0

Plain bearing materials

There are ductile (< HB 50), soft (HB 50-100) and hard (> HB 100) bearing alloys.

Plastic materials include babbitts, lead bronzes, aluminum alloys, and silver; for soft bronzes - tin, tin-lead, tin-lead-zinc; to hard ones - bronze, aluminum-iron and cast iron.

For highly loaded high-speed bearings designed to operate in the field of liquid lubrication, plastic alloys are used almost exclusively in the form of thin layers applied to steel (less often bronze) bushings and liners.

Soft and hard alloys are used for the manufacture of boundary and semi-fluid lubricated bearings operating at moderate speeds.

Babbitts

Babbitts are alloys of soft metals (Sn, Pb, Cd, Sb, Zn), characterized by the presence of hard structural components in a plastic matrix.

Babbitts are characterized by a low coefficient of friction, ductility, good run-in and wear resistance.

Plasticity ensures uniform distribution of the load over the bearing surface: it becomes relatively safe for small solid particles (metal dust, solid oil oxidation products) to enter the bearings, which are pressed into the babbitt and rendered harmless.

The disadvantage of babbitts is their low fatigue resistance, especially at elevated temperatures.

Babbitts can be paired with normalized or improved steel shafts (HRC 25-35), but to increase bearing durability it is more advisable to heat treat the shafts to a hardness > HRC 50.

High-tin babbitts, which are alloys of tin and antimony with small additions of copper (introduced to prevent segregation); Babbitt structure is solid SnSb crystallites embedded in plastic eutectic.

The main brands of high-tin babbitts are B89, B83 (the numbers indicate the tin content as a percentage).

Their thermal conductivity is (3.0–4.2)·10–2 W/(m·°C); coefficient of linear expansion (22-24)·106. Modulus of normal elasticity E = (5-6)·104 MPa. Density 7.3 kg/dm3. Hardness at 20°C HB 20-30; compressive yield strength 40-60 MPa. At 100-120°C, hardness and yield strength are reduced by approximately half.

Melting point of tin babbitts: beginning 240-250°C, end 400-420°C.

Babbitts are poured at 450-480°C onto liners preheated to 250°C. Centrifugal pouring gives the best results. Pouring into chill molds and under pressure is also used.

The thickness of the filling layer in bearings of conventional design is 1-3 mm. The fatigue resistance of Babbitt fill increases with decreasing thickness of the fill layer, as well as with increasing rigidity of the liner-bed system. Recently, the thickness of the fill has been increased to 0.25-0.4 mm. Even better results will be obtained by electrolytically depositing a layer of babbitt 10-20 microns thick on a porous bronze substrate.

A decrease in the strength of Babbitt fill at elevated temperatures is prevented by intensive oil cooling of the bearings. All this makes it possible to increase the specific loads on bearings with Babbitt filling to 10-15 MPa.

In order to save scarce tin, low-tin babbits have been developed and introduced into industry, which are more or less complete substitutes for high-tin babbits.

Lead-tin babbits B16, B6, BN, BT consist of 60-75% lead, 5-20% Sn, 10-20% Sb with small additives Cu, Cd, Ni, Fe. 0.3-1% As is introduced as modifiers.

The antifriction qualities of lead babbitts under semi-liquid lubrication conditions are lower than those of high-tin babbitts. Their thermal conductivity is (1.2–2.4)·10–2 W/(m·°С), density is 9.5–10 kg/dm3. The hardness and mechanical properties are approximately the same as those of tin babbitts. Corrosion resistance is significantly lower.

Under liquid lubrication conditions, the difference between lead and tin babbits is hardly noticeable.

Tin-free babbits BK1, BK2 consist almost entirely of lead with additives of ~1% Ca and Na. The antifriction properties and corrosion resistance of lead babbitts are improved by introducing Sr, Ba, Li, and Te in small quantities.

The composition and properties of tin and lead babbits are given in table. 28.

Cadmium babbits contain 90-97% Cd with additives of Cu, Ni, Ag and other metals that form solid structural components in the plastic cadmium base. The hardness of cadmium babbitts is HB 30–40, the coefficient of linear expansion of these babbits is ~30·10–6 1/°С, and the thermal conductivity is (8.4–10.0)·10–2 W/(m·°С).

Antifriction qualities are high. The disadvantage of cadmium babbitts is their low corrosion resistance.

Aluminum-tin alloys containing up to 20% Sn are used in bimetallic thin-walled liners. The most common alloys are the AO20-1 type (20% Sn; 1% Cu; the rest Al) and the AO6-1 alloy (6% Sn; 1% Cu; 0.5-1% Ni; 1-1.5% Si; the rest AI). The hardness of antifriction aluminum alloys is HB 35—45; thermal conductivity 0.18–0.24 W/(m °C); coefficient of linear expansion (20–22)·10–6 1/°С, density 2.7 kg/dm3.

