History of artistic forging

The history of artistic forging begins in several points of the ancient world - in China and Mesopotamia, in Egypt and in Europe, in the area inhabited by Celtic tribes. It was there that forged products were first discovered, which, in addition to utilitarian, also had artistic significance.

History of artistic forging

Ancient craftsmen decorated their products with images and ornaments. Artistic forging was noted in all sectors of the economy - they decorated weapons and household utensils, grilles and fences, parts of mechanisms and objects of worship. After the flourishing of the art of artistic forging in the ancient world, medieval craftsmen largely lost the achievements of the times of the Roman Empire. The patterns have become much simpler, twisted rods have practically disappeared. The Renaissance was also a renaissance for the art of artistic forging. Ancient secrets were rediscovered, new methods and artistic techniques were developed. Italian craftsmen from the principalities in the regions of Milan and Turin were especially famous for creating magnificent armor and weapons.

Forged Products

Wrought iron rocking chair

The beginning of the widespread use of water and steam energy to mechanize the work of forges and hammers led to the beginning of a technical revolution - it became possible to produce forged products in large quantities. However, artistic forging has not lost its special position and continues to be valued today precisely for its uniqueness.

ARTISTIC FORGING

ART FORGING, a type of decorative and applied art, the works of which are created using the forging method. From 4th to 3rd millennium BC e. K. x is known in Egypt, Mesopotamia, and Asia Minor. copper and meteorite iron; Indians of the North. and Yuzh. America knew K. x. native iron. In the 1st millennium BC. e. the art of blacksmiths in Europe, Asia and Africa developed, processing raw iron, copper, silver, and gold; revolution in the art of K. x. associated with the spread of steel.

Artistic forging. Ax lock. The work of a Russian master of the 17th century. Art Museum-Reserve “Alexandrova Sloboda” (Alexandrov, Vladimir region). Photo by D. V. Solovyov

The Middle Ages were the heyday of blacksmithing: utensils, weapons, armor, jewelry, household items (hammers, locks, candelabra, weather vanes, etc.), gratings, doors, gates were forged masterfully, with fine details; products were decorated with reliefs, perforated patterns, notches, and painting. Romanesque grilles 11th–12th centuries. assembled from vertical rods; the gaps between them were filled with symmetrically arranged flat spirals, 4-petal clover leaves and other patterns. He grows up in Gothic art. the ornament of the grilles was often covered with gilding. During the Renaissance in Italy, when the construction of mansions for the nobility became widespread, fences, bars for balconies and interiors, etc. appeared. decorative metal elements designed to decorate private gardens and parks. Mn. the cities became centers of blacksmithing: weapons were produced in Damascus, Milan, Augsburg, household products were produced in Nuremberg and Venice, lattices were produced in Toledo and Prague, and utensils were produced in Herat and Mosul. In the 17th–18th centuries. the famous masterpieces of Kh. were created. Means. scale (fences, gates, lanterns) for Versailles, Paris, Nancy.

Artistic forging. The lattice of the “Fountain of Amphitrite” on Place Stanislaus I in Nancy (France). 1750s Based on the project by J. Lamour.

K. x. was widespread in Ancient Rus'. Blacksmiths participated in the construction of cathedrals in Novgorod, Pskov and other cities, created bars for windows, front gates, doors with applied flowers, twisted handles, and patterned crosses on the tops of churches. Traditions of K. x. remained until the 19th century. in the works of Tula gunsmiths and in the people. art (buckles, door locks, lights, hooks). At 18 – beginning. 19th centuries K. x. I mean I played. role in creating the appearance of St. Petersburg (grids of bridges and embankments, parks and palaces; the fence of the Summer Garden from the Neva), Tsarskoe Selo and other palace and park ensembles. In Baroque art in Russia, complex alternation of elements using plantings was practiced. motifs, with the effect of perspective, destroying the single plane of the fence. During the period of classicism, entire spatial compositions were created from metal on balconies and fences of mansions.

At the turn of the 19th–20th centuries. K. x. widely used in modern architecture (in European countries and Russia); Often the pattern from the gratings moved onto the wall of the house and then developed in stone or plaster along the facade. With the advent of rolling and forging-stamping production, manual production. replaced by stamping and casting. At 20 – beginning. 21st centuries interest in manual K. x is being revived. both in Russia and in other countries.

Forging tools

The set of tools of the ancient blacksmith was simple, but it was very expensive. It included:

- A forge is a device for heating a workpiece to a high temperature.

- Hand bellows for blowing coals.

- An anvil is a massive metal casting or forging on which the workpiece is shaped into the desired shape.

- Blacksmith hammer and hammer.

- Ticks.

- Mandrels, chisels, etc.

- Container with liquid for cooling forgings.

With this minimum set, a blacksmith could forge simple products even under a bush. Nomads and any army of antiquity carried marching forges and sets of tools with them. The technological capabilities of camping forges were enough to forge arrowheads, horseshoes and other parts of horse equipment, repair metal parts of carts, and straighten a damaged blade or armor.

But in order to forge a ship's anchor or a cart axle, a stationary forge was required. A heavy large anvil, a large forge and bellows with hand or foot drive attached next to it were installed in it. A strong workbench and a large vice were also installed. A large number of accessories, linings, punches, clamps, as well as measuring instruments in accordance with the era were also added to the tool composition. The blacksmith did not work alone - an apprentice with great physical strength and endurance first inflated the bellows so that the blank in the forge became red-hot, and then struck with a large forge hammer in the place that the master blacksmith had marked with a small hammer - the handbrake.

In a modern artistic forging workshop, there have been no fundamental changes in the composition of the tool, except that the measuring tool has become more accurate, and instead of installing a bulky forge and bellows, it has become possible to heat the workpieces in muffle furnaces or induction.

A special group of equipment stands out for cold forging - changing the shape of metal rods, rolled products or pipes in a cold state by applying mechanical force. It includes various machines for cold forming of rod and profile blanks

Cold forging technology has become widespread because it allows you to obtain inexpensive entry-level artistic products without lengthy training and complex equipment.

gallery

Technological processing of metal by forging includes a variety of techniques and methods, which are dictated by the nature of the material and the tasks facing the artist-blacksmith...Technological processing of metal by forging includes a variety of techniques and methods, which are dictated by the nature of the material and the tasks facing the artist-blacksmith. During the forging process, the master uses a variety of techniques, using different tools, alternating them in various combinations and sequences.

