Cutting a profile pipe with a miter saw with a metal disc - is it possible?

IMHODom › Forums › hands from shoulders › Cutting a profile pipe with a miter saw with a metal disc - is it possible?

This topic has 9 replies, 7 voices, and was last updated by kaifsheg 5 years, 11 months. back.

Greetings. I don’t have a pendulum saw and/or a band saw at hand, so a question has arisen, but I need to make a cut on a profile pipe (ferrous metal, 50x50x2).

Accordingly, the question is: is it realistic to use miter saws with a metal (cutting) blade and, if so, what should the speed/power be?

Is it realistic to use a jigsaw with metal files and, accordingly, what should be the power?

clarification to the question:

1. The purchase of a band saw/pendulum does not fit into the budget of this design; cutting to order, again, is excluded - it’s too tedious with delivery, etc.

2. The problem with the grinder is to get more or less close to 90g. cut, that’s why I want to use a miter saw (on which 90 degrees are set) or a jigsaw along the guide.

- village of Dzerzhinskoye

Budget-friendly, here’s a pendulum for a simple angle grinder.

You can put a metal disc on a crosscut saw, but you can’t put a wood disc on a grinder, the speeds are different, everything can end badly...

Maybe it will be useful for someone, I haven’t used abrasive discs for a long time, like meadows..., we cut everything with diamond “turbos” on stone, one disc lasts for a year or two.. at a price of 300-500 rubles, it pays for itself every 10-20...

There are cutting machines for metal. The price of Interskolovsky and other Chinese is about 2.5 thousand... (probably). They are just right for abrasive discs. I wouldn't spoil the trim. There is a lot of plastic on it, and as you know, it burns from sparks. There are also metal discs for trimming with carbide tips (a disc with teeth but a different shape compared to wood). It costs about 6 thousand.

- Tomsk

For some reason, my friend, you charged 6 thousand for the disk. At these prices, it’s easier to buy an angle grinder complete with a pendulum.

- Rainbow

jigsaw - definitely not considered, nonsense, sawing pipes with a jigsaw...

cross-cutting with a cutting disc - the saw will not last long, the disc will not fit, you need to tinker with the adapter, and the speed and power are not the same... also not an option

The stand for the grinder is flimsy, uncomfortable, the corners are floating, it is very advisable to mount it permanently, otherwise the grinder may behave unpredictably. If you need to cut a little, you can get by with it. the lesser of evils. but if you need to cut in the future, I strongly advise you to buy a cutting machine. 6-8 thousand, but it's worth it.

- The science

Maybe it will be useful for someone, I haven’t used abrasive discs for a long time, like meadows..., we cut everything with diamond “turbos” on stone

And which one exactly? I tried several - they get very hot. I tried solid ones for waterless cutting

I had the matrix for a year, in daily use, until the car was opened, and the grinder didn’t do a leg... Of course it saws more slowly than an abrasive, but on roofs it beats itself off in 2-3 days... I sawed tiles, pipes and fittings...

And he really turned it down. Apparently the manager deceived me at the store.

I saw how a corner with a 5 mm flange was cut with such a disc. thick. It's sawing!

- Rainbow

With a miter saw in the usual sense, you can cut wood, plastic and soft metals (aluminum profile). such saws usually have a power of 1.3-1.8 kW, a blade of up to 200-300 mm, and a speed of 4000-5000 rpm.

pipes and other metal are sawed using cutting machines. they look roughly the same as trimmers, but have differences in characteristics. power from 2.2 kW, disc from 350 mm, speed up to 4000 rpm.

with seemingly small differences in characteristics, the linear speed of the disk of a crosscut saw will be approximately 1.5 times less than that of a cutting saw, with the latter having a higher power. thus, the crosscut tool simply will not carry the load when sawing metal.

We also must not forget about the problems associated with the compatibility of tools and disks (thicknesses, diameters, mounting dimensions).

Is it possible to cut metal with a miter?

Metal cutting can be carried out using both hot and cold methods. The hot method is based on heating the separation site to the melting temperature. These are methods such as laser cutting, cutting with electrodes, gas cutting (plasma), autogenous cutting.

