Quite a lot of owners of individual houses in places remote from large populated areas have to independently solve the problem of providing water to their homes. At the same time, the most popular method of water intake is a water well, which is often drilled with your own hands.

Before starting drilling work, a suitable technology is selected depending on the financial capabilities of the owner and the required water volumes. It is worth noting that the type of well source chosen is directly related to its piping, the equipment used for lifting and in-house water consumption.

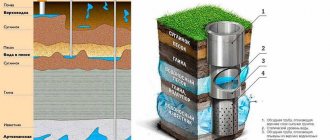

Rice. 1 Types of water intake structures

Cluster drilling

The method bears this name because the finished pattern of mouths and faces resembles a kind of bush.

Wells from several faces, grouped on one site, converge at one mouth. In the case of this method, installation and preparatory work is significantly reduced, the number of working transport communications, power lines and water supplies is reduced. A special feature of the cluster method is a certain condition for constructing a well. In particular, the most important condition is that the trunks do not intersect each other.

Disadvantages of this method:

- It is required to stop the operation of wells until the completion of construction of a certain structure for fire safety purposes.

- High risk of crossing the completed glasses.

- A major overhaul of such a structure is quite complicated.

- When drilling underwater, it is difficult to eliminate griffins.

Cluster drilling is used in cases where it is necessary to increase oil and gas recovery in a productive area, or when restarting an idle well. Well construction using the cluster method can be three-barrel, double-barrel parallel, double-barrel sequential.

The design of the bush has a conical appearance with the top in the form of a well platform. The volume of installation and preparatory work depends on the location of the mouth of the bush, and the area of the territory for future alienation from the bush also depends on this. The maximum efficiency of this drilling method is achieved in swampy areas.

Where to drill

To keep drilling costs to a minimum, you need to determine the location where the well should be. There are several rules for drinking sources:

- The nearest building is at least 30 meters away.

- At least 100 m from potential sources of pollution (road, cesspool, production workshop, etc.).

But this is not all that needs to be taken into account when you need to drill a well for water. Cost and time costs directly depend on the depth of groundwater. Therefore, before drilling, you need to find out where the water comes closest to the surface. This can be done in several ways:

- Analysis of vegetation on the site. Determine which crops grow in large quantities. There are catalogs on the Internet that indicate the length of the rhizome. This is the depth of the nearest layer of water.

- Frames and pendulums. This method is not particularly accurate, although watchmen claim that this is how the location for a well was previously determined. There is no magic here. The dowser monitors the deviations of the frame or pendulum and draws conclusions.

- Geological exploration of the site. The most accurate method. The disadvantage is the need to spend money on test drilling. It is necessary to hire specialists who will study the cut and determine where the water approaches the surface of the earth at the minimum distance.

But there is an equally effective way - talk to your neighbors. They will tell you whether the water rises during floods and whether it floods basements. And if there is a well or borehole in an adjacent area, you can focus on their depth. There will be differences, but they will be minor.

Industrial drilling methods

The auger method is used when working in areas with sand and gravel soil. Aquifers can be located at a depth of several tens of meters. With this method, the soil is pushed outward by the blades of a rotating device. This production method is considered quite fast. But it is more often used in the construction of small-sized structures.

Impact drilling diagram

In the percussion-rope method, a powerful pointed chisel is used to excavate soil rocks. It produces forward-return movements, destroying the soil. For more efficient production, a special weighting rod is used. It is attached to the drilling structure.

The most productive method of excavating soil during the construction of water intake devices is considered to be the rotary method. Its efficiency is several times higher than the rope-impact method. This is achieved due to certain design features of the installation:

- during the work, a roller bit is used as part of the drill string;

- its rotation is carried out using a rotor;

- To increase productivity, a heavy duty drill pipe is used;

- the well walls are treated with a special flushing solution;

- For the final construction of the well, casing pipes, filtration devices and pumping units are used.

Features of manual drilling

The manual drilling method requires a lot of physical strength, but allows you to save on equipment. It is used when installing wells no more than 25 meters deep and is carried out until the drill reaches the waterproof layer.

In the case of manual drilling, use:

- a set of drilling heads (drill bit, drill spoon, coils, bailers);

- rods;

- winch or electric hoist;

- casing;

- for working at great depths - a drilling rig.

The shaft sinking process consists of the following steps:

- A small hole 40-50 cm deep is dug in which the drill will be placed.

- Then one person begins to rotate the drill; when it goes deep enough, you will have to rotate it with two people, then with four people.

- Every 50-70 cm of entry into the ground, the drill must be pulled out and cleaned so that dirt does not cover the entire head.

- If the soil is too hard, the resulting hole must be filled with water.

When the shaft is filled with water from the inside, work stops. Now all that remains is to pump out the dirty water with impurities - approximately 5-7 liters. For this you will need a pump.

The main advantage of the manual method is low cost, uniform barrel structure along the entire length. However, it can only be used at shallow depths. The flow rate and service life of such a well leave much to be desired.

Equipment

Rotary drilling cannot be carried out without special equipment, which includes the following devices and mechanisms:

- tower;

- rotor;

- drilling rig with drive;

- piston type pumping equipment;

- drill swivel;

- mechanisms and equipment for performing cleaning using a washing solution;

- traveling system consisting of a crown block;

- gutter;

- vibrating sieve;

- hydrocyclones (commonly used in oil drilling).

The mobile version of the rotary drilling rig has all of the above components, except for the cleaning system using a flushing solution.

Characteristics of rotary drilling

This method of making deep wells is considered the most common. The operating principle of the installation is to destroy the soil layer using a chisel. It is driven by a rotor. A separate electric motor is required to rotate it. The soil is washed away using direct or reverse flushing.

The equipment allows you to work in rocky or semi-rocky areas, to develop wells up to 150 m deep, but the technology is used under the following conditions:

- The hydrogeological characteristics of the site and the depth of the water horizon were calculated.

- An underground source has the pressure inherent in an artesian well.

- It is possible to constantly supply the work area with process water.

In warm regions, this drilling method can be used even in winter.

Equipment and tools used

Rotary drilling requires a frame or lattice type derrick. It contains equipment for work. The tower makes it easier to lift the column. The installation contains:

- tower;

- bit;

- motor and drive;

- working column and rotor;

- pumps;

- system for cleaning the flushing liquid;

- mechanism for lifting the working tool.

In automatic installations, it is possible to adjust the speed of rotation of the drill. The chisel is made from high-strength metal alloys. Its shape is different. These parameters are selected individually.

Rotary drilling is a method of rotary-vibration drilling, in which soil destruction is carried out using a bit driven at the bottom of the well by the rotor of the drilling rig.

The uniqueness of rotor technology

This well construction method involves the use of a bit. The walls of the mine should be strengthened with casing pipes. To select a flushing method, the type of soil and the amount of liquid required are taken into account. Backwashing is preferable. It is technologically more complex, but allows for better opening of the aquifer. It also ensures a higher flow rate of the well.

