Types of hole drills, operating features

The need for this equipment arises when vertically installing various types of structures into the ground or in agriculture when planting seedlings .

In addition, hole drills can be used for drilling holes in ice during winter fishing. The capacity of the equipment depends on the volume of planned work. Pit drills are conventionally divided into the following main varieties:

- Manual:

- Motorized (gasoline or electric engines are used as a power drive).

- Non-motorized (driven by the physical effort of the operator).

- Mounted.

Mounted hole drills

To operate this equipment, the operator does not need to use his physical strength - the dimensions, weight and power of the machine on the base of which the hole drill is mounted are used.

It is interesting that such units are not only factory-made; quite often there are also home-made devices, which, if you have the necessary tools, materials and skills for their manufacture, are much cheaper than factory ones. Most often, wheeled vehicles are used as a basis, but if holes need to be drilled in hard-to-reach places, then it is better to use tracked tractors or all-terrain vehicles.

Manual hole drills

The simplest version of a manual hole drill consists of the following parts:

- Powder coated steel base.

- Steel helical blades located on the bottom of the base.

- A handle attached to its upper part.

The number of blades, their diameter, the length of the base, as well as the design of the handle are very different. The unit can be collapsible and can also be equipped with various kinds of additional attachments.

The maximum drilling depth for various models of a manual version of a gasoline hole drill is from one to three meters. This indicator varies depending on operating conditions and equipment configuration of the device.

Hand-held hole drills can even be used to perform large-scale work, such as installing bridge supports or forming holes for pouring a foundation.

The equipment, in which the role of the power plant is played by a gasoline internal combustion engine, is completely autonomous due to the presence of a large fuel tank. As for electric driven hole drills, they are either equipped with a rechargeable battery, which lasts for a fairly short time, or are powered via a cable from the mains, which significantly reduces their mobility.

The force from the engine in gasoline units is transmitted through hydraulic or mechanical transmissions. This equipment is most often operated by one person, however, there are high-power models that require the physical strength of two operators to fully operate. Some types of hole drills can drill at different angles .

There is a wide selection of units on the market - from lightweight portable models to professional hydraulic ones, which are equipped with extensions that significantly expand the range of their functionality.

What should you pay attention to first when choosing equipment for drilling wells?

The most important initial data for the correct choice of unit are:

- Its general characteristics.

- Power of the power plant.

- The maximum diameter of holes it can drill.

- What is the purpose of a hole drill - is it for household or professional use?

Studying all the above parameters will not only provide an opportunity to familiarize the potential buyer with the tool in detail, but will also help to compare the production capabilities incorporated into it by the designers with the planned scope of work.

Varieties

There are a huge number of different models of equipment of the type in question, implemented on the basis of the MTZ-80 (82) tractor, since it is a universal tool for using various attachments - not only soil drilling units, but also any other hydraulic type.

Most often you can find a drilling machine of the BM-205D model on sale. There are also other types of hole drills:

| Name | Tractor used as a chassis | Attachments |

| BM-205D-01 | MTZ-80 (82) | Special loading device for working with various soils |

| BM-205D-01 | MTZ-80 (82) | Plow for snow removal and land cultivation |

| BM-205V | MTZ-80 (82) | Snow plow |

| BM-205V-01 | MTZ-80 (82) | Boot device |

| E-01-60 | MTZ-80.1 and its modifications | Absent |

All models have their own specifics and special operational purpose. Some easily cope with both frozen and regular soil. Others can only work with regular soil.

Most often, the equipment in question is equipped with the following attachments:

- winches,

- dumps,

- brushes.

This type of device is often needed MTZ-82 as an auxiliary device when performing drilling operations.

They allow you to remove waste soil, and also, if necessary, perform various actions with supports, for the installation of which hole drills are used.

BM-205-D

The drilling and crane machine number 205-D has outstanding operating parameters that allow it to perform a wide range of work.

If necessary, the well drilled by this machine can be of different sizes.

Another important advantage of the technology in question is the presence of a lifting mechanism. It allows you to successfully work with fairly large weights.