Basically, all techniques can be reduced to the following basic operations: upsetting, drawing, chopping, cutting, punching holes, bending, twisting, notching the pattern, stamping the relief.

Sequential operations for manufacturing pliers

Upsetting This is an operation that is used to increase the cross-section of some part of the workpiece due to its length (height). The sediment can be complete and local. When the settlement is complete, the entire metal is deformed. With local precipitation, only part of the metal is deformed. Accordingly, heating is done - full or local. Sludge is used in the following cases. To obtain individual thickenings on the forging (by upsetting the ends or the middle) when forging decorative elements with a variable cross-section. For example, floral ornamental motifs (thickened nodes on the stem, fruits, berries, etc.) After upsetting, the forging is additionally processed by crimping and tamping. As a preliminary operation before bending at an angle to replace the missing metal to form the angle. When upsetting, the forging is heated, placed vertically on the anvil and hit with a handbrake or sledgehammer on the upper end. The length of the forging should not exceed the diameter by more than 2 - 2.5 times, otherwise bending will occur.

Upsetting techniques: a - upsetting in a vice; b - sediment on the anvil; c - settling of the end to form heads; d - formation of a reserve of metal for bending at an angle

When upsetting, it is important to observe the following conditions: the ends of the workpiece must be cut at an angle of 90°, the workpiece must be straight. If it is necessary to upset a workpiece in a small area with a large difference in cross-section, the heated workpiece is immersed in cold water, excluding the area to be upset. This operation must be carried out quickly, the workpiece must not be kept in water, it is necessary to monitor the heated end. This technique is used in the manufacture of bolt heads or large construction nails. Some blacksmiths upset the ends of the workpiece this way: they bend the heated end at an angle of 90° and, turning it over, hit the bent end of the metal. The difficulty with this technique is to avoid making a fold in the bent end during the upset. It is good to use this technique for mountain welding. The upsetting of the ends of the workpieces can be done in a vice: the heated workpiece is secured in a vice so that the part of the metal that needs to be upset rises above the jaws. The height of the upset part should be 2.5 times greater than the cross-section of the workpiece. This operation must be performed quickly, because when clamped in a vice, the heated metal quickly cools down from contact with the jaws. Having quickly secured the workpiece, they set it down with a handbrake. When upsetting the ends of workpieces with a large cross-section, it usually happens that the force of the vise jaws is insufficient and upon impact the workpiece slides in the vise. In this case, if the workpiece allows, hangers are made in it. When working with long forgings, there are cases when it is necessary to produce an upset in the middle of the workpiece. All of the listed methods are unacceptable in this case (in particular, it is impossible to produce upset by striking the object itself against the anvil). In this case, in the upsetting zone, the workpiece is bent in the shape of the letter Z and hit from above along the bend with a handbrake; After upsetting, the workpiece is straightened. In addition to the techniques listed above, there are others using devices. Drawing This operation is used to increase the length of the workpiece by reducing its cross-section. The heated workpiece is placed on the anvil and pulled out with hammer blows. The hammer head has a surface that is both smooth and convex, and when a blow occurs, the metal is, as it were, squeezed out in all directions both along the length and width of the workpiece. Having rotated the workpiece 90°, they hit the convexity that resulted from the first blow. So, periodically turning and moving the workpiece, it is pulled out. Thus, the main thing is that during the drawing process the cross-section should always be square. To speed up drawing, forging can be done on the horn of an anvil; in this case, the metal will stretch (flow) between the two convexities, which contributes to a faster increase in the length of the workpiece. Another version of the hood is with rolling, or spreading. The rolling shape is most often semicircular. The direction of drawing depends on the location of the rolling on the forging (lengthwise or transversely). The hood at the end is used in the manufacture of nails, nails, punches, jigs and other products. The heated workpiece begins to be pulled out, retreating slightly from the end, and during the drawing process it is fed towards itself. During work, you need to make sure that the square that was obtained during the forging process goes to the end of the forging. This is achieved by the strength and nature of the blows. You need to finish the stretching with light blows. In Fig. 2, a - d shows drawing techniques.

Rice. 2 Extraction: a - extraction sequence; b - hood with 90° tilt; c — hood on the anvil horn; g'- hood with rolling

Chopping is an operation by which a forging is divided into parts. To do this, the workpiece is heated to a dark red heat, placed on an anvil and, setting a blacksmith’s chisel, cut through three-quarters of its thickness; turning the workpiece over, set the chisel again and chop it off with strong blows. When working hot with forging chisels, it is necessary to periodically cool the chisel when chopping thick workpieces, since the chisel blade releases when it comes into contact with the heated metal for a long time. Before placing the chisel on the workpiece again, you need to lightly tap the anvil chair to knock off drops of water from the chisel. When working on the face of an anvil with chisels and other cutting tools without a backing, you need to be especially careful and careful and ensure that the workpiece is not cut through. This can ruin the anvil face. Cutting (cutting) is an operation as a result of which the workpiece is only cut. This technique is widely used in artistic forging. The cut sections are bent, stretched, they undergo various types of forging, after which they turn into flowers, curls or leaves. This technique is especially widely used in the manufacture of zhikovins, svets, etc. When cutting, the workpiece is cut on one side (the front). The first blows are made light; they only cut a groove. The heating should be low - this allows you to take your time and calmly cut the metal. After cutting, the material is heated and cut with strong blows. During the cutting process, the chisel is placed in the guide groove only at the moment of impact. Hammer blows should be rare but strong. The hammer hammer must strike at the moment when he is convinced that the chisel is installed correctly.

Chopping (cutting) is the separation of a part of metal along the outer contour.

It is used for forging decorative products of complex shapes: overlays, quilts, etc., i.e. where it is necessary to cut off the part along the contour.

Felling is an operation similar to lopping. Used for cutting metal along the internal contour.

The operations of cutting and cutting are similar to cutting, with the only difference being that cutting is carried out on a thinner sheet using hand chisels and in a cold state.

Chisels are used in different profiles: semicircular, straight, coal, etc. If chopping and cutting are done on an anvil with an iron lining, then the notching is done at the end of the tree.

