Home / Pumps

Back

Published: 02/25/2021

Reading time: 3 min

1

577

To equip a line with natural or forced movement of coolant, you will need to install a circulation pump, because without it you cannot count on uniform heating of the radiators. Although the task is not the most difficult, some nuances should be taken into account long before the manipulations are carried out. First, I want to look at why such equipment is needed, after which I will describe in detail the installation in different connection diagrams.

Interested people will find the information regarding the installation of the unit useful; I will give it step by step. It is equally important to correctly install the circulation pump in the heating system and connect it to the network to ensure maximum safety for everyone living in the house. At the end of the article there will be not only expert advice on the recommended operating speed, but also a list of the best product manufacturers.

- 1 Why do you need a pump in a heating system?

- 2 Installation diagrams in various types of systems

- 3 Where to mount the circulation pump for heating: supply or return

- 4 Installing a circulation pump in the heating system step by step

- 5 How to connect the circulation pump to electricity

- 6 At what speed should the pump in the heating system operate?

- 7 Best manufacturers of pumping equipment for gas floor-standing boilers

Why do you need a DHW pump?

The DHW circulation pump is designed to create pressure and constant circulation of water in domestic water supply systems. After opening the tap, you have to wait a long time for the water to become hot, and the further the water supply point is located from the DHW input, the more time this requires. The pressure in the system does not always meet even the minimum requirements, preventing you from washing properly.

Circulation pumps for domestic hot water are installed for the following purposes:

- Ensure stable pressure in the system - for this, hot water is diverted into a special buffer tank, after which it is supplied under pressure to water supply points.

- Ensure instant supply of hot water - the circulation pump for hot water supply is connected to a closed pipeline. Water is constantly in motion. Thanks to circulation, the cooled liquid mixes with the heated one. As a result, immediately after opening the tap, hot water is supplied to the consumer.

The parameters of the domestic water supply make it necessary to install hot water supply in both private and apartment buildings.

Choosing a circulation pump for hot water supply - expert advice

Lack of hot water pressure when opening a tap is a fairly common phenomenon found in private and apartment buildings. One of the effective means of solving the problem is a circulation pump for hot water supply.

Installation of pumping equipment for hot water supply, according to existing building codes, is optional for premises with a heated area of up to 500 m²; in practice, installation may be required even if there are 2-3 separate hot water points.

Circulation pump for hot water supply: what is it used for and how does it work

You already understand that having installed a hot water pump, you will not wait until cold liquid flows from the tap. The only thing that is not entirely clear is the operating principle of this pump. It is simple and consists of constructing a closed circuit through which hot water constantly circulates. That is, a ring along which water moves endlessly and is periodically heated to a given temperature. A faucet can be installed or a mixer connected anywhere in this ring.

Anticipating your next question, I will say that hot water does not enter this circuit through a heating device that uses fuel to heat the water. This circuit is powered from the heating boiler through a special heat exchanger called an indirect heating boiler - the water here is heated by the heating system. In fact, a battery (coil) is mounted inside such a boiler, upon contact with which the water heats up. This is not a instantaneous water heater - it is a storage boiler that has at least five connection pipes. Two of them are used for connecting to heating, two for circulating hot water (supply and return, so to speak) and one for supplying cold water to the tank.

Recirculation pump for hot water photo

If we describe the operating cycle of such a unit, it looks like this. When the tap on the mixer is closed, the water moves in a circle thanks to the circulation pump and is heated by the coil to the maximum temperature limit. As soon as you open the mixer, water flows out - at the same time, fresh cold water enters the indirect heating tank from the water supply, which is immediately heated from the coil. In general, the same thing happens here as in a conventional electric storage water heater, only instead of a heating element it uses a coil.

Main characteristics

Hot water pumps must provide the specified circulation mode. To achieve this, all devices have certain parameters:

- Operating pressure . This is an indicator that determines the pressure in the pipeline.

- Performance. A value that determines the amount of water that the pump pumps per unit of time.