Main characteristics of the BM-205-D machine:

| Characteristic | Meaning |

| Drilling depth (maximum), m | 3,0 |

| Well diameter, mm | 36, 50, 63, 80 |

| Maximum possible working weight, t | 1,25 |

| Maximum lifting height, m | 7 |

| Operating angle range, degrees. | 60-105 |

| Drilling rig torque, N×m | 4900 |

Dimensions of BM-205D when folded:

- length, mm – 6,800;

- width, mm – 2,500;

- height, mm – 3,950.

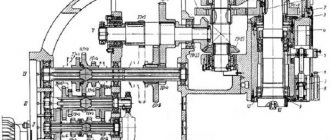

Photo: hole drill BM-205-D based on the MTZ tractor

Dimensions of the drilling rig during operation:

- length, mm – 6,590;

- width, mm – 2,500;

- height, mm – 7,600.

The weight of the entire drilling and lifting rig together with the tractor is as much as 6,450 kg.

The indicated dimensions allow you to perform a wide range of work of various kinds in places where the amount of free space is extremely limited and a full-size drilling rig simply will not fit.

BM-205-V

The technical characteristics of the BM-205-V pit drill allow it to be used at construction sites, as well as in other places where a drilling rig capable of performing large volumes of work in a short period of time is required.

BM-205-V has the following parameters and design features:

- the method of performing drilling operations is cyclic;

- drilling angle – 60-102;

- type of drive transmitting rotation - mechanical;

- torque value , N×m – 4,900;

- rotation speed of the equipment, rpm – 40-90;

- drilling speed , m/h – 15.

The dimensions of the drilling machine in question are quite small. When folded they are:

- length, mm – 7,400;

- width, mm – 2,100;

- height, mm – 3,990.

During operation, the overall dimensions of the BM-205-B are:

- length, mm – 7,400;

- width, mm – 2,100;

- height, mm – 7,500.

The total weight of the unit including the base is 6,500 kg. During operation, the BM-205-V hole drill consumes a fairly large amount of fuel - 13 liters, which is a consequence of its high performance on any type of soil.

Photo: BM-205-V hole drill based on the MTZ tractor

There are several modifications of this installation, equipped with various additional equipment.

E-01-06

Quite often you can find an MTZ tractor equipped with an E-01-06 hole drill. This attachment exists in several modifications, which differ from each other only in the diameter of the drill:

| Designation | Drill diameter, mm |

| E-01-060 | 200 |

| E-01-060-01 | 250 |

| E-01-060-02 | 300 |

| E-01-060-03 | 350 |

| E-01-060-04 | 400 |

Main technical parameters of the pit drill E-01-060 and all its modifications:

- torque value , N×m – 1,300;

- maximum rotation speed of equipment , rpm – 80;

- maximum power , kW – 25;

- maximum drilling depth , mm – 1,500;

- maximum drilling depth when using a special extension , mm – 2,500.

Important! E-01-060-02 is designed for working with soft soils. Drilling into frozen soil or anything similar in hardness is undesirable.

Photo: drilling rig E-01-60

The model in question is quite compact and lightweight - only 235 kg.

This allows you to install and dismantle this drill as quickly as possible, with minimal time and effort.

It is possible to install a special high-strength auger. With its help, you can cope even with very hard soil, and also avoid equipment breakage if it gets into a metal pipe lying at great depth.

The screw can be replaced very quickly; the design includes a quick-release mechanism specifically for this purpose.

Manual petrol hole drill Iron Mole Compact

The world's smallest manual gasoline hydraulic hole drill is produced at the Iron Mole company. This is the Iron Mole Compact model, widely used on construction sites and in the construction of low-rise buildings around the world.

The main positive aspects of this tool are:

- Small sizes.

- High level of reliability.

- Easy maintenance.

- Lightweight control handles.

- Reliability and simplicity of hydraulic drive design.

- Availability of reverse rotation of the drilling tool.

- High rate of equipment payback.

- Availability of a reliable four-stroke gasoline engine with high power.