Holes in forgings are made using punching. These operations are performed at high temperatures. A punch (punch) is installed in the place to be punched and blows are applied strong enough so that the punch of the punch penetrates three-quarters of the thickness of the metal. The location of the future hole should be located above the round hole of the anvil; if it is small in size, then use a square hole. As a result of the first blows to the lower parts of the forging, bulging occurs under the chin. Without removing the beard, move the workpiece onto the face of the anvil and make a light blow to the beard - the exact outline of the place where the beard should be placed a second time will appear on the convexity. After removing the beard, the workpiece is turned over and the beard, cooled in water, is placed on the convexity above the hole made during the first blows. It is very important that the working part of the beard is cone-shaped and ends in a small platform. The diameter of the barb should be slightly smaller than the required hole. - Then a mandrel with a diameter equal to the required hole size is inserted into the resulting hole.

As a result of this punching, the cut out section of metal is called an otter. If it is necessary to connect mutually intersecting workpieces of the same cross-section, then the hole is cut and dispersed using a beard. This technique was used by old masters in the manufacture of window grilles.

When obtaining holes of a square or other cross-section, a mandrel of the desired profile is inserted into a preheated round hole. In order to get a hole in a square workpiece going through the edge, use the bottom of the lining, which holds the square when hitting the edge (face).

If it is necessary to make a hole in a workpiece of round cross-section, the walls of which should be equal to half the thickness, it is necessary to lightly hit the handbrake in a heated state to make a plane on which to place the chisel. This allows the workpiece to be cut exactly in the middle. The same method is used for punching holes through the edge.

When punching holes larger in diameter than all available mandrels, use an anvil horn. To do this, the workpiece is cut, spread with the largest mandrel, put on the horn in a heated state and forged with a handbrake. As can be seen from what has been described, when making holes, a chisel (cleaver) is also used, which should not have a straight blade, but a curved one, with chamfers on the edges running from the hole to the blade. In Fig. 74, a, b shows techniques for punching holes. Bending is a forging operation in which a forging is given a curved shape along a given contour. When bending thick workpieces, the original shape and cross-sectional dimensions in the bending zone are distorted (when bending thin workpieces, this phenomenon can be neglected). To eliminate shape distortion and shrinkage, it is necessary to settle the area where the workpiece is supposed to be bent before bending. The greater the bend angle and the smaller the rounding radius, the more pronounced the tightening phenomenon is. The shrinkage cannot be eliminated by straightening, but distortion of the cross-sectional shape (ovality) can be easily corrected by straightening and ironing.

Bending at an angle is performed on the edge of an anvil with pre-heating of only the bending area. The heated workpiece is installed so that the future bend edge on the workpiece coincides with the front edge of the anvil, and is pressed from above with a sledgehammer. The handbrake is used not to hit the end of the workpiece, but closer to the edge of the anvil. If it is necessary to bend the workpiece without a bend radius (at an angle of 90°), use a fork. Using a fork, the workpiece is prepared for bending (see Fig. 75. d), after which the angle on the edge of the anvil is straightened using a handbrake and a smoother. Bending at an angle of 90° without a rounding radius (in a vice). The heated workpiece is bent on the edge of the anvil, clamped in a vice and struck at the end of the metal. In the bend zone, metal sedimentation (thickening) occurs, a reserve of which is necessary to straighten the angle.

If a long strip or rod needs to be bent several times (and the bends are located close to each other), bending is done on shperaks with a horn of a suitable shape.

If it is necessary to bend the workpieces at any angle, then use a lower one, which is made during the work process. The heated workpiece is placed on the lower part, on top, perpendicular to it, there is a plate equal in width to the part that needs to be bent, and with a strong blow of a sledgehammer it is pressed (bent) into the lower part.

In the absence of a lower one, you can use a fork, which can also be bent while working on the product.

Sometimes, after bending in a fork, the bale is straightened using a smoother or on the square horn of an anvil.

Bending along an arc is an operation that is performed on the horn of the anvil or the sprockets corresponding to the arc. Complex profiles are bent on mandrels, templates and a bending plate.

Pattern bending is done when the same element is repeated many times in a product. A template for the future element is bent from a sufficiently thick strip of metal. It is fixed at one end in a vice or it can be mounted on a lining and bent around the heated workpiece. The peculiarity is that when making a template you need to be careful and make it with great care, because future elements of the product will copy the template. Bending on a cone. When making a decorative element - a conical spiral - a tool is used - a cone, which is a conical mandrel, the cross-section of which determines the internal cross-section of the future spiral. The heated metal rod is fixed together with. mandrel in a vice and bend around to the top of the mandrel. The coils must be placed one to one. The end of the rod, which serves as the top of the spiral, undergoes various changes. If the section of the rod is thin enough, then the work is carried out in a cold state. In this case, the iron is released. Is bending without a cone used in the manufacture of a spiral that can be bent without a mandrel? as if to myself.

The end of the rod is bent at an angle of 90°. When heated, they are secured in a vice and bent towards themselves.

With a sufficient number of turns, the spiral is heated and the end, which is the top of the future conical spiral, is pulled out. When making various kinds of decorative elements, you need to be especially careful when completing them: not only this element, but the entire product as a whole depends on the quality of their execution. In Fig. 75, a - b shows bending techniques and some finishing elements.

The essence of this operation is that one part of the forging is rotated relative to the other around a common axis.

There are two different options.

- Part of the workpiece is rotated through an angle of up to 180°. For example, individual elements of decorative items (leaves, flowers) are bent (rotated) for greater plastic expressiveness. Twisting 180° is done on the shperak on the anvil horn using a handbrake; smaller elements? pliers.

- Twisting is carried out repeatedly at an angle of 360°. This technique was used in the manufacture of forged window grilles.

Twisting of thin blanks is carried out by two blacksmiths. Having grabbed the workpiece with pliers, they rotate it in two opposite directions simultaneously. Twisting of thicker forgings is carried out using a crank, while the other end of the workpiece is clamped in a vice. Wide strips are easy to grip with a fork. The most beautiful decorative elements, rich in chiaroscuro, are obtained from two round rods tightly twisted together. When twisting and twisting, the workpiece must be heated to a bright red heat; at lower temperatures, twisting requires greater effort, and cracks may occur in the metal.

