Water flow sensor (relay) for the boiler and pump - types, how it works and how to do it yourself

Now we will figure out why a water flow sensor is needed (also called a “flow switch”) and look at the principle of its operation. You will also learn what types of these sensors there are and how to install it yourself.

In everyday life, sometimes an emergency switching on of a pump without water occurs, which can lead to equipment breakdown. Due to the so-called “dry running,” the engine overheats and parts are deformed. In order for the pump to function at maximum efficiency, it is important to ensure an uninterrupted water supply. To do this, you need to equip the heating and hot water supply system with a device such as a water flow sensor.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

Design and principle of operation

A water flow sensor is a device that monitors the pressure inside the water supply system; it is connected to the pump via pipes.

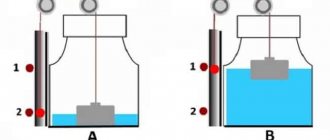

Standard circuit of a water flow sensor:

- relay;

- set of plates;

- There is a wide chamber inside the device;

- a small float, which is placed inside a stationary flask;

- outlet feed channel;

- Most models are equipped with an adjustment valve installed at the outlet.

The principle of operation of the sensor: when there is no liquid flow, it automatically pauses the pumping station and does not allow dry running, and when water appears, it starts the device.

Application area

Water flow sensors are usually found in devices where it is necessary to constantly monitor the life support system and observe a certain operating mode.

Most often, water flow sensors are used in boilers operating on gas. Modern gas boilers equipped with such sensors are used for both heating and water heating.

The device, which is located on the tap water supply pipeline, when water enters, sends a signal to the boiler control board and the operation of the circulation pump stops. Then the board turns on the nozzles responsible for heating the running water, and the water in the heat exchanger begins to heat up. When the tap closes, the sensor notifies that the water supply has been stopped.

Most households are equipped with autonomous water supply systems, thanks to which you can have the most comfortable conditions.

The function of the water flow sensor is that when you turn on any of the devices connected to the water supply system, the sensor turns on the pump and water begins to flow.

When choosing a water flow sensor, be sure to consider the throughput of the devices and their size.

Types of water flow sensors

According to the type of design, relay and fitting devices are distinguished. In addition, there are varieties based on pressure levels.

A relay-type water flow sensor is used for pumps with low power. Typically these models are single-chamber. Experts note their low conductivity. Models with a vertical arrangement of plates are available, their maximum pressure is at least 5 Pa.

Protection systems are often used in the P48 series. Thanks to all these indicators, there are practically no water leaks, and such devices are also characterized by good operating stability.

The most widely used water flow sensors for pumps are in-line models. Their plates are usually placed horizontally, and some samples are equipped with two valves. Their maximum pressure is approximately 5 Pa. Protection systems are most often class P58. Conductivity is directly dependent on the size of the fitting.

Low pressure sensors are applicable for pumps with a power of no more than 4 kW. The size of the chamber affects the conductivity. Most often on the market you can find a water flow sensor for a pump with two floats. Their price is low and you can easily choose the right model.

High pressure models are usually produced with one extended fitting, the plates are mounted horizontally. Experts advise installing such samples in centrifugal pumps. Maximum pressure does not exceed 6 Pa, protection system class P70.

Also, according to the mechanism of action, it is divided into:

- a water sensor based on the operating principle of a Hall sensor: it signals not only the flow of water, but also the speed of its flow;

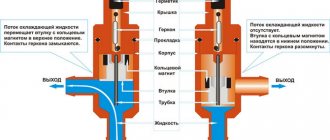

- a reed switch sensor operating on the principle of a magnet: inside it there is a magnetic float, which, as the water pressure increases, moves around the chamber and affects the reed switch.

Design and principle of operation of a reed switch water flow sensor

DIY installation and manufacturing

Most water flow sensors are included in the design of the devices, so they need to be installed only in the event of a breakdown and the need to replace them.

However, there are cases when the water flow sensor must be mounted separately, for example, if it is necessary to increase the water supply pressure. This is due to the fact that in the central water supply system, the pressure is low and does not reach the norm.

And in order to turn on a gas boiler in hot water supply mode, you need good pressure.

