A circular saw is a universal tool for cutting all kinds of parts and elements. To carve wood with this tool, you need to familiarize yourself with some rules that will make the work easier and help you safely cut the object into small parts. 5 tips on how to properly cut wood with a circular saw will greatly simplify your renovation task.

Make cuts without stopping

It is advisable not to stop while cutting wooden parts. The circular saw should move smoothly through the material and not be interrupted. Otherwise, there will be unevenness and cuts on the boards that will interfere with the further use of the wood.

The movements should be smooth and soft so that the disc does not become dull and moves smoothly along the board. It is also advisable to check the length of the cord in advance. If it does not reach, use an extension cord. Otherwise, the tree will also not be cut evenly.

Classification of circular saws

The most obvious basis for categorizing circular saws is to classify them according to the size of the blade and the corresponding depth of cut:

- small discs (cut 40−46 mm);

- disks with an average diameter (cut 50−55 mm);

- large discs (cut 65-70 mm).

There are also electric saws of the level of industrial logging and factory conveyors with a cutting depth of 65-140 mm, but they do not belong to hand tools.

In addition, you should pay attention to the material of the disc, the shape and direction of the teeth, and the power of the electric motor.

Adhesive cutting tape

To ensure that there are no chips on the material, and the veneer retains its original appearance, you can use adhesive or, in other words, masking tape. It will not leave marks on the wooden board, and will also protect the wood from visible mechanical damage.

The tape is attached in the place where the cut will be made. Next, you should carefully saw the board, after which you can remove the masking tape. It can only be dismantled away from the cut and at a right angle. The main thing is not to pull the tape upward so that the plywood does not delaminate.

Criteria for choosing circulars

Hand tools should be selected based on technical characteristics. The main 5 of them are:

- Power . The larger, the more productive the circular saw, but at the same time it becomes heavier.

- Disc diameter . The impressive dimensions allow you to cope with workpieces of increased thickness.

- Depth of cut . A key parameter that accurately characterizes the capabilities of the device.

- Number of revolutions . High revolutions give the disc teeth an initial acceleration, but over time the kinetic energy fades.

- Weight . Heavy units are difficult to move around the site, but they have decent performance.

When choosing a spare saw blade, you should know the mounting diameter , otherwise it will not be possible to install it on the tool head without an adapter. The most popular sizes: 16 , 20 and 30 mm.

In addition to the basic ones, there are additional options that can significantly make the operator’s life easier:

- Smooth start . The engine starts without jerking: gradually at minimum speed.

- RPM support . The disk rotation speed does not drop even under load.

- Adjustment of angle and depth . Allows you to adjust the cutting geometry.

- Power on lock . Protects the start button from accidental pressing.

- Laser level . Helps to align the tool along a clear line.

- Immersion . A special mechanism gradually lowers the cutting teeth into the workpiece. This makes it possible to start work not from the edge of the blank, but right from its middle.

How to saw a long board in half

A circular saw can also cut very long materials. To do this, you need to carefully prepare the workplace. You need to either put slats under the board, or saw on sawhorses. The technology is almost the same.

The key is to allow the end of the board to fall slightly as you cut, but not to lose the position of the circular saw. At the end of the work, the sawn piece will simply fall to the floor, which will be the end result. The main thing is that the board does not fall off before it is completely cut.

Circular saw design

The electric circular saw was created by Mitchell and Sillivan, founders of the famous equipment manufacturer SKIL. The device, called Skilsaw, the prototype of today's circular saw, was released in the mid-20s of the last century. However, today the saw looks completely different than it did at that time.

An electric circular saw for wood is a hand-held tool that is designed for longitudinal and transverse cutting of timber, wood materials, plastic blanks and soft non-ferrous metals.

The design of the circular saw itself has not changed much since its creation. Naturally, the device today is more ergonomic and powerful, and weighs much less. Fundamental changes occurred only with saw blades. Specialists are constantly developing new and improving old saw blades.

The main components of the saw:

- electric powertrain

- gear housing

- protective cover

- platform and guide.

The case is most often made of durable heat-resistant plastic, sometimes of metal. Since working with a circular saw is often necessary in dusty conditions, developers are increasingly paying attention to ventilation and cooling systems, as well as sawdust removal. All modern models are connected to industrial vacuum cleaners.

There are also quite unique options. For example, the Worx WT431KE saw from, which changes its angle of inclination up to 60 degrees. Thus, the master can work with the saw in the way that is convenient for him, according to his individual anatomical features. This engineering solution was created by WORX and implemented exclusively in devices from this manufacturer.

All circular saws have a commutator electric motor with a power of 500 to 2500 W. The power indicator affects the depth of cut and the number of revolutions of the saw blade.