Aluminum alloys have high fatigue resistance and can operate at specific loads up to 50 MPa. Prone to enveloping the shaft. Increased oil pumping and the use of shafts of increased hardness (> HRC 50) are required.

For non-critical bearings, cheap zinc-aluminum alloys such as TsAM 10-5 (10% Al; 5% Cu, the rest Zn) and TsAM 9-1.5 (9% Al; 1.5% Cu) are used. Their hardness is HB 60-80; linear expansion coefficient (30–32)·10–6; density 6.2 kg/dm3. The antifriction qualities of zinc-aluminum alloys are mediocre. It is necessary to use shafts with a hardness of more than HRC 50. Non-standard high-aluminum zinc alloys (30-40% Al; 5-10% Cu; the rest Zn) have the best qualities. Their hardness is HB 50-60.

Not Found

| Prev. Track. home |

Recommendations for the selection of materials.

Depending on the operating conditions of the bearing assembly, the grade of material for the polymer bushing is selected. When selecting a bushing material, it is necessary to take into account the requirements for the durability of the bearing assembly, taking into account the maximum wear rate of the bushing, operating conditions (presence of abrasive, moisture, nature of the load, etc.). Recommended polymer materials are given in table. 25a-25v. Technical specifications for rolled-up bushings made of metal fluoroplastic (Table 26 - 28).

The internal diameter of the bushings is checked after pressing them sequentially into both caliber sockets, made on one side according to the upper and on the other side according to the lower limit deviation H8 for the corresponding diameter of the seat in the product. Diameter d

must meet the fit requirements H7 and H8 depending on the type of bushing.

A sketch of a gauge for a bushing with a diameter d

= 10 mm is shown in Fig.

4. Pressing of bushings is carried out using press-fitting punches with shoulders to rest against the end or shoulder of the bushing. The diameter of the pressing punches is made according to the G7 fit, and the roughness parameters of the working surface are within the limits of Ra

0.63 and

Ra

0.32 µm. Before applying force to press in the bushing, it is necessary to install it relative to the hole in the product so as to exclude the possibility of the bushing moving skewed.

Rice. 4. Gauge for bushing

The outer diameter of the bushings is guaranteed by the dimensions of the equipment. The thickness and structure of the antifriction layer of the bushings is checked on microsections under a microscope with a magnification of 30-50 times. The service life of the bushings is 3 years. The internal diameter of the seat in the product is made according to H7 with the surface roughness parameter Ra

= 0.63 µm.

The deviation from the alignment of hole A

relative to hole B is no more than 0.03 mm (Fig. 5).

Rice. 5. Deviation from the alignment of hole A

relative to hole

B

25a. Recommended polymer materials

| Operating mode | Lubrication | Material | ||

| p, MPa, no more | V, M/S, no more | Рv, MPam/s, no more | ||

| 5,0 | 0,3 | 0,25 | Without lubrication | Thermoplastics: polyamide resin, polycaprolactam, secondary nylon |

| 5,0 | 5,0 | 20 | Periodic | Same |

| 5,0 | 0,7 | 0,80 | Without lubrication | Compositions based on thermoplastics with the addition of 5-10% antifriction fillers (silver graphite, molybdenum disulfide, talc) |

| 5,0 | 0,7 | 0,80 | Periodic | Same |

| 7,5 | 10 | 20 | Thermoset plastics: phenolic plastics, fiberglass, textolite, wood plastics | |

| 7,5 | 10 | 25 | Thermosets filled with graphite | |

256. Valid values for /pav/

(MPa m/s) during operation of TPS1*

| Material | Housing type SK 2* or gear diameter, mm | Working diameter d of bearing 3*, mm | |||||||

| 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | ||

| SFD, STD (base - polycetal) | SK | Periodic lubrication | |||||||

| 6,5/10,0 | 3,8/6,0 | 2,2/3,5 | 1,6/2,7 | 1,2/2,0 | 1,0/1,6 | 0,8/1,3 | 0,6/1,0 | ||

| 200 | 4,5/7,4 | 3,0/4,8 | 1,8/3,0 | 1,4/2,4 | 1,1/1,8 | 0,9/1,5 | 0,7/1,2 | 0,5/1,0 | |

| 100 | 3,2/5,0 | 2.3/3,2 | 1,5/2,0 | 1,2/1,8 | 1,0/1,6 | 0,8/1,4 | 0,7/1,2 | 0,5/1,0 | |

| SFD-VM, SFD-BS, SFD-DM, SFD-AF (polycetal (base), PTFE, MoS2, etc.) | SK | 9,0/13,0 | 7,0/9,0 | 3,6/5,0 | 3.0/4,0 | 2,2/2,8 | 1,6/2,2 | 1.2/13 | 0,9/1,4 |

| 200 | 7,0/10,0 | 5,0/7,0 | 3,0/4,0 | 2,6/3,3 | 2,0/2,6 | 1,5/2,1 | 1,1/1,7 | 0,8/1,3 | |