Advantages and disadvantages of rotary drilling

The advantages of this technological process are:

- large drilling depth;

- the possibility of reaching a water carrier in rocks;

- large well diameter (up to 20 cm);

- low energy consumption.

The only drawback of the method is the need to use washing.

Oblique method

To perform the inclined drilling technique, the following tools and materials are required:

Drilling earth tool:

- Cleaver;

- Beam;

- Twine;

- Long drill guide pin;

- Cable;

- Casing;

- Metal cable.

This method is most often used when repairing communications, especially in cases where a residential building has already been constructed, but it is necessary to install sewerage or water supply through the foundation. To avoid digging deep trenches, inclined drilling is used. To begin with, calculate the angle of inclination so that the lower part of the hole coincides with the end of the embedded pipe.

The earth drill is installed in a pre-selected location and immediately given the desired angle of inclination using a transverse beam laid on the trench. A guide pin is installed on the drill, allowing you to maintain the direction specified before starting work, and drilling of the hole begins. Here, continuous monitoring of the process is required, since when deepening or deviating from the desired trajectory, the walls of the pit should be trimmed.

When the pit is ready, a casing pipe is lowered into it, repeating the diameter of the well.

Casing pipe structure

A cable and a metal cable are passed into the pipe, then the required cable or hose is pulled into the pipe using the cable. A string is tied to the cable, with the help of which, if necessary, the cable is pulled back.

If the power cable is located in the pipe, the hose or cable can be easily replaced. In this case, you can cope only with the help of inclined drilling alone, while you will not have to dig a deep trench and violate the integrity of the foundation.

Tips and tricks

Drilling a water well with your own hands is difficult and problematic. Some tips and recommendations:

- In order for the water in the source to always be clean, it is necessary to ensure an influx of fresh air. Several ventilation holes at the top of the structure will help with this.

- The upper part should be equipped with a folding hatch. This will allow you to quickly inspect the mine and remove pumping equipment from it.

- At the end of the drilling work, it is necessary to collect water and send it to a laboratory for analysis. This will reveal the content and composition of impurities in it. Water sampling for analysis should be done after some time, and not immediately after drilling is completed.

- Water quality can be improved by installing filtration equipment.

Technologies and methods of water drilling are different and have their own specifics. Before starting drilling operations, you need to collect the necessary data, stock up on tools and equipment. It is advisable to acquire basic skills.

Areas of use of such technology

Among the points of application of core drilling, it is worth highlighting several main ones.

Mining industry – development of mountain deposits of solid minerals.

The result of the pass is a core with a solid structure, which is used to analyze the rocks in this area. It is periodically removed to find out the pattern of rock occurrence in this area.

Autonomous water supply - the organization of the process requires exploration of the subsoil of private landholdings in order to have access to underground sources of water. Hydrogeological drilling is necessary to select the location of a water well.

Construction - for drilling a dictating well for driving piles - arranging pile foundations. Builders need to know at what depth the sand layer will be or where large stones will begin. The stability of the building depends on this. This technology is ideal for drilling large diameter holes in reinforced concrete structures.

This method is suitable for vertical passage of wells, horizontal and at the desired angle.

Drilling depth

The location of aquifers relative to the soil surface depends not only on the region and hydrological features. The quality of water that is the target of drilling plays a role. Experts distinguish three key aquifers that differ in water quality, capacity of moisture reserves, and depth.

Not far from the surface (3-10 m) there is the first layer of water, called perched water. This is exactly the kind of water that you can get to without much difficulty if you drill with your own hands. It is extremely rare to encounter hard rocks along the drilling path, therefore, with a little experience and a simple tool, it is possible to construct an Abyssinian well (this is the name of a well for extracting moisture from perched water). The thickness of the surface water layers is small, so you should not count on a debit higher than 0.5 m3 per hour. The quality of water in most cases is low, which is only sufficient to meet technical needs.

The occurrence of sandy aquifers is at a depth of 10-35 m. The water here is of satisfactory quality, the inflow capacity is greater (discharge up to 1 m3). It is hardly advisable to drill with your own hands to a sandy water carrier, although experience shows that some diligent water “prospectors” succeeded in this if the horizon was at a shallow depth (up to 15 m). In most cases, mechanized drilling methods are used to construct a well “on sand”.

The deepest are the limestone aquifers (30-250 m), which you definitely cannot reach by drilling with your own hands given their very superficial location relative to the soil surface. In order to get loose limestone that carries the highest quality artesian water, sometimes not every drilling technique is suitable. The water inflow here is much higher (3-5 m3) and depends on the thickness of the formation and the perfection of the well. Now let’s look at the currently used methods of drilling water wells, including those that can be done with your own hands.

Artificial curvature method

Artificial curvature of the drill bit axis is applicable when drilling oil or gas wells is necessary. Artificial diversion is divided into cluster and multi-hole. This method is successfully used in the following cases:

- For working with deep layers under slopes;

- When the completed barrel deviates;

- When oil occurs under a layer of salt deposits;

- If necessary, bypass crumbling areas;

- To open layers located under the bottom of a reservoir;

- When constructing a face into layers under residential buildings;

- If it is impossible to remove the backfilled well;

- To step aside with a new direction;

- To save time on drilling;

- When drilling using the cluster method in flat areas;

- When passing through a coal seam for degasification.

The forced curvature process requires special motors, including an electric drill, a turbo drill and a screw motor.

https://youtube.com/watch?v=f74Rdq0gXeQ

Types of drilling methods

Previously, drilling of water-bearing wells for personal use was carried out mainly by hand. This was a labor-intensive and lengthy process, so not every owner of a plot or cottage could boast of having their own source of water supply.

Gradually, mechanized drilling replaced manual methods due to the significant facilitation and acceleration of the process.

Today, almost all aquifer wells are drilled using a mechanized method, which is based on the destruction of soil, supplying it to the surface in one of two ways: dry, when waste soil is removed from the well using mechanisms, and hydraulic, when it is washed out with water supplied under pressure or gravity.

There are three main methods of mechanical drilling:

- Rotational (soil is developed by rotation).

- Impact (a drilling projectile destroys the soil with impacts).

- Vibration (soil is developed by high-frequency vibrations).

The rotational method is considered the most highly productive, 3-5 times more efficient than the shock method and 5-10 times more efficient than the vibration method. In addition, the rotational method is the most inexpensive and accessible; it is often used as the main method of manual drilling.

Mechanical rotary methods of drilling water wells have replaced ineffective manual methods.

In turn, the rotary drilling method, widely used for the construction of water wells, is divided into four main types of drilling:

- core;

- screw;

- shock-rope;

- rotary.

Each type of rotary drilling has its own characteristics and is performed with equipment specially designed for this purpose. Let's look at these types of drilling in more detail, determine what their differences are and what method needs to be used in each specific case.

Multi-hole method

This method consists of drilling two shafts from the main downhole nozzle, and the main shaft is used more than once.

In this case, the working area and filtration surface increase, but the volume of drilling work in the surface formation is reduced.

Depending on the auxiliary shafts, the following types of multi-hole construction are possible:

- Radial - horizontal main trunk and radial - auxiliary.