- Power. This is an indicator that determines the maximum force that can be applied to the shaft of the device.

- Supply voltage . There are pumps that operate on 380 or 220 VAC. In addition, there are low-voltage models (12.24 or 36 V), which are safer to use.

- Construction type . Many models have differences in the rotor design. They provide their advantages, but also have disadvantages.

- Purpose. There are pumps for hot water supply or for heating systems.

Pump parameters are its main indicators that determine the user’s choice. Purchasing a pump without familiarizing yourself with its technical characteristics is extremely risky. It is necessary to ensure full compliance with the system requirements and pump parameters in order to obtain the expected effect from its operation.

You should not choose a model “for growth”, with a large margin in all respects. The pump will only consume excess electricity and make noticeable noise, without improving the circulation in any way.

How does a circulation pump work in a hot water supply system?

The operating principle of the DHW circulation pump is almost identical to that used in heating systems. The purpose of the installation is to increase and stabilize the missing water supply pressure.

Circulation pumps in domestic hot water systems of private residential buildings operate as follows:

- A closed hot water system is installed, consisting of: a storage tank, shut-off and control valves, pumping equipment and a circuit connected to water distribution points.

- Hot water is drawn into the container. The pump creates the necessary pressure, forcing a certain amount of water to constantly circulate in the pipeline circuit.

- When the tap is opened, the consumer immediately receives hot water under pressure, sufficient to take a shower, quickly draw a bath, etc.

Most models of pumping equipment designed for hot water supply have electric motors based on a “wet rotor”. All moving parts are completely immersed in water. The “wet” design has many advantages: no need for maintenance, quiet operation, low energy costs.

Along with this, there is a danger of dry running. The coolant plays the role of a lubricant. Without lubrication, bearings instantly fail.

Circulation pumps used in hot water supply systems of multi-storey residential buildings are often called booster pumps, since their task is mainly to create sufficient pressure in the water supply system.

How to calculate a circulation pump for heating?

The performance of such a device is usually marked with the letter Q. This value is the heat transferred per unit of time.

For calculation use the following formula:

Q=0.86R:TF-TR

The parameters used in this formula are indicated in the table.

| Designation | Parameter | Unit |

| Q | Coolant flow | m³/hour |

| R | Thermal power required for heating the room | kW |

| TF | Liquid temperature in the supply line pipe | °C |

| TR | Temperature in the pipes leaving the system | °C |

In European countries, the R indicator depends on operating conditions and is calculated in connection with certain standards.

Namely:

- In houses with no more than two apartments, the power of the circulation pump for heating is taken at 100 W/m².

- In multi-apartment buildings - 70 W/m².

When calculating pumping equipment for rooms with poor thermal insulation, the readings of the above indicators are increased. With good insulation, R values are taken in the region of 30-50 W/m².

Kinds

There are many types of pumps. They differ from each other in their technical characteristics and purpose. There are pumps:

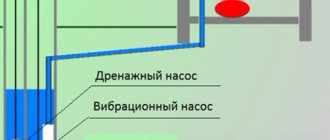

- Drainage. Used to pump excess ground (soil) water.

- Submersible. This pump must be submerged in water to operate properly.

- Self-priming (or surface) . The suction pipe is lowered into the water, and the pump itself is on the surface.

- Increasing pressure (or increasing) . Used to increase pressure in the system, ensures normal operation of plumbing fixtures, washing machines and dishwashers.

- Industrial. Unlike the household model, the industrial model has increased power, durability, and is able to work in difficult conditions. The cost of industrial models is significantly higher than that of household ones.

It must be taken into account that circulation pumps are allocated to a separate group.

They are also divided into two categories:

- for DHW;

- for heating.

The first category is designed for a maximum water temperature of up to 65°, the second is capable of working with water heated to 90°.

Pressure and capacity also differ (heating pumps usually show higher values).