In such situations, an auxiliary circulation pump is installed, which is equipped with a water flow sensor. First the pump is installed, and then the sensor. It follows that as soon as water starts flowing, the sensor will turn on the pump and the pressure will begin to increase.

Pressure booster pump for Grundfos UPA 15-90 water supply system with built-in water flow sensor

Making a water flow sensor with your own hands is not difficult. First you need to install the camera, then you need to cut out three plates, they should be mounted horizontally, there should be no contact between them and the bulb. For a simple design, one float will be enough.

It is rational to install the fitting on two adapters; the valve must withstand a pressure of at least 5 Pa.

Manufacturers

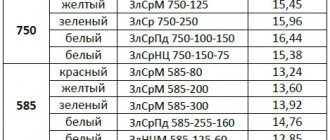

ManufacturerCharacteristics

| Water flow sensor for pump Grundfos UPA 120 (Denmark) | Designed to provide water supply to an individual house or apartment equipped with an individual water supply system. The automatic sensor switches on when there is a steady flow of liquid in the range of 90-120 liters per hour. The main function is to protect the pump from idling. The pump starts at a water flow rate of 1.5 liters per minute. The operating voltage of the sensor is 220-240 V. Frequency of consumption current - 50-60 Hz. Maximum current consumption - 8 A. Power consumption - up to 2.2 kW. Operating temperature range - 5-60 degrees Celsius. Protection degree - IP 65. Price - about 1,800 rubles. |

| Water flow sensor GENYO - LOWARA GENYO 8A (Poland) | Used to control the pump of a household water supply system based on actual water consumption. The main feature of the sensor is monitoring the pressure in the water supply during operation. The pump starts at a water flow of 1.5 liters per minute. Operating voltage - 220-240 V. Frequency of consumption current - 50-60 Hz. Maximum current consumption - 8A. Power consumption - up to 2.4 kW. Operating temperature range - 5-60 degrees Celsius. Protection degree - IP 65. Price - about 1,800 rubles. |

| Flow sensor 1.028570 (Italy) | Designed for installation in gas double-circuit boilers of the Immergas brand. Compatible with models: Mini 24 3 E, Victrix 26, Major Eolo 24 4E | 28 4E. Designed for installation in gas boilers of the Immergaz brand, chimney and turbocharged versions. Made in a plastic case with a threaded connection. Hall sensor 1.028570 allows you to receive water at a stable temperature at the outlet of the hot water supply circuit. Price - approximately 2,400 rubles. |

Application area

Water flow sensors are usually found in devices where it is necessary to constantly monitor the life support system and observe a certain operating mode.

Most often, water flow sensors are used in boilers operating on gas. Modern gas boilers equipped with such sensors are used for both heating and water heating.

The device, which is located on the tap water supply pipeline, when water enters, sends a signal to the boiler control board and the operation of the circulation pump stops. Then the board turns on the nozzles responsible for heating the running water, and the water in the heat exchanger begins to heat up. When the tap closes, the sensor notifies that the water supply has been stopped.

Most households are equipped with autonomous water supply systems, thanks to which you can have the most comfortable conditions.

The function of the water flow sensor is that when you turn on any of the devices connected to the water supply system, the sensor turns on the pump and water begins to flow.

When choosing a water flow sensor, be sure to consider the throughput of the devices and their size.

DIY water flow switch - Safety Portal

Taking good care of the equipment that supplies water significantly extends its service life and guarantees uninterrupted operation of the system. This requires not only timely inspection and proper care, but also equipping the pumps with a full set of protection devices. Preventing the possibility of a serious breakdown is much cheaper than repairing or buying a new unit. Do you agree?

Installing a water flow switch will protect the motor of both surface and deep-well pumping equipment. After all, most often when the motor burns out, it is easier to buy a new pump than to change it. We will tell you how this important protective device works, how to choose it and include it in an autonomous water supply.

The article provides valuable recommendations for installing devices to protect pumps from operating in “dry running” conditions. The technology of customization for individual requirements has been analyzed. For a better understanding of the considerable amount of information, photographs, diagrams, video reviews and manuals are attached.

Functional purpose of the flow switch

In household water supply systems, the action of a pumping station without water quite often occurs and threatens an accident. This problem is called “dry running”.