- Branched - consists of two inclined trunks and an inclined main one.

- Horizontally branched - similar to the previous type, but the angle of the auxiliary trunks is ninety degrees.

The choice of the type of multilateral structure is determined by the shape of the auxiliary shafts and their placement in space.

How are wells drilled for water supply?

Any well is designed to lift water from a deep water layer to the surface. Its principle of operation is based on arranging a trunk in the form of a pipeline by installing a casing (pipe) so that the downhole part with a coarse filter is inside the water source, while the lift of the liquid is ensured by a submersible or surface type pump.

Thus, water penetrates through the holes in the bottom of the column and is forced up the wellbore to the surface.

Kinds

Taking into account the design features and depth, the following types of water wells are distinguished:

- Abyssinian well (tube well). It is constructed by driving a pipe into the ground, and therefore the depth is no more than 6-10 m . The water rises from the uppermost layer (groundwater) and is significantly polluted. It can be used for technical purposes or for drinking, but only after boiling.

- Well on sand . It is drilled to a depth of 14-25 m , which allows the use of any drilling method. Usually it is lined with a pipe with a diameter of 12-20 cm. The flow rate of such a well is small and it is intended for small farms. The work uses a centrifugal pump installed on the surface.

- An artesian well is drilled to the lower, productive water layer at a depth of more than 50 m . The water in it is absolutely clean and is used for drinking. Lifting from it can only be done using a submersible pump.

Functional units

Any well, regardless of depth and type, has the following functional zones and components:

- Bottom-hole zone or water intake . This is the lower part of the well, which is located in the water layer. Here, through the perforation, water enters the casing. A required element is a filter .

- Casing (pipe) or suction line. Its task is to provide a sealed channel for water from the bottomhole zone to the entrance to the pump (pump water intake), which must be equipped with a check valve to prevent reverse water flow.

- Pump . It ensures the rise of water, for which it creates a certain pressure.

- Hydraulic accumulator or storage tank . This unit is responsible for protecting equipment from water hammer , providing a water reserve and creating the required pressure in the water pipeline.

- Pressure switch and control equipment.

- Well head . This is the upper, above-ground part of the well, protecting it from contamination from above, freezing and distribution of raised water.

Equipment

To install a water well, you need the following supplies and equipment:

- Pump . It is selected taking into account the depth and productivity of the well, the size of the casing, and the length of the water main. When the shaft depth is up to 10-12 m, a surface, centrifugal pump of the required power is most often used. For deep wells, a submersible pump is used. It requires a support cable, a safety cable and a submersible electrical cable.

- Pumping station with an automatic process control system. It must have monitoring devices and overload protection devices.

- Hydropneumatic tank . It is designed to maintain stable system pressure and optimize pump operation. A constant water level in it is maintained using a level switch. The dimensions of the tank depend on the power of the equipment and the flow rate of the well. The volume can vary widely from 20-30 to 1000 liters. Containers with a volume of about 100-150 liters are considered optimal.

- Caisson . The well head can be arranged in different ways, but the most popular is a caisson, which is a metal box (tank) that seals the wellhead. It is mounted with a small depth (up to 1-1.2 m) and has dimensions sufficient to accommodate connecting equipment and an operating person.

- Communications . Cable, wire to ensure reliable power supply and water pipes from the caisson to the points of water consumption.

We recommend: How to properly dig a foundation pit and trench for the foundation of a private house? Soil development manually and with an excavator

The upper part of the well and the water supply system are located in the zone of soil freezing, and therefore they must be reliably insulated.

Installation sequence

The submersible pump is mounted in the following sequence:

- installation of a check valve (if it is not included in the pump kit);

- fastening on a cable and connecting the cable;

- immersing the pump to the required depth;

- installation and connection of a hydraulic accumulator (hydropneumatic tank);

- connection and adjustment of the control and monitoring system;

- installation and connection of fine filters;

- connection to points of consumption (heating equipment, mixers, etc.).

Downhole device diagram

A standard deep well device with a submersible pump has the following basic design :

- perforated casing water intake with settling tank;

- coarse water filter;

- submersible pump with check valve and water intake;

- a conduit or pipe (hose) for raising water connected to a pump;

- waterproof cable for power supply to the pump;

- borehole or extended top of wellbore;

- head, caisson;

- shut-off equipment (ball valve);

- control devices, pressure gauge (up to 8-10 bar);

- pumping mechanism with ball valve.

The well operation scheme is quite standard:

- Water under the pressure of the formation seeps into the settling tank and accumulates in it.

- When the pump is turned on, water rises along the casing, enters the pump water intake and is directed up the water pipeline.

- In the caisson, water is directed to a hydraulic accumulator, where a certain supply is created, after which it enters the water supply system.

Types of wells

There are 3 main types of wells:

- filter;

- artesian;

- Abyssinian.

Filter well (for sand)

The filter well is dug to a depth of 40-50 meters. The limit for it is the sand layer. Drilling of wells of this type is not carried out deeper than this.

Scheme of an artesian well with a conductor

Artesian are considered the deepest types. The depth of their drilling ranges from 50 to 400 meters. The main purpose of such holes is to obtain clean artesian water of high quality.

Abyssinian - the shallowest. The depth of their drilling does not exceed 30 meters. When creating holes of this type, a submersible pump is not used due to the small diameter of the pipe.

For private houses, organizations that drill wells dig a filter-type well to a depth of 40 to 50 meters. Such water wells are often called artesian, which leads to a substitution of concepts. Their difference from filter wells is not only in depth, but also in the quality of the water received. There is a big difference in the price of the work and the complexity of the work.

Device and circuit

The diagram shows water layers. The high water is fed by precipitation and lies at a depth of up to 10 meters. The quality of the water allows it to be used immediately for drinking. A source with interstratal waters is made independently. To obtain better quality water, an artesian well is made.

According to SNiPs and established standards, the source is protected from any kind of pollution. The distance from the septic tank is 15 meters. Cesspools at least 50 m away. More than 100 meters from warehouses and industrial enterprises. The distance from a neighboring source, residential buildings, chicken coops and barns is also taken into account.

Advice: drilling a well for water near trees with a large root system is difficult.

Features of the technology

First, let’s define what a rotary drilling method is. This is a special technology for drilling wells, which is used if it is necessary for a hydraulic structure to produce large volumes of environmentally friendly drinking water. In this case, the well will be characterized by stable and durable operation. In this case, this method is better suited than any other drilling technology.

The rotary drilling rig and the technology itself have the following advantages over other drilling structures and techniques:

- A well drilled in this way will have high productivity, that is, it will produce water in large volumes.

- Durability of hydraulic structures.

- The water supply from the well is stable (without a drop in level or interruptions).

- The quality of the extracted liquid will be at its best. It can be safely used for drinking purposes.

This method of drilling wells makes it possible to obtain a hydraulic structure that will have such a high flow rate that there will be enough water from the source not only to supply water to a residential building, but also to water the garden, fill swimming pools and other reservoirs, as well as to satisfy various technical needs.

