23.11.2018

When installing a septic tank, experts always report that the key to a long service life is proper care. To avoid having to call specialists in an emergency, you need to remember to check the functionality of the device. Equipment in a private house allows you to get all the advantages of the city's civilization. Other sewerage equipment options will be less effective. They often give off an unpleasant odor. Therefore, a septic tank in a private house is an ideal solution. One of the disadvantages of using them is the need to independently ensure that drains are cleaned and waste is pumped out on time.

Operating principle and design of a septic tank for a private home

To understand the importance of periodic maintenance, you need to understand the design of a septic tank.

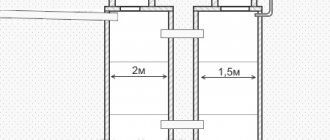

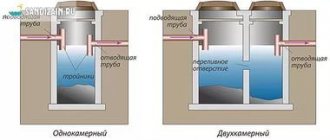

The simplest sewer system is a structure of several chambers constructed from concrete rings. This septic tank is easy to install and maintain.

The advantages also include energy independence - the system does not require electricity to operate. The main disadvantage of concrete septic tanks is the low degree of filtration. Wastewater treatment is carried out through sedimentation.

Maintenance of concrete septic tanks comes down to periodic pumping out of heavy waste using special technical equipment - fecal pumps and sewer barrels.

The performance of an autonomous sewage system can be increased by using various chemicals for cleaning a septic tank, thanks to which the water is better purified before being discharged into the ground.

Cleaning filters and drainage pipes ↑

The outlet filter is a relatively new accessory for a septic tank. It is installed at the outlet of the chamber to prevent large solid particles from entering the filtration fields. An outgoing filter helps prevent premature clogging of drain pipes. The device itself must be cleaned regularly. The frequency depends on the type and size of the filter and the intensity of use of the sewer system. Some models may be equipped with an alarm that sounds when the filter requires cleaning. Solid particles and other contaminants are removed with a high-pressure stream of water. The drainage pipes are washed in the same way, connecting the hose from the side of the ventilation outlets or through the distribution well.

Design differences and features of cleaning septic tanks from various manufacturers

Let's look at the features of servicing septic tanks from the most well-known manufacturers:

Eurolos

In the “PRO” and “BIO” models, the first section in which sludge is collected is serviced.

Maintenance of septic tanks Eurolos BIO - main work:

- Once every two years, sludge must be pumped out either with a sewer truck or a pump into a compost pit.

- If the loading elements are clogged, rinse with running water.

- When pumping out the first section, you must immediately fill it with water to restore the correct operation of the station.

The manufacturer's passport states: In conditions of high groundwater level, during conservation, it is prohibited to completely empty all chambers of the station.

Eurolos BIO stations do not require any other maintenance.

Topas

Septic tanks from this company are distinguished by their simple design. All elements can be easily removed and cleaned of dirt yourself. But you shouldn’t do this because the manufacturer will cancel the warranty.

Maintenance regulations for Topas septic tanks:

- Once a week, it is necessary to visually monitor the operation of the station for the presence of sharp, bad odors and the purity of the water.

- Every 3 months and only with the help of the service department, with entries in the service coupon, sludge pumping is required. 2.1 Washing the airlifts, nozzles and coarse filter 2.2 Cleaning the nozzles of the first and second cycles 2.3 Blowing the compressor filter

- Once a year, it is necessary to repair the compressor by replacing the membranes and cleaning the receiving chamber at the bottom of sediment and minerals.

- Every three years it is necessary to clean the bottom of the aeration tank receiving chamber from mineral deposits.

- Aerators will need to replace the aeration elements once every 10 years.

It doesn’t seem like much, but the manufacturer’s passport says that if persons without special skills interfere with the operation of the station, the warranty may be canceled. Therefore, it is worth contacting service providers and certified companies for service.

Biodeck

In Deka septic tanks, despite the compressor type, maintenance is less complicated than their popular analogues.

The manufacturer of Deca stations sets the following maintenance requirements:

- The hazard warning light should be checked daily

- A weekly check of the purity of the water from the station is required.

- A complete inspection of the installation for faults and bad odors should be carried out every month.

- Removing sludge from the bottom of the station, along with cleaning the compressor filter, must be carried out once every six months

- From the third year of use, more complex checks and maintenance begin - compressor repair, full service, replacement of aeration elements.

The manufacturer has not documented any other types of maintenance. We do not take into account special and rare cases.