As a rule, the liquid cools and lubricates the elements of the system, thereby ensuring its normal operation. Even short-term dry operation leads to deformation of individual parts, overheating and failure of the equipment motor.

Negative consequences apply to both surface and deep-well pump models. Dry running occurs for various reasons:

- incorrect choice of pump capacity;

- unsuccessful installation;

- violation of the integrity of the water pipe;

- low fluid pressure and lack of control over its level;

- accumulated debris in the pumping pipe.

An automatic sensor is necessary in order to completely protect the device from the threats posed by a lack of water. It measures, controls and maintains constant water flow parameters.

Pumping equipment equipped with a sensor has many advantages. It lasts longer, breaks down less often, and uses energy more economically. There are also relay models for boilers

The main purpose of the relay is to independently turn off the pumping station when the liquid flow is insufficient and turn it on after normalization of the indicators.

Design and operating principle

The sensor has a unique device, thanks to which it performs its direct functions.

The most common modification is the paddle relay. The classic building scheme includes the following important elements:

- an inlet pipe that passes water through the device;

- valve (petal) located on the wall of the inner chamber;

- an isolated reed switch that opens and closes the power supply circuit;

- springs of a certain diameter with varying degrees of compression.

While the chamber is filled with liquid, the force of the flow begins to act on the valve, moving it around its axis.

A magnet built into the back of the petal comes close to the reed switch. As a result, the contacts close, turning on the pump.

The flow of water is understood as the speed of its physical movement sufficient to turn on the relay. Reducing the speed to zero, resulting in a complete stop, returns the switch to its original position. When setting the response threshold, this parameter is set taking into account the conditions of use of the device

When the flow of fluid stops and the pressure in the system drops below normal, the compression of the spring weakens, returning the valve to its original position. Moving away, the magnetic element ceases to operate, the contacts open and the pumping station stops.

Some modifications are equipped with a return magnet instead of springs. Judging by user reviews, they are less susceptible to minor pressure surges in the system.

Petal relays have a large number of advantages. Among them are a simple and unpretentious design, instant response, no delays between repeated responses, and the use of a precise trigger to start the equipment.

Depending on the design solution, several more types of relays are distinguished. These include rotary devices equipped with a paddle wheel rotating in a water flow. The speed of rotation of the blade in them is controlled by touch sensors. If there is liquid in the pipe, the mechanism deflects, closing the contacts.

There is also a thermal relay that operates according to thermodynamic principles. The device compares the temperature set on the sensors with the temperature of the working medium in the system.

If there is flow, a thermal change is detected, after which the electrical contacts are connected to the pump. If there is no water movement, the microswitch disconnects the contacts. Thermal relays are characterized by high sensitivity, but they are quite expensive.

Device selection criteria

When choosing equipment that controls the force of water flow, you should carefully study its technical characteristics.

Particular attention should be paid to the operating temperature and pressure range for which it is designed, the diameter of the threads and mounting holes, the protection class, and application nuances. It is also important to clarify what materials the product is made from.

Experts consider devices made of brass, stainless steel, and aluminum to be the most reliable and durable. These materials protect the structure from the critical consequences of a common phenomenon in water supply systems - water hammer.

When considering different modifications of the relay, it makes sense to purchase a version made of metal. The housing and working components of such devices are highly durable.

This fact allows the equipment to withstand serious loads for a long time that arise due to significant pressure from the liquid passing through the sensor.

The pressure value at which the relay operates must correspond to the power of the installed pump. The parameters of the water flow circulating through the pipeline depend on this characteristic.

It is advisable to choose a device with two springs that controls the operation of the pumping station according to certain lower and upper pressure marks.

The operating temperature range of the sensor directly indicates its possible area of application. For example, models with a high limit temperature are designed for hot water supply circuits and heating systems. For cold water pipelines, a range of up to 60 degrees is sufficient

Another important criterion that deserves special mention is the climatic conditions necessary for the operation of the product. This refers to the recommended air temperature and humidity level that the device needs to provide in order for it to perform at its best.

The maximum permissible load for a particular device is determined by the protection class specified in the technical specifications.

When purchasing a flow sensor, you should check the thread diameter and the dimensions of the mounting holes in the equipment: they must fit perfectly with the pipeline elements. The correctness and accuracy of further installation, as well as the efficiency of the relay after installation, depend on this.

