility complete with an infiltrator.

After startup (first or after shutdown), the Biotank septic tank returns to normal operation within two to three days. Additional introduction of biological material (bacteria) is not required.

Advantages of Biotank septic tanks

- Suitable for installation on any soil – even clayey ones with a high groundwater level.

- Withstands toilet paper, as well as organic and chemical detergents in small quantities, getting into the sewer.

- In the event of a power outage, they can work autonomously for some time.

- They do not emit unpleasant odors.

- Maintenance is required every 1-3 years.

- The simplicity of the design minimizes the possibility of breakdown.

Reviews, advantages and disadvantages

Numerous user reviews indicate the undeniable advantages of Biotank 4 PR septic tanks and other models in this series:

- simplicity of design;

- small dimensions and the possibility of vertical execution, which makes it possible to install a septic tank in small areas;

- low cost compared to similar devices from other manufacturers;

- the ability of the installation to withstand short-term power outages and resume normal operation within 3-4 hours;

- no need to install filter fields;

- high productivity: for example, the Biotank 4 PR septic tank is capable of processing and efficiently purifying 800 liters of wastewater per day, which is quite enough for a comfortable stay for 4 people;

- low sensitivity to the “quality” of waste: the station is capable of processing even solid food waste and toilet paper that accidentally got inside;

- ease of maintenance and cleaning.

The installation is unpretentious in operation, especially in comparison with similar purification devices with forced aeration from other manufacturers, and can easily withstand irregular use in the countryside and in houses with seasonal residence (during conservation).

Despite the significant superiority of the positive aspects, there are also negative user reviews indicating shortcomings:

- Dependence on power supply.

- The need for regular pumping (about once a year) of the mineral sediment formed at the bottom of the container. Unlike similar aerobic treatment devices, for Biotank septic tanks, as well as other “Tank” models, it is necessary to order sewage disposal equipment very often, which leads to additional costs.

- Periodic replacement of the compressor - the most important element of the treatment system. Depending on the load on the septic tank and the intensity of its operation, the need to replace the compressor arises every 2-3 years of use.

It is worth noting that most negative reviews about the operation of the septic tank itself are associated with the owners’ failure to comply with the rules for installation and operation of the equipment. The presented video review of the device will help to clearly verify the reliability of the design itself.

A little about the manufacturer of this equipment

Logo Triton Plastic

Septic tank Biotank and a number of other plastic products used in the construction of treatment facilities are manufactured by a well-known company, whose main facilities are located in the Moscow region.

For more than ten years, it has been a leading domestic manufacturer of plumbing plastic equipment.

The enterprise is equipped with the latest foreign and Russian equipment. Products are produced using advanced technologies, thanks to which all plastic products fully comply with European standards and are environmentally friendly. This is confirmed by the availability of certificates of the appropriate type.

The creation of warehouse terminals in many regions of the country allowed the company to establish fast and timely delivery of manufactured products to the construction market, and primarily the Biotank series septic tank. The company's products are also exported to some foreign countries.

Products of the company Tank and biotank

Triton Plastic occupies a leading position in Russia among manufacturers of equipment for domestic sewerage. Thanks to its remarkable technical characteristics and environmental friendliness, the Biotank model septic tank has become widespread and is considered the most popular in Russia.

The expansion of the range of manufactured plumbing fixtures is carried out taking into account concern for the environment.

Features of operation and maintenance

Regardless of the volume and capacity, it is prohibited to dump diapers, personal hygiene products, plastic bags and plastic items, rags, and food waste into the septic tank Tank 1, 2, 3 and other models. Not only are they not processed by the septic tank, but they can also cause damage to the hull.

To avoid compaction and compaction of the sediment and impurities accumulated in the septic tank, the manufacturer recommends pumping it out once a year with a sewer truck, as well as cleaning the air compressor and changing the biological membrane. After emptying the chambers of the septic tank, it is necessary to fill it with water to resume the normal operating cycle.

Expert opinion

Albert Lyushin

Engineer-technologist with more than 15 years of experience.

Ask a Question

Volatile structures can operate autonomously for another 24 hours during a power outage. At the same time, the level of water purification does not exceed 80%. If power outages occur constantly, it is better to give preference to non-volatile anaerobic options or purchase a generator.

What it is?

The septic tank Tank is autonomous and operates without human intervention. The installation occupies a leading position among similar LOS (local treatment plant) in the Russian market. Manufacturer of septic tanks Tank, which offers affordable solutions for a sewer system with any number of drains.