Septic tanks Unilos Astra

The septic tank produced by SBM-Group, which has largely proven itself on the market, like other analogues, requires maintenance to maintain the operation of the station and the quality of cleaning.

Maintenance of Astra septic tanks:

- Remove sediment from the sump, clean the pump, filter for large particles, clean the walls in the secondary sump, blow out the air filter - once every 3 months.

- Every six months it is necessary to remove sludge from the sump in case you missed the procedure once every three months. You also need to remove hair in the aeration tank catcher.

- Once every 5 years, the aeration tank and surge tank are cleaned of sediment.

- Aeration elements will need to be replaced 10 years after installation.

Above is a short list of the main things that need to be serviced. Details about maintenance can be read in the article “How to maintain an Astra septic tank.”

Tver

One of the oldest manufacturers of septic tanks in Russia has perhaps the widest range of modifications on the market. But the principle of servicing them is for the most part similar, since all modifications were created on the basis of one model.

Rules and requirements for maintaining a septic tank Tver:

- Once every 3 or 6 months, manual pumping of sludge from the tertiary settling tank into the septic tank itself through airlifts is required. This is done by turning on the second and third taps alternately. But first you need to plug the first tap.

- The main chamber of the septic tank must be pumped out approximately once a year using a sewer truck or fecal pump.

- The brush load requires washing every 2-3 years and once every 5 years a complete replacement.

- Crushed dolomite in the bioreactor must be replenished every 2 years. Or as it dissolves.

- Cleaning and washing the walls of the septic tank and drain should be carried out every 2 years.

The manufacturer emphasizes that when the groundwater level is high, it is prohibited to empty more than one section of the station. Therefore, it is necessary to maintain it with extreme care.

Otherwise, the station is not much different from compressor-type septic tanks from other manufacturers, except that it needs to be serviced frequently, independently and carefully.

Welcome to Unipedia

- Articles

- Sewerage

- Everything about septic tank maintenance. Typical problems and solutions

A perpetual motion machine has not yet been invented; everything that surrounds us has the properties of breakdown. Troubleshooting work on a septic tank, whether factory-made or manufactured independently, depends on the signs of improper operation of the sewer system. After reading the information below, you will learn about standard and effective ways to solve problems that arise.

Common care questions:

- septic tank cleaning;

- flooding;

- elimination of pungent odors;

- care of the system in winter;

- biological agents;

- chemicals;

- structural damage.

Septic tank cleaning

No matter how equipped the septic tank is on the site, blockages are a common occurrence. Even preventive maintenance activities include cleaning. To save money, do this procedure yourself. You will have to clean the septic tank in several stages:

- cleaning collection containers;

- cleaning the pipeline system;

- cleaning the adjacent soil area.

After some time, slag deposits accumulate in the tanks. It is imperative to remove them; you cannot start something like this, otherwise everything will spill out. A similar event is done using special bacteria (we’ll talk about them later). The accumulated dirt undergoes bacterial transformations, changes its consistency, becomes more liquid, and is pumped out using a pump. Vacuum trucks are equipped with such systems. The option of obtaining fertilizers is also acceptable in this situation; to do this, you should first prepare a compost pit and send the mass into the pit instead of a sewer truck.

Coping with flooding

Finding yourself flooded doesn't feel good, but panicking won't help. The problem must be resolved as quickly as possible. It is necessary to establish the cause; not everything is visible at once. Flooding can be caused by a variety of reasons, including improper installation.

Defects in electrical septic tanks leading to undesirable results:

- pumping equipment is faulty;

- channel displacement;

- clogging of important elements;

- emergence of groundwater;

- incorrect calculation of volume.

It is difficult to identify a breakdown in a flooded septic tank; be sure to pump out the water, give it a little time to dry, and carry out diagnostics.

Groundwater, if this is the problem, should be drained by additionally equipping a drain, or it should be concreted. It is better to think through such moments at the time of installation, since cleaning the soil is much more difficult than repairing a septic tank.

Flooding associated with an incorrectly selected volume is eliminated by replacing the container.

Clogged sewer pipes

The difficulty in cleaning pipes using a chemical method (considered easy) is caused by the death of beneficial bacteria. It is better not to use this method without skill. It is better to use large-diameter pipes (cases of blockages are less common), but if this happens, there are several simple, harmless ways to fix it. Solid blockages are removed with a cable, scrolling along the entire radius of the pipe, then rinse thoroughly with hot water, avoid boiling water, especially if the pipes are not designed for this. If the design provides for triple connections (often clogged), it is necessary to provide technical openings for easy access.