This operation begins after the main shape of the product has already been forged. The purpose of the operation: to give a finished look to the forging. Does a hammer always leave marks? waviness. In addition, a hammer product (especially with sledgehammer marks) has a sloppy and unfinished appearance. Smoothing and final finishing consist of leveling the surface using trowels of various shapes. Ironing is carried out when the workpiece is heated dark red, moving the iron over the surface of the product and hitting it with a sledgehammer.

Sometimes only certain sections of the relief are smoothed. For example, only its most protruding parts, and the recess is made up “from under the hammer”. This gives a unique painterly quality to the product.

The ironing operation plays a big role in artistic forging; it gives the product a finished look.

Notching the pattern. This operation, like the previous ones, refers to the finishing, final types of forging.

Using a chisel in a cold or hot state, you can reproduce various strokes, notches or more complex patterns on the surface of the product, including graphic elements and font inscriptions. Notching is carried out on surfaces that are more or less flat and clearly visible on the finished product.

This operation also applies to the finishing of the finished product and is performed with the aim of enriching its texture by creating additional relief protrusions or grooves and recesses, for example, veins on leaves and petals, flutes on columns, etc. The work is performed with special tampers or punches.

According to archaeological data, the first forged products from native non-ferrous metals (copper, gold, silver), dating back to the 8th century. BC, there were various decorations - beads, rings, bracelets. The first items made of iron were also women's jewelry and they were valued more than gold. Samples of these products were found during excavations of ancient burials in the territories…

More details in the article “Manufacture of artistic products” Navrotsky A.G. "Artistic forging"

Types of blacksmithing

Blacksmithing works are divided into several subtypes:

- Free forging - a blank heated to the plasticity temperature lies on one side of the anvil, and forming blows are applied to the other with a hammer or special tools

- Stamping - a heated or cold workpiece is placed in a special form - a stamp, limiting it on all sides, and this form is already subjected to hammer blows or static pressure.

- Cold forging - cold bar stock changes shape on special machines.

Free forging is in turn divided into subtypes:

- Ordinary forging - the blank is given the shape of the finished product in one or several successive forging cycles

- Welding - joining two or more heated parts into one product

- Crushing is a preparatory operation during which the pasty iron mass is compacted and welded into a single ingot.

Interesting facts about artistic forging

- Forges are characterized by their small size and lack of windows. This is due to the nature of blacksmith work. The heating temperature of the metal was determined by eye, by the color of the heat.

- American scientists have identified the cost of a forge blow. It is equal to 10 dollars. This is 10 times more expensive than a hammer blow. The point is that the blacksmith must know where and with what force to strike. If the force is calculated incorrectly, all the work will go down the drain.

- In pagan pantheons, the patron gods of blacksmiths were especially revered. The peculiarities of metal processing and forging in ancient times were kept secret and were accessible only to initiates. Legends and secrets arose around them. Therefore, blacksmiths were valued by society, as were the gods who patronized them. With the advent of Christianity, the pagan gods were replaced by the cult of Kuzma and Demyan. The importance of blacksmithing is indicated by the number of surnames derived from the word “blacksmith”: Kuznetsov, Kovalenko, Schmidt, Smith, and so on.

- The temperature at which steel becomes available for forging is 850-1200 degrees. In ancient times, it took about an hour to heat a part to this temperature.

- Currently, model production begins with 3D modeling. This greatly simplifies subsequent work with metal.

- The words “forge” and “cunning” are of related origin. Previously, the work of a blacksmith was sacred, and “cunning” meant some kind of magical skill. Only over time did it acquire its modern meaning.

Types of modern forging equipment

Modern blacksmith equipment for artistic forging is practically no different in form and purpose from ancient or medieval ones. The materials have changed - hammers and anvils, hammers and punches, vices and clamps are made from modern high-strength alloys, which significantly increases their durability and efficiency.

Another important change is the heating method. The traditional forge with hand or foot bellows is giving way to muffle furnaces for small workpieces and induction heating systems. This significantly reduces labor intensity, harmfulness and danger to health and property.

Forging machines

Forging machines are used for cold forging - changing the shape of a bar or profile workpiece under mechanical influence. These include:

Snail with a collar and a rotating blade Twister for cold forging Gnut for cold forging Waves for performing wave-like bending of the workpiece

- Bends are the general name for machines for bending a workpiece in one or several directions along a given radius.

- Waves for performing wavy bending of the workpiece, with a given pitch and wave radius

- Twisters, or torsion bars - for twisting a workpiece (or group of workpieces) along the longitudinal axis

- Snails - for forming spiral curls at the end of the rod.

Cold Forging Machine

Twisted Pipe Making Machine

Cold forging is perfect for making elements of fences and trellises, balusters, scrollwork, interior decor items and landscape design. A machine for cold artistic forging is easy to make with your own hands if the master has the skills of metalworking and welding.

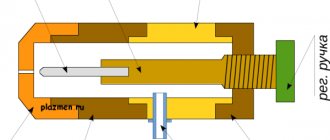

Induction heaters

The induction heater is designed to heat the blank to the plasticity temperature. Heating occurs due to the fact that eddy currents, or Foucault currents, are induced in the surface layer of a metal placed in a strong alternating magnetic field. With their help, you can heat the blank much more evenly, faster and safer than using a traditional forge.

An industrial induction heater, even of low power, costs tens or even hundreds of thousands of rubles. Therefore, many diagrams like “How to make an induction heater with your own hands” are published on the Internet. It is important to understand that the design of the device uses high voltage and high power. For self-production, you will need engineering knowledge in the field of high-frequency currents and the skills of an electrician.

Artistic forging in different architectural styles

The concepts of artistic metal forging and blacksmithing have their roots in the distant past. From time immemorial, people have used forged products in everyday life. Later, artistic forging began to be used to decorate churches, gardens, parks, alleys and one’s own home. Architectural elements made by artistic metal forging are beautiful and elegant. Artistic forged products can serve for decades and even centuries without losing their visual appeal.