| 100 | 5,0/7,0 | 3,8/5,0 | 2,8/3,6 | 2,4/3,0 | 1,8/2,4 | 1,4/2,0 | 1,0/1,6 | 0,7/1,3 | |

| One-time lubrication | |||||||||

| SK | 5,0/8,0 | 3,5/5,0 | 1,8/2,7 | 1,5/2,2 | 1,2/1,6 | 0,9/1,2 | 0,7/0,9 | 0,6/0,7 | |

| 200 | 3.5/5,0 | 2,4/3,5 | 1,6/23 | 13/1,9 | 1,0/1,5 | 0,8/1,0 | 0,7/0,8 | 0,5/0,7 | |

| 100 | 2,8/3,5 | 2,1/2,7 | 1,4/1,7 | 1,1/1,5 | 0,9/1,3 | 0,7/0,9 | 0,6/0,7 | 0,5/0,6 | |

| ATM-2 (polyamide b (base), graphite, thermoanthracite) | SK | 4,0/6,0 | 3,0/4,0 | 1,4/2,0 | 1,2/1,6 | 1,0/1,2 | 0,7/0,8 | 0,6/0,7 | 0,5/0,5 |

| 200 | 3,0/4,0 | 1,9/2,8 | 1,2/1,8 | 1,0/1,4 | 0,8/1,0 | 0,6/0,7 | 0,5/0,6 | 0,4/0,5 | |

| 100 | 2,0/2,8 | 1,5/2,0 | 1,0/1,4 | 0,8/1,2 | 0,6/0,9 | 0,5/0,6 | 0,4/0,5 | 0,3/0,4 | |

1* The numerator indicates the permissible value /p„v/

bearing with a clearance corresponding to the E10/h8 fit, and in the denominator - with a clearance corresponding to the D10/h8 fit.

2* SC - body wall. 3* TPS width / = 0.8 d,

working layer thickness / = 0.04

d

For bushings operating at elevated temperatures, provide fastening in the product that prevents axial displacement and rotation (rolling, punching, glue fitting, etc. ). After installing the bushings into the product, their internal diameter must correspond to the designated type of bushing; it must be checked with a smooth gauge. Shaft coating - smooth chrome plating with surface roughness parameters Ra

0.63 µm for bushings made according to H8, and

Ra

0.32 µm for bushings made according to H7. Other types of coatings are allowed that provide reliable protection of the shaft from corrosion and do not increase surface roughness.

25th century Acceptable fpaV

(MPa m/s) during TPS operation

| Working diameter of the bearing, mm | Housing type (see table 256) | ||

| SK | Gear diameter, mm | ||

| 200 | 100 | ||

| 10 | 0,160/0,200 | 0,140/0,175 | 0,120/0,140 |

| 15 | 0,120/0,160 | 0,100/0,130 | 0,080/0,100 |

| 20 | 0,090/0,135 | 0,070/0,105 | 0,050/0,080 |

| 25 | 0,075/0,105 | 0,060/0,090 | 0,045/0,070 |

| 30 | 0,060/0,085 | 0,050/0,070 | 0,040/0,055 |

| 40 | 0,050/0,070 | 0,045/0,060 | 0,040/0,045 |

| 50 | 0,045/0,060 | 0,045/0,055 | 0,035/0,040 |

| 60 | 0,045/0,055 | 0,040/0,055 | 0,035/0,040 |

Note. The numerator shows the permissible values / • paV

with a thermal conductivity of the material equal to 0.3 W/(m °C), in the denominator - at 0.8 W/(m °C).

26. Rolled-up bushings made of metal fluoroplastic

Bushings are used in sliding friction units. Dimensions, mm

| d | D | D.I. | S | L | ||

| Rows of lengths | ||||||

| 12 | 16/18 | 22/25 | 2/3 | 10 | 12 | 16 |

| 14 | 18/20 | 22/25 | 2/3 | 12 | 14 | 18 |

| 16 | 20/22 | 25/28 | 2/3 | 14 | 16 | 20 |

| 18 | 22/25 | 28/32 | 2,5/3,6 | 14 | 18 | 22 |

| 20 | 25/28 | 30/36 | 2,5/4 | 16 | 20 | 25 |

| 22 | 26/30 | 32/36 | 2,5/4 | 16 | 22 | 28 |

| 25 | 30/32 | 36/40 | 2.5/4 | 16 | 25 | 32 |

| 28 | 32/36 | 38/42 | 2,5/4 | 16 | 28 | 36 |

| 32 | 36/40 | 42/48 | 2,5/4 | 20 | 32 | 40 |

| 36 | 40/42 | 45/48 | 2,5/4 | 22 | 36 | 45 |

| 40 | 45/48 | 50/52 | 2,5/4 | 25 | 40 | 50 |

| 45 | 50/55 | 55/58 | 3/4 | 28 | 45 | 56 |

| 50 | 55/60 | 60/65 | 3/5 | 32 | 50 | 63 |

| 55 | 60/35 | 67/71 | 3/5 | 36 | 56 | 71 |

| 60 | 65/70 | 71/75 | 3/5 | 40 | 60 | 71 |

| 65 | 70/80 | 75/85 | 3/6 | 45 | 68 | 80 |

| 70 | 75/85 | 85/90 | 3/6 | 50 | 71 | 80 |

| 75 | 80/85 | 85/90 | 3,5/6 | 50 | 75 | 90 |

| 80 | 85/90 | 90/95 | 3,5/6 | 50 | 80 | 100 |

Values of D, D1, S

in the numerator for thermoplastic bushings, in the denominator for thermoset bushings.