The hydraulic drive of this model of pit drill has the most simplified and lightweight design, in comparison with large drilling rigs, requiring simple maintenance, expressed in seasonal changes of oil and oil filter element.

A serious advantage of this model of manual gasoline hole drill is the modular principle of its design, thanks to which it is easy to transport and easy to work with.

The weight of the handles of this machine is less than that of similar drills equipped with mechanical gearboxes. Thanks to this, auger drills rise to the surface more easily, and control is simple and effective.

The hydraulic components that are equipped with the Compact petrol motor drill are produced by leading European manufacturers, who guarantee the highest reliability and durability of their products. The unit is equipped with connectors of the BSP type, which can be easily replaced. The hoses leading to the control handles have quick-release connections that significantly speed up and simplify the transportation of the unit.

It is possible to use the hydraulic station separately in conjunction with a number of other hydraulic tools.

The set of drilling tools installed on the Compact petrol hole drill is part of the Pengo system, the cutting and guiding knives of which are made by forging. As an additional option for this unit, you can purchase several auger drill extensions that can significantly speed up the drilling process.

The Compact petrol hole drill, equipped with a hydraulic drive , is designed specifically for use on construction sites as both the main and auxiliary drilling tool, especially in places where it is not possible to use large drilling units.

Specifications Iron Mole Compact

This petrol hole drill is equipped with a four-stroke overhead valve OHV engine, model Tecamech T212. Its power is 7 hp and its displacement is 212 cubic meters. centimeters. The fuel used for it is AI 92 gasoline. The volume of the fuel tank is 4 liters .

Tractor hydraulic system

The MTZ type tractor is equipped with a specially designed hydraulic system. It is thanks to it that it is possible to quickly and easily connect the BM-205D, as well as any other equipment.

The hydraulics that drive any type of hole drill are extremely reliable and efficient. It has the following performance characteristics:

- type – separate-aggregate;

- total number of cylinders creating traction force, pcs. – 3 (installation of additional ones is possible);

- type of hydraulic pump – gear;

- amount of liquid supplied by the pump per unit of time, l/min – 45;

- the maximum possible pressure in the system , limited by a special valve, MPa – 16.

The cylinders used in the system are double-acting. The piston stroke is controlled hydromechanically.

The cylinders themselves have the following parameters:

- main diameter, mm – 100;

- external diameter, mm – 75;

- piston stroke length, mm – 200.

Part of the hydraulic system is a mechanism used to attach all sorts of specialized equipment.

The coupling device is made of high-strength metal, which allows you to operate attachments even in the most extreme conditions without any consequences.

Powerful manual German hole drill Stihl BT 360

This equipment is designed to work with two operators. The main buyers of the Stihl BT360 are people professionally involved in construction. For household use, it makes no sense to purchase such a powerful device - you can find something simpler and cheaper. However, if there is a need to drill many wide wells up to 2.5 meters deep , this model is ideal.

The engine power of the Stihl BT360 is 6 hp. pp., and it is capable of providing fast and high-quality drilling of large-diameter holes. The instrument weighs about 29 kg.

As for transporting the drill, there are no problems here, since its frame can be folded and conveniently transported in most vehicles.

Technical characteristics of Stihl BT360

This equipment is equipped with a 2-stroke proprietary power unit with a capacity of 6 hp, with a displacement of 360.3 cubic meters. centimeter _ The fuel used is AI 92 gasoline mixed with stihl oil (ratio of 50 ml of oil per 1000 ml of fuel).

The spindle rotates at a speed of 50 revolutions per minute and provides a drilling depth of up to 2,500 mm with drilling tools of different diameters - from 90 to 350 mm. As for the weight of the device, it is 28.5 kg.

The industry produces a wide range of models of hole drills, in various price categories, designed to solve a variety of tasks. To make the right choice, you should pay attention to how widely known the brand is, how close the service centers serving this brand are located, and, of course, whether the characteristics of the unit correspond to the tasks that will be assigned to it.