Experienced blacksmiths today create forged architectural artistic elements that carry a dual function: protective and decorative. For example, artistic forging Moscow creates forged gates, wickets, fences, gratings and other forged products that help protect and fence the house and surrounding area from unwanted entry, and at the same time they decorate the home, emphasizing the good taste and well-being of the owner. Other forged products are no less popular: forged garden furniture and home furniture, accessories, fireplace grates, staircase and balcony railings, made in one artistic style or another.

Over the centuries, artistic styles replaced each other, interest in forging either faded away or was revived with renewed vigor, but each of the “great styles” was reflected in forged products. Both then and now, blacksmiths create artistic forging products belonging to different styles: Gothic, Baroque, Rococo, Renaissance, etc.

When choosing a particular style of forged products, you should remember the need to combine it with the overall style of the entire house or apartment. Only in this case will artistic forging organically fit into the space and environment of your home, and you will experience true pleasure from daily contact with the creations of an ancient, but eternally relevant craft.

Gothic style

The flowering of medieval art, as most of us know and imagine it, is associated with the Gothic. Capturing the minds of contemporaries for two, and in some countries for three centuries, the Gothic style left a mark on history incomparable with the legacy of the Romanesque era.

Like the Romanesque style, Gothic was closely associated with the church, and it was the main city cathedral - tall, filled with allegorical and symbolic images and richly decorated - that was the standard Gothic building. The massiveness and squatness of Romanesque buildings is replaced in Gothic by visual lightness and aspiration upward (it is no coincidence that one of the periods of development of this style is called “flaming Gothic”), towards the inaccessible heavens. This is also emphasized by the pointed, pointed shape of the arches, doors and windows. The monochrome color scheme of the Romanesque era explodes in Gothic buildings with the bright colors of huge stained glass windows, and the slightly primitive and tense poses of Romanesque sculptures give way to realistic and viewer-facing Gothic sculptures.

The later Middle Ages were also marked by the flourishing of urban culture. The massive construction of rich houses of the nobility, guild houses, town halls, municipalities, markets and other private and public buildings requires the development of not only architecture and engineering, but also crafts. The house of any medieval nobleman and successful merchant during this period is filled with the fruits of the painstaking manual labor of skilled craftsmen: the walls are hung with tapestries from the best weavers, the furniture is covered with ornate patterns by the hands of carvers, the leather pages of the Bible amaze the imagination with bright miniatures, and the decoration of the table is the delicate products of virtuoso glassblowers.

Blacksmithing also does not stand still. New industries and specializations are developing (blacksmiths are now divided into “needle makers”, “saw makers”, “nail makers”, “lock makers” and dozens of other categories), as well as new artistic forging techniques - primarily the widespread practice of combining forged and sheet parts in one product . Forged products penetrate into all spheres of life, from the manufacture of armor and weapons for numerous military campaigns to traditional forged grilles and small household items - holders for splinters, keys, caskets, etc.

Signs of the Gothic style in artistic forging:

- the extremely geometric nature of the pattern, its main constituents are parts of a circle;

— structural and compositional basis – vertical;

— a limited set of motifs, usually plant-themed (oak leaves, grapes, royal lilies, trefoil, multi-petal rosettes, etc.);

— use of a rod with a complex profile;

- predominantly pointed end of rods.

Despite the fact that Gothic is often called a dark era, its influence on the culture of subsequent periods was very great and, undoubtedly, has not yet been exhausted. The end of the 18th – beginning of the 19th centuries was marked by romantic sentiments in art, and, as a result, a revival of interest in mystical and mysterious Gothic. The interest in this style was so great that even the movement of neo-Gothic (in Russia - pseudo-Gothic) emerged. Neo-Gothic, which absorbed all the main canons and stylistic techniques of the style that gave birth to it, gave us many beautiful monuments, including, for example, the famous Big Ben tower and Tower Bridge.

Today, the features of Gothic architecture are very popular in private construction, since they allow you to create bright, high-status houses, but maintaining the logic of this style is impossible without the use of artistic forging. Forged grilles with decorations in the form of lilies and peaked tips, massive forged lanterns and a black forged staircase will best emphasize the unique beauty of the Gothic style of your home.

Modern and artistic forging

Like many extraordinary phenomena, modernism did not arouse much enthusiasm among its contemporaries. Today, in the world's capitals, tourists walk in droves along the “paths of modernism,” and the sophisticated soft forms, observed from the modernists, are replicated by architects and designers. At the beginning of the last century, this unique style remained the preserve of eccentric individualists. “Shameless modern style,” the poet Valery Bryusov wrote about it, expressing the general opinion of ordinary people.

Art Nouveau praised the combination of beauty and rationality, sought to combine architectural and decorative tasks, was fascinated by “fluid” forms that reproduced the surrounding nature, and loved exquisite pictorial effects. The exterior and interior in Art Nouveau are closely connected and filled with interpenetrating motifs. The smooth lines of the platbands are continued in the fantastic plant forms of stairs and lamps, majolica panels on the facades echo paintings, etc.

Increased demands for decorativeness and the need to maintain the unity of complex statistical solutions in all details gave impetus to an unprecedented flowering of applied art. Art Nouveau brought ceramics, glassblowing, weaving, woodcarving and other crafts to unprecedented heights. Artistic forging turned out to be especially consonant with this style, because the amazing plasticity of forged metal made it possible to easily reproduce the most bizarre natural forms. Art Nouveau saw an unprecedented development and synthesis of various arts: for example, the combination of forged and glass elements or forging and wood gave rise to interior and decorative items of amazing complexity and harmony. Overall, Art Nouveau provided a long-term interest in painstaking handwork and masterful forging that continues to this day.

Signs of the Art Nouveau style in artistic forging:

- mainly two types of compositions - linear decorative compositions and linear compositions using volumetric elements;

— the curl plays the most important role, its lines are as smooth and fluid as possible;

— asymmetrical compositions and ornaments;

- widespread use of finishing embossing on sheet metal in combination with forging, as well as combinations of various metals and alloys - copper, brass, bronze - to enhance the artistic impression;

— the return of traditional methods of metal processing and a wide range of technical techniques (threading, welding, riveting, etc.).

The aesthetics of Art Nouveau, not immediately understood by contemporaries, was properly appreciated later. Today she is again on the wave of popularity. At the same time, unlike other “big styles” of the past, modernism is equally appropriate in a representative country estate and in an intimate city dwelling. For modernism, it is not scale that is important, but unity of style. Therefore, when using forged products, which are mandatory in modernity, you must understand that to create an authentic style, you will need to maintain complete unity of forged grilles, door handles, forged lanterns and other elements.

