Purpose

The main function of industrial oils and lubricants is to minimize wear of rubbing components and reduce energy consumption to overcome friction in various equipment components. In addition, substances remove heat from contacting elements, clean the surface of dirt and other particles, and seal friction areas.

All industrial oils and lubricants are divided into mineral, petroleum and synthetic. Based on their state of aggregation, they distinguish between liquid lubricating oils, which have fluidity, and also greases, the standard state of which is pasty.

Features of choice

In the process of selecting compositions for lubricators that are used in industrial equipment, it is necessary to take into account the purpose of the equipment, the properties of the contacting surfaces and operating conditions. For example:

In addition, many oil manufacturers have developed special tables for selecting a substance based on information about the operating conditions of the equipment. In the selection cards you can find recommendations for all oils used. For example, multi-purpose fluids are used if the speed parameter of the components in the assembly is up to 300,000, the temperature is from 50 to 100 °C, the load factor is C/P

If the constant temperature of the bearings during operation of the device is >100 °C, high-temperature fluid is used. At values >150 °C, a special substance for extremely high temperatures is required. For low-temperature environments, where the bearing heats up to 50 °C, low-temperature lubricants are used.

The technology used in the food industry uses substances that are compatible with food. For heavy shock loads and frequent starts and stops of devices, special compounds for severe loads are used.

For pneumatic tools

The oil ensures the longevity of the operation of pneumatic tools. The devices use the energy of compressed air, so various seals are used in the devices. They are made from rubber intended for use in friction systems where there is a need for a large volume of lubricants. The oil processes the components and the pneumatic system functions without failure.

The main criterion for selecting oil for such equipment is viscosity. It is reflected on the packaging in the form of ISO markings. The ISO standard is used to classify viscosity. The packaging contains a standard and a number that determines the viscosity level. A substance with a viscosity index of 46 and 100 can be used to service equipment in general and its compressors in particular. A substance with an index of 46 is suitable directly for lubrication, and in devices with an oil system, materials with an index of 100 are used.

For compressors

Compressors today are widely used in many areas: in industry, construction, medicine, everyday life, etc. In order for the equipment to function properly for as long as possible without failures, it is necessary to pay increased attention to maintenance and the lubricants used.

High-quality compressor oil should have the following properties:

Thus, in such equipment it is necessary to use lubricants that have the above properties. If at least one indicator of a substance does not meet technical requirements or operating conditions, its use is not recommended.

For machines

A high-quality lubricant for machine tools should have the following characteristics:

The defining characteristics of oil for machine tools: density, viscosity, flash point and pour point, ash content, acid number and sulfur content. To be sure which substance to use in a particular model of machine, you must follow the manufacturer’s recommendations, which are reflected in the operating instructions for the equipment.

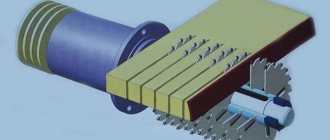

What is a lubricator

Initially, you should understand the device and the area of application of the part. A lubricator is a unit that serves as a source of lubricant for the moving components of pneumatic devices.

The air mixture entering the rotating parts guarantees an extension of the operating life of the installation and eliminates accidental breakdowns caused by wear of friction pairs.

The lubricator is used in grinding machines, valves, engines, gearboxes, and high-pressure pressure lines.

As of 2021, there are 2 types of designs.

- Magistralnaya. Used to service multiple tools. The device is mounted inside the highway no further than 10 meters from the distant device.

- Linear. Has an identical design. However, the application is limited to a single device. Installation is carried out directly in front of the working handle.

Manufacturers

Many companies produce oils and lubricating compounds for lubricators used in industrial equipment.

SKF is one of the leading manufacturers of lubricants and lubricants for refilling equipment. The company offers a wide selection of lubricants and substances intended for equipment components for a variety of purposes, which can be refilled with lubricators.

Main types of lubricants:

Using information about the rotation speed of mechanisms, temperature, load conditions and other parameters, you can select the best option for specific equipment.