Trusted Instruments

Among the entire range of relays, the two models that are in approximately the same price category are in greatest demand - about $30. Let's take a closer look at their characteristics.

Genyo Lowara Genyo 8A

Development of a Polish company engaged in the production of electronic equipment for control systems. Designed for use in domestic water supply systems.

Recommendations for installation and configuration

Liquid flow relays are installed for devices that require constant control and compliance with a certain operating mode. Often they are equipped with equipment at the production stage. However, there are also circumstances when a separate installation of the sensor is required.

Rules for installing relays in the system

Installing a safety device that detects the presence or absence of water flow in the system is a reasonable step in cases where it is not possible to be present while the pumping equipment is operating.

It is not required only in two cases:

- Water is pumped from a large well with unlimited resources by a low-power pump.

- It is possible to independently turn off the installation when the water level drops below the designated norm.

The device is installed on horizontal sections of the pipeline. In this case, you need to ensure that the membrane assumes a stable vertical position.

The device is mounted to the drain pipeline using a threaded coupling. Usually a special socket is provided for this.

If the pumping equipment does not have a hole for mounting the sensor, you can replace it with a brass tee. In addition to the relay, a pressure gauge is connected to it, showing the current pressure in the network

Before you start directly screwing the device, it is advisable to seal the threads well with flax or thread, sold in specialized departments.

It is better to wind it clockwise towards the end. This method of fastening increases the reliability of fixation.

In order not to damage the relay, you should screw it in very carefully, slightly tightening it with a wrench. The optimal distance between the product and the pipeline is at least 55 mm

When installing a factory sensor, you need to focus on the arrow shown on the body. The direction indicated on it must coincide with the direction of flow of the liquid passing through the device.

If contaminated water is transported through the pipeline, it is recommended to install cleaning filters, placing them near the sensor. Such a move will ensure the correct operation of the product.

At the final stage of installation work, the dry-running relay is connected to the electrical network:

- a wire core is screwed to the free ends of the two groups of contacts;

- a ground connection is attached to the sensor screw;

- the device is connected to the pump by connecting two devices with a regular wire, matching the colors of the cores.

After connecting to the network, all that remains is to check the functionality of the system. The fact that the device is ready for full operation will be indicated by an increase in pressure marks on the pressure gauge and the automatic shutdown of the pump when the limit value is exceeded.

Self-adjustment procedure

For adjustment, the sensor has special bolts. By loosening or tightening them, you can reduce or increase the compression force of the spring.

This sets the pressure level at which the device will operate.

Almost always, manufacturing companies produce equipment with adjusted settings. Despite this, sometimes additional self-adjustment is required

In most cases, setting up automatic equipment is not difficult.

It is advisable to adhere to the following algorithm:

- drain the liquid from the system until the pressure mark reaches zero;

- turn on the pumping unit and slowly let the water back in;

- record the flow pressure indicator when the pump is turned off with a sensor;

- start draining again and remember the indicators at which the pumping equipment will start working;

- open the relay and use the adjusting bolt to set the minimum level of compression of the larger spring required to activate the device and start the pump (more compression increases the degree of pressure, less - reduces it);

- in a similar way, adjust the compression force of a smaller spring mechanism, setting the limits of the maximum pressure, upon reaching which the relay measuring the water flow will turn off the pump.

Having completed all the described manipulations, you should make sure that the adjustments made are correct. To do this, the pipeline is filled with liquid and then drained, assessing the sensor’s response when the set values are reached.

If the test result is unsatisfactory, the procedure is repeated.

Having insufficient experience and qualifications, it is better to seek help in adjustment from specialists. They will analyze the specific situation, take into account the technical characteristics of the equipment and select the most correct pressure level values

To ensure that the pipeline through which the liquid passes works properly and stably, regular annual checks of the flow sensors are carried out. If necessary, the operating parameters are adjusted.

Water flow switch for pump: characteristics, principle of operation, installation

Ensuring the efficient operation of pumping units is the key to the uninterrupted functioning of the water supply and heating systems they serve.

To solve such an important task, pipelines are equipped with additional technical devices, one of which is a water flow sensor (or water flow sensor).