Note that a new type of such devices is cordless circular saws. The most interesting new product is the BOSCH GKS 36 V-LI Professional circular saw, which runs on high-quality lithium-ion batteries. The device with a disk with a diameter of 165 mm (4000 rpm) has a weight of 4.8 kg.

How to cut a window in a piece of plywood

Sometimes the boards need to be sawn inside, cutting out the so-called “window” from the common part. But this must also be done in compliance with special rules. First you need to mark a point at the cut site. It should coincide with the corner and middle parts of the circular disk. During the entire process, the marked cutting line should be slightly to the side.

The main thing is to smoothly lower the circular disk into the plywood so that a return blow does not occur. Then, at full power, you can directly cut. Completion of work can only be carried out when the tool has completely stopped.

The structure of a circular saw

Last but not least, the popularity of the circular hand saw is due to the simplicity of this tool. The circular electric hand saw consists of the following elements:

- saw blade;

- electric motor;

- housings with a handle or two;

- a protective casing, the function of which is to cover the disk from above and below;

- a holding platform necessary to position the disc;

- a riving knife, which is necessary to prevent the disc from getting stuck in the wood during work.

The saw blade is secured to the electric motor shaft with several bolts. Accordingly, replacing it will not take much time.

How to cut a small piece of board without sawhorses

You can easily use a circular saw to cut small elements. To do this, you don’t even need to use sawhorses, but simply place the board edge-on on the toe of your foot, with your shin serving as support. Next, you should draw a cutting line, align the tool along it and make a cut.

The main thing is to maintain a safe distance from the incision to the leg. It must be more than 30 centimeters. At the end, the sawn element will simply fall to the floor, where the client should lie under the sawdust in advance.

A circular saw is suitable for cutting elements of any complexity and shape. You must follow the rules and safety requirements so as not to spoil the material and injure yourself. Therefore, these tips will help you avoid mistakes when cutting wooden boards with a circular saw. They must be adhered to, then the work will be done efficiently and without defects.

How to choose a saw

What is the best circular saw? It is very difficult to answer this question; it all depends on the amount of work, the materials used for processing, as well as individual preferences. In the process of choosing a high-quality circular saw, you will have to study in detail a large number of characteristics. Most circular saws have a seven-inch saw blade, suitable for a wide range of jobs. Models are sold that have a larger diameter saw blade, but they are not needed for cutting beams and beams.

In addition, an important characteristic is the degree of inclination with which the saw operates. Almost any circular saw can be set to a bevel angle of 45, but there are also models with a bevel angle of up to 55 degrees and even more. Cutting at an acute angle is a very convenient function of a circular saw.

The fundamental indicator when choosing a saw is the depth of cut. This indicator directly depends on the diameter of the saw blade. But at the same time, the larger the saw blade, the higher the power of the saw should be, which in turn affects the power of the motor and, accordingly, the weight of the tool.

You can find saws on sale that are equipped with laser guides, which are very helpful in the process of sawing boards or making long cuts, for example, on multi-layer plywood. Some models also have LED backlighting, making it easier to work in dimly lit areas.

Some circular saws have an interesting plunge function, which makes it possible to cut workpieces not only from the end of the board, but from anywhere on it. Craftsmen are also interested in the chip removal system. This system saves significant time. With this saw you don't need to clean up your workshop. In addition, not everyone knows that wood dust is very harmful to health. Therefore, it is better to purchase a model with such a system.

Before purchasing, you need to think about what material you will process with this tool. Hard types of timber, such as oak, can only be sawed with a very powerful saw. The higher the power, the easier it is to work.

Almost all saws in the starting configuration have a small amount of equipment. Most often, only guides are present. It’s rare to find models that come with a safety clutch that prevents the saw from kicking back if the blade jams.

