Sawing schemes

You should decide on a work plan in advance.

One of the most important tasks of the sawyer is to choose the most rational cutting scheme. The compliance of materials with the goals set, the amount of output per unit volume of forest and, as a result, the profit of the enterprise will depend on this.

The master must have impressive experience and a special flair for the material in order to determine in advance the order of work, where to start and how exactly to act in the process. Such a skill comes only with time as a result of long work at the sawmill.

There are three standard log cutting schemes:

| Sawing diagram | Peculiarities |

| Circular | After removing the first slab, the log is turned over 180˚ and placed on the resulting edge. Then during the process it is turned over 180˚ or 90˚ more times, usually at least five turns are practiced. |

This is the most rational and economically beneficial method, however, in the absence of mechanisms for turning over when manual labor is used, the resulting productivity may be reduced

Read also: Period of oscillation of a spring pendulum on earth

Used for low-quality raw materials, for which the listed disadvantages are not so important

This method is considered productive and is used in industry when processing raw materials of medium and low quality.

Scheme for sawing logs on a band sawmill with step-by-step instructions.

Important! The cutting scheme is selected in accordance with the quality of the raw material, the purpose of the board and the capabilities of the equipment.

Types of Band Saws

Narrow wood band saws are the most common type of band saw, which are used for longitudinal sawing of wood on a band sawmill. Narrow wood band saws are characterized by low cost, ease of use and low labor costs.

Wide wood band saws are a professional cutting tool used for sawing wood on band saws. Wide wood band saws increase sawing productivity on a band sawmill due to high cutting speed and professional equipment.

It is necessary to buy saws for a band sawmill with a reserve so that you can sharpen one batch of saws and use another batch of saws in sawing on a band sawmill. Sawing

cutting logs on a band sawmill is considered the most effective.

In our catalog we always have the best band saw brands: Woodmizer, Armot, Seiver, MFLS, Bako, Uddeholm, Karl Rengen.

All of these bandsaw manufacturers have good reviews and have established themselves as manufacturers of quality cutting tools.

The price of band

saws

for wood depends on the technical characteristics of the band saws:

- saw length

- saw width

- saw blade thickness

To make

band saws,

a pre-prepared tape is welded into a ring.

Band saws are made from different materials

, depending on what

material

they are intended for cutting. To avoid unstable cutting of wood, it is necessary to adjust the position of the saw on the pulleys. During operation, to increase the service life of the band saw, it is necessary to properly tension it on the pulleys.

Sawing tool

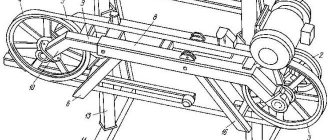

Modern band sawmill.

Logging is carried out using a special tool. For normal work by today's standards, you need a special machine for cutting logs with your own hands, which is called a sawmill.

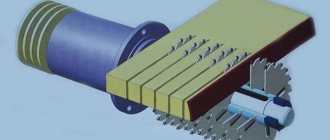

There are two types of sawmills: disk and belt. Circular saws use circular saws and are considered less efficient, as they have a larger cutting thickness (from 6 to 9 mm), less accuracy and depth.

The band sawmill is equipped with a different system: the saw is a band mounted on rotating rollers. The cutting thickness is approximately 1.5 – 3 mm, which is quite economical in terms of waste to chips.

Modern models are distinguished by high accuracy and productivity; they are automated and have a tilting mechanism for lifting and turning logs in the case of circular sawing or sawing timber.

Using a chainsaw, you can only cut a log in half, but if you use a special frame, you can cut the log into boards right in the forest.

Working with a frame and a chainsaw.

Important! The band sawmill is considered the most efficient and cost-effective.

Technical parameters and design features

The band saw consists of:

- C-shaped cast or welded bed.

- Upper and lower pulley.

- Blades with teeth.

- Electric motor.

- Brake mechanism.

- Guide ruler.

Machines with horizontal saw installation are considered the most powerful; they are capable of sawing not only frozen wood, but also hard trees. The best wood band saws are used in sawmills.

Conclusion

Sawing logs is considered one of the most difficult and important tasks in logging and lumber production. The quality of the product and the income of the enterprise depend on the chosen scheme, well-designed work order and preparation of the tool.

The video in this article will tell you about the types of sawmills and methods of cutting wood.

Forest sawing is a cycle of actions using a variety of technologies aimed at obtaining lumber from round timber suitable for further use in industry. The duration and labor intensity of the process depend on the chosen method of processing round timber, as well as the time of year.

Tools and equipment

Trunks and large branches are used for production. All material is divided into groups according to thickness and presence of bark. Often, timber processing enterprises have workshops near the harvesting site, in which machines for the initial processing of wood are installed.

Manual debarking of wood

Wood that has not passed the debarking stage can be used on floors or as ridge beams in the corresponding interior, or as a supporting device during construction.

Industrial debarking of forests

If another option for using the wood is planned, then sawing is carried out, resulting in the following segments:

- unedged and semi-edged (rough material from which the bases of the floor, walls or ceiling are mounted);

- edged (intended for finishing flooring).

The cutting can be carried out by a mobile organization that has all the necessary tools.

Wood cutting map

Rational use of the material is ensured by compliance with the cutting map. This allows you to reduce costs due to waste, the percentage of which the card can significantly reduce. The tools and types of forest processing equipment used depend on the volume, desired quality and size of the finished lumber.