Its use makes it possible to control failures that may periodically occur in pipeline systems and, accordingly, minimize the risk of failure of pumping equipment.

Lobe flow sensors, non-adjustable

Purpose and benefits

When operating domestic water supply systems, there are often situations when the pump turns on when there is no liquid in the pipes.

Such situations, if they occur frequently and continue for a long time, cause overheating of the pump motor and deformation of its parts, which ultimately leads to failure of the entire device.

The water pumped by pumping equipment simultaneously performs lubricating and cooling functions, so “dry running,” as it is also called, negatively affects the technical condition of both circulation and submersible pumps.

In order to prevent the occurrence of the described situations, they use a water flow sensor for the pump, operating in automatic mode. Sensors that monitor water flow are successfully used to control the operation of pumping stations serving hot and cold water supply systems, as well as heating systems.

Sensor location diagram in the water supply system

The automatic device in question monitors the parameters of the flow of water that passes through it, and in cases where they differ from the standard ones, it automatically turns on or off the pumping equipment. Working on this principle, the sensor not only protects pumping equipment from “dry running”, but also ensures constant water flow parameters.

Among the advantages of operating pumping equipment on which a fluid flow sensor is installed are:

- reducing energy consumption and, accordingly, reducing the cost of paying for it;

- minimizing the risk of failure of pumping equipment;

- increasing the service life of pumping equipment.

Design features

The main tasks that water flow control sensors installed in domestic pipelines solve are to turn off pumping equipment at a time when there is no liquid in the system or its flow pressure exceeds the standard value, and turn it on again when the pressure drops. An effective solution to these important problems is provided by the sensor design, which consists of the following elements:

- a pipe through which water enters the sensor;

- a membrane that makes up one of the walls of the inner chamber of the sensor;

- a reed switch that provides closing and opening of the pump power supply circuit;

- two springs of different diameters (the degree of their compression regulates the pressure of the fluid flow, at which the water flow switch for the pump will operate).

Main components of an industrial flow sensor

The device of the above-described design works as follows:

- Entering the inner chamber of the sensor, the water flow puts pressure on the membrane, displacing it.

- The magnetic element fixed on the back side of the membrane, when it is displaced, approaches the reed switch, which leads to the closure of its contacts and the pump being turned on.

- If the pressure of the water flow passing through the sensor drops, the membrane returns to its original position, the magnet moves away from the switch, its contacts open, and accordingly, the pumping unit is turned off.

The operating principle of a flow sensor based on a permanent magnet and a reed switch

Sensors that monitor water flow are installed quite simply in pipeline systems for various purposes. The main thing is to choose the right device, paying attention to its operating parameters and characteristics of the pumping equipment.

Main characteristics

When choosing water flow sensors to equip a pipeline system, the following parameters must be taken into account:

- material for manufacturing the body and internal elements;

- operating pressure for which the sensor is designed;

- temperature range of the liquid to control the flow of which the device will be used;

- protection class and requirements for operating conditions;

- diameter of mounting holes and thread parameters in them.

Each of the above parameters affects the operational features of water flow sensors, so it is worth considering them in more detail.

The reliability of such a device, its ability to withstand loads arising during operation, as well as its durability depend on the material from which the sensor body and its internal parts are made. When choosing a fluid flow sensor, it is better to give preference to models for the manufacture of which various metals were used - stainless steel, brass or aluminum.

Manufacturers and model range of sensors

So, now we can talk about manufacturers.

- NEP TUN. This brand can be classified as Russian. The company offers customers simple and comfortable integrated solutions, as well as the latest wireless technologies, motion sensors and remote-controlled sockets, etc. The manufacturer has a developed service system.

- RSW+/ Neр tun Р ro W/ Neр tin А quaсo ntro l 220 V – in this case, the elements are selected separately according to the manufacturer’s catalog. Additional types of sensors and taps can be added to the basic package. Mini ½” is a ready-made budget solution for wired sensors. The control unit is designed for connection via cable. This is the best package for standard requirements.

- Bugatti ProW+2014 3/4 (20 mm) has advanced functionality, and this allows you to simultaneously connect a large number of sensors with different types of communication.