Drilling equipment E-01-06

Designed for drilling only in soft soil, not suitable for working on frozen soil or layers similar in hardness. The E-01-06 drilling machine exists in several modifications, differing only in the diameter of the drill. Light weight and simple fastening design allow for quick installation and dismantling of equipment. Main technical parameters:

- hole diameter depending on the model - 20, 25, 30, 35, 40 cm;

- drilling rig weight – 235 kg;

- maximum drilling depth – 1.5 meters (when using an extension – 2.5 meters);

- torque – 1300 N/m;

- rotation speed of the equipment – 80 rpm;

- weight – 235 kg.

Manual gasoline hole drills: operating principle and design

Pit drills are designed for digging small wells, holes and pits.

Thanks to the use of this equipment, you can significantly speed up and simplify the work process. Manual gasoline devices have become very popular. The need to use these devices arises when it is necessary to install various structures, as well as in the agricultural sector for planting seedlings. In addition, hole drills are often used by fishermen to create holes in frozen bodies of water. Equipment power indicators are determined by the volume of necessary activities.

Conventionally, all hole drills are divided into the following types:

- Manual: non-motorized and motorized.

- Mounted.

Attachments

To operate such a device, you do not need to use physical force - the weight, dimensions and power indicators of the machine on which the hole drill is installed are used. It is noteworthy that such units can be manufactured independently using certain materials, devices and knowledge. By the way, such devices will cost much less than factory ones.

often used as a base . And if you need to make a hole in some hard-to-reach area, it is better to install a hole drill on an all-terrain vehicle or a crawler tractor.

Design of a manual hole drill

The simplest manual equipment includes the following elements:

- Steel base coated with special powder ;

- Steel blades-screws, which are located at the bottom of the base;

- Handle located on top.

The length, diameter, number of blades and handle design can also vary. The equipment can be dismountable and equipped with some additional devices.

Drilling depth varies from one to three meters. This indicator is directly dependent on the configuration and the conditions under which the equipment will have to be used.

Hand-held hole drills are also often used for installing bridge supports or creating holes for foundations.

Gasoline hole drills are autonomous, as they are equipped with a fuel tank . If we talk about electric hole drills, they can be equipped with a removable battery or powered from a household electrical outlet, which negatively affects the mobility of the equipment.

The force from the motor in gasoline-type devices is transmitted through a mechanical or hydraulic transmission. Such a device is controlled by one person, but more powerful models require two or even three operators at once.

There is now a huge range of devices on sale: from compact and lightweight to hydraulic professional ones, which are equipped with special extensions.

Additional devices

The drilling installations under consideration can be equipped with special additional devices. They have a narrow specialization.

Most often, their main purpose is the installation and dismantling of power transmission line supports. The following types of devices can be found on sale:

- DRU-01,

- DPO-01.

DRU-01 – additional fastening device. It is required to perform all kinds of work with rotten wooden supports of various diameters.

Do you know the technical characteristics of the MTZ-50 tractor equipped with a D-50 engine? By clicking on the following link https://spez-tech.com/tehnika/raznoe/osobennosti-bureniya-skvazhin-malogabaritnyimi-ustanovkami.html, you can familiarize yourself with the features of drilling wells with a small-sized drilling rig.

And here you will find out why Japanese Kubota tractors have earned recognition in the Russian market.

DRU-01 allows you to fix them in one position, thereby creating safe conditions for electricians to perform various works at height. This device also makes it possible to simplify the installation of the support, since it fixes it in the well before backfilling.

Equipment can be connected or disconnected extremely quickly, literally in a matter of minutes.

DPO-01 is a special additional device for removing supports and other similar objects from the ground. Made in the form of a hydraulic cylinder. It allows you to create a force whose value is 8 thousand kg × s.

Thanks to the use of DPO-01, installed on hole drills, the supports are removed extremely quickly and easily, which makes it possible to save a lot of time.

Model characteristics

Iron Mole Compact

The most compact gasoline hole drill is considered to be the “Iron Mole Compact”. This equipment can often be seen on construction sites and during the construction of low-rise buildings.

This tool has the following advantages:

- Compact dimensions.