A rotary drilling rig is used when it is necessary to drill a deep well for water. The essence of the method is as follows: a shaft with a tip in the form of a chisel is lowered into the drill pipe. As the shaft rotates, the bit destroys the rock. Rotation is carried out due to the functioning of a hydraulic installation.

To clean the well of the rock in it, a special flushing solution is used. It is fed into the pipe penetration. In this case, two delivery methods can be used:

- Drilling fluid is pumped into the drill pipe using special pumping equipment. After this, it is squeezed out through the annulus. This method is called direct flushing. It is he who is shown in the video at the end of the article.

- The second method is done differently. The solution is fed into the annulus and then, using pumping equipment, is pumped out of the drill pipe along with crushed rock. This method is called backwashing.

The backflushing method has one undeniable advantage - using this technique it is possible to obtain a hydraulic structure with a large flow rate, since the opening of the aquifer occurs at the highest quality. Among the disadvantages is the need to involve complex high-tech equipment, which is why this technique is more expensive.

The advantage of rotary drilling with direct circulation is its relative cheapness compared to the second method. That is why this method is most often used when drilling water wells on private property.

Selecting a well type

Drilling water wells is a process that requires technical savvy and some preparatory steps. First of all, you should determine what type of well to drill, and also analyze whether the produced water is suitable for consumption.

The wellbore can be:

- Filter - sand well;

- Without filter - artesian well;

- A tubular well.

Artesian

Drilling an artesian type well involves drilling to a depth of up to two hundred meters - porous limestone lies at this depth. The advantage of artesian water wells is the uninterrupted supply of water regardless of the time of year, since at such a depth the water will not freeze. The lifespan of a well reaches fifty years.

Drilling principle

Sandy

Sand wells are drilled to a depth of up to thirty meters. Such a well consists of a buried pipe, at the end of which a filter is installed that retains large mechanical impurities and sand. A sand well can provide water to a summer cottage or a small country house.

The advantage of a sand well is the ease of drilling and the relatively low cost of constructing and maintaining the well. The disadvantage is:

- low productivity;

- probability of siltation;

- ingress of ground or surface water into the well.

In addition, a sand well usually lasts no more than ten years.

Well

Scheme and installation of an Abyssinian well

A well installed to extract clean water is called Abyssinian or tubular. It is drilled to a depth of fifteen meters, and the face is constructed with factory-made concrete rings. If there is a good spring on the site, the well quickly accumulates water.

When deciding on the type of well, consider the volume of water you need for consumption and the regularity of water consumption. For example, a sand well will fully provide a summer cottage where people live only in the spring and summer.

If you need to provide water to a house where you live all year round, an artesian well is suitable as the most acceptable option for autonomous water supply.

Basic methods of drilling wells

Depending on the type and condition of rocks in the near-surface layer, the diameter and type of rock-cutting tool, drilling method, type of cleaning agent and drill string, the following main methods of drilling wells are used.

- 1. Installation of the well direction pipe into a hole previously dug by hand. After installation in the pit, the direction pipe is either cemented or buried. This method is used when drilling large-diameter wells with roller bits with flushing the well with a clay solution (mainly oil and gas wells) and when drilling exploration wells using the percussion-rope method.

- 2. Drilling a well “dry”, i.e. without flushing or purging. This option is used when drilling from the surface of the earth in cases where the upper interval of the geological section is represented by sedimentary rocks using conventional projectiles (without a removable core receiver). For drilling, the core set is equipped with a carbide bit of the SM or SA type, and drilling is carried out with slow rotation of the column and increased loads to a depth of 2-3 m to the bedrock. If the bedrock lies deeper, then they drill “dry” to the maximum possible depth, and then install a guide pipe and drill to the bedrock with flushing with a smaller tool.

It is possible to drill “dry” by planting a casing string equipped with a crown or shoe into loose granular rocks with rotation and under the influence of increased axial load to the maximum possible depth. After this, the casing is not removed, but the rock inside the column is drilled out with flushing using a smaller core set.

3. Drilling with blowing with a pneumatic hammer or roller bit can be used in any, including hard, weathered rocks, rocks saturated with large fragments and to significant depths. This method is recommended for various drilling conditions, but only if core is not required in the drilling interval. For drilling, you can use, for example, a P-105 air hammer (bit diameter 105 mm) and a compressor providing an air pressure of 0.2-0.5 MPa. For rapid drilling, it is advisable to have a mobile compressor with a set of drilling tools in the organization specifically for drilling operations.

When drilling through unstable, alluvial, and loose rocks, drilling with an air hammer can be carried out from the surface with advanced fastening of the wellbore, when the destruction of the rock at the bottom is accompanied by clogging of the casing, equipped with a shoe or a special bit. According to this scheme, drilling is carried out in accordance with the OD, ODEX and DEPS methods of Atlas Copco.

4. Drilling with flushing with diamond or carbide tools is carried out when drilling from underground mine workings without installing casing pipes, if the rocks are stable and not prone to swelling and collapse.

In this case, process water is removed from the well by the spout and enters the sump through a groove.

The wellhead when drilling horizontal or rising wells drilled from underground mine workings must be equipped with a special wellhead sealing pipe when using an SSC drill for drilling. Then the delivery and extraction of the core receiver and overshot is carried out due to the adjustable hydraulic pressure in the sealed space of the wellbore.

The option of drilling with flushing is also practiced when drilling wells from the surface of the SSC. In this case, drilling is carried out with water washing using a SSC core set with a carbide or diamond bit to the maximum depth and a core receiver with a core is removed to the surface. Process water, at the initial stage, flows out of the well and is removed outside the drilling rig through a groove. Next, drilling is carried out with a larger casing pipe left in the well and emerging on the surface of the core pipe, equipped with a reinforced shoe. After drilling with the casing, drilling with the SSC drill continues, and drilling with the casing is carried out until the casing enters dense bedrock.

Drilling with flushing is also carried out when drilling with a double column KGC (hydraulic core transport). In this case, water circulates through the gaps in the column and enters the sump without overflowing or contacting the walls of the well.

Limestone well drilling technology

Within the Moscow region, aquiferous limestones occur extremely unevenly, from 20 m in the south to 200 m in the north, but the most common distribution of the artesian horizon is at a depth of over 100 m.

Due to the great depth of artesian waters and, accordingly, high formation pressure, a water well on limestone can be pressurized, sometimes self-flowing.

Advantages of an artesian well:

- possibility of drilling anywhere;

- stable water quality;

- long service life;

- high performance.

Disadvantages of an artesian well:

- technological complexity of drilling;

- high cost of drilling;

- high mineralization of water is possible;

- legal entities require a license to use subsoil.

Due to the ubiquity of water-saturated limestone, as well as the high yield of artesian wells, such a well is the optimal solution for monumental buildings, housing cooperatives, as well as industrial purposes.

Drilling artesian wells is a rather complex process due to the depth and hardness of the rocks. Depending on the geological conditions in different areas of the Moscow region, certain problems arise during the drilling process.