With dry rotor

A dry rotor pump is a design in which only the impeller comes into contact with the working medium. The remaining components and parts remain dry, which contributes to better cooling of structural elements.

The main advantage of this type of design is the absence of the possibility of airing the flow, which is extremely undesirable for heating systems. In addition, the presence of suspended matter and mechanical particles in the water is not dangerous for pumps of this type, since the service life of the impeller is quite long.

The disadvantages of dry rotor models include:

- high noise level during operation;

- low reliability of the design, the need for periodic maintenance, lubrication, and replacement of bearings.

Typically, dry rotor pumps are used for heating systems.

With wet rotor

This type of design is more common due to its advantages.

This type of design works in contact with moving water, which gives a lot of positive aspects:

- The noise level is significantly reduced.

- Water acts as a lubricant, so all moving parts wear out little. This allows the use of plain bearings, which have a longer service life under such conditions.

However, there is a serious drawback. When air bubbles enter the flow (due to cavitation or leakage), noise, heating and wear of structural parts increase sharply.

To remove air, the structure has special vents that operate both automatically and manually. The user can always release the air if he notices a change in the pump's operating mode.

Selecting a pump based on design features

The most important structural difference between one model and another is the type of rotor of the unit.

And on this basis, all circulation pumps are divided into units:

- With a “wet” rotor

Circulation pump with a “wet” rotor

Moreover, circulation pumps with a “wet” rotor involve placing the “pressure part” of the unit - the rotor and impeller - in the pumped medium. That is, hot water plays the role of both a cooling medium and a lubricant. Therefore, “wet” type units operate for a very long time and make virtually no noise. And the “wet” pump is very cheap and does not require maintenance. That is, a unit with a wet rotor can simply be “set and forgotten.”

But with all the advantages, “wet” pumps also have their disadvantages, among which we need to highlight a very low efficiency (up to 40-45 percent) and limited positioning of the device (the pump can only be mounted in a horizontal position).

Therefore, “wet” pumps are purchased by owners of domestic water supply and heating systems installed in small houses. Such a pump is not suitable for anything more.

- With a dry rotor

Circulation pump with a “dry” rotor

In turn, circulation pumps with a “dry” rotor involve the separation of the “power plant” from the pumped medium. That is, the rotor of the unit remains dry, so a problem arises with both lubrication and cooling. Moreover, the first problem is solved during periodic inspection, and the second - with the help of a built-in fan.

As a result, “dry” pumps are “more expensive” than wet ones both at the purchase stage and during maintenance. However, all the above-mentioned efforts will be rewarded with almost twice the productivity compared to “wet” pumps, which reaches up to 70 percent.

Therefore, “dry” pumps are purchased for integration into industrial and municipal heating and hot water supply systems.

When and how it is advisable to use a hot water circulation pump

Such a scheme for hot water supply in a house is not always advisable - in short, in small houses with 3-5 rooms it is unjustified. For such cases, a conventional double-circuit heating boiler is suitable - the short length of the hot water supply lines will not make you wait long for heated water to flow from the tap. Another thing is large houses with several bathrooms and a complex heating system. This is where a hot water supply system with a circulation pump shows itself one hundred percent. What problems are solved in this way?

- First of all, there is always hot water in the tap - there is not a second of waiting until you get heated water.

- The second point is the increase in pressure in the system. In large houses, as a rule, pipes stretch over a long distance - the result of the long length of pipes is a weakening of the pressure in the system, which is compensated by the recirculation pump for hot water.

These are the main tasks of the hot water supply ring circuit. As a bonus, it provides a couple more benefits.

- Saving water - that is, cold water does not drain into the sewer. The one that flows from the tap while you wait for hot water to appear in a standard system using a double-circuit boiler or a conventional boiler.

Saving fuel resources.