These types of cutting are used in most cases in production.

Flame cutting

Cold cutting includes such methods as guillotine cutting of metal, cutting with a grinder, cutting with hand tools, for example, scissors, a hacksaw, or a drill attachment. The most progressive and convenient method is cutting metal with a miter saw, which is designed specifically for working with metal.

Typically, a miter saw with a standard configuration and a medium-power engine is used for cutting work on wood, but miter saws for metal and wood are produced, which, provided the correct metal saw blades for the miter saw are used correctly, can cut metal, but mainly non-ferrous and plastic , and, of course, wooden blanks.

Should you choose a miter band saw or a metal miter saw?

The operating principle of band saws is that the cutting tool is not a disk, but a band blade and a special gear mechanism located on it. The operating speed is quite slow, approximately 100 revolutions per minute, but this tool can cut fairly large diameters, both logs and metal pipes.

Diagram of a band saw for cutting metal

Like any tool, band saws come in:

- Household, when the frame in which the saw blade itself is fixed is fed manually. It is used for irregular work when sawing soft grades of steel. According to the technology, lubricating and cooling liquid is not used in these machines.

- Semi-professional saws, in which the frame is lowered using hydraulic feed. Coolant must be used in this equipment. They can cut hard steel grades.

- Professional saws are fully automated equipment where the work is performed by an operator. Good speed of work, quality of cutting, usually the presence of rotating jaws that allow sawing at an angle of 45 degrees.

Professional band saw for cutting metal

A big plus of the saws is the band blade itself, which can be installed on a machine of any manufacturer and power.

The Jet J-349V semi-professional saw has very good reviews at a price starting from 36,000 rubles.

A good option is a semi-professional band saw from JET

Can work with workpieces from 125 x 125 mm, its weight is 19 kg.

Manufacturer: Switzerland – Taiwan.

When choosing a pendulum saw, you need to take into account its operating principle: productivity, accuracy of work and the ability to cut at any set angle. The principle of operation of the pendulum is that the cutting mechanism itself works on the same principle as the pendulum works: up - down. Its main part is a circular saw.

A metal miter saw compared to other tools has the following advantages:

- a tool with many functions;

- with the help of a pendulum unit the cut itself is obtained with high precision;

- the operating speed is quite high;

- It is very easy to buy a pendulum miter saw for metal, as well as to set it up for work;

- Easy to maintain and change the saw blade.

One significant disadvantage of such a saw is its high price, especially if it is a professional tool. For metal, a professional tool is used.

There are also inexpensive trimming tools from a Russian manufacturer, for example from the company Elektropribor PO -2400 Dm, which can work with metal, their cost starts from 5,450 rubles.

https://www..com/watch?v=tXa7pel5Fec

An excellent option for dry cutting of ferrous metals is a trimming machine from the Russian-Taiwanese manufacturer Messer DRC 355 at a price of 43,000 rubles. The reviews are all excellent, the design is successful, the quality of workmanship matches the price.

Messer DRC 355, saw with pendulum mechanism

https://www.youtube.com/watch?v=tXa7pel5Fec

You can buy a miter saw for metal at Leroy Merlin. There they are much cheaper than in other stores, for example Metabo CS 23 with a 355 mm disc costs 10,980 rubles, Corvette 431 for 7,800 rubles.

Can a miter saw cut ferrous metal?

There is a lot of controversy among professionals about the miter saw for cutting metal. Those miter saws that have an angular speed of up to 5000 revolutions and a power of up to 1.8 kW, even when using carbide metal cutting blades for a miter saw, can cut thin sheet, non-ferrous metal, plastic, but ferrous metals are not suitable for them.

If you take a pipe or other rolled product, there are special cutting machines for this, which are almost the same as miter saws, but have different technical characteristics.

This is a serious tool that an amateur would not buy to cut off a piece of corner once a month.

So, for example, the linear speed should be at least 1.5 times less, the power should be from 2 kW, the disk should be larger, the average size 350 mm.

Bosch metal cutting machine

If you buy a pendulum-type metal miter saw, its price will depend on the manufacturer and the purpose of the saw. If a professional-type saw is intended for sawing wooden blanks, plastic sheets and non-ferrous metal blanks, naturally its price will be cheaper.