Empire style

Like Rococo, Empire in its essence is not a completely independent style, but rather the limiting point in the development of classicism, to which it reached by the end of the 18th - the first third of the 19th century. The name of the style comes from the French word “empire”, and this is the whole essence of the Empire style, imbued with the idea of glorifying state power and military successes. The Empire style reached its greatest flourishing in the two largest empires of its time - Napoleonic France and Russia during the reign of Alexander I.

Along with observing the traditional canons of classicism in architecture and art, the Empire style is characterized by extreme monumentality and civic pathos. Massive forms, large undivided planes of facades and monumental porticoes became characteristic features of Empire architecture. In the decor from the ancient heritage, the Empire chose mainly ancient Greek and Roman military motifs: armor, laurel wreaths, lictors' bundles, shields, etc. Memorial architecture in the form of various triumphal arches, columns and memorial steles, also richly decorated with mythological and thematic military symbols, became widespread.

Artistic forging turned out to be in great demand in Empire aesthetics, but, as often happens, it did not demonstrate either truly outstanding examples or genuine development. The deliberate sculpturality, linearity and massiveness of the compositions characteristic of the Empire style gravitated more towards the casting technique, which experienced its rise during this period.

Signs of the Empire style in artistic forging:

- wide use of various sculptural forms (palmettes, laurel wreaths, reliefs, ribbons, etc.);

- characterized by simple straight lines and shapes: circles, crosshairs, etc.;

— linearity of the composition.

Due to its specific monumental character, the authentic Empire style is difficult to implement in private construction and interior design. At the same time, a wrought iron fence in this style can serve as an excellent introduction to a mansion designed in a classical style. A strict ornament using images of military armor and laurel wreaths will perfectly emphasize the solidity and status of such a house.

Baroque - artistic forging and forged products

Ambiguously perceived during the period of its spread, this style eventually entered the history of European art on an equal footing with its other main movements. Baroque did not linger for long at the forefront of Western European aesthetic thought (in different countries, the heyday of this style occurred in different periods, limited to the mid-17th - late 18th centuries), but left behind a rich heritage.

Speaking in opposition to the severity and frozen beauty of classicism, the Baroque proclaimed contrast, splendor, exaggeration in everything and dynamic images as the basis of its art. Although a consensus on the origin of the term “baroque” itself has not yet emerged, the existing hypotheses are quite varied: some lead it from the Italian barocco (“vicious”, “prone to excess”), others from the Portuguese perola barroca (literally “pearl with vice"). In any case, contemporaries already saw in Baroque culture exaggeration and grotesqueness, which, indeed, were its integral features.

The changes taking place in the art of this period also reflect profound social changes. The Baroque era is a time of heyday for entertainment and entertainment, inaccessible either to medieval culture with its strict Catholic dogmas, or to the Renaissance with its penchant for intense philosophical searches. Walks, masquerades, the development of theater and secular music firmly entered the life of the Baroque man and turned his consciousness upside down.

Baroque style in architecture and interior is always demonstrative luxury and an abundance of decorative details. Complex curvilinear forms, ornate decorations and an abundance of sculptural compositions make it possible to instantly distinguish a baroque building from a number of others. In the interior, Baroque reveals even more: the dominance of gilding, the use of contrasting colors, bright frescoes and paintings on marble, large stucco moldings, carved furniture made of precious wood, silks and tapestries, amazing in its decorativeness - all this created suitable decorations for Baroque entertainment.

Blacksmithing experienced a real flourishing in this era. When constructing palaces and other large structures, blacksmiths work hand in hand with architects, developing complex decorative products that are in tune with the entire external and internal appearance of the building. Forged masterpieces, such as gilded Versailles grilles, are mentioned in the memoirs of contemporaries, and major masters create entire albums with sketches and samples of their forged products - balcony railings, balustrades, fireplaces, door rings, etc.

Signs of the Baroque style in artistic forging:

- sculpture, relief and splendor of forms;

- the curl repeats the kinks and ridges characteristic of the entire style as a whole, while at the same time being enhanced by leaves, flowers and other similar elements;

- characterized by the emergence of two curls from one center;

— the middle of the curl is often strongly twisted and protrudes from the plane of the ornament;

- weaving relief elements into the ornament - masks, crowns, coats of arms, vases, birds, etc.;

— the cross-section of the rod is rectangular or has a complex relief shape.

Baroque is in many ways a child of its time, and is difficult to transfer to modern soil. When recreating it in architecture and interior design today, it is necessary to strictly observe all the canons of this style and carefully approach every detail, otherwise there is a risk of getting something tasteless. And, of course, true Baroque is unthinkable without forged parts, be it the forged fencing of a French balcony or an openwork forged gazebo over an artificial pond.

Rococo

By the middle of the 18th century, Baroque aesthetics briefly received its continuation in a new style - Rococo, or Rocaille (from the French “shell, decorative shell”). Like Baroque, it developed the traditions of classicism, but it is not easy to discern strict classical features in the playful and mannered forms of rococo.

In Rococo, artists and architects for the first time in many centuries decisively abandoned strict symmetry, placing emphasis on spontaneous and imaginative articulations of forms and patterns. This style began to attach great importance to the illusion of perspective, so straight lines and flat surfaces are uncharacteristic for it, and where it is impossible to do without them, they are usually carefully disguised with complex figured elements. Decorative elements of the Baroque era - all kinds of masks, vases, leaves, flowers, cherubs and other similar details - acquire an even more refined and capricious character, so that the real object is often barely visible behind its sophisticated form.

Rococo received especially wide development in the interior. Rich stucco in Rococo interiors descends from the ceiling along the walls to the floor itself, bright baroque contrasts give way to delicate pastel colors, and the furniture becomes even more subtle and elegant than in previous periods.

For artistic forging, the Rococo era became a period of decline. Large forms such as fences recede into the background before the all-consuming decorativeness, giving way to smaller ones. Forged architectural and interior elements lose their independent meaning and act more as auxiliary details.