Efele

Efele materials are specially developed for the maintenance of chain drives. All types of substances are divided into 3 groups: food grade, chain lubricants, and chain oils with graphite.

The lubricants are also suitable for automatic processing systems, including lubricators. Considering the characteristics, Efele products can be used in almost any industrial equipment.

NTN-SNR

The materials of this brand have high temperature and performance characteristics, excellent adhesion, structural stability and resistance to washout, which provides the treated components with protection and a long service life. The stability, heat resistance and water resistance of materials is achieved due to the organic components included in their composition, which allows the use of lubricants in a wide range of equipment.

The main advantages of NTN-SNR lubricants:

Unlike standard substances from other manufacturers, SNR formulations use high-quality materials that provide the mixtures with good performance characteristics.

Weicon

The company develops lubricants for various industries, ranging from production, maintenance and repair, to maintenance and technical service. The brand's specialization includes the production of the following types of lubricants:

In addition, Weicon produces anti-corrosion compounds that provide long-lasting protection for metal surfaces. The mixtures consist of natural and synthetic resins with pigments of zinc, aluminum, copper, brass and stainless steel. The compositions are resistant to elevated temperatures and aggressive environments in general.

Source

What is a pneumatic tool?

Pneumatic tools include various types of screwdrivers, grinders, pneumatic drills, chisels, riveting hammers and other items designed to increase labor productivity with the least amount of physical force.

To operate effectively, pneumatic tools need care and, most importantly, high-quality lubrication. Due to a number of advantages, pneumatic tools compete with power tools.

The main features of pneumatic tools include their safety, low noise and vibration levels. It is simple and unpretentious in operation, operates in a wide range of temperatures, under various conditions.

The main advantage is the high power of pneumatic motors with a small size and weight.

In other words, pneumatic tools provide high labor productivity with low personnel fatigue.

However, for long-term and productive operation of pneumatic tools, it is necessary to comply with the technical requirements, which indicate the lubrication regime and recommended lubricants.

Lubricator oil for tire changer

Any pneumatic tool requires regular checking of the oil level. It is very important to monitor this: if there is not enough lubrication, the friction of moving parts of the equipment increases, and this, in turn, leads to accelerated wear of the entire system.

The oil level in the lubricator of the tire changer should be checked daily. If necessary, you need to add or change the technical fluid. To do this:

In addition, do not forget to check the oil supply setting. The machines have special regulators that allow you to adjust the operation of the dispenser in accordance with the manufacturer’s recommendations.

Another important point is the timely removal of condensate. Water negatively affects the operation of the tire changer, so it should be drained from the filter regulator regularly.

When servicing pneumatic equipment, do not forget to clean and lubricate all moving parts, tighten loose fasteners, and check the condition of the drive belt.

Splitters and connectors

Pneumatic splitters are often called air tees or air hose tee fittings. Branchers allow you to connect additional lines to the main output of the compressor for simultaneous operation of several pneumatic tools.

Air tees are divided into two types:

- Herringbone splitters

. Allows the outlet lines to be connected to the main hose rather than to the compressor. Made in the form of a cross with four outlets. Dimensions are selected according to the diameter of the air hose. The most popular splitters are 8, 10 and 12 mm; - Threaded tee fittings

. Equipped with an inlet and three outlets with threads of a certain size. Designed for use in conjunction with threaded adapters and connectors.

To connect terminal equipment, it is customary to use quick-disconnect connections (QDC). With their help, you can quickly and reliably connect a wrench, spray gun and other equipment. The BRS also allows you to disconnect the pneumatic tool from the line without stopping the air supply. A herringbone or threaded connection is used as a fitting.

There are two types: “BRS dad” and “BRS mom”. Most often, “male” fittings are installed on pneumatic tools, and the “female” connector is screwed onto the hose to the compressor.

When using powerful impact wrenches and other productive equipment, it is important to select a coupling with high throughput. Unlike the standard version, it is designed for high pressure and flow of compressed air.

What kind of oil is poured into a tire changing machine?

For all devices based on working with compressed air, only specialized technical lubricants are used. Do not use brake fluid or other products not recommended by the manufacturer.