- Highest reliability.

- Easy maintenance.

- Small mass.

- Ease of operation.

- Fast payback.

- Availability of a powerful motor.

A huge “advantage” of this model is its modular design , which allows you to easily transport the equipment.

The device also has BSP connectors, which are very easy to change.

This hole drill is used both as a main and an additional tool . Its use is relevant for places where it is not possible to operate massive drilling units.

This model is equipped with a 4-stroke Tecamech T 212 engine with a power of seven horsepower. It is suitable for AI 92 gasoline. The fuel tank capacity is four liters.

Using this hole drill you can make a hole with a diameter of 350 millimeters. You can work with it on sand, peat, sandy loam, loam and plant soil.

The weight of the device does not exceed 35 kilograms.

Stihl BT360

This unit is usually operated by two people.

Stihl BT360 is purchased by people who are engaged in construction professionally. There is no point in buying such a device for domestic use. The Stihl BT360 has a 6-horsepower motor that can drill large holes. If we talk about moving this unit, then there will be absolutely no problems with this, since the design of its frame folds easily.

This device is equipped with a push-pull unit. It is filled with AI 92 gasoline and branded oil (fifty milliliters of the mixture is required per liter of fuel).

This equipment allows you to drill holes with diameters up to three hundred and fifty millimeters and depths of up to two and a half thousand millimeters. The weight of the device is 28 kilograms.

What is a pit drill?

It will not be possible to dig a neat deep hole of small diameter with a shovel. For this purpose, a drill for holes was invented in the form of a pointed rod with a disk or auger type tip. It easily goes into the ground with little effort, like a large corkscrew, and rises up without rotation. After the hole drill has been buried to a certain depth, it must be periodically raised to remove soil hanging on the blades. The result is a hole with smooth edges.

Pit drill device

The design of an amateur tool for drilling wells differs significantly from the design of industrial devices. In its simplest design, a garden manual hole drill has no drive and consists of two handles at the top and a long shaft with screw or disk blades. Motor drills consist of a larger number of units:

- drive – petrol, hydraulic, electric;

- transmissions;

- working body (drill);

- extension cord;

- frames

Characteristics of a drill

Inspecting the appearance of a well drilling device provides little information. Let's look at the approximate characteristics of manual type hole drills and mechanisms equipped with an engine for domestic use in garden plots:

- The diameter of the wells

is for petrol up to 350-450 mm, for hydraulic up to 600 mm, for models without drive 110-400 mm. - Number of workers

– up to two people for hydraulic devices and motor drills. - Drill length

– model without engine 1.5 m (with extension up to 2.5 m), with hydraulic drive or gasoline engine up to 10 m. - Weight of the device

- models without a drive weigh 2-5 kg, a petrol manual drill weighs up to 60-75 kg, hydraulic drills weigh up to 300 kg. - Engine parameters

- two- or four-stroke. - Screw parameters

– single-thrust or double-throw.

Machine Yamobur BM-205-V

A universal hole drill based on the MTZ tractor is used for drilling work both on non-frozen soils and in permafrost conditions. The unit is complemented by a front-end loader to perform related loading and unloading operations, cleaning the site and backfilling trenches.

The equipment is highly productive and is actively used where it is necessary to perform a large volume of drilling work in a short period of time.

Features and main parameters:

- overall dimensions in transport/working position (length/width/height) – 7.4*2.1*3.99/7.4*2.1*7.5 m;

- weight with base – 6,500 kg;

- cyclic drilling method;

- type of rotary drive – mechanical;

- plane inclination angle – 60-102 degrees;

- maximum drilling depth – 2-3 meters;

- drilling speed – 15 m/h;

- torque – 4900 N/m.

What is a hole drill for?

There is a voluminous list of construction work or activities in the garden that require drilling a large number of holes in the ground. Drilling with a hole drill helps:

- When installing a columnar foundation.

- When planting a large number of shrubs or trees.

- In deep loosening of soil.

- In installing fences.

- In arranging trellises for climbing plants.

- When laying communications.