Signs of the Rococo style in artistic forging:

— basically only the vertical axis of symmetry is preserved, the pattern is often located at an angle to this axis or asymmetrically;

- the nature of the curl is broken, strongly stretched and curved in different directions, even visually straight lines have a slight bend;

— lack of major compositional accents;

— pattern elements (leaves, flowers, bouquets, etc.) occupy almost all the free space of the product.

The playful Rococo style gives interiors a truly aristocratic shine, but in order for it to look organic, it must be carefully observed in all details.

Renaissance

It is difficult to imagine styles more dissimilar from each other than Gothic and Renaissance. The striking nature of their differences is especially striking when we consider that they followed one after the other. But if you know that in their ideological foundations they relied on completely different value systems, much becomes clearer.

The Renaissance, or Renaissance, is limited to different time frames in different regions of Europe, but generally fits into the period from the mid-14th to the mid-17th centuries. It became an exceptionally striking transition from the Middle Ages to the Modern Age, giving the world many masterpieces of architecture and art. Drawing inspiration from the era of antiquity, the Renaissance put humanism with its attention to man and harmony in everything at the forefront of its aesthetic searches. Symmetry and precise proportions, combined with a great interest in the decorative side (which, of course, was not present in the genuine art of the ancient world) - these are the main features of this style.

The worldview of the Renaissance was a rather noticeable blow to medieval Christian values, including in relation to luxury and wealth. From now on, demonstrative luxury was not reprehensible, and wealthy citizens did not miss the opportunity to surround themselves with elegant interiors and precious things. Stunning paintings, statues, expensive fabrics, amazingly fine jewelry and other excesses have become common elements of the decor of rich houses.

Blacksmithing during the Renaissance continued to develop progressively, mastering more and more subtle and complex techniques. It was during this period that the technique of stitching appeared, which makes it possible to achieve the effect of the intersection of spirals of different curls with each other. Thanks to this, the palette of patterns used in forging and the range of forged products are significantly expanded.

Signs of the Renaissance style in artistic forging:

— strict centricity of the composition (the development of the pattern occurs from the center);

- the main element of the pattern is spiral curls, often intersecting with each other, including in the shape of a “figure eight”;

— the significance of the external frame is reduced to constructive necessity, the main composition develops without relying on the external contour;

- a rod of predominantly round cross-section.

The Renaissance style in a modern interpretation is especially good in the interior. Its strict harmony, subject to the rules of the “golden ratio,” allows you to create a true haven of peace at home, where you can take a break from the storms of life. Mosaic details, wall and ceiling paintings, leather-upholstered “Strozzi chairs” on three legs and, of course, forged elements in the form of forged bars on the windows or forged door trim will bring the spirit and luxury of the Renaissance into your life.

Classicism

Like the Renaissance, classicism was guided by the ideals of ancient aesthetics. But under the influence of the ideology of the modern era coming from the middle of the 17th century, this orientation was more external than the deep internal character to which the Renaissance gravitated.

The idea of proportionality, harmony and harmony in classicism is sharpened to the limit. Any work of classical art had to be created taking into account strict canons, developed on the basis of the ideas of ancient art theorists and corresponding to a certain hierarchy of high or low genres. Classicism was based on eternal values and produced equally majestic works that forever separated the rational Modern Age from the rebellious quests of the Middle Ages.

Classical architecture is easy to distinguish from architecture of any other style. The main features were given by the noble simplicity of the ancient temple - these are strictly symmetrical facades decorated with columns and rotundas, and pediments with bas-reliefs on mythological themes, and a passion for a calm color scheme, broken only by majestic gold, purple and azure, and the choice of finishing materials, among which Marble plays an important role. Decorative elements of classical buildings and interiors are restrained and also based on popular ancient symbols such as the head of a lion, sphinx, etc.

Signs of classicism in artistic forging:

- the widespread combination of forging and casting (or chasing) in one work, with the help of which it is easier to recreate the most important ancient symbols - wreaths, reliefs, spears, etc.;

- lush, developed curl shapes, sometimes the curl is deliberately elongated and has an oval shape;

— the main emphasis in the composition is on sculptural details;

- predominantly rectangular section of the rod.

Like many major historical styles, classicism repeatedly returned to the attention of architects and artists in later periods. Thus, the end of the 19th and beginning of the 20th centuries was marked by the emergence of neoclassicism, which became an attempt to resist the aesthetic “chaos” of eclecticism and modernity. At the same time, neoclassicism itself could not fully withstand the rigor of true classicism, and some Baroque and Renaissance features can be found in its aesthetics.

Today, many private houses and residences are being built in the classicist style, the owners of which seek to emphasize their social status and join this truly royal aesthetic. In this case, a wrought iron fence with traditional decorative elements and openwork wrought iron stair railings, highlighting the massiveness of the marble steps, look especially appropriate.

Technological features of artistic forging

The process of manual artistic forging of metal is divided into several separate operations. It begins with heating the blank in a forge or other type of heater. Depending on the quality of the coal, the air supply to the forge and the mass of the billet, heating can take from several minutes to several hours. When making products with a complex shape, a large number of parts or holes, the product may cool down. Then it is returned to the forge and heating is repeated.

The actual forging operations are as follows:

- Draft. Hammer blows are applied from top to bottom, the original height decreases and the width increases. This is preparing the workpiece for drawing.

- Hood. Impacts on the workpiece are applied along the longitudinal axis, and the workpiece is flattened in the direction of the blows, and its length thus increases.

- Dispensing is a subtype of hood, used to increase the diameter of hollow workpieces.

- Firmware - making holes, recesses or grooves.

- Twisting is the repeated rotation of one part of the workpiece relative to another. In this case, a vice, pliers are used, and if the workpiece has a significant cross-section, special gates are used.

- Chopping is the process of cutting a product into two or more parts. It is also used to correct the shape and size of the product. Sometimes a finished product is cut out of a blank using curly stamps.

- Bending – is carried out to change the shape of a product in the manufacture of ring-shaped or bent-shaped parts.

- Welding is the joining of two or more parts into a single piece.

When forging metal with your own hands, you should follow the general sequence of operations, while in the manufacture of each specific product, some of them may not be necessary.

Upon completion of forging, the product is dipped into a container with liquid for cooling and hardening. Traditionally, water is used, but when forging special types of steel, such as damask steel, various acids and oils are used. Legend has it that after forging a sword, some craftsmen cooled it by sticking it into the body of a slave.