Technical requirements.

Deviations for bushing sizes are in accordance with GOST 11710-66.

For dimensions D

and

d

it is allowed to make a chamfer - see Vol. 1, Ch.

V. It is allowed to manufacture a key with rounded edges and not for the full length of the bushing. The surface of the bushings must be smooth, without burrs, swelling, cracks, delaminations, or dents. After pressing the bushing, additional processing along hole d

is not allowed.

27. Bushings with a collar made of metal fluoroplastic

Bushings made of metal fluoroplastic tape operate under friction conditions without lubrication.

Dimensions, mm

| d (off by H7 and H8) | D (off no u7) | D.I. | S | s ±0.1 | r | h | L-0.2*** |

| 5 | 7 | 12 | 1,0 | 0,3 | 1,0 | 0,9 | 4-8 |

| 6 | 8 | 14 | 4-10 | ||||

| 7 | 9 | 16 | 4-10 | ||||

| 8 | 10 | 18 | 4-12 | ||||

| 10 | 13 | 20 | 1,5 | 0,5 | 1,5 | 1,4 | 6-16 |

| 12 | 15 | 22 | 6-18 | ||||

| 14 | 17 | 24 | 8-22 | ||||

| 16 | 19 | 26 | 8-24 | ||||

| 18 | 21 | 28 | 10-26 | ||||

| 20 | 23 | 30 | 10-30 | ||||

| 22 | 25 | 33 | 12-34 | ||||

| 24 | 27 | 36 | 12-36 | ||||

| 26 | 29 | 39 | 16-40 | ||||

| 28 | 31 | 42 | 16-42 | ||||

| 30 | 33 | 45 | 16-44 | ||||

| 32 | 35 | 48 | 16-48 | ||||

| 34 | 37 | 52 | 18-56 | ||||

| 35 | 38 | 54 | 18-56 |

| d (off by H7 and H8) | D (off no u7) | D1 | S | s ±0.1 | r | h | L-0.2*** |

| 38 | 41 | 57 | 1,5 | 0,5 | 1,5 | 1,4 | 18-56 |

| 40 | 43 | 60 | 18—60 | ||||

| 42 | 45 | 65 | 20-60 | ||||

| 45 | 50 | 67 | 2,5 | 0,8 | 2,0 | 2,4 | 22-60 |

| 48 | 53 | 73 | 24-60 | ||||

| 50 | 55 | 75 | 26-65 | ||||

| 55 | 60 | 82 | 28-65 | ||||

| 60 | 65 | 90 | 28-65 | ||||

| 65 | 70 | 95 | 28-65 | ||||

| 70 | 75 | 105 | 30-65 | ||||

| 75 | 80 | 112 | 30-65 | ||||

| 80 | 85 | 120 | 32-65 | ||||

| 85 | 90 | 125 | 32-70 | ||||

| 90 | 95 | 130 | 36-70 | ||||

| 100 | 105 | 40-70 | |||||

| 110 | 115 | 150 | 40-70 | ||||

| 120 | 125 | 160 | 40-70 |

*Size for reference. ** Dimensions are given for the bushing in working condition. ***Size L

within the specified limits, take from the series: 4; 6; 8; 10; 12; 14; 16; 18; 20; 22; 24; 26; 28; thirty; 32; 34; 36; 38; 40; 42; 44: 46; 48; 50; 56; 60; 65; 70 mm.

Material: metal fluoroplastic tape with a base made of steel 08kp according to GOST 1050-88 and corrosion-resistant steel 08Х18Н10Т according to GOST 4986-79. Coating for bushings made of steel 08kp: KdZ, except for surfaces A

and

B.

The size of the gap at the joint in the free state of the bushing is no more than 0.2 mm.

The deviation from the perpendicularity of surfaces A and B relative to B is no more than 0.1 mm over a length of 100 mm. Deviation from parallelism of the sleeve joint line relative to surface B is

no more than 0.3 mm over a length of 100 mm. The difference in bushing thickness is no more than 0.03 mm. Before installation, bushings, shafts, and axles are thoroughly washed until preservative grease and dust are completely removed from their surface and wiped dry with paper or soft cloth napkins. The use of rags or rough fabrics contaminated with abrasive particles for wiping is not allowed. It is not allowed to use metal brushes or brushes to remove dirt. The washed and dry working surfaces of the shafts, axles and bushings are lubricated with an even layer of CIATIM-201 type grease. No lubrication is required during further operation. Lubrication of friction units operating at elevated temperatures (from +100 to +260 °C) is not performed during installation.

