Heating pipes using hot water

This method is best suited for cases where the trench where the pipe is located can be easily opened. For example, it is not buried underground, but is located in a concrete channel, which is not a problem to quickly access. In addition, this technology is only suitable for steel pipelines. The frozen section of the pipe is first wrapped in rags and then poured with boiling water. In a relatively short period of time, you can warm up a frozen area.

When heating pipes with hot water, it is important not to damage them. Areas that do not require heating must be covered with heat-insulating material, otherwise ice may form elsewhere.

Heating with an open fire

This method is used only for frozen steel pipes. When working, you need to use a blowtorch or a gas burner; if these tools are not available, you can use a regular fire. Important tip: you need to put a sheet of metal under the pipe so that the heat is reflected better. The frozen part of the pipeline is heated by an open fire, and the resulting water gradually spreads throughout the system. This method is used only when pipes are visible.

Recommendations from experts

Viktor Sergeevich Vasyukov, plumbing specialist: Any pipes can freeze under certain conditions. To prevent this from happening, even at the stage of their installation it is necessary to provide for all available options for their insulation.

Dmitry Pavlovich Rodionov, master plumber: Polypropylene pipes are connected with fittings, which at the junction do not contribute to the narrowing of the internal diameter of the pipe. Therefore, the process of eliminating ice plugs is greatly simplified when compared with pipes made of metal.

Warming up a frozen pipeline with a hairdryer

A hair dryer can quite successfully remove ice plugs. However, this heating method can only be used in situations where the pipeline is easy to reach. For example, in cases where it is located inside a building. This technology is not suitable for pipes made of polymer materials, because a construction hair dryer produces too high a temperature. In the worst case, the plastic will melt and the water supply system will have to be changed.

The metal pipeline can be warmed up with a hairdryer, but this will take quite a lot of time. This process can be accelerated by using a sleeve made of any dense material, for example polyethylene. The sleeve is placed on the desired area, and a hair dryer is inserted inside it and connected to a power source. Heated air collects in the sleeve, which acts on the pipeline, heating it evenly over the entire surface.

The water pipe is frozen: what to do?

Winter. It was frosty. We open the water, but it’s not there. Naturally, we understand that the water supply was caught somewhere. Not a pleasant situation. You'll have to start looking for the problem area. The most vulnerable are the boundaries between earth and air, as well as open, uninsulated areas.

If the water supply is made of propylene and laid in an open area, then it is not difficult to detect the plug. With slight bending (without fanaticism), the characteristic cracking of breaking ice will be heard in such places. In such a situation, you are incredibly lucky, because removing the ice jam will be quite simple.

If the water supply is frozen somewhere under the floor, in the wall or (even worse) underground, then you will have to work hard here.

The main reasons for freezing of a water supply system in the ground are considered to be its shallow burial (less than the probable depth of soil freezing), poor-quality insulation, extreme drop in temperature and low water circulation (the owners have left, sleep at night, rarely use it, etc.).

Defrosting pipes using a welding machine

This technology for heating pipes was invented by savvy owners of private houses. The method consists of applying electricity to the frozen area from a welding machine. Depending on the degree of freezing, the current can be adjusted down or up. The wires from the welding machine are connected to the ends of the frozen section and wrapped with wire. The equipment is then turned on for about half a minute. After a short break, this process is repeated. If during such exposure the pipe does not heat up, the current of the device is increased.

Industrial systems for defrosting pipelines operate on this principle. The terminals of this device are connected to the ends of the area that needs to be defrosted. The device is plugged into the network and a current is applied to the pipe. Using such a device, a pipe 25 meters long and 6 centimeters in diameter defrosts in about 1 hour, therefore, if the structure has a diameter larger than 6 centimeters, it is better to defrost it in separate parts, it will be faster.

How to warm up a plastic pipe

Above we presented methods for heating metal structures, but what about plastic pipelines? To do this, you can use moderately hot water (no more than 80 degrees Celsius) or use a heating cable. With hot water heating technology, everything should be clear, but most owners of private houses have not even heard of a heating cable. In order to defrost a section of pipe with a cable, you need to wrap it with metal foil.

A special heating cable is wound on top of the foil. You should be careful, in order to avoid cable failure, the turns of the system must be located at a distance of at least 9 centimeters from each other. Thermal sensors are installed on the heating cable, which turn off the system when heated to a certain temperature. The cable is connected to a power source and heats up the desired area.