Technological techniques

However, in his work, the blacksmith uses the basic techniques of metal deformation, which allow him to modify the workpiece in accordance with his own idea, the customer’s sketch or the designer’s layout.

- Extraction (broaching). The purpose of this operation is to increase the length of the workpiece. In this case, the part is placed on an anvil and forged along its entire length and on all sides, turning the workpiece around its axis. The same technique is used to flatten the edges of various elements (for example, flowers, leaves), making them thinner. Blacksmiths also use flat or shaped strikers to perform broaching.

- Draft. The action is opposite to the hood. By striking the end of the workpiece, its length is reduced. Simultaneously with the upsetting, the master also trims the part, avoiding excessive deformation. A type of precipitation is landing. It is used when it is necessary to reduce not the entire part, but only part of it. To perform this technique, the part of the workpiece that requires upsetting is heated or a ring tool is used to limit deformation.

- Twisting (twisting, twisting). It is performed by two blacksmiths, or on a workpiece secured in a vice using a crank tool.

- Chopping. This operation is used when there is a need for separation or branching. Chopping is done using a hammer and chisel, first on one side, then on the other. Sometimes a special tool is used, which is placed on the anvil under the part.

- Bending. A technique of metal deformation, with the help of which a blacksmith gives a curve to straight lines.

- Firmware. Allows you to obtain a blind or through hole in the workpiece. To do this, use the flashing tool.

- Ironing. One of the finishing techniques when various defects on a part are eliminated or edges are applied.

- Drawing patterns. The most creative work, during which each master applies his own artistic methods, giving the work uniqueness.

- Assembly. Although modern technology has eliminated this technique, art blacksmith shops, which use manual labor, highly valued in the market for forged products, still use riveting, welding and assembly using screws and screws.

Hot metal forging is a labor-intensive and painstaking work that requires no small amount of knowledge, experience and skill, but the result is worth it - from under the golden hands of the master a product appears that has beauty and individuality.

Types of artistic metal forging

The most complex and refined products are produced using traditional hot forging. Using this method, you can forge both ordinary lattice rods and openwork forging elements, such as leaves and flowers, stylized animal figures and intricate ornaments.

Hot artistic metal forging

Cold forging does not allow one to achieve the same heights of artistic expression, but it has its obvious advantages: low cost and high repeatability of products in a series.

Cold forging

Cold forging is sometimes also referred to as the embossing technique. In this case, a pattern consisting of many dents and dashes that form a highly artistic image is applied to a thin sheet of metal using a set of pointed tools and a hammer.

Basic artistic forging techniques

Each type of forging of metals and alloys has its own technologies and processing methods. Artistic forging, taking into account its specifics, uses in its arsenal almost all the basic techniques of blacksmithing, with the help of which any creative idea can be expressed in metal.

Disembarkation

The purpose of the operation is to reduce the length of the workpiece while simultaneously increasing the cross-section. In hot hand forging, the heated part is placed vertically on an anvil and hammered at the upper end. By heating individual places and holding the part with tongs, thickened nodes, bends, volumetric or flat elements of the intended decoration can be made on it.

Broach

Broaching is the opposite operation to upsetting and is used to lengthen the workpiece. The direction of impact when broaching is across the axis of the part with its rotation or advancement along its length.

Depending on the shape of the workpiece (flat, round, hollow, ring) and the equipment used, the broaching technique includes many techniques. Individual broaching techniques can be called by their own terms - spreading, flattening or rolling.

Rounding

The operation is used in hot forging methods and consists of rounding the edges of profile blanks. Initially, the corners of the workpiece are forged, bringing it to an octagonal cross-section. The final rounding is performed using special crimps or cutout hammers.

Threading

Threading various elements through each other is a common technique actively used in artistic forging. Threading is carried out in two ways - by assembling according to the principle of chain links or by flashing a hole in one of the elements. In this case, chisels of the required shape and size are used for the operation.

Decoration of ledges

Ledges of various shapes in the artistic forging technique are made for both decorative and technological purposes in order to secure the parts together. The ledges are made using sharp anvil ribs or special backing equipment.

Bending

Bending is a common technology actively used in artistic forging. Special machines and devices have been developed for bending, allowing craftsmen to work according to their own templates.

Elements of forged patterns

Cold forging products can be classified as one of the typical elements:

Elements of forged patterns

- Curl. A spiral curl can be unidirectional or bidirectional, that is, with a change in the direction of twisting the spiral. In practice, when using a 10-12 mm rod, you can get up to 5 turns of the spiral

- Double curl, or Chinese lantern. This is a spatial structure of two or more elements, each of which is a regular double-row spiral. Produced on a twister

- Volyuta. The curl is single-sided or double-sided, used for finishing grilles, balustrades, and furniture.

- Twist. A rod (or several rods) twisted along the longitudinal axis. Used for balusters, decorative elements, handles of fireplace tools

- Top. Used as the final element on the bars of gratings, it is a peak to which a series of curls are attached.

All these elements can be obtained using hot forging methods, however, the labor intensity of the work and the required qualifications of the blacksmith, and, consequently, the cost, will increase many times over.

Classification of decorative elements

The main difference lies between hot and cold forging.

Hot forging

If we are talking about creating complex products from artistic forging of steel with extensive ornaments, then this can only be done using hot classical forging with heating of the metal to forging temperature and achieving sufficient plasticity of the workpieces.

If the product is made of steel with a low carbon content, the heating temperature will be quite sufficient at 1000 - 1100 ° C. The higher the proportion of carbon in the steel alloy, the lower the forging temperature level. The workpieces are heated in furnaces or forges that use solid fuel.

Stamping or cold forging

Stamping or cold artistic forging is carried out at normal temperature or slight heating to the level of initial structural changes in the metal - approximately 200 - 250 ° C.

It is difficult to say which type of forging is better. Cold forging is much more comfortable to work with, does not produce scale on the surface, and forged products are distinguished by the accuracy of their shapes and sizes. Cold forging is excellent for making relief patterns on sheet metal; it can be used to forge capricious non-ferrous metals.

But with hot forging, any modifications and shapes are possible - the breadth of embodiment of artistic ideas is much greater.