In the Volokolamsk region, difficulties can be created by granite deposits found near Sychevo and Cheredovo. Although in a number of settlements the aquiferous limestones are not located deep, from 30 to 50 meters. Also, aquiferous limestones do not lie deeply near the bed of the Moskva River in the Voskresenskaya region. In the Kashira region, the first limestones lie at a depth of about 40 m, however, they do not have sufficient water yield and only complicate further drilling to water-saturated carbonate rocks located at a depth of 70 - 140 m. In addition, unstable rocks are found in the section, which leads to an increase in consumption drilling fluid. It is necessary to select casing pipes of larger diameter to cover these rocks. In the Lotoshinsky, Ruzsky and Odintsovo regions, drilling is complicated by boulders found in the rock. In the rock section of the Chekhov region there are crumbling limestone rocks that require reliable metal casing.

The optimal solution for drilling artesian wells is rotary drilling. Due to the simultaneous impact of axial load and torque on the rock cutting tool, drilling productivity is significantly increased.

Hydraulic drilling is suitable for rocks of categories V-XII. The hydraulic hammer is installed between the core set and the drill pipes. By means of drill pipes, drilling fluid is supplied to the bit and rotated. The flushing fluid removes cuttings from the bottom, cools the bit, and also drives the impact machine. As the drilling fluid flow rate increases, the energy of a single impact increases, which leads to an increase in the intensity of rock destruction.

In relatively soft rocks, an increase in the axial load speed increases the drilling speed, and in hard abrasive rocks, with an increase in the axial load, the wear of the rock cutting tool increases.

In hard rocks, it is advisable to use a pneumatic hammer. Pneumatic percussion drilling is a type of rotary impact drilling, using a submersible drill hammer - a pneumatic hammer, powered by compressed air energy. The piston striker of the air hammer applies translational and reciprocating movements along the shank, which is part of the bit, which rotates along with the hammer. The bottom hole is cleared of drilled rock by blowing the well. As the well deepens, the drill string increases in length.

The diagram of air percussion drilling is shown in Figure 11.

Figure 11. Scheme of air percussion drilling 1 – bit, 2 – air hammer, 3 – drilling tool, 4 – rotator with an electric motor, 5 – feed mechanism, 6 – compressed air supply hose, 7 – compressor, 8 – control panel.

Preliminary work

After the drilling machine is installed, a special commission arrives to check the equipment, technology and quality of work.

When the drilling rig is ready, pre-drilling work begins. As soon as the drilling machine is installed and the construction of the structures is completed, the drilling rig is inspected by a special commission. The foreman of the drilling team, accepting the commission, together with it monitors the quality of work, checks the equipment and compliance with labor protection.

For example, according to the method of execution, lamps must be in an explosion-proof casing; emergency lighting at 12 V must be distributed throughout the mine. All comments made by the commission must be taken into account before the start of drilling work.

Before drilling begins, the equipment is equipped with the appropriate equipment: a square hole, drill pipes, a bit, small-scale mechanization devices, casing pipes for the conductor, instrumentation, water, etc.

The drilling rig should have houses for living, a gazebo, a dining room, a bathhouse for drying things, a laboratory for analyzing solutions, equipment for extinguishing fires, auxiliary and working tools, safety posters, first aid kits and medicines, storage for drilling equipment, and water.

Drilling tower installation diagram.

After the drilling rig has been installed, a series of work begins on re-equipping the traveling system, during which equipment is installed and small-scale mechanization equipment is tested. Drilling technology begins with the installation of a mast. Its direction must be set exactly in the center of the tower axis.

After centering the tower, drilling is carried out according to the direction. This is lowering the pipe to strengthen the wells and filling its upper end, which should coincide in direction with the gutter, with cement. After the direction in the process of drilling wells has been established, the alignment between the axes of the rotor and the tower is checked again.

In the center of the well, a square hole is drilled and lined with a pipe in the process. Drilling the well hole is carried out with a turbo drill, which is held by a hemp rope to prevent too rapid rotation. One end of it is attached to the leg of the tower, and the other is held in the hands through a block.

Features of an automatic pumping station

This solution (automatic pumping station) is almost ideal when the well depth is small. Its main components are:

General structure of an automatic pumping station.

- water intake on which a mesh and check valve are located;

- pump;

- pressure regulator;

- hydraulic accumulator;

- automation;

- pressure gauge

An external pump can be installed either indoors or in a pit. If the well is not located in the basement, but next to the house, then the water pipe must be located at a depth that exceeds the level of soil freezing in your area. At the entrance to the house, a comb must be installed, which will ensure that all consumers are connected to the water supply.

Process steps

The technology is implemented in the following sequence:

- The surface is cleaned of debris and foreign objects.

- Not far from the future hole, a two-meter deep hole is dug to drain the flushing liquid.

- A hole is punched in the ground to accommodate the drill, the crown is connected to the core pipe, and it is expanded as the drilling progresses.

- Afterwards, with drill pipes - the upper one is fixed in a drilling rig powered by an engine - in this way, drilling begins.

- When the pipe is completely filled, it is lifted to the surface, extracting the rock from it with a hammer, the blows are not applied too hard.

- The drill is again immersed in the well and drilled until the required depth is reached.

Drilling is carried out with flushing, but if there is not enough water for this, the work process is carried out dry. If specialists use diamond tools in their work, they use a special emulsion for regular washing.

In the case of sandy soil, add liquid glass, clay mass, and strengthening the walls of the hole to the solution.

For soils with an unstable structure, the well is strengthened with casing pipes during the deepening process. Often, instead of washing with water, they use cheaper blowing with compressed air.

Equipment for blowing wells with compressed air

Features of auger drilling

Of all the drilling methods, this is considered the simplest and most effective. The destruction and removal of soil from the mine is carried out by rotating a screw-like device. The diameter of the well is 10-60 cm, and the maximum depth is 25 m. No additional equipment is required to remove soil.

Equipment and tools involved

The main tool used in the work is an auger. This is a metal rod with blades. In addition, industrial types of vehicle-based equipment are also used.

Most of these installations are equipped with shells that are empty inside and have reverse locks that prevent the working tool from moving in the opposite direction. Cooling of the cutting surface occurs through the broken soil. Drilling using such installations is carried out practically without interruption, so the consumption of time and electrical energy is reduced.

Auger drilling technology

First, a penetration of up to 2 m is carried out, after which the tool is removed from the shaft into which the casing pipes are placed. They prevent the collapse of the well walls. This makes it possible to use the method on loose soils. Work continues until the aquifer is reached.

Pros and cons of using an auger

This technology has the following advantages:

- high level of productivity;

- simplicity and accessibility of technology;

- relatively low cost;

- the soil rises to the surface during drilling;

- Possibility of use on hard and dry areas;

- no risk of soil erosion.

Drilling with an auger is a fast and inexpensive method that does not require organizing a reservoir for the flushing fluid.

The only disadvantage of auger drilling is the impossibility of using it in the presence of rocks in the ground.

Drilling a sand well

To drill a well with your own hands, you can use the percussion method. In the selected area, prepare a platform for mounting the tripod.