If you take a miter saw for cutting metal, for example, the Makita LC 1230 brand, its price starts from 25,900 rubles, it cuts both thin-walled pipes and rolled products with a 3.5 - 4 mm wall.

At the same time, users note that for thick workpieces they simply have to change metal saw blades for a miter saw more often, which are not cheap to buy.

Here is such a serious tool - miter saw Makita LC 1230

The diameter of the disc is 305 mm, it is with direct drive, with an engine power of 1750 W, maximum revolutions - 1300 per minute.

There are also good reviews about the Makita 4131 pendulum miter saw, which can cut metal up to 5 mm thick. The tool has many additional useful options. This includes protection against engine overheating, shaft locking, the ability to adjust the depth of the cut itself and a locking button from accidental activation. Excellent insulation during assembly. Price from 21,700 rubles.

Therefore, the answer to the question whether it is possible to cut metal with a miter saw will be: of course it is possible, but not with any saw and not with any disc.

To buy a good and working metal blade for a miter saw, you need to remember that it must be a carbide blade with a large number of teeth, more than 60.

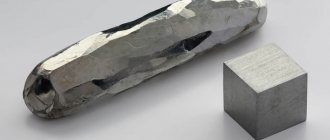

It should be made of steel with a high carbon content and alloyed with molybdenum, nickel and chromium for greater hardness and strength.

Wheels from Makita are in good demand; their price starts from 5,300 rubles; Bosch is in the same price range. If you take Hitachi, then the same diameter of 305 mm can cost 3850 rubles.

Hitachi metal cutting disc

If you take a brand like SMT, manufactured in Italy - Germany, its discs are even more expensive, from 6800 rubles, they cut steel, cast iron, metal profiles, sheets. Tungsten carbide soldering tips, 90 teeth.

Discs from the Jet company are also of fairly good quality and cost from 4,900 rubles. They can serve for a very long time, up to a year, then they are sharpened and returned to work.

How to make a miter saw for metal with your own hands

Of course, Makita takes first place in this tool segment - both the quality of the tool and the relatively low price, but for a lover of various types of crafts it still “bites”. Therefore, craftsmen make such instruments themselves.

You can buy a cheap cross-cut saw, for example, from the company P.I.T RSM 355-C, and replace the bed from it with a flatter and thicker one. The fasteners also need to be changed. You can remake and make other inexpensive miter saws of higher quality, the main thing is that the technical characteristics of the engine suit you.

There are options for making such a saw from a grinder, but with such a saw you are unlikely to be able to cut workpieces efficiently and accurately, but it can be used for infrequent and irresponsible work.

You can make another type of cross-cutting, however, it will turn out to be quite difficult to work with, but the mechanism itself will work smoothly. You need to stock up on an electric motor with a power of at least 1000 W, a metal sheet for the frame, an angle and a channel, a hinge unit, a powerful tight spring, a grinder for work, as well as a welding machine and various metalwork tools.

Using a miter saw to cut metal.

I read somewhere that it is absolutely impossible. And it turns out you can” > I wonder what diameter of the circle he used.

I think 200x32 mm through the adapter washer. Everything is possible in our country)))

In some TV program I saw how men cut a steel profile with a circular saw, only not like a pendulum, but one that moves along a bar. They had a metal disk there and it seemed like they were even leaking coolant.

Yeees. Our people apparently have a lot of health.

2 BEARDED What risks do you think exist?

acrobat wrote: What risks do you think exist?

Burning of the edges of the workpiece, an increased probability of destruction of the disk at such speeds, and as a result, unfinished work and possible injuries, shaking or complete failure of the tool, waste of time and effort (which we don’t like to count) on remaking and fine-tuning an obviously poorly made tool .

It’s possible, there are special discs; usually partition installers often cut duralumin profiles with such a tool.

Serg wrote: duralumin profiles are often cut with such a tool.

Duralumin profile, aluminum profile - another story. I'm talking about steel - pipes and angles, for example.

