Which wires are better to choose - aluminum or copper?

Property owners often have difficulty deciding which wiring is better - copper or aluminum. This question faces private developers and owners of city apartments that are planning major renovations. Not only the operational characteristics of the housing, but also the safety of the owners’ residence depends on the correctness of the decision made. In order not to make a mistake in choosing electrical wiring, you need to understand the pros and cons of each material, find out the common points and fundamental differences.

Copper or Aluminum: Which is Best for Wiring?

Nowadays, the vast majority of electricians use copper wiring instead of aluminum. But why? Why is copper better than aluminum? The answer is in our article.

In the USSR, all wiring was aluminum, but in modern new buildings you will no longer see such wiring. But why is copper better than aluminum? Which wiring is better for your home: copper or aluminum? We tell you why the material of the wires changed so quickly and irrevocably.

Advantages and disadvantages

Aluminum wiring has the following advantages:

- Small mass. This feature is important when installing power lines, the length of which can reach tens or even hundreds of kilometers.

- Affordability. When choosing a material for wiring, many are guided by the cost of the metal. Aluminum has a correspondingly lower value, which explains the lower price of products made from this metal.

- Resistance to oxidative processes (relevant in the absence of contact with open air).

- Availability of protective film. During operation, a thin coating forms on aluminum wiring, protecting the metal from oxidative processes.

Aluminum also has a number of disadvantages that you need to be aware of:

- High metal resistivity and tendency to heat. For this reason, the use of wires smaller than 16 sq. mm is not allowed (taking into account the requirements of the PUE, 7th edition).

- Loosening of contact connections due to frequent heating when passing a heavy load and subsequent cooling.

- The film that appears on an aluminum wire upon contact with air has poor current conductivity, which creates additional problems at the junction points of cable products.

- Fragility. Aluminum wires break easily, which is especially important when the metal frequently overheats. In practice, the service life of aluminum wiring does not exceed 30 years, after which it must be replaced.

Advantages

This metal is lightweight. This advantage is particularly noticeable in situations where large amounts of aluminum cable need to be used. Thus, the lightness of this metal makes aluminum cable a favorite when laying power lines. It's worth noting that aluminum is a very common metal and costs less than copper. Actually, these two factors became the reason for the use of aluminum wiring in housing construction in the USSR.

Another feature that can be considered as an advantage is corrosion resistance. Although there are some nuances here. The fact is that the surface of aluminum upon contact with air immediately (almost instantly) oxidizes. A film forms on top, which subsequently protects the rest of the wire from oxidation. The downside is the poor ability of the film to conduct current. As a result, problems arise in the passage of current at the cable junctions.

Dependence of resistance index on temperature

The temperature coefficient is a value that is equal to the change in the voltage of a part of the circuit and the resistivity of the metal as a result of changes in temperature. Most metals tend to increase resistivity with increasing temperature due to thermal vibrations of the crystal lattice. The temperature coefficient of resistance of copper affects the resistivity of copper wire and at temperatures from 0 to 100°C is 4.1 10− 3(1/Kelvin). For silver, this indicator under the same conditions is 3.8, and for iron it is 6.0. This once again proves the effectiveness of using copper as a conductor.

We advise you to study How to distinguish a battery from a rechargeable battery

The concept of “specific copper” is often found in electrical engineering literature. And you can’t help but wonder, what is this?

The concept of “resistance” for any conductor is continuously associated with an understanding of the process of electric current flowing through it. Since the article will focus on the resistance of copper, we should consider its properties and the properties of metals.

When it comes to metals, you involuntarily remember that they all have a certain structure - a crystal lattice. Atoms are located in the nodes of such a lattice and move relative to them. The distances and location of these nodes depend on the forces of interaction of atoms with each other (repulsion and attraction), and are different for different metals. And electrons revolve around atoms in their orbits. They are also kept in orbit by the balance of forces. Only this is atomic and centrifugal. Can you imagine the picture? You can call it, in some respects, static.