OCCUPATIONAL SAFETY REQUIREMENTS DURING WORK

3.1. When starting a circular saw, you must first make sure that there are no people in the area where the machine is operating. 3.2. The workpiece must be fed onto the saw evenly, without jolts. 3.3. During operation, it is necessary to ensure that workpieces with nails or other metal objects do not fall into the machine. 3.4. When sawing long boards or beams, you cannot hold them suspended, but use stands. 3.5. If the work is performed by two people, then it is necessary to coordinate their actions with the actions of the auxiliary worker. 3.6. You cannot saw glued panels, parts and products if the glue has not dried. 3.7. Shaped sawing of workpieces should be done in special templates equipped with clamping devices. 3.8. The warped part must be laid with the concave side down. 3.9. Do not allow the saw blade to clamp at sharp turns of the cutting line. 3.10. If the saw blade is clamped, you need to pull the part back and then put it back through the cut. 3.11. It is forbidden to stand yourself and not allow a helper or other persons to stand close to the working saw. 3.12. Do not cut workpieces while wearing gloves to avoid catching them and injuring your fingers. 3.13. It is necessary to constantly remember and ensure that your hands are not in the danger zone. 3.14. During operation, you need to constantly monitor the operation of the circular saw, promptly cleaning it from sawdust. 3.15. It is not allowed to remove or install protective guards on moving parts of the machine while it is in operation. 3.16. It is prohibited to operate a circular saw without a safety guard. 3.17. While the machine is operating, you cannot repair it, lubricate it, clean it, or remove scraps or sawdust. 3.18. You cannot measure the dimensions of workpieces and parts near the cutting tool of a working machine. 3.19. Workers must not pass or receive anything through the machine while it is in operation. 3.20. Removing cuttings or sawdust from the machine is allowed only with special hooks, brushes, and sweeps; It is prohibited to remove waste wood and debris from the machine by hand. 3.21. While working, you should be extremely careful and not be distracted from your duties. 3.22. When working on a circular saw, the following fire safety rules must be observed: - the machine should be cleaned of dust and sawdust at least once per shift; — when the machine is operating, local ventilation suction must be running; — lumber, finished products, wood waste, and flammable liquids should not be stored in large quantities.

Mid-range saws

Makita HS7601 (8500 RUR)

Specifications:

- Power : 1200 W

- XX frequency : 5200 rpm

- Disc diameter : 190 mm

- Bore diameter : 30 mm

- Weight : 4 kg

Advantages:

- High power

- Durable and comfortable body

- Multi-level adjustment

- Reliability and unpretentiousness in work

Flaws:

- Lack of a soft start system - “jerky” start

Bosch GKS 190 (RUB 10,000)

Specifications:

- Power : 1400 W

- XX frequency : 5500 rpm

- Disc diameter : 190 mm

- Bore diameter : 30 mm

- Weight : 4.2 kg

Advantages:

- High power

- Good ergonomics

- Precise cuts both straight and at an angle

- Convenient sawdust removal system

Flaws:

- No bottom guard

- High price

GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1. An employee who is at least 18 years old, who has undergone a medical examination and has no contraindications for health reasons, who has the necessary theoretical and practical training, who has undergone introductory and initial workplace safety briefings and training according to a special program, and who is certified by a qualification, is allowed to perform work on a circular saw. commission and received permission to work independently. 1.2. In order for an employee to be allowed to work independently on a circular saw, he must undergo an internship under the supervision of an experienced worker. 1.3. An employee who operates a circular saw (hereinafter referred to as the employee) must periodically, at least once a year, undergo training and testing of knowledge of labor protection requirements and receive permission to perform high-risk work. 1.4. An employee, regardless of qualifications and work experience, must undergo repeated training on labor protection at least once every three months; in case of violation of labor safety requirements, during a break in work for more than 30 calendar days, he must undergo an unscheduled briefing. 1.5. An employee who has demonstrated unsatisfactory skills and knowledge of safety requirements is not allowed to work independently on a circular saw. 1.6. An employee allowed to work independently on a circular saw must know: the structure of a circular saw and the safety requirements when working on it. Safety precautions when using instrumentation. Safety requirements when setting up and participating in machine repairs. Rules, regulations and instructions for labor protection and fire safety. Rules for the use of primary fire extinguishing agents. Methods of providing first aid in case of accidents. Internal labor regulations of the organization. 1.7. An employee sent to participate in work unusual for his profession must undergo targeted training on the safe performance of the upcoming work. 1.8. The employee is prohibited from performing work to which he is not authorized in accordance with the established procedure, as well as using tools and equipment that he does not have the skills to handle safely. 1.9. When processing wood and wood products on a circular saw, the worker may be adversely affected mainly by the following dangerous and harmful production factors: - moving circular saw blade; — unprotected moving elements of the machine; — moving products, workpieces and materials; — increased dust content in the air of the working area; — increased noise level in the workplace; — insufficient illumination of the working area and surfaces of workpieces; - electric current, the path of which, in the event of a short circuit, can pass through the human body; — the presence of a large amount of flammable waste (sawdust, shavings, chips, etc.), blanks and finished products, which can lead to a fire. 1.10. A worker operating a circular saw should be aware that wood defects (deviations from the normal structure of its fibers) can become potential hazards, especially when manually feeding material to the cutting tool. 1.11. During work, the employee must use the necessary personal protective equipment from exposure to hazardous and harmful production factors. 1.12. To prevent the possibility of a fire, the employee must comply with fire safety requirements himself and prevent other employees from violating these requirements; Smoking is permitted only in designated areas. 1.13. Considering the increased fire danger of the room in which wood is processed, the employee should not allow the accumulation of wood waste, sawdust, shavings, clutter the workplace and passages, and also store flammable and combustible liquids. 1.14. Due to the high risk of injury from a circular saw, the employee should not allow strangers to work on it. 1.15. The employee is obliged to comply with labor and production discipline, internal labor regulations, and the work and rest regimes established for him. 1.16. In case of illness or poor health, the employee should report his condition to his immediate supervisor and seek medical help. 1.17. If an accident occurs with one of the employees, the victim must be given first aid, report the incident to the manager and maintain the situation of the incident, if this does not create a danger to others. 1.18. The employee, if necessary, must be able to provide first aid and use a first aid kit. 1.19. To prevent the possibility of illness, employees should observe personal hygiene rules, including thoroughly washing their hands with soap before eating. 1.20. It is not allowed to perform work while intoxicated or in a state caused by the consumption of narcotic drugs, psychotropic, toxic or other intoxicating substances, as well as drink alcoholic beverages, use narcotic drugs, psychotropic, toxic or other intoxicating substances at the workplace or during work. time. 1.21. An employee who violates or fails to comply with the requirements of labor safety instructions is considered a violator of industrial discipline and may be subject to disciplinary liability, and, depending on the consequences, to criminal liability; if the violation is associated with causing material damage, then the perpetrator may be held financially liable in the prescribed manner.