Simply check which oils are approved for use with your machine, and then order oil with the same characteristics. Choose products from well-known and trusted manufacturers, for example, Shell, Total, BP, Esso, etc.

This article is an addition to the basic instructions for BRIGHT equipment. In it you will find recommendations from our service center employees, following which, your equipment will last many times longer than its stated service life.

Two main recommendations for all BRIGHT stands:

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

A modern tire changing machine, despite its apparent simplicity, is a rather complex device. It uses electromechanical, pneumatic, electronic and hydraulic components (mainly in truck tire changing machines) and elements. Moreover, the machines are designed for constant and long-term use.

Let's take, as an example, the issue of the intensity of operation of a tire machine during the so-called high season. As a rule, at this time tire shops work 12–14 hours a day, and some around the clock. Typically, one specialist works at one tire station (one tire changer and one balancing machine). Depending on the qualifications of the employee, servicing a car takes from 40 minutes to one hour. During this time, it is necessary to remove 4 wheels, change the tires, balance the newly assembled wheels and install them on the car. That is, it takes from 10 to 15 minutes to service one wheel. This means that if a service point operates 12 hours a day, then about 50 wheels are disassembled and assembled on one tire machine. At the same time, during the work process, all components and mechanisms of this machine are intensively exploited.

When developing and producing CORGHI tire fitting equipment, the company's engineers pay priority attention to the issues of its reliability and durability. This approach is one of the fundamental methods of CORGHI's work in the global market, where it is rightfully among the industry leaders. Many years of experience working with CORGHI equipment in Russia have shown that tire machines of this brand can operate for 10–12, and sometimes more, years. It’s not so rare that our specialists come across equipment at car repair shops and tire shops , which was produced in the 90s. And these machines do not lie dead weight, but have been successfully performing their functions and tasks for many years.

The service life of tire fitting equipment, of course, is determined by a number of factors, among which the quality of its manufacture plays an important role. However, another important factor is the attitude of service station specialists towards the equipment. After all, it’s no secret that a tire changing machine requires timely and correct maintenance. And usually, reputable manufacturers of auto service equipment indicate requirements and recommendations for the operation and maintenance of their tire changers in the operating instructions. Such “manuals” are supplied with the equipment. However, these instructions are often lost during long periods of work. Given the importance of the issue under consideration, we decided to once again remind everyone that the service life of a tire changing machine depends on the people who operate it.

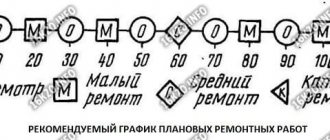

There are a number of activities that need to be carried out with established regularity - daily, weekly, monthly and annually. They are the key to the long service life of the tire changing machine.

The tire service area must be cleaned daily. Using a scraper and brush, it is necessary to clean the turntable every day, removing dirt, dust and other deposits from it. It is also necessary to wipe the cylinder rods from dust and dirt. To carry out this work, do not use compressed air, water jets or strong solvents.

The issue of cleaning a tire changing machine from dirt accumulated during a shift is very important. Modern tire changing machines include a lot of moving elements (clamping jaws, columns with tire changing heads, rods of various cylinders, etc.). The sand and other solid particles found in this mud are an abrasive material and contribute to increased wear of these components and mechanisms.

In addition, we recommend using only mild solvents for cleaning, since the use of strong solvents for cleaning, as well as dirt and sand, leads to increased mechanical wear of the treated elements. It is also important to check the proper operation of the movable bolts, mounting head rollers and bid breaker. The accumulation of dirt on these components reduces their performance and can lead to damage to the machine.

And finally, one more recommendation that is often neglected at car service centers. At the end of the working day, it is necessary to turn off, that is, disconnect the machine from the air line.

What kind of oil to pour into the lubricator

Pure lubricant without foreign additives or mechanical inclusions is poured inside the device. Some liquid purification models are equipped with additional filters. This approach is necessary due to design features: the spout nozzle, as a rule, is no more than 1 mm in diameter, which allows the smallest particles to easily clog the hole.