- In drilling wells.

Types of hand drills

Homemade devices help with small volumes of excavation work. It should be remembered that working with a manual hole drill requires considerable effort. If the wells are deep or there is hard soil, it will not help. If you have to install piles or a long fence, then drilling holes can take a lot of time. Renting a hydraulic drill or purchasing a reliable motor drill will be the best solution in a difficult situation.

Types of manual hole drills by type of drive:

- Manual mini hole drill without drive.

- Gasoline motor drill.

- Electric drill.

- Hydraulic hole drill.

Types of drills according to the design of the nozzle:

- Auger hole drills

- with a screw blade for drilling deep holes of small diameter. - Disc hole drills

– the working part consists of disk halves fixed at an angle of 25º.

Petrol hand drill

The device, powered by a gasoline engine, allows you to drill holes in soil of any hardness. The absence of connection to a power source makes the tool autonomous. You can work with it in the field and even on a river for drilling ice. In the latter case, a nozzle with a stronger cutter angle is required. A modern gasoline hole drill is equipped with shock-absorbing springs to reduce vibrations and unpleasant vibrations, which makes its operation more comfortable.

Types of gasoline hand drills:

- Heavy

– professional equipment for hard soils with high power, equipped with a 3 or 4 stroke motor, requiring 2 operators to operate. - Lungs

– amateur equipment, operated by one operator. Suitable for drilling wells up to 2 m deep in black soil, sand or loam.

Electric manual hole drill

The design of this device consists of a compact electric motor with two handles and a clamping mechanism for fixing the auger-type working mechanism. Electric drills are less common than motorized drills. At the time of peak loads, the electric motor, connected to the auger using a rigid coupling, heats up more and breaks down more often. With a tool power of 1200 W, it is barely enough to drill a 150 mm hole in garden soil.

- Relatively silent operation.

- Quick readiness for work.

- Highly environmentally friendly.

Disadvantages of electric manual hole drills:

- The range is limited by the length of the connection cord.

- At lower voltage, the engine heats up more.

- The reliability of the tool is worse compared to a gas drill.

Hydraulic manual hole drill

The cost of such a device is high; when used on a garden plot for one-time use, it is more profitable to rent it. A hydraulic hole drill is a productive and powerful technique that allows you to drill holes with a diameter of 30 cm and a depth of up to 5 m (using extensions up to 30 m). The drive is carried out from the hydraulic system of the tractor or a special mobile station. The weight of the hand tool is about 30-60 kg.

Advantages of a hydraulic drill:

- The presence of a reverse function allows you to drill in all directions, which makes it easier to pass through hard, problematic soil.

- Hydraulics absorb the main vibration loads, so working with such a drive is more comfortable.

Types of hole drills for various jobs. Characteristic.

Purpose and types of pit drills

Yamobur

– universal special equipment for drilling holes, wells, holes of different depths. It significantly facilitates and also speeds up work, without the use of physical force. This equipment is used to perform a variety of work, not only construction.

Pit drills are called both manual and mechanical equipment. All of them can be divided into four types:

- Manual.

To use them you do not need to have much knowledge or professional knowledge; they are quite easy to use. The tool is indispensable and widely used in dacha farming. The drill consists of a drill with augers, a handle and additional extensions. The most common ones have a diameter from 50 to 110 mm with a drilling depth of up to 1.5 m. - On a tractor basis.

It is an attachment for carrying out larger work, producing holes 1-2.5 m deep and up to 20 cm in diameter. The attachment itself is small in size. - Based on a car.

This special equipment drills wells up to approximately 20 m and is mainly used for large-scale construction. The vehicle's high cross-country ability allows it to be used in off-road conditions and in regions with harsh climates. - Drilling rigs.

A complex of drilling structures and structures is used mainly when working at great depths. But it is still possible to drill shallow wells with a diameter of 2-3 m to a depth of 32 m, during geological exploration and engineering work. To an average depth of up to 650 m for structural exploration of solid minerals. Or deep exploration and production wells for oil and gas up to 6200 m.