The same coolant that heats your home is used to heat hot water. Naturally, this saving occurs only in winter - in principle, in summer it also works economically, but this is not visible at first glance. Savings in summer occur due to the storage tank, rather than direct heating of water in the water supply. Pump for hot water supply photo Among other things, the pump itself allows you to save resources. He can do this solely due to the ability to program the on time. Let's just say that hot water is not used at night, which means there is no need to operate the circulation pump for hot water. Therefore, you need to program it so that it turns on half an hour before you go to the bathroom. What are the savings here? When circulation stops, the water in the circuit quickly heats up and the heat exchanger stops taking heat from the heating circuit. In turn, the coolant in it cools less, as a result of which less fuel will be needed to heat it to a given temperature.

Circulation pump for hot water (DHW): operating principle and selection rules

To increase the efficiency of heating and hot water supply systems, they are equipped with a recirculation pump, the task of which is not only to increase the pressure of the medium transported through them, but also to ensure its circulation in a continuous mode. In some cases (in particular, when installing autonomous hot water supply and heating systems), only a recirculation pump can cope with this task.

Circulation pump in a hot water supply system

Before equipping a hot water supply or heating system with a recirculation pump, you should understand how this equipment works. It is also advisable to study the principle of operation of the circulation pump.

How to choose a pump for hot water supply

First you need to understand the difference between a heating circulation pump and a domestic hot water pump. It consists of three points. First of all, this is the ability to withstand a certain coolant temperature. If heating circulation pumps are capable of working with coolant heated to almost 100 degrees, then DHW pumps can only withstand heating up to 65 degrees. Secondly, heating pumps are made of cast iron, and domestic hot water pumps are made of brass. And thirdly, pumps for hot water supply at home have less power reserve.

At first glance, it may seem that a regular heating circulation pump can be installed in the hot water supply system - unfortunately, this is not the case. These two types of pumps are not interchangeable, which must be taken into account first of all when approaching the issue of choosing a circulation pump for a hot water supply system.

In addition, when choosing this equipment, it is necessary to take into account the following points.

- Specifications. This is a calculation - a correlation with the necessary indicators. What is taken into account here is the loading of the system (so to speak, water collection) and the required flow force. The system load is determined based on the number of installed plumbing fixtures, the number of users and the intensity of use. Water consumption is calculated based on the average value per point (on average it is about 150-180 l/hour), and the flow strength is calculated based on the length of the pipelines. On average, in order to push water through a 10 m long pipe, a pump must create a pressure of 0.6 m of water column. So if the characteristics of the pump indicate that it lifts water by 4 m, then it can be used with a pipeline length of 60 m.

- Functionality. This is the ability to program the DHW pump. The cheapest option is a pump with a mechanical on timer. The most expensive and, according to many users, convenient is a pump with an electronic programmer. Modern models allow the pump to independently select the optimal operating mode. It not only automatically adjusts to the intensity of hot water use, but also independently switches to night mode and, accordingly, back to day mode.

Manufacturer.

Everything here is more or less clear - the fact that the quality of a product depends entirely on the attitude of the manufacturer to his work is no secret to anyone. It is the manufacturer, based on the quality of his product, who sets one or another warranty period for it. For your information, a circulation pump for hot water supply can be considered high quality if the manufacturer’s warranty is at least 7 years. Such pumps, under moderate loads, are quite capable of coping with the tasks assigned to them for 10-12 years. You shouldn’t save money here—or rather, you should, but within reason. Circulation pump for DHW photo Also, when approaching the issue of choosing a circulation pump for DHW, it is worth mentioning double pumps for hot water - they simultaneously supply coolant to the indirect heating boiler, and the hot water heated by it is pushed through pipelines. It’s a good thing, but expensive—separately, these two pumps would cost less.

And finally, I’ll say a few words about modern pump manufacturers who have already proven themselves exclusively on the positive side. Grundfos is considered the undoubted leader in this industry today - it supplies the market with economical pumps equipped with several protections. Pumps of this brand are protected from dry running and, as a rule, have built-in pressure sensors. The second manufacturer of pumping equipment that is worth paying attention to is Wilo. German by origin, who offers circulation pumps for hot water supply, as they say, for every taste and color - in the range of these products you can find pumps with a mechanical timer and with electronic control. As they say, for all occasions and for any budget. And an economical option called DAB - despite the low cost, the company produces very high-quality equipment with a long warranty period.