Important! The use of inappropriate transmission and motor type formulas is strictly prohibited. These mixtures can damage sensitive structural elements.

The lubricant is selected based on factory recommendations. In 90% of cases, the exact labeling of liquids can be found on the pages of the user manual.

The most popular manufacturers of lubricating oils for pneumatic tools are the following brands:

- Mobil;

- FESTO;

- fillin;

- Liqui Moly;

- Craft.

DOMOSTROYPlumbing and construction

Any pneumatic tool requires regular checking of the oil level. It is very important to monitor this: if there is not enough lubrication, the friction of moving parts of the equipment increases, and this, in turn, leads to accelerated wear of the entire system.

The oil level in the lubricator of the tire changer should be checked daily. If necessary, you need to add or change the technical fluid. To do this:

In addition, do not forget to check the oil supply setting. The machines have special regulators that allow you to adjust the operation of the dispenser in accordance with the manufacturer’s recommendations.

Another important point is the timely removal of condensate. Water negatively affects the operation of the tire changer, so it should be drained from the filter regulator regularly.

When servicing pneumatic equipment, do not forget to clean and lubricate all moving parts, tighten loose fasteners, and check the condition of the drive belt.

Device price

The cost depends on several factors:

- Material of manufacture (steel, iron, brass, etc.).

- The volume of the container into which oil is poured for further distribution.

- Type of instalation.

- The number of points that the device can lubricate at a time.

- Capacity and maximum pressure.

- Manufacturer (domestic devices are 10-20% cheaper than their foreign counterparts).

As a rule, the least expensive option is to purchase a lubricator through an online store, where products for air tools are offered at discounted prices. In ordinary construction stores you can find the most popular devices that are used in conjunction with equipment for garages, workshops, construction compressor equipment, and are used for industrial and domestic purposes.

A pneumatic line in a car service center or service station ensures the delivery of air from the compressor to consumers, acting as the “circulatory system” of a pneumatic tool. Another important function is to prepare air for the operation of the instrument. In this material, we will understand the structure of the pneumatic line and select air preparation modules for trouble-free operation of the tool.

Pneumatic line device

To connect the end equipment you will need the following components:

- Hoses

and reels; - Splitters, connectors and quick-release connectors

for switching lines and connecting impact wrenches with tire changers; - Air preparation equipment

, which includes lubricating modules (lubricators), air filters and pressure regulators.

Hoses directly affect the reliability of the line and the correct functioning of the tool. In order for the same impact wrenches to work in accordance with their passport specifications, it is important to fulfill the following conditions:

1. Select a hose with suitable operating pressure and internal diameter. A high-performance tool may have more stringent requirements for hose strength and capacity;

2. When installing the pneumatic line, a balance was maintained between the length of the hoses and the number of splitters. The more branches are planned, the more carefully it is necessary to select the cross-section of the distribution hoses and take into account the performance of the compressor;

3. Distributors and quick-release connectors (QDCs) of suitable cross-section were used.

What kind of oil is poured into a tire changing machine?

For all devices based on working with compressed air, only specialized technical lubricants are used. Do not use brake fluid or other products not recommended by the manufacturer.

Simply check which oils are approved for use with your machine, and then order oil with the same characteristics. Choose products from well-known and trusted manufacturers, for example, Shell, Total, BP, Esso, etc.

This article is an addition to the basic instructions for BRIGHT equipment. In it you will find recommendations from our service center employees, following which, your equipment will last many times longer than its stated service life.

Two main recommendations for all BRIGHT stands:

Maintenance of the BRIGHT balancing machine

Commissioning. BRIGHT balancing machines are delivered from the factory already calibrated, but before commissioning it is recommended to calibrate the factory parameters. To do this, you need a balanced wheel on a steel disk with a diameter of 15 inches (380 mm), a weight that corresponds to the weight specified in the instructions (50-100 grams). And then you should step by step follow the instructions for your stand model.