Note! VOCs from the manufacturer are presented in different volumes and numbers of chambers, which accordingly helps them serve different numbers of residents in the house.

Important features of the VOC Tank septic tank:

- The presence of stiffening ribs that guarantee the integrity of the structure even under the most difficult installation conditions.

- The containers (chambers) are cast, which guarantees their strength and tightness.

- The wastewater is processed with a high purification rate, which makes it possible to use it for technical purposes without any problems.

- The sewerage and wastewater treatment system is compact, since there are structures that are located not in breadth, but deep in the soil. But a rectangular, horizontal Biotank can only be installed in areas with deep groundwater.

Important! Horizontal designs are convenient because you can add additional chambers to increase the productivity of the installation.

Models

Manufacturers offer several options for Biotank septic tanks. Models differ in performance and body shape. Available in horizontal and vertical installation options. The choice of model is carried out depending on how the installation diagram is drawn up.

The vertical model is convenient where you can allocate a small area for installing a septic tank. To install it, you will need a small but deep pit. But on the other hand, a horizontal septic tank is more productive and allows you to modify an already working model if there is a need to increase the productivity of the installation. The manufacturer produces three basic models:

- The younger model is designed to serve a home with up to five people. The total volume of the installation is 2000 liters; the installation purifies up to a cubic meter of liquid per day.

- The average performance model has a volume of 2.5 thousand liters, it is suitable for a house with five to six residents. Daily productivity – 1.2 cubic meters.

- The older model can serve up to 9 people, its volume is 3000 liters, and its productivity is 1.8 cubic meters.

Price

If you also decide to purchase the system described in the article, you must understand its varieties. For example, “Biotank-3” will cost 39,500 rubles, and with installation the price increases to 56,700 rubles. The capacity of the tank is 1000 liters, and the productivity is 600 liters per day. The structure weighs 105 kg and its dimensions are 1200x800x1850 mm. You can also find Biotank-4 on sale, for which you will have to pay 45,500 rubles. Together with installation, the price is 69,400 rubles. For this septic tank, the capacity increases to 1500 liters, and the productivity is 800 liters per day. The equipment weighs 128 kg and its dimensions are 1200x200x1850 mm.

Possible breakdowns

Like any equipment, the Biotank septic tank can fail. However, if you carefully study the negative reviews, you can understand that most breakdowns are caused by operating or installation errors.

Deterioration in cleaning quality

If the septic tank begins to supply muddy water with an unpleasant odor, you should find the reason that caused the deterioration in the quality of cleaning. It could be:

- Failure of electrical equipment. If for some reason the electrical part of the equipment does not work, the installation switches to an autonomous mode of operation, that is, the aerobic stage is excluded from the cleaning process. As a result, the quality of cleaning is noticeably reduced;

- High sediment levels. If too much compacted sediment accumulates in the receiver, then the volume of this part of the septic tank decreases, which negatively affects the quality of primary settling.

- Blockage. An object that cannot be recycled can result in poor operation of the unit.

Advice! It is necessary to warn all households that it is strictly forbidden to throw rags, plastic bags, baby diapers and other things into the sewer system that cannot be recycled by the treatment plant.

- Death of bacteria. If a large amount of an antiseptic substance gets into the septic tank, the bacteria involved in cleaning may die. This will lead to a decrease in the quality of work. Do not dump large amounts of bleach, antibiotics, potassium permanganate and other disinfectants into the sewer.

- Incorrect installation. If during the installation process the septic tank body was not leveled, or the pit preparation process was carried out incorrectly, then the treatment plant will not work correctly.

Hull damage

If during installation or during operation a crack forms on the body of the septic tank, then the ground at the installation site will be constantly wet and sewer odors will be felt. Installation or operating errors can lead to such a breakdown. Basic installation errors that can damage the housing:

- Careless unloading. If during unloading work the septic tank is dropped from a height, a crack may form on the body. Sometimes this damage is hardly noticeable, but it interferes with the normal operation of the cleaning system.

- Improper preparation of the pit for installing a septic tank. Before installing the equipment, the bottom of the pit is compacted. Then a layer of sand is poured, which is also compacted. When groundwater rises high, it is necessary to lay a reinforced concrete slab on the bottom, to which the septic tank is attached with bandage belts.

- Careless installation of a septic tank. When installing a septic tank in a pit, special equipment is usually used. Low-performance models can be installed manually, subject to certain rules.