28. Smooth liners made of metal fluoroplastic

Inserts from

metal fluoroplastic tapes operate under friction conditions without lubrication.

Dimensions, mm

| d (off according to H7, H8) | D (off by u8) | S | s ±0.1 | L— 0,2 | d (off according to H7, H8) | D (off by u8) | S | s ±0.1 | L-0.2 |

| 5 | 7 | 1 | 0,3 | 4-8 | 38 | 41 | 1,5 | 0,5 | 18-56 |

| 6 | 8 | 4-10 | 40 | 43 | 18-60 | ||||

| 7 | 8 | 4-10 | 42 | 45 | 18-60 | ||||

| 8 | 10 | 4-12 | |||||||

| 10 | 13 | 1,5 | 0,5 | 6-16 | 45 | 50 | 2,5 | 0,8 | 18-65 |

| 12 | 15 | 6-18 | 48 | 53 | 18-70 | ||||

| 14 | 17 | 8-22 | 50 | 55 | 18-75 | ||||

| 16 | 19 | 8-24 | 55 | 60 | 20-80 | ||||

| 18 | 21 | 10-26 | 60 | 65 | 20-90 | ||||

| 20 | 23 | 10-30 | 65 | 70 | 24-90 | ||||

| 22 | 25 | 12-34 | 70 | 75 | 24-90 | ||||

| 24 | 27 | 12-36 | 75 | 80 | 26-90 | ||||

| 26 | 29 | 16-40 | 80 | 85 | 26-90 | ||||

| 28 | 31 | 16-42 | 85 | 90 | 26-90 | ||||

| 30 | 33 | 16—44 | 90 | 95 | 26-90 | ||||

| 32 | 35 | 16-48 | 100 | 105 | 26-90 | ||||

| 34 | 37 | 20-50 | 110 | 115 | 26-90 | ||||

| 35 | 38 | 20-56 | 120 | 125 | 26-90 |

*Size for reference. ** Dimensions are given for the bushing in working condition. Technical requirements.

Material: fluoroplastic tape with a base made of steel 08Х18Н10Т (ОХ18Н10Т) according to GOST 4986-79.

Coating for bushings made of steel 08kp: KdZ, except for surface B.

The size of the gap at the joint in the free state of the bushing is no more than 0.2 mm.

The deviation from the perpendicularity of surfaces A

and

B

relative to surface

B is

no more than 0.1 mm over a length of 100 mm.

Deviation from parallelism of the sleeve joint line relative to surface B is

no more than 0.3 mm over a length of 100 mm. The difference in bushing thickness is no more than 0.03 mm.

29. Recommended durability of bushings based on the number of cycles under variable load

| d bushings, mm | Load, MPa, no more | Possible wear, mm, no more | |||

| Denomination | Deviation | 250 | 125 | 62,5 | |

| Cycles, no more | |||||

| 5-18 | By H8 » H7 | 15000 | 60000 | 150000 | 0,10 |

| 7000 | 30000 | 75000 | 0,05 | ||

| 20-40 | By H8 » H7 | 10 000 | 50000 | 100000 | 0,12 |

| 5000 | 25000 | 50000 | 0,07 | ||

| 4 and higher | By H8 » H7 | 10000 | 50000 | 100000 | 0,20 |

| 5000 | 25000 | 50000 | 0,10 | ||

The rotation of shafts, axles and other parts in the bushings should be easy, without jamming. Recommended loads on bushings and durability.

The recommended durability of the bushings in terms of the number of cycles during reciprocating rotation of the shaft with a deflection angle of ±30°, variable cyclic load from zero to maximum and operating temperature within ±60 °C should correspond to that indicated in the table.

29. The sliding speed should not exceed 0.01 m/s. When the temperature rises to 260 °C, the loads should correspondingly be reduced by 2 times. In the temperature range from -60 to +260 °C, the change in loads should correspond to the schedule (Fig. 6). Bushings operating under loads not exceeding 50 MPa should be used taking into account the permissible pv

given in table.

30. The operating temperature should be from -60 to +60 °C. With

an increase in temperature above +60 °C, the permissible loads and

pv

should gradually decrease, as shown in Fig.