The type of projectile depends on the type of soil - dense clay soil is pierced with a glass, and loose clay soil is pierced with a bailer. The glass can be turned into a bailer by welding a cone with a metal ball on the inside of the pipe.

The tower is assembled in the form of a tripod made of metal pipes; a pulley for a moving rope is attached at the top. At the base there is a lifting mechanism and a shaft on which the rope is wound.

Drilling a sand well

In the place where the well is planned, a recess of half a meter is made for the casing. The projectile must fall into this hole. The projectile rises and drops sharply into the recess. Every meter, the drilling tool is lifted and cleaned of adhering soil.

Exploration drilling and water analysis

Exploration drilling is carried out to determine the quality source of water on the site, as well as to analyze the produced water. Sometimes it serves as a temporary source until a decision on a capital well is finally made. The reconnaissance table is called a needle.

The most accurate result will, of course, be given by exploratory drilling.

To do this, you need a drill rod, a drill assembly and casing, which will form one whole. The drill remains in the ground. Such a well is performed using percussion technology. No special drilling tools are required for this. The penetration is up to three meters per hour, and the maximum depth is up to fifty meters.

The simplest filter will have a spear-shaped tip at the end, a hole in the middle, and a ball valve at the top.

The water obtained in this way is sent to any laboratory for the study of natural resources to be tested for minerals, the activity of hydrogen ions, the content of metals, alkalis, and dissolved acids.

Features of drilling operations in different soils

When carrying out rope-impact drilling with your own hands, depending on the types of soil present, you should adhere to a number of recommendations.

Soft, non-flowing soil

The easiest way to work is with a driving glass. A winch lowers it to the surface of the soil. When enough rock has collected inside the glass, it is removed outside.

Loose soil

A bailer with a valve is used. It prevents the rock from spilling out, which is extracted only on the surface. In this case, it is mandatory to strengthen the walls of the face. For this purpose casing pipes are used. They go deeper into the soil under the influence of their own weight, which helps extend the life of the well.

The diameter of the casing pipes should be slightly larger than the drill, which ensures its penetration to the desired depth.

Rocky rock

A chisel is used to crush the soil, and a bailer is used to extract it out. To expand the diameter of a well, using a casing string is not enough. To do this, use a special expander with moving cutters. It is lowered through the casing. When it reaches the required depth of the face, the cutters unfold. They cut the soil, which facilitates the movement of the casing.

Details

Core type

Nuances of the core type

The core type refers to the rotational method of the mechanical type. It is used to extract clayey soil types or sandy soils of dense consistency using cylindrical cores. A thick-walled metal pipe acts as a drilling rig.

On top of the projectile, rods are attached to a special place; they are necessary to build up the drill string. The drill is equipped with a crown at the bottom, which is selected depending on the type of soil at the drilling site.

The ring-shaped crown destroys soils by passing through soil layers. The core is not destroyed inside. To make the drilling process easier, when work is carried out in loamy hard soil, clay, or rocky soil, a flushing liquid is supplied to the bottom hole.

Attention! With the core method, soils are not destroyed; they are captured using a core pipe and pulled out with a core in the shape of a cylinder.

Soils after slaughter can be removed from the mine by washing; to do this, a large volume of water is pumped into it. Instead of washing with water, you can use blowing with compressed air, which is delivered inside using a compressor. This method is used to equip wells reaching a thousand meters in depth, 8-20 centimeters in diameter.

Wells are drilled using ZIF, or UKB, or UGB units, which are equipped with KAMAZ, KRAZ, and tractors. In the manual type of drilling, the core-type pipe is made shorter, it is called a glass or bell. The core pipe has a design similar to an upside-down glass.

The core drilling method is used if:

1. explore for minerals.

2.exploration wells are drilled.

3.drill aquifer wells, regardless of depth, filterless springs in rocky soil.

If private wells are constructed, the core type is used before auger or rotary drilling begins. The method allows for exploration with well preparation. The core type is also used together with the shock-rope type. The clay type of soil is drilled using a core pipe, then looser layers of sand, gravel, and pebbles are removed with a bailer; the soils are simply not retained by the core device.

This method has lower productivity compared to the screw type. With auger drilling, the process goes faster, but it is not possible to extract the spent soil out in full. The methods are practically never used together. But if this happens, then using an auger they dig out the beginning of the shaft.

Attention! Cores in the form of columns help to make a section of the soil, which allows you to study the soil.

Set of tools and equipment in core type

To perform core drilling, special tools are needed. These include:

1. drilling bits made of diamond material or steel. Win, tungsten.

2. core type pipe.

3. a pipe used to lift sludge.

4.rods that extend the drilling string.

5.couplings, adapters for joining pipes, gland for flushing.

When drilling rocks, the crown quickly becomes unusable and must be replaced. The crown is made of an expensive material that can withstand heavy loads; the most common material option is diamond material. All tools should be positioned level with respect to the drill axis.

Features of the technology

With the core type, soils pass through, keeping them in the pipe due to their dense consistency. The core is pushed out of the pipe by tapping it with a sledgehammer.

Step-by-step work process:

1. The drilling bit is joined to a core-type pipe.

2. A rod is attached to the pipe, with the help of which the equipment is expanded.

3, the rod is fixed on top inside the drilling machine.

4. The drilling column rotates through the machine, screwing into the soil.

5. the core fills the pipe.

6. Having passed up to 70 centimeters, the column is removed to the surface, the rods are disconnected to completely remove the core pipe.

7.rocks are removed from the pipe.

8. The equipment is again placed in the shaft, increasing the equipment using rods.

This process occurs until the aquifer is reached, then the well must go fifty centimeters deep into the soil, which is considered waterproof and lies below. If the purpose of excavation is not to fix the aquifer from above, then the soil can be drilled using the flushing method. In this situation, the flushing liquid is supplied through a hose into the pipe. And the solution removes the soil outward.

Pros and cons of the method

The core drilling type is considered the fastest among other mechanical types. The disadvantages include the impossible removal of loose soils and pebbles filled with moisture from the mine. To work in rocky soils, you need to use a chisel.

This method has many advantages. These include:

1.High level of productivity, it is possible to construct wells with a depth of more than one hundred meters.

2.reducing the load on equipment.

3. Drilling equipment can be mobile and compact.

Attention! Core drilling is one of the fastest methods of developing wells. A well in a sandy area can be equipped within one day. If you make a well manually, it will take many more days.

Auger type of drilling

About the method

In a private home, auger drilling is often used. With this type of drilling, no additional equipment is required to extract the developed soil from the source shaft. The method is similar to screwing, at the same time you can deepen the passage of the shaft and remove soil.

Installation is carried out using a screw in the form of a rod with metal blades. Going deeper into the soil, the auger destroys them, and the soil is retained on the blades. The design of the auger device does not allow rocks to be completely removed from the face. This method is convenient for removing the top level of soil.

Attention! The screw method is considered fast and inexpensive, but it requires the organization of a container to fill with flushing liquid.