For operation of the BRIGHT balancing machine. To extend the life of expensive-to-replace electronics, you must carefully monitor the network voltage. If there are suspicions of sags or surges in the network, then you need to purchase a voltage stabilizer. It is also very important to keep the machine clean, especially carefully ensuring that the shaft is clean and dry. Always use a protective cover. It is not recommended to pack weights on the shaft.

With light loads on the BRIGHT balancing machine, calibration of the ruler and shaft is performed once a year, and with heavy traffic - once a season!

Maintenance of BRIGHT passenger tire changing machine

For correct operation of the BRIGHT tire changing machine for passenger cars, you will need an air supply of 8 atmospheres and a stable network of 220/380V. Air is supplied to the stand through an air preparation unit, which is included in the factory package, with optimal settings for correct operation. Before starting, it is necessary to check the air pressure and the presence of oil. To do this, after connecting the air to the fitting, adjust the pressure on the pressure gauge to 8 atmospheres of air using the large yellow handle (Fig. 1). Monitor the presence of condensate and drain it after each shift!

Next, the air enters the oil block, which should always contain oil (Fig. 2). BRIGHT passenger car tire changers are supplied with an already filled oil block. In case of absence or depletion, it must be replenished. To do this, unscrew the glass beaker and fill it 2/3 full with oil. It is strictly forbidden to touch the small yellow oil supply regulator, made for a slotted screwdriver! (shown in Fig.3)

At the factory, the oiler is optimally configured - one drop of oil is supplied for three pneumatic operations. This can be observed in the window located on top of the oil block. If you do not add oil, the cuffs in the pneumatic cylinders will quickly wear out, which will lead to air leakage and loss of force on the pneumatic cylinders.

The brand of oil corresponding to the machine is written on a yellow plate located near the air preparation unit (it can be seen in three pictures). If the recommended brand of oil is unavailable, it is permissible to use a “spindle”.

It is necessary to ensure the cleanliness of the tire changing table and cam group and clean them regularly. Check the tightening torque of the bolts once a week.

Maintenance of the BRIGHT truck tire changing machine

Tire changing machines for trucks are reliable and convenient to operate due to the remote control console (unit) away from the machine to a place convenient for the master. This allows you to closely monitor all tire fitting processes. The forces on the stand arise from the work of high-tech, reliable hydraulic cylinders. The rotation of the expanding cams (tulip) to grip the wheel is carried out using a 3-phase asynchronous electric motor at 380V.

For reliable operation of the stand, it is necessary to monitor the technical condition of the expansion mechanism (tulip) - regularly clean and lubricate it. Also pay attention to the condition of the hydraulic cylinders. Do not allow dust and dirt to get on their polished surfaces. In case of severe operating conditions of the BRIGHT tire changer for trucks, cleaning should be carried out regularly.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

A modern tire changing machine, despite its apparent simplicity, is a rather complex device. It uses electromechanical, pneumatic, electronic and hydraulic components (mainly in truck tire changing machines) and elements. Moreover, the machines are designed for constant and long-term use.

Let's take, as an example, the issue of the intensity of operation of a tire machine during the so-called high season. As a rule, at this time tire shops work 12–14 hours a day, and some around the clock. Typically, one specialist works at one tire station (one tire changer and one balancing machine). Depending on the qualifications of the employee, servicing a car takes from 40 minutes to one hour. During this time, it is necessary to remove 4 wheels, change the tires, balance the newly assembled wheels and install them on the car. That is, it takes from 10 to 15 minutes to service one wheel. This means that if a service point operates 12 hours a day, then about 50 wheels are disassembled and assembled on one tire machine. At the same time, during the work process, all components and mechanisms of this machine are intensively exploited.

When developing and producing CORGHI tire fitting equipment, the company's engineers pay priority attention to the issues of its reliability and durability. This approach is one of the fundamental methods of CORGHI's work in the global market, where it is rightfully among the industry leaders. Many years of experience working with CORGHI equipment in Russia have shown that tire machines of this brand can operate for 10–12, and sometimes more, years. It’s not so rare that our specialists come across CORGHI equipment at car repair shops and tire shops, which was produced in the 90s. And these machines do not lie dead weight, but have been successfully performing their functions and tasks for many years.