How to calculate the pressure of a DHW pump

An accurate calculation of pump parameters can only be made after obtaining the following data:

- Congestion of the water supply system.

- Sufficient flow force.

The required pressure of the DHW circulation pump must be sufficient to create a comfortable pressure while simultaneously turning on the taps at all water points. How is the calculated pressure of hot water supply calculated:

- The average water consumption for a point taken into account is 150-180 l/hour. Accordingly, in a house with two bathrooms and a kitchen, you will need to install a pump with a capacity of at least 0.7 m³/hour. When making calculations, it is necessary to take into account the hydraulic resistance of the hot water supply system, which for a private house is in the range of 0.1-0.2 atm.

- Pressure - the height and length of the water pipeline also affects the calculations. It is generally accepted that for every 0.6 m of water column there are 10 lm of water circuit. If the technical documentation of the pump provides pressure parameters of 4 m, this is enough for a water circuit with a length of 60 running meters.

Such calculations help to obtain the average heat consumption of hot water through the circulation pump, which is enough to select suitable equipment for a small private house. Online calculators provide assistance in calculations and selection of a suitable model.

Calculations when organizing hot water supply with a circulation pump in an apartment building and large-area cottages should be carried out by a design and installation organization that will be responsible for the performance of the system.

Selecting a DHW pump based on performance characteristics

The main purpose of the circulation pump is to maintain the optimal speed of coolant flow through the wiring, at which it would be possible to record the temperature of the liquid in the “return”.

Therefore, the key operational criteria influencing the choice of a circulation pump include the following parameters:

Circulation pump for domestic hot water systems

- The value of the pressure, measured in the height of the water column - the pressure in the distribution, and therefore the return temperature, will depend on this criterion.

- The flow rate value is calculated using a special formula as a quotient of the power of the heating installation (divisible) and the temperature difference in the pressure pipe and return pipe (divisor).

- The heat transfer value of a heating system, calculated based on the area of the heated room and the estimated heat losses.

Moreover, the selection process looks like a comparison of all the parameters described above in order to compare the pump pressure with the heat transfer and flow rate of the heating system. As a result, only an experienced designer or heating engineer can extract a specific recommendation from this data.

Where to buy a circulation pump?

How to make the right choice?

When selecting equipment, it should be taken into account that circulation pumps are of dry and wet type. In the first case, the engine rotor is not in direct contact with the liquid, in the second case it is. For large houses, it is better to choose dry type pumps. They are characterized by good performance, but are very noisy. It is better to install them in a separate room. Wet pumps are great for small spaces because they create minimal noise during operation.

It is equally important to pay attention to power. Low-power equipment will not be able to supply liquid to the upper floors, and overly powerful equipment will circulate the coolant strongly, so it will not have time to heat up.

Installing a circulation pump in a domestic hot water system

Installation of the pump in the domestic hot water system must be carried out in accordance with the manufacturer’s recommendations and existing building codes. Installation work is carried out as follows:

- Installation location of the DHW circulation pump - the module is mounted on the return line. This arrangement prevents air from entering the station - airing leads to a decrease in the performance of the system. For this reason, the pump should be installed exclusively on the return water supply.

- A check valve is installed immediately after the pump and in front of the storage tank. Shut-off valves must be installed before and after the station.

- The connection to the mains is made via a UPS for power supply. After a power outage, the uninterruptible power supply continues to ensure autonomous operation of the equipment for from several hours to a day. (how to choose the right UPS for pumping equipment, read here).

- To distribute pressure evenly, a complex DHW control system is installed, including several distribution manifolds and special pressure reduction valves.

- It is prohibited to start the electric motor at idle speed. After the pump has been installed in the hot water supply system, the water circuit is filled, a test run is performed and the functionality is checked.