Cleaning the soil layer

After the water level has subsided, the layer of soil and crushed stone is loosened and replaced with a new layer. Replacing the filter mound, partial or complete, directly depends on the degree of contamination.

Additional treatment can be carried out by additionally equipping a septic tank. A drainage well is the right way, provided there is no groundwater. Infiltrator – mounted with a septic tank, an easy, affordable method that does not require special costs or skills.

Unpleasant odors

Everyone doesn't like pungent and nasty smells. Installing a septic tank involves confining odors inside the structure. What to do if odors burst to the surface and burst into the house?

Let's look at the reasons for this misunderstanding. The spread occurs due to two main consequences:

- the design is not equipped with ventilation ducts;

- The simplest organisms cannot cope with processing.

The ventilation issue is solved by cutting an air duct between the septic tank and the equipment; it is better to lead it to the roof. An additional ventilation system consisting of pipes is laid and placed in the post-treatment area. A draft is created in the sewer system. The stench will go through the riser.

The reason is bacterial ballast, which is eliminated with a bioactivator, which is additionally purchased. The installation is guaranteed to remove the inconvenience within a few days. Additional equipment with a compressor and aerator allows you to improve the performance of microorganisms.

Microorganisms for a septic tank

Bacteria that enter a septic tank with human waste cannot cope with heavy discharges. Special microbes are introduced into the septic tank system. It makes no sense to purchase biological complexes during normal operation of the installation. The appearance of uncomfortable odors may be caused by a reduction in the amount of biological material. The consequence of this phenomenon may be:

- use of chemical cleaning agents;

- sudden temperature changes;

- excess body fat;

- siltation.

Eliminating the above reasons for the death of beneficial bacteria will not immediately restore the population. It is necessary to additionally purchase special microorganisms for the normal operation of the entire structure. Compositions should be selected based on the problem that has arisen, taking into account the design features and volumes. The required application criteria and properties are indicated on the packaging of the biological product. Please read the instructions carefully. Microbes are aerobes and undergo a decomposition process in several stages, without the participation of oxygen, which is excellent for structures without ventilation.

The mass of bacteria must be added strictly according to the instructions provided, otherwise the mass will lose its viability.

The right composition will instantly eliminate the problem of nasty aromas.

Use gentle cleaning agents.

Severe temperature conditions

Performance during the cold season is reduced due to freezing. Placing below the frost line relieves anxiety, but in regions where it is very cold in winter, additional insulation of containers and pipes is required. Otherwise, you will find the drain frozen. The most terrible of problems! It will only thaw at temperatures above zero. The consequences can be different, for example, the death of organisms.

Septic tanks not intended for use in winter are preserved. Preservation is carried out by removing contaminants, complete cleaning with the help of bacteria, which starts 2.5 weeks before the process. After such manipulations, bad odors will not appear.

Chemicals

A chemical method of combating unpleasant consequences is used when the microflora has already died. Chemicals are aggressive and burn everything away. Special products for septic tanks are powerful reagents and should not be used without protection. Chemistry will cope with any blockages and odors.

After major chemical cleaning, it is worth purchasing biological material.

System Damage

Mechanical damage occurs during installation. The method of elimination depends on the nature of the damage and the material of the elements. In some cases, it is better to replace the damaged area. It is better not to repair factory designs yourself; breaks in the circuit are possible. Consult a specialist.

There are other methods of sewer maintenance. Cleaning stations are similar devices. You can resort to the help of professionals, for a fee, of course.

Maintaining a septic tank is not the most pleasant part, but the family’s living comfort depends on it. Prevention is better than repair.

Large septic tank for a country house

Septic tank operation

Septic tank with biofilter

The principle of operation of a biochemical septic tank

Scheme of operation of a septic tank with soil treatment

List and frequency of septic tank maintenance work

The frequency of maintenance work on septic tanks depends on the operating conditions and the manufacturer’s recommendations.

Expert opinion

Albert Lyushin

Engineer-technologist with more than 15 years of experience.

Ask a Question

Autonomous sewerage requires special attention during the first year of service. During this time, all errors made during installation may appear. After the first year of use, the risk of breakdown is reduced significantly, with proper operation and timely maintenance.