This drilling is used in many areas, during the construction of geological exploration wells, during the laying of communications, during the construction of bored-type wells, and partly during the drilling of a water well.

The method is usually used in the construction of an Abyssinian type well. Drilling destroys the soil from above, and facilitates the construction of a needle well in dense soil. This method can be used to develop wells with a depth of up to thirty meters for loose and soft soil types, and up to twenty meters for medium-dense soils. When the work with the auger is completed, the casing is installed, the shaft is cleaned using a bailer.

The auger method is not used in rocky soil types. With its help, you can partially begin drilling a well, up to a maximum of one hundred and twenty meters. Then it is combined with a rotary type, or a core type, or a shock-rope type.

Necessary equipment

Drilling with an auger requires a special drilling rig. The main mechanism is represented by a drilling tool in the form of a screw. The part is made from high strength metal. By burying the tool into the soil, it is expanded using augers of a suitable size.

Sometimes the kit includes blade-type chisels. With their help, you can go through loose soils; sometimes chisels are used for hard types of soil. They have round or cone-shaped heads.

Attention! For hard-to-reach places, installations that are equipped with cars with a powerful engine are suitable.

Modern units have full projectiles that have reversible locks to prevent the tool from moving in the opposite direction. The developed soil cools the cutting parts of the structure in the auger. The developed soil is taken out, passing along spirals. This makes the drilling process continuous, while reducing energy and time costs.

Features of the technology

When a soil layer of up to two meters is passed, the auger should be removed to insert the casing into the well. Using an auger, you can drill a well with a diameter of 50 to 200 millimeters. The size depends on the parameters of the drilling equipment.

The casing pipe is used to prevent the collapse of the mine walls. Casing installations are required in wells with loose, non-cohesive soils. When drilling sandy loam and loamy soils, augers are used whose blades are located at an angle of thirty to sixty degrees. If you drill dense sandy soils, use blades with an angle of ninety degrees. If the augers have a smaller inclination of the spiral turns, then a larger amount of loose soil is thrown onto the surface.

Attention! With the auger type of drilling, there is no need for flushing fluid; the developed rocks are extracted using blades.

Positive characteristics of the method

Using an auger, you can equip a well in a short time. In this case, the auger and the inclination of the bit must be suitable for the size of the well. The advantages of the method include:

1.soil is removed from the well immediately during work.

2.possibility of rapid continuous deepening into the soil.

3.no need to flush the wellbore.

4.Using a compact installation, you can drill in the basement of a house.

The main disadvantage of the method is the inability to drill in loose soil, as well as in very hard soil. However, with the help of an auger they drill on loams, mixed soil types (sandy loam with clay), and soft clay soils.

When constructing water-bearing wells, it is necessary to combine the method with the shock-rope method in order to clear the shaft of soil. This quality is considered a disadvantage of the method.

Attention! The coil auger is used in the manual drilling method. The device is capable of destroying rocks, capturing them with blades to extract them upward.

Rotary drilling method

About the method

The method refers to the rotational-vibration type of drilling. During the process, the soil is destroyed using a chisel, which moves under the action of a rotor. The car engine drives the rotor, or a separate electric motor with a drive shaft is used for this.

To remove soil from a well, direct or reverse flushing is used. The liquid is fed into the barrel by gravity or using a pump.

Attention! Artesian wells are drilled using a rotary type using a bit.

Drilling with this method is used to develop wells in rocky, semi-rocky soil, if the wells are up to one hundred and fifty meters deep.

To carry out drilling, observing the following conditions:

1. The site must be studied in the hydrological section; it must be clear that rocky soils will have to be drilled. It must be known at what level the aquifers lie.

2.water underground has a pressure characteristic of artesian springs.

3.you can easily deliver process water to flush the well.

This type of drilling can be used throughout the year in warm areas of the country. In northern regions, the time period is limited because the rinsing liquid may freeze.

Set of tools

Drilling is carried out using a frame or lattice tower; a lifting device and other device mechanisms are placed on it. The derrick can be used to raise and lower drilling strings to the source.

The column contains such structural elements as:

1. tower of frame or lattice type.

2.motor with drive shaft.

3. rotor with drill string.

4.pump to clean the barrel.

5.lifting equipment, swivel, pressure line, seals.

If the installation is located on a car, then use its engine. Engine power controls the number of revolutions of the drilling equipment. A gear device in the rotor causes the main pipe to rotate, and then the bit begins to rotate. The device is made in different shapes, using high quality materials, for example, diamond-coated steel.

Attention! The type of soil influences the choice of size and shape of the bit in order to give the drilling process the greatest efficiency, speeding up penetration.

Nuances of technology

With the rotary type of drilling, the stages of work must be followed. There are 3 main stages:

1. destroy rocks using a chisel.

2.carry the destroyed rocks out using a flow of liquid.

3. strengthen the well with casing pipe.

Washing has two methods: reverse, direct. Working conditions affect the type of flushing: well depth, soil type.

In a private home, when drilling with a rotor, direct flushing is used. It consists of the following stages:

1. A chisel with a large diameter is placed into the soil.

2.rotate the bit using a rotor.

3. Place drill pipes, weighted pipes between the rotor and the bit.

4. Using a pump, the soil is removed with pressure.

5.install the casing pipe.

6.drill using a small diameter bit, repeating the drilling process again.

If backflushing is used, soils are removed using pipes in the drill string, and fluid is poured between the pipes and the walls of the shaft.

The water flows without pressure into the prepared container, where it is cleaned of debris, then returned to the column to remove more new soil.

Pros of the rotary type

Using a rotor, you can drill deep wells with aquifers in limestone. Other advantages include the following qualities:

1.high level of quality when opening aquifers in rocky soil.

2. It is possible to build wells with a large cross-section of 20 meters.

3.The drilling process is fast, low energy consumption.

The disadvantages include the need to flush the well. The method has more advantages than disadvantages, so this disadvantage is offset by the number of positive characteristics.

Selection of pumping units for industrial wells

Water is removed from the water intake structure using special pumps. When choosing them, the following factors must be taken into account:

- power of the drive used;

- Type of equipment;

- working pressure level;

- performance of the pumping unit.

Pumping units are used to pump clean water, which may contain a small amount of foreign impurities. Corrosion-resistant metal alloys are used to make the pump housing. The electric motor is reliably protected by a sealed shell.

Submersible pumping units are used to draw water from an industrial well. Their working blades are immersed in water. The pump is secured using a stainless steel cable.

Submersible centrifugal pump design

During the final arrangement of the structure, water intake structures are installed in it. They are used to deliver water to the consumer.

Basic terms

Drilling is the process of constructing a well by destroying rock.

A well is a cylindrical mine opening, constructed using special tools, characterized by a large length and small diameter. The main parts of the well are the mouth - 1, the trunk - 2 and the bottom - 3 (Figure 1).

Well production (not to be confused with accounting debit) is the volume of water that can be extracted from a well per unit of time. Measured in l/s or m3/h. The most important parameter for selecting water-lifting equipment and uninterrupted operation of the source.