- Altronics WT-04, WT-03 are special examples of relatively inexpensive gadgets for use in domestic conditions. They are quite easy to install. By the way, the devices consist of a sensor in the form of a tape, which is connected to the power supply. Wireless central control units and alarm systems must be purchased separately for the sensors. The Altronics SM-01 is an incredible example of stand-alone wireless sensors. It can work independently or using the main wireless control panel, which will need to be purchased separately.

- “ Akv act opozh” is a Russian-made brand that was able to demonstrate expensive affordable solutions. Attention may be drawn to ready-made basic sets of equipment in order to detect leaks.

- Classic 1-25 Radio Pro is a set that can rightfully be called exemplary, which makes it possible to simultaneously connect radio sensors and cable sensors. The equipment is sold ready-made, after purchase you can immediately install it yourself, and the kit includes ball valves with servo drives.

- The Classic 2-15 is a type of corded equipment that allows you to perform all the basic tasks during leak detection, and this includes shutting off the pipeline.

- The “Classic” sensor is also a standard set that connects to a cable, but at the same time it has a non-standard beautiful body design.

We hope that this article helped you choose a water sensor that will protect your pipes and heating system from leaks.

Do-it-yourself water flow sensor - Metalist's Guide

Ensuring the efficient operation of pumping units is the key to the uninterrupted functioning of the water supply and heating systems they serve.

To solve such an important task, pipelines are equipped with additional technical devices, one of which is a water flow sensor (or water flow sensor).

Its use makes it possible to control failures that may periodically occur in pipeline systems and, accordingly, minimize the risk of failure of pumping equipment.

Lobe flow sensors, non-adjustable

How to signal a water leak

The solution to the problem came into everyday life from the yachting world. Since the ship's lower tier rooms (especially holds) are located below the waterline, water regularly accumulates in them. The consequences are clear, the question is how to deal with it. It is irrational to assign a separate sailor on watch for control. Then who will give the command to turn on the sump pump?

There are effective tandems: a water presence sensor and an automatic pump. As soon as the sensor detects that the hold is full, the pump motor turns on and pumping occurs.

The water sensor is nothing more than a regular float on a hinge connected to the pump switch. When the water level rises by 1–2 cm, the alarm and the sump pump motor are triggered at the same time.

Comfortable? Yes. Safely? Of course. However, such a system is unlikely to be suitable for a residential building.

Therefore, a more sensitive alarm system against leaks is needed. This is a question of sensors, and the executive part comes in two types:

1. Alarm only. It can be light, sound, or even connected to a GSM network. In this case, you will receive a signal on your mobile phone and will be able to remotely call an emergency team.

2. Turning off the water supply (unfortunately, this design does not work with the heating system, only water supply). After the main valve, which supplies water from the riser to the apartment (it does not matter whether it is before or after the meter), an electromagnetic valve is installed. When a signal is sent from the sensor, the water is shut off and further flooding is stopped.

Naturally, the water shut-off system also signals a problem in any of the above ways. These devices are offered in a wide range by plumbing stores. It would seem that material damage from a flood is potentially higher than the price of peace of mind. However, the majority of citizens live by the principle “until thunder strikes, a man will not cross himself.” And more progressive (and prudent) homeowners make a water leakage sensor with their own hands.

DIY water flow switch

Now we will figure out why a water flow sensor is needed (also called a “flow switch”) and look at the principle of its operation. You will also learn what types of these sensors there are and how to install it yourself.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

In everyday life, sometimes an emergency switching on of a pump without water occurs, which can lead to equipment breakdown. Due to the so-called “dry running,” the engine overheats and parts are deformed.

In order for the pump to function at maximum efficiency, it is important to ensure an uninterrupted water supply.

To do this, you need to equip the heating and hot water supply system with a device such as a water flow sensor.

Water flow switch for pump: characteristics, principle of operation, installation

Ensuring the efficient operation of pumping units is the key to the uninterrupted functioning of the water supply and heating systems they serve.

To solve such an important task, pipelines are equipped with additional technical devices, one of which is a water flow sensor (or water flow sensor).

Its use makes it possible to control failures that may periodically occur in pipeline systems and, accordingly, minimize the risk of failure of pumping equipment.

Lobe flow sensors, non-adjustable

Device installation

The selected water flow sensor must match the technical characteristics and parameters of the pump and pipeline.