General information about the tool

Along with jigsaws, circular and circular saws, the miter is capable of cutting metal sheets, profiles, and various types of pipes. The design of the device is simple - the main elements are a frame (base), a handle with a start button, a saw blade, a gearbox and a motor. The latter comes in two types:

The advantage of the first is ease of maintenance, the second is a long service life and less noise during operation.

The motor is connected to the saw blade via a belt or gear drive. They have advantages and disadvantages. For example, a belt is almost silent and eliminates vibration of the disk, but can slip during long-term operation, forcing the user to stop the process. The toothed one is free from this disadvantage, but it is noisy and vibrates slightly.

The working body of a miter saw is a disc. It is made of durable metals, since it bears a serious load. There are wavy lines or cuts on the surfaces of some removable elements. This is done to reduce noise during operation, as well as to compensate for temperature deformation.

Types of pendulum saws

It is easier to classify a miter tool than, for example, an electric jigsaw, which can be mechanical or electric. The products under consideration are divided according to the following criteria:

- appointment;

- the presence of a broach function;

- saw blade parameters.

Household and professional equipment and machines are distinguished by purpose. The former are distinguished by low power (up to 1500 W), compactness, and cost up to 20-25 thousand rubles. Example - Bosch GKM 18 V-LI 0 L-BOXX (battery model for 15 thousand rubles), Kolner KMS 210/1400 for 4000 rubles, domestic Caliber PTE-900/190M with a power of 900 W at a price of 4500 rubles.

A cross-cutting machine is equipment not for home work, used only in enterprises that produce rolled metal products and are engaged in cutting or other processing on a daily basis. Such machines cost tens and hundreds of thousands of rubles, their power exceeds 1000 W, and they weigh several centners. An example is domestically produced machines TsT 10-4 (3 kW, 360 kg, 105 thousand rubles) or TsKB-40 K (5.5 kW, 700 kg, 340 thousand rubles).

Professional trimmers for sheets, profiles and pipes occupy an intermediate position according to the specified parameters. For example, Makita LF 1000 (1650 W, from 60 thousand rubles), DeWalt 27111 (1500 W, from 50 thousand rubles).

Having a drawing option gives the user a slight advantage when processing long sheets or pipes. The models have two parallel slats on which the cutting disc is mounted and moves freely along them. A tool with a broach is distinguished by a large cutting width of the part, as well as particularly small teeth on the disk. Also, the tool sometimes has a laser pointer for easy marking and process control. Metal trimming with broaching weighs more than usual, and the presence of the option increases the cost by 20-30%.

The parameters of the cutting blade are the most important classification criterion. They have two diameters - external (at least 20 cm) and internal (also known as landing; about 3 cm). The size of the teeth determines the depth and width of the cut, and the material determines the ability to work with a particular metal.

Now, a few words about manufacturers you can trust.

Rating of miter saws with broaching

Einhel TC-SM 2131 Dual

Budget trimming unit for cutting shalevka, cutting fence boards and timber. This device is more suitable for rough work when you need to quickly cut wooden pieces without a perfectly accurate size. The device works with disks with a diameter of 210 mm and a 30 mm mounting socket. The maximum cutting width with broaching is 310 mm, and the depth is 62 mm. The device can also cut at an angle of 45°, but the depth will be 36 mm.

The miter saw is equipped with a 1800 W motor that accelerates the attachment to 5000 rpm. For better visualization of the cut there is a laser marker. During operation, it can become clogged with dust, so it needs to be wiped from time to time. A dust bag is included. You can also connect a vacuum cleaner to it if you wish. If you're looking for an inexpensive trimmer for rough work, this is the model for you.

BISON ZPT-255-1800-PL

The domestically produced cross-cutting machine is equipped with a 1800 W motor. It works with discs with a diameter of 255 mm with a 30 mm socket. The broaching system allows you to cut workpieces with a width of 305 mm in one cut. In this case, the depth of immersion of the disk into the workpiece is 75 mm. Like the previous unit, this miter saw can cut at an angle of 45°, but here the miter depth is already 55 mm - this is a good indicator for a saw for the money.