A water well is drilled directly to the aquifer and, depending on the depth and flow rate, is an excellent source of water for both domestic and industrial purposes.

Figure 1. Well diagram

A water well, like any other, is a complex technical structure and its productivity, service life and water quality depend on compliance with drilling technology, as well as the correct choice of well design.

The determining factors when choosing a technology for drilling a water well are the depth of groundwater, as well as the rocks that make up the section at the drilling site. The correctly chosen technology will allow you to drill a well in the shortest possible time, eliminate accidents and complications during the drilling process, and most importantly, obtain the maximum flow rate corresponding to the given geological conditions.

The essence of technology

The soil-destroying device is a core drill (drill bit) - a special tool with carbide cutting parts or diamond inserts.

Core drill

With its help, professional drillers quickly create holes of the required depth and diameter in the ground.

Core drilling of wells is carried out by craftsmen at high speeds of the main part, so the installation is subject to heavy load. To construct a crown - a durable and comfortable ring made of a steel billet - a hollow cylindrical piece with sharp cutters - hard alloys are used: tungsten, steel or diamonds will also win.

The crown moves strictly along the edge, and the rock from the inside remains untouched. After the working shaft is filled with soil, samples are periodically removed for examination from the core receiver and determining the geological section of the site.

The small diameter of the drill, up to 160 mm, allows you to overcome up to several hundred meters per shift, it all depends on the hardness of the rock.

After performing core drilling and studying the results, it is easy to begin auger drilling with complete extraction of the well contents.

The nuances of installing casing pipes

It can be metal, asbestos cement or plastic. Each of the materials has its own advantages and disadvantages. Concrete casing pipes are rarely used. This is usually production. The material is heavy, brittle, and prone to splitting. Therefore, in the process of drilling wells, either steel or HDPE is used.

The metal oxidizes, unless it is stainless steel, which is expensive. The oxide causes deterioration in water quality. Over time, it turns brown and has a metallic taste. You will have to install a filter and clean the well. Welded connections. They are the weak point, and after depressurization, groundwater with dirt gets inside the casing.

Low pressure plastic (LDPE) is lightweight, which simplifies installation. The inner surface is smooth and does not form deposits. Corrosion is not a problem, the connections are sealed. The sections are twisted using the provided threads, and no special means are required for this. The only drawback is the limitation on the depth of the well. This material is not suitable for an artesian well.

Classification and general characteristics of drilling methods

The drilling process consists of the destruction of rock at the bottom of a hole (well) with a drilling tool and the removal of destruction products (drill fines) from it.

For all drilling methods, the following basic operations are performed: preparation and installation of the drilling machine to begin work, drilling (rock destruction) with cleaning the bottom of the well from destruction products, increasing the drill string to achieve the required drilling depth and disassembling it after completion of work, changing worn-out drilling tools and moving the machine to a new point for drilling a hole or well.

Currently, rotary, impact-rotary, impact-rotary and rotary-impact methods of drilling holes and wells (mechanical drilling methods), as well as fire and combined drilling are used. The effectiveness of using explosive energy during explosive drilling of wells, as well as high-voltage electrical discharges during electric pulse drilling, is being investigated.

During rotary drilling, the tool rotates around an axis coinciding with the axis of the hole or well and is simultaneously fed to the bottom with a certain force. The magnitude of the force is set based on the condition of exceeding the ultimate strength of the rock for indentation on the area of contact of the cutting blades of the tool with the rock. In this case, sequential destruction from indentation and chipping of rock particles from the face occurs. Destruction products are removed using twisted rods (when drilling holes), augers (when drilling wells), flushing the bottom with water or blowing with air.

At mining enterprises they use: rotary drilling of holes with cutters using hand and core drills; rotary (auger) drilling of wells with cutters and diamond tools using drilling machines.

In percussion drilling, a tool (chisel or bit) strikes the bottom and destroys the rock under the blade. After each blow, the tool is rotated through a certain angle, which ensures consistent destruction of the entire face area and obtains a circular cross-section of the hole or hole.

When rotary impact drilling with conventional and down-the-hole drills (rotary hammers), the tool rotates intermittently only in the intervals between blows by a rotating device mounted in the hammer. In some designs of drill hammers, the rotation of the tool occurs during the period when the piston strikes the tool.

In rotary impact drilling, down-the-hole hammers and independently rotating drill hammers deliver blows to a continuously rotating tool. Rock destruction with these drilling methods occurs only as a result of the penetration of the drill bit during impacts.

During rotary-percussion drilling, impacts are applied to a tool that continuously rotates under a large axial force. Fracture occurs both as a result of tool penetration during impacts, and as a result of rock chipping during tool rotation.

Drilling with roller bits is carried out both in the impact method with pure rolling bits and in the rotary-impact method - with sliding bits, in which the teeth, along with rolling along the face, cut the rock with a sliding movement along the surface of the face.

During fire drilling, rock destruction at the bottom of wells occurs due to thermal stresses that arise during rapid heating of the rock surface by streams of hot gases (2000°C) escaping from the burner nozzles at supersonic speed (2000 m/s or more).

During explosive drilling, rock destruction at the bottom of wells occurs by successive explosions of small explosive charges. There are two known methods of explosive drilling: cartridge - using cartridges of liquid or solid explosives that explode at the bottom from an impact or a detonator, and jet, in which liquid explosive components (fuel and oxidizer) are supplied through the drill to the bottom and a liquid flat charge is formed. The explosion of this charge is caused by the injection of a drop of an initiating composition (a eutectic alloy of potassium and sodium).

During electric pulse drilling, the destruction of rocks at the bottom of the well occurs due to electrical breakdown of its section by a high-voltage (up to 200 kV) discharge. The instantaneously released energy in the breakdown channel destroys the rock, which is removed from the bottom by a flow of dielectric circulating in the well (solar oil, water, etc.).

Combined drilling methods are being developed in which there is a joint impact on the bottom of the impact tool and a cutter (percussion-cone method), cutters and cutters (cutting-cone method), cutters and a fire torch (thermal-cone method), a fire torch and an impact tool ( thermal shock method).

Percussion-rope drilling

With this method, the destruction of the rock is carried out due to a sharp mechanical impact, namely the fall of a heavy object from a height. Such an item is a downhole glass - a piece of steel pipe with a drill at the end. Several holes are made in the pipe body for quick cleaning of soil when pulled out. The glass is freed from the rock every 50 cm of penetration.

A cable or rope is attached to the back of the glass, the other end of which is located at the top of the drilling derrick. A tower is a prefabricated structure made of logs, metal beams or pipes with a height of 2 m. For drilling wells with a depth of 20 m, cable-impact drilling rigs are used.

Advantages

The impact method has a number of advantages.

- It can be used to work with durable rocky soils

- The glass does not spoil the aquifer and well walls and is easy to clean.

- The method can be used to study the characteristics of soil on certain layers.

- The well can be installed immediately after drilling is completed.

Flaws

The disadvantages of the method include the following points:

- Low drilling speed.

- Cannot be used on sandy soil.

- The method is only suitable for vertical drilling.