Now let's add dynamics. An electric field begins to act on a piece of copper. What happens inside the conductor? Electrons, torn from their orbits by the force of the electric field, rush to its positive pole. Here you have the directed movement of electrons, or rather, electric current. But on the way of their movement they come across atoms at the nodes of the crystal lattice and electrons that still continue to rotate around their atoms. At the same time, they lose their energy and change the direction of movement. Now does the meaning of the phrase “conductor resistance” become a little clearer? It is the atoms of the lattice and the electrons rotating around them that resist the directional movement of electrons torn from their orbits by the electric field. But the concept of conductor resistance can be called a general characteristic. Resistivity characterizes each conductor more individually. Including copper. This characteristic is individual for each metal, since it directly depends only on the shape and size of the crystal lattice and, to some extent, on temperature. As the temperature of the conductor increases, the atoms vibrate more intensely at the lattice sites. And electrons rotate around nodes at higher speeds and in orbits of larger radius. And, naturally, free electrons encounter greater resistance when moving. This is the physics of the process.

For the needs of the electrical engineering sector, widespread production of metals such as aluminum and copper, the resistivity of which is quite low, has been established. Cables and various types of wires are made from these metals, which are widely used in construction, for the production of household appliances, busbars, transformer windings and other electrical products.

One of the most popular metals in industries is copper. It is most widely used in electrical and electronics. Most often it is used in the manufacture of windings for electric motors and transformers. The main reason for using this particular material is that copper has the lowest electrical resistivity of any material currently available. Until a new material with a lower value of this indicator appears, we can say with confidence that there will be no replacement for copper.

Pros and cons of aluminum cables

Copper wires are superior to aluminum wires in a number of technical characteristics. But cables made of silver metal are still in demand and find their application. This is explained by the advantages that aluminum wiring has:

- low weight and flexibility during installation;

- cheapness;

- oxidation resistance.

Electrical wiring made from aluminum noodles will cost less.

It is not without its drawbacks:

- poor thermal and electrical conductivity;

- high resistance and its dependence on temperature;

- low strength, fragility.

Important! When working with aluminum cables, you must remember their low strength. If you bend the current-carrying wire 3-7 times, it is highly likely to break. If the break is under the cable insulation, it may go unnoticed until the repair is completed.

Resistivity of copper and aluminum for calculations

Despite the fact that this topic may seem completely banal, in it I will answer one very important question about calculating voltage loss and calculating short-circuit currents. I think this will be the same discovery for many of you as it was for me.

I recently studied one very interesting GOST:

I advise you to read this document, because... there's a lot of useful stuff there.

This document provides a formula for calculating voltage loss and states:

I didn’t understand anything =) Apparently, when calculating voltage loss and when calculating short-circuit currents, we must take into account the resistance of the conductors, as under normal conditions.

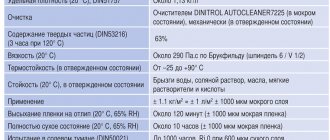

It is worth noting that all table values are given at a temperature of 20 degrees.

What are normal conditions? I thought 30 degrees Celsius.

Let's remember physics and calculate at what temperature the resistance of copper (aluminum) will increase by 1.25 times.

R1=R0 [1+α (T1-T0)]

R0 – resistance at 20 degrees Celsius;

R1 - resistance at T1 degrees Celsius;

T0 - 20 degrees Celsius;

α=0.004 per degree Celsius (copper and aluminum are almost the same);

Т1=(1.25-1)/ α+Т0=(1.25-1)/0.004+20=82.5 degrees Celsius.

As you can see, this is not 30 degrees at all. Apparently, all calculations must be performed at the maximum permissible cable temperatures. The maximum operating temperature of the cable is 70-90 degrees depending on the type of insulation.

To be honest, I don’t agree with this, because... this temperature corresponds to a practically emergency mode of the electrical installation.

In my programs, I set the resistivity of copper as 0.0175 Ohm mm 2 /m, and for aluminum as 0.028 Ohm mm 2 /m.

If you remember, I wrote that in my program for calculating short-circuit currents, the result is approximately 30% less than the table values. There, the phase-zero loop resistance is calculated automatically. I tried to find the error, but I couldn't. Apparently, the inaccuracy of the calculation lies in the resistivity used in the program. And everyone can ask about resistivity, so there should be no questions about the program if you indicate the resistivity from the above document.

But I will most likely have to make changes to the programs for calculating voltage losses. This will result in a 25% increase in the calculation results. Although in the ELECTRIC program, the voltage losses are almost the same as mine.