A nice feature of the saw is the presence of an engine brake. Thanks to it, after turning off the power, the engine stops almost instantly, which also makes the disk stop abruptly (no need to wait long). The laser marker on the body of the unit quite accurately shows the line along which the disk will go. The kit comes with a dust collector, but users complain that chips do not fall into it. We recommend connecting the vacuum cleaner immediately. For the money, this is a good machine for cutting wood and composite materials.

Bosch PCM 8S

This “German” is intended for semi-professional use at home and in the carpentry workshop. It weighs relatively little (11.4 kg), which makes it suitable for transportation to sites. For example, it can be used to conveniently carry out commercial orders for installing doorways. The cutting depth here is 65 mm, and the broach width is 220 mm. Users note good build quality, reliable construction and high-quality cast sole (base). In inclined mode at an angle of 45°, the crosscut saws to a depth of 40 mm. A laser marker and LED backlight are responsible for good visualization of the cutting line.

To make it more convenient to saw a long board, the manufacturer has provided blocks that lengthen the sole. They are attached to the sides of the sole, 2 pieces on each side. The device also comes with a spacious dust container and a branded Optiline Wood saw blade. The manufacturer provides a 24-month warranty on the device.

Metabo KGS 254 M

A good-quality miter saw with a 305 mm broach system and a cutting depth of 92 mm. Although the unit can be taken to sites, it is still quite heavy (16.3 kg) and is best used for stationary work. The device is capable of cutting not only dense wood, but also composite materials and even aluminum. The maximum angle of inclination of the disk is 47°, at which the cutting depth of the workpiece is 47 mm. This saw is equipped with a motor brake, which almost instantly stops the rotation of the saw blade after turning off the power.

There is a wide, strong stop with a corrugated surface for better fixation of the workpiece. The upper part of the stop on the right side is folding so that the blade can cut at an angle. Users note the high accuracy of the settings: angles, length and width are clearly adjusted to 0.5 mm. Thanks to such precise settings, the cut is perfect and adjusting the skirting boards or lining is very easy. The kit also includes a bag for collecting sawdust.

Makita LS1016

This is a professional power tool for carpentry and carpentry work. The saw is exclusively for stationary use. Its main advantage is the soft start function, which limits the starting current, accelerating the disk slowly. Thanks to this, tool jerking is completely eliminated. The trimmer also has excellent build quality and a reliable, durable design. This unit works with discs with a diameter of 260 mm with a 25 mm seat. Its broach width is 279 mm with a maximum cutting depth of 91 mm. At a 45° angle saw, the cutting depth is 58 mm.

The manufacturer has equipped the device with a speed maintenance system: when the load increases, the power increases, and when it decreases, it decreases. Thanks to this, the rotation speed of the disk always remains at the same level and the quality of the cut does not decrease. This saw is top notch for the money. However, given the rather high cost, it is worth taking only if you plan to carry out commercial orders. For home use only, it is better to take something cheaper.

What other tools are needed for a carpentry workshop:

Recommendations for choosing a product brand

The best miter saw in terms of safety, manufacturability and work comfort is a product from one of the following companies:

Most of them offer table expansion for the workpiece, but cutting large parts sometimes requires additional supports. These are found in, for example, the LF 1000 model. This simplifies the user’s work. In this case, the moving part of the makita metal saw enters a stable frame, in which there is an area for setting the cutting angle.

The best trimmers in terms of reliability and stability are those whose frame is made of aluminum or magnesium alloy. They are durable, stable, but at the same time they weigh acceptable. An example is the Bosch GCM 10, popular among professionals, weighs only 15 kg.

The leader among saws with a possible inclination of the cutting edge to the workpiece is Hitachi. While Bosch, Metabo or Makita mostly allow you to set the cutting angle to only 0, 90 or 45 degrees, the Japanese concern offers the user the ability to rotate by 15; 22.5; 30 degrees. This option forces you to add a rotating device to the design, due to which, however, the weight of the installation for cutting profiles, sheets or pipes will still not exceed 30 kg. The price increases by 15-25%.

Tips for choosing a miter saw

The tips below are a must read before purchasing a tool.

- For rare and short-term work, choose household equipment (low power, compactness, price no more than 15 thousand rubles), for regular work - professional equipment (price 15 thousand and above, power - more than 1 kW).