There are also several types of drill

- Annular;

- Non-removable;

- Collapsible;

- Auger.

What kind of work are pit drills used for?

Yamobur is a universal special equipment for drilling holes and wells. It is used in many areas, from gardening, where it helps plant seedlings, to construction, for drilling holes in the ground for poles. It can be used even for small geological studies, as well as laying electricity lines. The use of this technology will replace the physical labor of dozens of people and increase the speed of work.

What to look for when choosing a hole drill

The choice of hole drills is very large, which means that you can find special equipment that meets all the necessary requirements. A petrol pit drill is well suited for small earthworks; it is popular in summer cottages and gardens for planting green spaces, installing fences and enclosures. It is often used by fishermen. During construction work, it is better to use a pit drill in Moscow and the Moscow region on the basis of a car; its drilling depth is much greater than that of a manual one, and it is more mobile in comparison with drilling complexes. In cases with poor road traffic, a GAZ or KAMAZ-based hole drill is well suited. The Yamobur all-terrain vehicle will be able to perform the assigned tasks in any conditions.

When choosing equipment, carefully consider the entire process of future work and possible difficulties during drilling:

- Find out the category of soil, the presence of rocks;

- Determine the depth and diameter of the well;

- If you use a car as a base, you should take into account the length of the boom reach.

The equipment is selected based on the basic parameters and technical characteristics. In order not to miscalculate and take into account all working aspects, you should consult a specialist in this field.

How to choose a hole drill?

Let us immediately note that it is easier for compact installations to find application on the farm, using them for loosening, planting bushes, and fishing. Powerful hand drills for poles are expensive devices. If you are not engaged in professional construction or installation of supports, then it is better to rent such mechanisms. Let us describe the main criteria for selecting drilling devices:

- Auger diameter

- it is advisable to have a tool with several types of removable attachments. - Drive power

- on light soils, a 3.5 hp manual hole drill is suitable; in heavy soils, equipment from 5 hp is required. and more. - Installation weight

– to operate devices weighing more than 20 kg, two operators will be required. - The equipment

includes extension cords, augers for working with different soils, frozen soil and ice, support stands for heavy equipment.

How to make a manual hole drill?

The easiest to manufacture are hand drills without a drive. Their design consists of several elements that can be easily made in a home workshop using a household grinder with a welding unit. We offer approximate instructions on how to make a manual hole drill with your own hands:

- The blades are made of a metal circle up to 4 mm thick. You can bend a solid piece into a screw shape or weld two semicircles at an angle.

- Experts recommend equipping the blades with a carbide cutting edge.

- You can use factory saw blades to make blades; in this case, you will get ready-made working edges.

- A square tube or a solid shaft is used in the form of a rod.

- The length of the workpiece is equal to the depth of the well plus an additional 50-60 cm.

- For drilling deep wells, it is better to use composite rods with a connecting coupling.

- The T-shaped handle is made 40-60 cm long.

- The tip of the rod is made in the form of a drill, cone or sharp triangle.

Special equipment Yamobur BKM-2MT

One of the specialized drilling rigs based on MTZ, designed to develop water wells when the water layer occurs at a depth of up to 20 m. It is also used to develop holes for power line supports, communication poles, columnar foundations in soils of categories 1-4. Main characteristics:

- overall dimensions in transport/working position (length/width/height) – 5.8*2.5*3.9/5.3*3.6*7.25 m;

- maximum drilling depth – 6 m;

- hole diameters – 36, 42, 50, 60 cm;

- operating angle – 60 – 105 degrees;

- type of drilling – rotary;

- expandable auger drill.

We understand the structure and characteristics of hole drills

The main purpose of a hole drill is to dig shallow holes, wells or holes (usually cylindrical in shape). The use of such equipment greatly speeds up the pace of work and simplifies the process, which would otherwise take much more time and effort.

Yamobur on a caterpillar base

Pit drills are used almost everywhere, and this explains their practicality and efficiency. They fill a rather narrow niche in industrial equipment, which so far have not been able to fill with similar equipment, since it simply does not exist.