Rules for using aluminum wiring

Thus, we can come to the conclusion that using aluminum wiring in a residential building is not one of the best options. However, it is quite acceptable if certain requirements are met:

- Use a wire with a cross-section of at least 16 square millimeters.

- Connect individual parts using special clamp contacts. In addition, each of them must be treated with a special lubricant to prevent oxidation. Thanks to this treatment, it is possible to reduce the level of resistance, which will eliminate heating of the wiring.

§ 45. Calculation of conductor resistance. Resistivity

We know that the cause of the electrical resistance of a conductor is the interaction of electrons with ions of the metal crystal lattice (§ 43). Therefore, it can be assumed that the resistance of a conductor depends on its length and cross-sectional area, as well as on the substance from which it is made.

Figure 74 shows the setup for conducting such an experiment. Various conductors are included in the current source circuit in turn, for example:

- nickel wires of the same thickness, but different lengths;

- nickel wires of the same length, but different thicknesses (different cross-sectional areas);

- nickel and nichrome wires of the same length and thickness.

The current in the circuit is measured with an ammeter, and the voltage with a voltmeter.

Knowing the voltage at the ends of the conductor and the current in it, using Ohm's law, you can determine the resistance of each of the conductors.

Rice. 74. Dependence of conductor resistance on its size and type of substance

We advise you to study Light sources for a children's room

After performing these experiments, we will establish that:

- of two nickel wires of the same thickness, the longer wire has greater resistance;

- of two nickelin wires of the same length, the wire with a smaller cross-section has the greater resistance;

- Nickel and nichrome wires of the same size have different resistances.

Ohm was the first to study experimentally the dependence of the resistance of a conductor on its size and the substance from which the conductor is made. He found that resistance is directly proportional to the length of the conductor, inversely proportional to its cross-sectional area and depends on the substance of the conductor.

How to take into account the dependence of resistance on the material from which the conductor is made? To do this, calculate the so-called resistivity of the substance.

Specific resistance is a physical quantity that determines the resistance of a conductor made of a given substance with a length of 1 m and a cross-sectional area of 1 m2.

Let us introduce the letter designations: ρ is the resistivity of the conductor, I is the length of the conductor, S is its cross-sectional area. Then the conductor resistance R will be expressed by the formula

From it we get that:

From the last formula you can determine the unit of resistivity. Since the unit of resistance is 1 ohm, the unit of cross-sectional area is 1 m2, and the unit of length is 1 m, then the unit of resistivity is:

It is more convenient to express the cross-sectional area of the conductor in square millimeters, since it is most often small. Then the unit of resistivity will be:

Table 8 shows the resistivity values of some substances at 20 °C. Specific resistance changes with temperature. It has been experimentally established that for metals, for example, the resistivity increases with increasing temperature.

Table 8. Electrical resistivity of some substances (at t = 20 °C)

Of all the metals, silver and copper have the lowest resistivity. Therefore, silver and copper are the best conductors of electricity.

When wiring electrical circuits, aluminum, copper and iron wires are used.

In many cases, devices with high resistance are needed. They are made from specially created alloys - substances with high resistivity. For example, as can be seen from Table 8, the nichrome alloy has a resistivity almost 40 times greater than aluminum.

Porcelain and ebonite have such a high resistivity that they almost do not conduct electric current at all; they are used as insulators.

Questions

- How does the resistance of a conductor depend on its length and cross-sectional area?

- How to experimentally show the dependence of the resistance of a conductor on its length, cross-sectional area and the substance from which it is made?

- What is the resistivity of a conductor?

- What formula can be used to calculate the resistance of conductors?

- In what units is the resistivity of a conductor expressed?

- What substances are conductors used in practice made from?

The superiority of copper over aluminum for wiring

Electrical conductivity

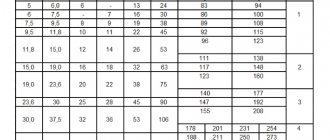

Copper is superior to aluminum in electrical conductivity. The electrical resistivity of copper is 0.017 Ohm*mm 2 /m, while that of aluminum is 0.028 Ohm*mm 2 /m. That is, the electrical conductivity of aluminum is 65% of the electrical conductivity of copper, so for the same load, aluminum wire will have to be taken with a cross-section a “step” higher than copper.