It is worth understanding that the price of service, as well as the conditions, largely depend on what is being serviced. For example, servicing an installation from one manufacturer will cost 8,000 rubles per year, while another station will require at least 15 thousand.

Companies involved in the maintenance and repair of septic tanks offer clients the following services:

- Diagnostics – preventive inspection and testing of the functionality of all elements of an autonomous sewer system. The service also includes an analysis of the main indicators of the pump - power and pressure. Average price from 2000 rub.

- Replacement of worn and faulty elements identified during the diagnostic process - filters, floats, injectors, distributors, tubes and other parts. Average price from 4000 rub.

- Compressor repair and maintenance is a popular service used by owners of aeration stations. The service center performs troubleshooting and evaluates the feasibility of repairs - in some cases it is easier and cheaper to replace the old compressor with a new one. Average price from 3000 rub.

- Restoring the tightness of the housing caused by violations of installation rules, mechanical damage, and soil heaving. The price depends on the complexity of the damage and the need to replace equipment.

- Conservation is relevant for owners of suburban plots of seasonal residence. Average cost from 3000 rub.

- Cleaning the pump chamber with high-pressure apparatus – effectively removes any contamination; Average price from 2000 rubles .

- Washing of coarse filters; Included in the cost of service and not performed separately.

- Pumping out water in case of flooding. The reason may be the wrong choice of installation location, as well as clogging of the outlet lines. Average price from 1500 rub.

Regardless of the mode, operating conditions and type of septic tank, the minimum frequency of service is once every 2 years. For many manufacturers it is much more common - from 4 months for most compressor stations, according to the manufacturer’s regulations.

To avoid unscheduled maintenance and repair of equipment, you should adhere to the following rules:

- Do not use aggressive chemicals or chlorine-based compounds in the drain.

- Minimize fatty waste.

- Do not pour non-degradable waste down the drain.

- Add aerobic bacteria periodically throughout use. Addition is not required if the use is 24 x 7 x 365 - all year round.

- If you turned off the power to a septic tank at sub-zero temperatures, bring the compressor into the house before turning it on. It should warm up to room temperature. Otherwise, there is a high probability of membrane rupture. If you have a pump septic tank, you do not need to remove and bring the pump into the house.

What is a septic tank

A septic tank is a treatment facility that purifies up to ninety percent of wastewater and discharges it back into the soil. Unlike conventional drainage pits, which only accumulate waste, this solution has functional parts, mechanisms and parts that require maintenance. Because of this, there are certain rules for operating septic tanks that must be followed.

You will learn further about how to use a septic tank correctly, what to pay attention to, and what should absolutely not be allowed.

How much does it cost to clean a septic tank?

Now in almost every city there are companies that service and repair autonomous sewers.

Professional organizations enter into contracts with septic tank manufacturers and undergo special training and certification to improve the quality of the services provided.

The cost of cleaning a septic tank depends on the volume, model and nature of the work. In addition, the price is affected by the remoteness of the site - this determines the amount of transportation costs.

If desired, you can conclude a comprehensive contract for a year with a fixed cost for each type of work.

The average price for full maintenance of a model designed for 5 people is 4,000 rubles.

Expert opinion

Albert Lyushin

Engineer-technologist with more than 15 years of experience.

Ask a Question

You can perform autonomous sewer maintenance yourself. In this case, you will have to purchase special tools and equipment, as well as study the maintenance instructions that are included when purchasing a septic tank.

But in the absence of experience in performing similar work, it is recommended to refrain from self-service and call professionals

Cleaning methods

The main method of cleaning a septic tank is to use a sewage pump. To carry sludge you will also need a special container, and disposal can be carried out in a compost pit or a specially designated place. The most acceptable way is to call a sewer truck, because the process of cleaning a septic tank is not the most pleasant. Calling a vacuum cleaner will cost money, but it will save you from an unpleasant process. The walls are washed using a high pressure washer. Carrying out this process manually is quite difficult, and sometimes even impossible.

If a septic tank is used as a regular storage tank for sewage, then its contents must be disposed of using a sewage disposal machine; the contents of such septic tanks cannot be used as fertilizer under any circumstances. But if the interval between pumping out the contents of the septic tank is a large amount of time, then the fecal matter can become viscous and it will become quite difficult to remove it with a pump. To liquefy this mass, you will have to use chemicals that contain nitrates, ammonium and formaldehyde.