- Incorrect backfilling of the pit. To prevent deformation of the housing during the backfilling process, the installation is pre-filled with water. To prevent damage to the body during freezing and thawing of the soil, a specially prepared mixture of dry cement and clean sand is used for backfilling.

An operating error, as a result of which a crack may appear on the body, is the absence or improper preparation of the septic tank for shutdown for the winter. If the septic tank is used year-round, no special preparation is required before the onset of winter. But if the model is used in a summer residence, then before stopping for the winter, it is necessary to carry out conservation. The compressor must be removed (it should be kept warm). The chambers are filled two-thirds with water, and two-liter plastic bottles filled with sand are lowered into them on ropes.

So, you can find both positive and negative reviews about Biotank septic tanks, but, of course, there are significantly more positive reviews of this equipment. In most cases, breakdowns of a treatment plant are associated either with improper installation or with equipment operating errors.

Tank or Topas

Since these two installations are well known, the question often arises: what is better to choose: a Tank or Topas septic tank? Although their popularity is high, they have fundamental differences, as well as similar characteristics.

What they have in common is their compact design; they can process large quantities of wastewater. The daily volumes of Topas are larger, but the Tank can filter many different wastewater, while Topas cannot. In addition, you won’t be able to repair the latest installation yourself; moreover, you won’t even be able to determine the cause. Taking all this into account, it is impossible to say who is the clear leader in consumer preferences - both settings are very popular.

The tank from Triton Plastic is a modern solution for organizing a sewer system. The variety of models and performance allows us to say that it will be possible to select the VOC “Tank” for any autonomous sewage system.

Positive reviews

“Biotank” (septic tank) has many positive characteristics, this is confirmed by consumer reviews. From them you can find out that this system is universal and compact. The first quality is confirmed by the fact that the treatment plant can be located in areas with any geological conditions. If we are talking about a traditional septic tank, then it is impossible to use it on clay soils or soils where groundwater lies high.

As buyers emphasize, the “Biotank” (septic tank) has very compact dimensions; its installation does not require too much space, so this option can be called the most suitable for small suburban areas. Consumers claim that space is also saved due to the fact that the owner of the site does not need to install an infiltrator. One cannot fail to note the simplicity of the design. A septic tank almost never fails, and if it does, it happens much less frequently compared to those models that have a more complex structure.

Installation design

Housing design

- Capacity. A cast polymer tank with no joint lines or seams. Compactness and stability are ensured by the rectangular shape. The ribbed walls act as lugs and facilitate the anchoring process.

- Hatch (one or two). Located at the top of the container. Sealant is used to secure the necks.

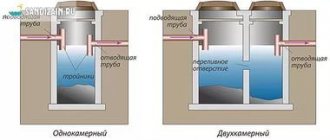

- The internal structure consists of several chambers (depending on the model), separated by partitions with pipes for water overflow. For example, in the Tank 2 septic tank, heavy impurities are separated in the receiving chamber, in the second, light impurities are processed by anaerobes, and in the third, a biofilter is installed for final water purification.

The polyethylene from which the body is made is an environmentally friendly and safe material, does not react with moisture and chemical compounds, and is not susceptible to erosion and oxidation. High activity of microorganisms does not affect the strength of the polymer. At the same time, cast polyethylene is affordable and makes the septic tank budget-friendly.

Among the disadvantages, the body material does not withstand external soil pressure well, so to prevent ruptures, installation requirements must be strictly followed.

Inside, the body consists of three sections. In the first, wastewater is collected and settled. Mechanical, organic and other large contaminants settle to the bottom under the influence of gravity.

The water flows by gravity into the second chamber, where microorganisms process the remaining organic compounds. The third section is equipped with a biofilter that separates residual impurities.

Biofilter functions

A biofilter is a container for multiplying and maintaining the activity of colonies of microorganisms. Floating bioload is necessary for the settlement of bacteria. Preference is given to anaerobic, settling on the bottom and walls of the container.

To increase the area of mechanical cleaning, plastic filtration products are poured into the septic tank. Polymers quickly float up and are localized near the inlet pipe. The material does not affect the activity of microbes and is chemically stable.

Another function of the biofilter is centrifugal separation. Water is supplied to the section at an angle, unwinds and is cleaned of heavy suspended matter. The principle of centrifugal separation is based on vortex microflows that are formed when liquid is drained.