For example, you need to power a load of 5 kW. For it you will need to take either a copper wire with a cross section of 2.5 mm 2, for example, NYM 3x2.5 , or an aluminum wire with a cross section of 4 mm 2. Since aluminum wire is more voluminous, it will take up more space in the cable ducts, and it will require terminals for socket groups that are larger in size than for copper ones. Considering this, copper is more convenient to use for wiring in the house.

Oxidation

Both copper and aluminum oxidize during operation under the influence of air. However, with copper, oxidation occurs much more slowly, and the film itself (greenish coating) is quite easily destroyed, so it conducts current quite well (although the permeability deteriorates slightly). In aluminum, oxidation occurs much faster, and the oxide film itself is very dense and does not conduct current well. Oxidized connections on twists, clamps or terminals most often cause contact burning. You can remove the oxide film with quartz-vaseline lubricant, but it is not so easy to find it in stores, and this requires additional costs and maintenance time.

Mechanical strength

Copper wire is more flexible and durable than aluminum. During the installation process, the cores have to be bent, for example, for connection in distribution boxes and sockets. Copper conductors can withstand repeated bending without damage, but aluminum conductors can only withstand 5 to 10 bends, and then they break.

Aluminum wiring creates particular problems when it is necessary to repair connections in junction boxes - the old aluminum already has microcracks, so with one wrong move the wire may break off and you will have to remove part of the plaster in order to pull out at least a little of the wire.

Thermal conductivity

This parameter characterizes the ability of the conductor to dissipate heat. The higher the thermal conductivity coefficient, the better the metal dissipates heat. Copper has a thermal conductivity coefficient of 389.6 W/m* °C, and aluminum has a coefficient of thermal conductivity of 209.3 W/m* °C. That is, copper dissipates heat almost twice as well as aluminum. This is especially important at connections where the wire gets hottest. At the same load, copper will remove heat twice as fast (or rather, not heat up).

Which wiring material is best?

Now let's look in more detail which wire is better, copper or aluminum. In this regard, many stereotypes and misconceptions have appeared, which we will discuss below:

Copper wiring

When buying or building a house or apartment, it is advisable to use this type of wiring. However, keep in mind that by replacing the wiring in the apartment you have not yet received a reliable network that can withstand heavy loads. Do not forget that the input cable from the staircase panel to the apartment in old apartments is always made of aluminum. This section should be replaced, because its conductivity is now the weak point of the new network.

Advantages of copper wiring

Comparing the parameters presented below with the parameters of aluminum will allow you to make the right choice in the future. Copper, as a material for electrical wiring, has a number of advantages, which include:

- good conductivity (even after oxidation, the film on the surface does not interfere with the passage of electric current);

- service life reaches 50 years;

- high mechanical strength (the core can easily withstand bending and twisting up to 10-15 times);

- ease of installation (the industry produces several types of wires with different parameters and cores that are convenient to work with).

How to choose the right cable for PEU

In the USSR, most of the housing stock was equipped with aluminum power cables; this was the norm, the current standard. This did not mean at all that the country was poor and could not afford to massively use copper in electrical engineering, rather the opposite. It’s just that electrical network designers decided that it was economically advantageous to use aluminum rather than copper.

It must be admitted that at that time the pace of construction was so enormous that the electrical industry was provided with orders for five years in advance. During this period, the well-known Khrushchev buildings were built, in which a significant part of Russians still live. Therefore, the economic effect from such a massive use of aluminum cable products was indeed significant. Today the realities are completely different, and aluminum power cables are not used in new residential buildings, but only copper cable products, which corresponds to clause 7.1.34 of the PUE.

For aluminum power cable, the above section of the PUE left another area of application. Thus, it is preferable for lines supplying distribution networks to be made with aluminum current cores, in projects where their design cross-section will be 16 mm2 or higher. In addition, a large area of current receivers, which relates to the maintenance of electrical equipment of objects: pumping, fan and heater electrical installations can power cables with aluminum current cores with a cross-section of more than 2.5 mm2.

To summarize the above, we can confidently say that the existing standards clearly separate the areas of application of aluminum and copper power cables, taking into account all their technical and cost characteristics. However, today designers, architects, and electrical engineers working on electrical power supply projects must overcome the bias towards the use of aluminum products, especially since this technology has made great strides in the quality of this metal. This approach will make it possible to use economical aluminum during installation, which will provide significant savings throughout the country.