The service life of tire fitting equipment, of course, is determined by a number of factors, among which the quality of its manufacture plays an important role. However, another important factor is the attitude of service station specialists towards the equipment. After all, it’s no secret that a tire changing machine requires timely and correct maintenance. And usually, reputable manufacturers of auto service equipment indicate requirements and recommendations for the operation and maintenance of their tire changers in the operating instructions. Such “manuals” are supplied with the equipment. However, these instructions are often lost during long periods of work. Given the importance of the issue under consideration, we decided to once again remind everyone that the service life of a tire changing machine depends on the people who operate it.

There are a number of activities that need to be carried out with established regularity - daily, weekly, monthly and annually. They are the key to the long service life of the tire changing machine.

The tire service area must be cleaned daily. Using a scraper and brush, it is necessary to clean the turntable every day, removing dirt, dust and other deposits from it. It is also necessary to wipe the cylinder rods from dust and dirt. To carry out this work, do not use compressed air, water jets or strong solvents.

The issue of cleaning a tire changing machine from dirt accumulated during a shift is very important. Modern tire changing machines include a lot of moving elements (clamping jaws, columns with tire changing heads, rods of various cylinders, etc.). The sand and other solid particles found in this mud are an abrasive material and contribute to increased wear of these components and mechanisms.

In addition, we recommend using only mild solvents for cleaning, since the use of strong solvents for cleaning, as well as dirt and sand, leads to increased mechanical wear of the treated elements. It is also important to check the proper operation of the movable bolts, mounting head rollers and bid breaker. The accumulation of dirt on these components reduces their performance and can lead to damage to the machine.

And finally, one more recommendation that is often neglected at car service centers. At the end of the working day, it is necessary to turn off, that is, disconnect the machine from the air line.

The weekly maintenance schedule for a tire changer involves checking the oil level in the hydraulic system (for truck tire changers), checking for the presence of condensation in the water separator cup (if the level is exceeded, you must drain the condensate manually), as well as checking the oil level in the lubricator (if necessary, it must be topped up). The importance of the oil level criterion in hydraulic systems is obvious. It's like the oil level in car engines. There is no need to talk about the consequences of insufficient oil in engines. An important issue is the presence of oil in lubricators of pneumatic systems. This oil is designed to create an “oil mist” that reduces friction of the moving elements of these systems, which means that wear on the system as a whole is reduced. Condensate, but in reality it is water, on the contrary, negatively affects the operation of pneumatic systems. Special glasses are used to collect condensate, from which this condensate must simply be drained in a timely manner.

Monthly service for tire changing machines also involves a number of operations. In particular, once a month it is necessary to lubricate the moving parts of the mounting head rods, guide movable arms, rollers, and also check for play and gaps in the guide rollers, fixing mechanisms of vertical and horizontal rods. If any play or gaps are detected, adjustments must be made. In addition, it is necessary to check the rate of oil flow through the dropper. The normal rate is 1 drop of oil for every 4 bead lift cycles. If necessary, you will need to make adjustments, which are done using the adjusting screw.

And finally, monthly maintenance operations must be carried out annually, as well as a complete oil change in the hydraulic system (for truck tire changers).

Any pneumatic tool requires regular checking of the oil level. It is very important to monitor this: if there is not enough lubrication, the friction of moving parts of the equipment increases, and this, in turn, leads to accelerated wear of the entire system.

The oil level in the lubricator of the tire changer should be checked daily. If necessary, you need to add or change the technical fluid. To do this:

In addition, do not forget to check the oil supply setting. The machines have special regulators that allow you to adjust the operation of the dispenser in accordance with the manufacturer’s recommendations.

Another important point is the timely removal of condensate. Water negatively affects the operation of the tire changer, so it should be drained from the filter regulator regularly.

When servicing pneumatic equipment, do not forget to clean and lubricate all moving parts, tighten loose fasteners, and check the condition of the drive belt.