- The more powerful the engine, the less it will heat up during operation, the higher the performance of the tool and the larger the disk you can install yourself if replacement is necessary.

- Many discs indicate the manufacturer's recommendations regarding the material to be cut or its type (for sheets/pipes/profiles); pay attention to this.

- Models with a spacious blade for work are more expensive, but they are much more convenient for cutting metal.

- The design welcomes the presence of a cutting depth limiter - this way you can select a groove for processing the workpiece in width.

- Evaluate whether you need laser illumination, broaching and similar options. If not, don't overpay.

- If the blade guard does not cover the blade during operation, it is a poor tool and dangerous to operate.

- The wider the workpieces will be cut with a miter saw, the larger the diameter of the disk should be.

- The heavy weight of the device will cause fatigue when cutting, although its cost is higher than its compact counterparts.

This material briefly examines the types of miter saws for metal and tips for choosing. You can describe your experience using devices or give advice on choosing a tool to visitors to our site.

Miter saw for metal: varieties, reliable manufacturers

There are quite a lot of tools for cutting metal, however, only a pendulum (or miter) saw provides the ability to make an angular cut.

It is used to make window stops, door frames and many other products that are used everywhere. However, specifically in this article only a miter (pendulum) saw for metal will be considered.

- general information

- Pendulum saws: varieties The size of the cutting blade is the central classification criterion

We will try to answer the questions:

- What features does it have?

- How is it classified?

- What points to pay attention to before purchasing.

Can a miter saw cut metal?

cutting

profile pipe 50x50x2 with a miter saw and a metal disc. May be?

Greetings. I don’t have a pendulum saw and/or a band saw at hand, so a question has arisen, but it is necessary to make a cut on a profile pipe (ferrous metal, 50x50x2).

Accordingly, the question. Is it realistic to use miter saws with a metal (cutting) blade and, if so, what speed/power should it be?

Is it realistic to use a jigsaw with metal files and, accordingly, what should be the power?

clarification to the question:

1. The purchase of a band saw/pendulum does not fit into the budget of this design; cutting to order, again, is excluded. very troublesome with delivery, etc.

2. cutting metal with a miter saw with an abrasive disc? 1. cutting metal at a crosscut machine. The problem with the grinder. get more or less close to 90g. cut, which is why I would like to use a miter saw (on which 90 degrees are set) or a jigsaw along the guide.

What, some kind of special miter saw, only for wood? I saw these exclusively in sets for children's creativity,

so it seems that the trimmings are universal. Cutting a profile pipe 50x50x2 with a miter saw with a disk for the load when sawing metal. Here:

Rating of miter saw manufacturers

Miter saws, like other electric tools, are produced in many countries around the world by all well-known brands operating in this equipment market. The most popular in our country are:

- From foreign companies - (Germany), Makita (Japan) and Metabo (Germany).

- From domestic ones : “Bison” and “Enkor-Corvette”.

Miter saw model “Anchor Corvette-4-430”

For obvious reasons, domestic models are most popular in the budget segment of equipment, and more expensive foreign analogues are most popular in the class of professional tools. It is quite difficult to determine which manufacturers' models are the most popular, because... they are similar in basic parameters, and the choice of users in this case is based on personal preferences for the brand of tool based on previous experience with a specific brand.

Wood miter saw assembly saw

Anyone who has cut a large corner with a manual grinder knows how stressful and unsafe this work can be. https://imhodom.ru/node/14492 (write in PM)

There are cutting machines for metal. Cutting metal with a miter saw. Cutting metal with a band saw, miter saw and circular saw. The cost of Interskolovski and other Chinese is about 2.5 thousand (for sure). Cutting metal with a miter saw. They are just right for abrasive discs. I wouldn't spoil the trim. There is a lot of plastic on it, and as you can imagine, it glows with sparks. There are also metal discs for trimming with carbide tips (a disc with teeth but a different shape compared to wood). It costs about 6 thousand.

For some reason, my friend, you charged 6 thousand for the disc. At such prices, it is easier to purchase an angle grinder complete with a pendulum.

jigsaw It’s definitely not considered, it’s absurd, to cut pipes with a jigsaw.