Tool accessories

The main equipment for a circular saw is a saw blade. By the landing and outer diameter it is possible to tell whether it will fit a particular model. The depth of cut depends on the outer diameter, and the landing diameter is needed to purchase a device of this size.

Using the adapter ring, you can use blades of other fitting sizes. This method is not suitable for outside diameter.

Disks are chosen to solve specific problems, so it’s worth considering:

- the number and configuration of teeth and the recesses between them;

- tilt angle;

- outer (outer) diameter;

- sharpening geometry.

A neat cut without defects along the edge of the product is produced by a blade with fine teeth during the cutting process. High performance is inherent in devices with large, sparse teeth.

The following types of fabric are produced:

- Monolithic. They are rarely included in the package and are used for softwood. The disadvantage of the devices is the need to regularly sharpen the teeth and set them apart, but at the same time this is an advantage, namely, the service life of the disk increases due to the ability to resharpen.

- Carbide. Blades with specially brazed teeth are usually made of cobalt, tungsten or carbide. Their popularity is explained by the high quality of the cut. Devices are used for working with laminate, hardwood, and metal.

Depending on the material and type of operation, the type of disk blade is selected

Device and technical characteristics

The circular saw is designed to provide versatility, high performance and safety. The operating mechanism is based on the general principle of transmitting torque from an electric motor to the working body of a circular saw - to the saw wheel.

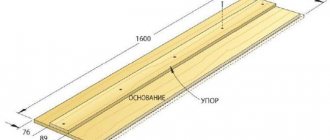

The design of a circular saw may differ depending on the type of work it performs. The typical design, taken as the basis for any modification of the saw, has several main functional elements:

- platform - base;

- an electric motor that transmits rotational energy to the saw blade;

- saw blade;

- a body equipped with handles for controlling the saw and holding it during operation;

- protective casing (upper and lower), protecting the saw blade from sawdust getting into the working mechanism;

- device for fastening the longitudinal stop;

- riving knife.

The design of a circular saw can also be supplemented with a depth gauge with a scale that allows you to evaluate the depth of penetration of the saw blade into wood or other material.

For convenience, some saws have a movable motor mount to the base, which allows you to adjust the angle of inclination using a fixing screw and scale.

The cutting depth at an angle of 90° is on average 45-70 mm. And at an angle of 45° from 28 to 48 mm.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. In case of detection of violations of labor protection requirements that pose a threat to health or personal safety, the employee must contact the work manager and inform him about it; Until the threat is eliminated, you should stop working and leave the danger area. 4.2. If a malfunction of the circular saw or auxiliary tool is detected during operation, work should be stopped immediately and notified to your immediate supervisor. It is not permitted to continue working with a faulty saw or tool. 4.3. The worker must turn off the machine in the following cases: - when leaving the machine even for a short time; — in case of temporary interruption of power supply; — when measuring workpieces and parts; - when smoke or a burning smell appears; — when lubricating, cleaning or cleaning the machine; — if the cutting tool breaks; — when a machine malfunction is detected; — when the material being processed is jammed in the machine or metal objects are found in it; - if electrical voltage is detected on non-current-carrying metal parts of the machine. 4.4. If a fire or signs of combustion are detected (smoke, burning smell, increased temperature, etc.), you must immediately notify the fire department by calling 101 or 112. 4.5. Before the fire department arrives, measures must be taken to evacuate people and property and begin extinguishing the fire. 4.6. In the event of an accident, you must immediately provide first aid to the victim, call a doctor by calling 103 or 112 or help take the victim to a doctor, and then inform the manager about the incident.