7. The axial load on the bushing shoulder should be no more than half the recommended radial load on the bushing and should be calculated on the surface area of the shoulder without radius roundings. For bushings with the worn-in layer removed after installation in the product, it is allowed to correct the shape of the hole (excessive ovality, taper, etc.) by drawing smoothing broaches with a tightness not exceeding 0.06 mm. In this case, the broach and bushing must be lubricated with CIATIM-201 grease or other grease. Friction coefficients in the absence of lubrication may increase as the antifriction layer wears out: P, MPa

Fig. 6. Change of loads in the temperature range from -60 to +260 °C

30. Allowable pv

for bushings with loads not exceeding 50 MPa

| Typical load applications when using bushings | Allowable values pv, MPa m/s (with wear not more than 0.1 mm) | |

| Shaft coating: smooth chrome plating; operating time 1000 hours | Other types of coatings in the absence of shaft corrosion; operating time 1000 hours | |

| Constant load of the rotating shaft, fixed in relation to the bushing…………………………………………….. | 0,31 | 0,23 |

| Constant load of the rotating shaft relative to the bushing…………………………………………………………………………………. | 0,42 | 0,31 |

| Variable shaft load during reciprocating rotation movement | 0,47 | 0,42 |

kinetic (µkin) - from 0.07 at the beginning to 0.2 at the end of the work static (µat) - 0.10 at the beginning to 0.22 at the end of the work. To increase durability, it is recommended to manufacture bushings with a completely removed running-in layer on a metal-fluoroplastic tape and strengthen the surface of the antifriction layer with smoothing broaches with an interference not exceeding 0.1 mm. The recommended form of broaching is shown in Fig. 8. Recommended method for calculating the dimensions of the reaming of bushings.

Calculation of the length of the workpiece development for bushings without a shoulder (Fig. 9).

Development length l

= π(

d +t1

+ 2

t2

+ З

t3

)

рv,MPa- m/s

Rice. 7. Changing permissible loads and pv

when temperature changes

Rice. 8. Recommended form of smoothing broach

where d -

the inner diameter of the bushing, taken according to the upper limit of deviation; (t1 is the thickness of the steel layer of the tape; t2 is the thickness of the layer of porous bronze; t3 is the thickness of the running-in layer of the tape. Calculation of the dimensions of the workpiece development for a bushing with a shoulder (Fig. 10)

Workpiece reamer height H = [ Hc +p(r+t1/2)/2 + (D1-(D+2r))/2 ] 1.2

Rice.

9. Reaming a blank bushing without a collar: a -

bushing:

b -

reaming

Rice. 10. Reaming the bushing blank with a collar: a -

sleeve;

b -

development: size H

c

- cylindrical part of the workpiece

where 1.2 is the shrinkage coefficient of the material during the manufacture of the bushing and for subsequent machining; Nc = L - r

Dimensions

l

and

l1

of the workpiece development

l

=π

(d

+

t1

+ 2

t2

+ 3

t3

);

/l = /+2 r1

Sin35°

where r, = H - H c

.

Examples of using bushings are shown in Fig. 11 and 12

Rice. 11. Example of using bushings without a shoulder

Rice. 12. Example of using collar bushings

404 Not Found

The requested URL /bottom.php was not found on this server.

Additionally, a 404 Not Found error was encountered while trying to use an ErrorDocument to handle the request.

Lead bronzes

Lead bronzes are alloys of Cu (40-70%) and Pb (30-60%) with additives of small amounts of Sn, Zn, Ni, Ag. In the USSR, the most common bronzes are BrS30 (30% Pb; the rest is Cu) and BrO5C25 (5% Sn; 25% Pb; the rest is Cu). High-lead nickel bronze BrS60N2.5 (60% Pb; 2.5 Ni) is also used.

Lead is practically insoluble in copper and is present in alloys in the form of rounded inclusions, more or less evenly distributed in the copper matrix.

Lead bronzes are stronger and harder than babbitts (HB 40-60). Unlike babbitts, their hardness and strength remain almost constant up to 200°C. Thermal conductivity 0.12–0.13 W/(m °C).

The disadvantage of lead bronzes is their reduced corrosion resistance (due to the presence of free lead). In addition, lead causes accelerated oxidation of the oil during operation.

The run-in properties and antifriction properties of lead bronze are worse than those of Babbitts. Bearings filled with lead bronze require particularly low roughness of friction surfaces, elimination of distortions, increased rigidity of the shaft-bearing system, increased oil pumping and thorough filtration, as well as increased surface hardness of the shaft (>HRC 50). The clearances in bearings filled with lead bronze are on average 30-50% larger than in bearings filled with Babbitt. It is advisable to use oils with a low acid number (< 1 mg KOH/g) and add antioxidant additives to the oil.

The working surfaces of bearings filled with lead bronze are processed by fine boring with diamond or carbide cutters with low feeds and high cutting speeds (10-13 m/sec).

Lead bronze is poured onto liners made of low-carbon steel in a layer 0.5–0.8 mm thick at 1050°C in graphite molds. To avoid segregation and to obtain a uniform and finely dispersed distribution of lead in the alloy, immediately after pouring, the liners are subjected to intensive cooling with water sprayed with compressed air.

Improved compositions of lead bronzes with 30% Pb with additives of Ni (up to 5%), Sn (up to 25%) and small amounts of S and Ca have been developed. The Ni additive increases corrosion resistance, S and Ca are introduced to prevent lead segregation.