It is optimal to carry out the installation before the first start-up of the water supply system. This ensures the prevention of faults and their consequences.

Installation steps include cutting in the sensor and connecting the electronics.

Installation is carried out in the direction corresponding to the arrow indicated on the relay body (shows the direction of water flow). The device is installed on a tee fitting that cuts into the pipe. The liquid is first drained from the pipeline. Location on the pipeline leaving the pump is recommended.

The protection is installed together with the pressure gauge according to the scheme recommended by the manufacturer.

To ensure a seal, the threads are sealed with plumber's tape or flax. Winding is carried out clockwise.

When contaminated water enters through a pipeline, the optimal solution is to install a filter in front of the sensor.

A break is made in the pump power cable, and a sensor is connected to the resulting section. Electrical connections must be made according to the diagram indicated on the accompanying documentation.

General installation rules

- When installing indoors, you can choose the degree of protection IP 20, outdoors - IP 64.

- The installation is carried out on a straight section, taking into account the distance to the turn and shut-off and control valves, equal to at least 5 pipeline diameters.

- The water flow sensor for the pump is mounted after the liquid flow meter.

- Ensuring the tightness of connections is achieved with special seals and proper quality of materials of the device.

- Compliance of the sensor with the pump according to technical characteristics.

- The relay is installed along the flow in accordance with the arrow on the body.

- Installation on horizontal and vertical sections of the pipeline is possible. Some manufacturers recommend installation only on a horizontal section of the pipeline. This information should be clarified in the technical documentation, but in any case, installation of the relay in which its housing will be directed downwards is excluded.

Particular attention is paid to screwing carefully to avoid damaging the relay. The recommended distance between the device and the pipeline is 5.5 centimeters.

Operating principle of leakage sensors

Speaking about the block diagram, everything is very simple. A certain element fixes the liquid at the point of its placement and sends a signal to the executive module. Which, depending on the settings, can give light or sound signals, and (or) give a command to close the valve.

How the sensors work

We will not consider the float mechanism, since it is not effective at home. Everything is simple there: the base is fixed to the floor, a float is suspended on a hinge, which, when floating, closes the switch contacts. A similar principle (mechanical only) is used in the toilet cistern.

The most commonly used sensor is a contact sensor, which uses the natural ability of water to conduct electrical current.

Of course, this is not a full-fledged switch through which 220 volts passes. A sensitive circuit is connected to two contact plates (see illustration), which detects even a small current. The sensor can be separate (as in the photo above), or built into a common housing. This solution is used on mobile autonomous sensors powered by a battery or accumulator.

If you do not have a smart home system, and water is supplied without any solenoid valves, a simple sensor with an audible alarm can be used as a starting option.

General principles for placing leakage sensors

Any owner of a premises (residential or office) knows where the water supply or heating communications are located. There are not many potential leak points:

Of course, ideally, the sensors should be located precisely under these devices. But then there may be too many of them, even for the DIY option.

In fact, 1-2 sensors per potentially dangerous room are enough. If it is a bathroom or toilet, as a rule, there is an entrance door threshold. In this case, water is collected as if in a pan; the layer can reach 1–2 cm until the liquid spills through the threshold. In this case, the installation location is not critical, the main thing is that the sensor does not interfere with moving around the room.

In the kitchen, sensors are installed on the floor under the sink, behind the washing machine or dishwasher. If a leak occurs, it will first form a puddle in which the alarm will sound.

In other rooms, the device is installed under heating radiators, since water supply pipes are not laid through the bedroom or living room.

It would not be superfluous to install the sensor in a niche through which risers of pipelines and sewers pass.

The most critical points of water breakthrough

With uniform operating pressure, the risk of leakage is minimal. The same applies to mixers and taps, if you open (close) the water smoothly. The weak point of the pipeline system manifests itself during water hammer:

How to properly place sensors

The contact plate should be located as close to the floor surface as possible without touching it. Optimal distance: 2–3 mm. If the contacts are placed directly on the floor, constant false alarms will occur due to condensation. Long distance reduces the effectiveness of protection. 20–30 millimeters of water is already a problem. The sooner the sensor works, the less losses.

Regardless of whether the leakage protection system is purchased in a store or made by yourself, you need to know the uniform standards for its operation.