Equipment for emergency defrosting

The most famous equipment for emergency defrosting of pipes at the moment is the “Dragon”. This device is recognized by professionals as one of the best for removing ice from a pipe. This device is a step-down transformer with a high transformation rate. Depending on the model, this device can deliver a current of up to 400 Amps, due to which you can very quickly heat up a frozen pipe.

The advantages of this system include a high level of fire safety when performing pipeline defrosting work, an effective system of protection against electric shock to a person or animal, and the presence of a built-in regulator that allows you to select the optimal ratio of thermal power. In addition, “Dragon” can operate from a classic household network; to do this, you need to reduce the load by reducing the current.

If you plan to heat a large pipe over a long section, it is recommended to use several of these devices at the same time. Before using the system, check for excess pressure in the pipeline structure; this is necessary to start water circulation during the heating process.

Special pliers, connected to the device using a cable of the required length, are installed at the ends of the frozen section of the pipe, then the device is turned on and all you have to do is wait. The pipeline defrosting process can take from 3 minutes to 1 hour. It all depends on the amount of ice formed.

How to melt an ice jam using a steam generator

In the case of polypropylene, you can also use a device such as a steam generator. In fact, it is also used for pipes made of other materials. But for polypropylene, one might say, it is ideal.

A steam generator is a special machine that regenerates steam and supplies it under pressure.

The essence of the process is quite simple. Heated steam is supplied inside the pipe under high pressure. As a result, the ice in the cork melts and turns into water. In this way, you can successfully melt an ice plug of any extent without fear of damaging the pipe. On sale today there are both specialized industrial steam generators and those with reduced power - intended for domestic use. Such steam generators do not require the operator to have any special skills. Anyone can master working with it. If you don’t have a special steam generator at hand, you can use the most ordinary multicooker or autoclave as one.

The order of work in this case will be as follows:

- The required amount of water is poured into the unit;

- The end of the heat-resistant hose is connected to the generator fitting;

- Its other end is pushed inside the water pipe - to the point where the ice plug is located;

- The generator turns on. Once the plug is melted, the hose can be easily moved inside the pipe. This indicates that the ice melting process is complete.

At the same time, at any stage of work, it is necessary to ensure that the device has the required amount of water.

Using steam generators

Defrosting pipes using a steam generator is suitable if it is possible to gain access to the inside of the structure, and in some situations the pipeline will have to be disconnected. Steam is supplied from the device through a hose, at the end of which there is a nozzle installed, which can significantly increase the efficiency of work. The hose moves through the pipe as the ice melts.

The use of a powerful steam generator is optimal when it is necessary to quickly eliminate an emergency situation associated with the formation of ice in a pipeline.

In addition to such equipment, you can use a device for hydrodynamic cleaning with hot water. The productivity of this installation is slightly less than that of a steam generator, but this does not make it less effective.

One of the benefits of de-icing pipes from the inside is that at the same time as the ice is removed, the system is cleared of unwanted deposits. This allows you to bring the pipe cross-section to a normal value and improve fluid circulation in the structure.

A steam generator for defrosting pipes also has an obvious drawback - its dimensions and cost. If electrical equipment can be purchased at any store and used for household needs, then a steam generator is a different case. This type of technology is used mostly by professional companies.

Measures to prevent pipeline freezing

At the first opportunity, when warm weather sets in, it is necessary to take measures to insulate the water supply in order to avoid such a nuisance in the future. Deformed areas will need to be replaced.

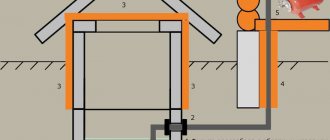

- Water supply pipes are laid below the freezing level of the soil.

- The pipe is wrapped in high-quality thermal insulation; if necessary, an additional heating cable is laid along the pipe.

Insulation of water pipes - The places where the pipe passes through the foundation are additionally insulated, since concrete freezes faster than soil. The pipe is placed in a pipe of larger diameter and foamed with polyurethane foam.

- The basement pipes are wrapped in thermal insulation: mineral wool, glass wool, or a special insulation for pipes in the form of a cylinder.

But while the frost is crackling outside, not all insulation methods can be used, and there is no point in chiseling the frozen ground. We can recommend one effective action - although this is a violation of safety rules: keep the tap slightly open so that the water flows in a small thin stream, and then the moving water stream will not allow ice to form.

How to warm up a frozen water supply: video

https://youtu.be/5J6mr1PFE_g