Along with high-lead bronzes, ductile (HB 60-80) bronzes containing 5-7% Pb, 5% P and 5% Zn are used for filling bearings.

What types of bushings are there?

The production of bushings differs depending on the scope of their application. There are several types that have their own individual characteristics.

- Transitional. This type of bushing is used to ensure the installation of low-cutting tools that have a conical tail.

- Bearing. Their purpose is determined by their name. And the main task of bushings is to ensure efficient rotation of the axis or shaft.

- Consolidating. Serve to ensure fixation of the inner rings in bearings. In addition, they provide fastening to other elements in conical-shaped products.

- Threaded. Designed to reduce friction.

- Composite. Used only for drilling tools and mechanisms.

- Slips. They separate independent moving parts of the mechanism, which should not have contact with each other during operation.

Although the bushing looks simple and seems like an insignificant element, it is often impossible to do without it. For example, in a milling machine it is one of the key transition elements.

Silver

For heavily loaded bearings of machines produced in small series, bearings with a friction surface made of silver (added with small amounts of Sn and Pb) are used.

Silver coatings are distinguished by ductility, softness (in the annealed state, HB 25-35), good anti-friction properties and high fatigue resistance.

The thermal conductivity of silver coatings is high - 0.36-0.42 W/(m °C). Linear expansion coefficient 18·10–6. Elastic modulus E = 8.2·104 MPa. Melting point 960°C.

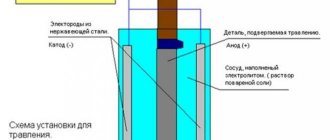

Silver is poured onto the surface of the liners in a layer of 0.1-0.3 mm or applied electrolytically onto a porous bronze or copper-nickel substrate in a layer 20-50 microns thick.

In some cases, to improve the connection with the liner, silver is poured onto a fine-mesh steel base. The sections of the steel matrix protruding to the surface increase the load-bearing capacity of the bearing.

In order to improve run-in, a layer of lead or lead-antimony spleen 10-30 microns thick is applied to the surface of the silver coating, which is covered with a layer of indium several micrometers thick to prevent corrosion.

It is necessary to use shafts of increased hardness (> HRC 50).

Oil supply pockets for liquid lubrication of smooth bearings

Dimensions, mm

Oil supply pockets, grooves and holes should not be placed in the loaded area of the bearing, either on the friction surface or on the contact surface.

| d | With | r | r1 | t | l |

| 40-50 | 17 | 14 | 3 | 1,5 | 6 |

| 50-60 | 20 | 18 | |||

| 70-80 | 27 | 24 | 4 | 2 | 8 |

| 90-100 | 34 | 32 | 5 | 10 | |

| 105-120 | 40 | 40 | 5 | 2,0 | 10 |

| 125 | 50 | 50 | 6 | 2,5 | 12 |

Multilayer coatings

In multilayer casting, a thin layer of tin babbit is applied to a substrate made of an antifriction alloy with a thickness of 0.2–0.5 mm. By making use of the valuable properties of tin babbits, this method dramatically reduces tin consumption and at the same time increases the fatigue resistance and resistance of the casting to shock loads.

Lead bronzes, aluminum alloys and bronzes are used as substrates. The best results are obtained by porous substrates made of sintered Cu–Al and Cu–Ni alloys (60% Cu, 40% Ni), which ensure a strong bond between the babbitt and the liner.

There are two methods of applying babbitt. When pouring, babbitt is applied in a layer of 0.3-0.4 mm. After processing, the thickness of the babbitt layer is 0.15–0.2 mm.

A more technologically advanced method is the electrolytic deposition of babbitt with a layer 15–20 μm thick on the surface of a substrate that has been thoroughly processed. With this method, it is necessary to use a porous substrate, which, when impregnated with babbitt, forms an anti-friction sublayer that ensures proper operation of the bearing in case of local or general wear of the surface babbitt layer.

Sometimes lead babbits are used as a surface layer. To prevent corrosion, an electrolytic layer of In with a thickness of several micrometers is applied to them, which is then subjected to diffusion by heating at 150°C for 2-3 hours.

Oil supply pockets for liquid lubrication of liners with collars

Dimensions, mm

Oil supply pockets, grooves and holes should not be placed in the loaded area of the bearing, either on the friction surface or on the contact surface

| d | With | r | r1 = l1 | t | l |

| 40-50 | 17 | 1 4 | 3 | 1 ,5 | 6 |

| 50-60 | 20 | 18 | 3 | 1,5 | 6 |

| 70-80 | 27 | 24 | 4 | 2 | 8 |

| 90-100 | 34 | 32 | 5 | 2 | 10 |

| 105-120 | 40 | 40 | 5 | 2 | 10 |

| 125 | 50 | 50 | 6 | 2,5 | 12 |

Bronze

Bronze is used for the manufacture of bearings operating in the area of predominantly semi-liquid lubrication at low peripheral speeds (bearings for auxiliary drives). Due to their increased hardness, they can withstand high specific loads.