- Maintenance – wet rotor pumps have a simple design, so they do not require inspection or repair during their entire service life. The filter will need to be cleaned and replaced from time to time. The frequency of maintenance of a pump with a dry rotor is once every 2 years. During the work, the lubricant is replaced and the housing is cleaned.

Insufficient pressure in the central water supply system necessitates the installation of a circulation pump for hot water in apartment buildings and private buildings, regardless of the heated area.

Design Features

For DHW circulation, centrifugal pumps with a “wet” rotor are mainly used. The operating principle of such a circulation pump is quite simple.

- Water entering the chamber of the recirculation pump through the inlet pipe is captured by the blades of the impeller, which is rotated by the drive motor shaft.

- Centrifugal force begins to act on the water, which throws it towards the walls of the working chamber, where increased pressure is created.

- Under the influence of pressure generated by centrifugal force, the liquid is pushed into the pressure line of the recirculation pump.

- The suction of the next portion of hot water into the working chamber occurs due to the fact that air rarefaction is created in the central part of such a chamber during the processes described above.

Design of a centrifugal circulation pump with a “wet” rotor

It should be borne in mind that a conventional centrifugal water pump is not suitable for heating and hot water supply, since the operating conditions of such equipment do not provide for a high temperature of the pumped liquid. For the manufacture of pumps that recirculate hot water, materials are used that are resistant to increased loads and high temperatures. In addition, such electric pumps, which operate primarily indoors, must be low-noise so as not to make living conditions in a private or apartment building uncomfortable. No less important characteristics of electric pumps for DHW circulation are compactness and efficiency in terms of electricity consumption.

When selecting pumping equipment that will need to work with hot water, you should also keep in mind that pumps for DHW recirculation differ in operating conditions from devices used to equip a heating system. Thus, pump models for a boiler room are designed to pump water whose temperature reaches 90°, while devices that circulate hot water can work with a liquid medium heated to 65°. As such, they are not interchangeable, although if necessary, an electric heating pump can be used to circulate hot water in DHW systems. However, replacing such devices cannot be done in the reverse order.

Domestic pumps are designed to recirculate water in small hot water systems

How to make the first launch?

The first start-up, as a rule, is made after the device is fully connected, the entire line is assembled and filled with water.

It is prohibited by the instructions to turn on the pump dry. This is fraught with breakdown and failure, as well as refusal of the warranty workshop to carry out repairs.

Before starting, you need to make sure that the system is completely ready for operation . Most designs automatically remove air when a special screw is turned.

You need to unscrew it half a turn (or more) and wait a few seconds until the air comes out and water flows out. For other pumps it is necessary to install a special air venting element (Maevsky valve).

Management methods

There is no need for continuous operation of the pumps, since the system is able to maintain water pressure for some time. Typically, the criterion is that the water in the system cools down to 50°, after which circulation needs to be started. There are two standard methods for controlling device operation :

By timer

For pipes with normal thermal insulation, it takes about 15-20 minutes for the flow temperature to drop to a critical value.

Therefore, a conventional time relay is often used, which is set to a certain value . It is adjusted in working order, determining the most convenient break in pump operation.

By sensor

Based on determining water temperature. For this, a temperature sensor (thermistor) is used, which gives a command to automatically start the pump when the flow temperature drops to a preset value.

This control method is considered more reliable because it is based on determining the state of the water rather than on a time average.

The most common types of breakdowns and how to fix them

The most common type of breakdown is the impeller stopping. The device hums but does not work properly. To solve the problem, you need to turn off the circulation, drain the water, disassemble the device and move the impeller. Typically, the cause is the adhesion of small particles or the entry of foreign objects into the flow.

The second most common type of malfunction is overheating . It occurs due to lack of lubrication on the bearings or due to the regular entry of air into the system. The problem can be solved if the rotating parts are well lubricated and all connections are reliably sealed.

Everything you need to know about hot water is presented in this section of the site.