The most common are tin, tin-lead and tin-zinc-lead bronzes (Table 29).

Tin bronzes of the BrOF type have good antifriction properties. Bronzes with a content of >0.5% Sn are cast (preferably in chill molds), those with a content of <0.5% Sn are stamped. The hardness of stamped bronzes can be reduced to HB 50-60 through softening annealing.

The introduction of lead (BrOS bronze) improves machinability, increases ductility and reduces the hardness of bronze. Bronze BrO5S25 belongs to the category of semi-plastic.

The most widely used are tin-zinc-lead bronzes, in which the content of scarce tin is reduced to 2-6%. Their ductility is higher than that of tin bronzes (elongation 6-15%); hardness HB 50-70. Tin-zinc-lead bronze BrOTsS 4-4-2.5 is used in the form of cold-rolled strips for the manufacture of thin-walled bushings.

Aluminum-iron bronzes of the BrAZh type, which have increased hardness (HB 70-100), are used for the manufacture of bushings operating at high loads and low speeds under conditions of semi-fluid and boundary lubrication (guide bushings for suction valves of internal combustion engines).

Bearings operating at high temperatures with boundary lubrication (exhaust valve guides) are made of heat-resistant iron-nickel-aluminum alloys of the BrAZhN type.

Thermal conductivity of antifriction bronzes is 0.06–0.12 W/(m °C); coefficient of linear expansion (16—18)·10–6; elastic modulus E = (8–10)·104 MPa.

Shafts operating in medium-hard bronze bearings must have a hardness of more than HRC 50, and in high-hardness bronze bearings more than HRC 55.

Sliding bushings

The tubular ring installed between the socket in the housing and the shaft is called a sliding sleeve. It separates the components of the moving assembly rotating relative to each other, which should not be in direct contact with each other. The entire bushing or just the sliding surface is made of antifriction material with a low coefficient of friction. Thus, the sliding bushing allows, by significantly reducing friction, to reduce rotational resistance, heating and wear of rubbing parts. Sliding bushings are designed for moderate radial loads and are of the same type as radial sliding bearings.

There are several criteria by which sliding bushings are classified. According to the manufacturing method, they are divided into rolled, sintered, and mechanically processed. Rolled-up sliding bushings are rolled into a ring of flat sheets a little less than one turn so that a slot remains along the side of the bushing. Sintered sliding bushings are manufactured using powder metallurgy, so they have a porous structure and can absorb 10-20% of lubricating oil by volume. The machined sliding bushing is machined from the workpiece. Rolled bushings are relatively thin, sintered and turned - more massive.

The shape of sliding bushings can be cylindrical or beaded. A cylindrical sliding bushing is a product in the form of a short pipe of even diameter. It can only withstand radial loads. Sliding shoulder bushings are cylindrical over most of their length, and at one end they have a washer-shaped extension, which is called a shoulder. They are designed for radial load combined with unidirectional axial load.

Lubricated sliding bushings have nipples on the housing for supplying lubricant. Those that do not require lubrication are called maintenance-free sliding bushings. Such bushings are more convenient to use, but less durable and have worse speed capabilities.

The main materials of sliding bushings are bronze, steel, antifriction cast iron, and polymers. Simple polymer sliding bushings use ordinary plastic, while high-quality ones use fluoroplastic (PTFE, also known as Teflon) or acetal resins (polyoxymethylene). The sliding bushing can consist of several materials: the base is usually made of steel, and the sliding surface is made of anti-friction material in the form of a thin gasket or applied layer. Among such materials are the same fluoroplastic, molybdenum disulfide and ceramic coatings. Some of these rubbing pairs require neither maintenance nor lubrication, which is a great advantage of plain bearings.

Sliding bushings are used in rotating and turning units of industrial equipment and moving machinery. These are, for example, conveyor rollers, fastenings of linear cylinders, joints of working parts of construction machines, machines for the pulp and paper, food and textile industries.

In general, sliding bushings are simple in design, resistant to adverse operating conditions such as temperature changes or contamination, but are poorly suited for long-term rotation at high speeds. Compared to sliding liners, they are easier to install and maintain, but are less resistant to high temperatures. Compared to rolling bearings, sliding bushings are incomparably more compact, but have a higher friction moment and lower load capacity.

Anti-friction cast irons

Antifriction cast irons are used as cheap substitutes for bronzes: gray AChK with flake graphite, high-strength AChK with globular graphite, malleable AChK with flake graphite and cuprous FM (Table 30).

The disadvantages of antifriction cast irons are fragility and high hardness (HB 160-250), which excludes the possibility of self-breaking in. Cast iron bearings are sensitive to misalignment, causing high edge pressures.

Cast iron bearings are used with shafts of high surface hardness (> HRC 55). Soft antifriction cast irons (AChS-3, AChV-2, AChK-2) can work in tandem with normalized or improved steels (HRС 25-35) under light loads.