Wood sawing machine

The most commonly used are a circular saw and various machines:

- The circular saw allows you to make precise cuts in various directions. Suitable for both professional and home use, it copes well with above-average round timber diameters;

- chainsaw;

- machines for clean bark removal;

- sawing on a band sawmill makes it possible to process dense logs; it is considered the most popular, since the output is high-quality material and a small amount of waste;

- disk machine: production of double-edged timber and unedged boards;

- a frame sawmill does not require a foundation, the technology using it allows you to install the equipment in close proximity to the felling site;

- the fine gauge is processed by universal machines, the output is high-quality building materials even from low-grade logs;

- sawing of round timber at a large woodworking enterprise should be carried out with the largest amount of lumber, differing from the rest in its special quality and precise dimensions. For this purpose, special lines are installed for sawing.

At the sawmill, timber and edged boards are obtained by cutting logs up to 7 m long and 15-80 cm in diameter along the longitudinal line. A circular saw has one or more disks and processes wood of different diameters according to their number.

If you need to process a small amount of wood at home, you can use a regular chainsaw.

Review of the Bosch GCB 18 V-LI model

The Bosch GCB 18 V-LI band saw is a compact band saw in its category, powered by a battery. The minimum weight (only 3.8 kg) and compact structure (dimensions 12.7 x 733 x 1 mm) make it possible to conveniently carry out the necessary work even in very hard-to-reach areas and limited space. The cutting depth (can reach 63.5 mm) allows sawing products from all popular materials. For example, the Bosch GCB 18 V-LI hand-held band saw will “chew” an aluminum profile, plastic and metal pipes in one go. A huge advantage of this device is the ability to cut plastic, rubber, metal, aluminum and other things not only straight, but also at a forty-five degree angle.

Despite such an amazing compactness, the Bosch GCB 18 V-LI tool is considered professional and copes with the assigned tasks at the highest level, even if they need to be performed in cramped conditions.

Thanks to the indicative circulation frequency at zero load (162 m/min), high-quality cutting of flexible objects made of soft and elastic materials is ensured.

This tool runs on an 18-volt lithium-ion battery. The main advantage of this power source is that it completely lacks memory effect and self-discharge properties. Also useful is the ability to recharge the battery at any time, regardless of the state of charge. When removed from recharging, the efficiency of the device does not decrease. It can be charged at any time, regardless of the charge level.

Thanks to Bosch's unrivaled premium lithium-ion technology, the product's operating life is significantly extended and the battery retains power for as long as possible.

Advantages of the Bosch GCB 18 V-LI tool

The Bosch GCB 18 V-LI has many advantages, of which the most important are the following:

- Accuracy of cutting due to the absence of vibration during operation and the presence of illumination of the working area (there is a built-in LED flashlight).

- Long operation on a single battery charge and impressive service life.

- Availability of a system to protect the power source from deep discharge, overheating and overload. This technology is called Bosch Electronic Cell Protection (ECP)

- High mobility due to the low weight of the corrugated aluminum shield.

- Stabilized roller guide saw blade.

- Protection against accidental switching off of the saw - the start button is blocked.

- Ability to work in hard-to-reach areas and in confined spaces.

- Ability to work with one hand, either left or right.

- Significant cutting depth.

- No sparks during operation even under the heaviest loads.

- Work without sparks.

- Availability of battery charge indicator. Thanks to the charge level signaling using three illuminated LED lights, the device can be charged on time.

- The presence of an arrow indicating the cutting direction of the saw blade adds even more safety.

- There is no possibility of overload if the device is used as intended.

- Soft, ergonomic, high-quality insulated handles.

Disadvantages of the Bosch GCB 18 V-LI tool

According to users, this tool is ideal for its category, size and price and does not have a single drawback.

Numerous users of this tool speak of it as a professional machine for working in cramped conditions. The capabilities and power of the Bosch GCB 18 V-LI saw fully correspond to its price, and this with such a low weight and compact parameters.

Video review of the Bosch GCB 18 V-LI model:

Cutting wood

Before choosing a tool, you need to decide on the type of cut, focusing on the annual rings of the log. There are several types:

- radial (along the radius);

- tangential (the cut is parallel to one radius and touches the annual rings);

- the fibers are located parallel to the cutting being performed.

Among the cutting methods, the one that is most suitable for a particular case is selected:

- Waddle. Sawing wood in this way is carried out for deciduous trees with a small trunk thickness, and is considered the simplest processing. Output: unedged elements and slabs.

- If you have another forest processing machine, then it is possible to cut up to 65% of the material to produce edged boards of equal width. First, the double-edged timber and boards on the sides are cut, and then a certain amount of edged lumber is obtained from the timber.

- More specific methods are sector and segment sawing. The number of elements in the first method varies from 4 to 8, and depends on the thickness of the trunk. After dividing, elements are cut from each sector along a tangential or radial line. The second method begins with the timber coming out of the central part, and boards are cut from the side segments in a tangential direction.

- For individual cutting of wood, the circular method is suitable. It is based on turning the log along the longitudinal line by 90° after each sawn board. This allows you to monitor the quality of the wood and promptly remove affected areas of the trunk.

| Simple (end-to-end) | The log is sawed to the middle, then turned 180˚ and sawed to the end. The scheme is as quick and simple as possible, but the boards are unedged, heavy and subject to maximum warping. |

| Sawing timber | The process resembles circular work with the difference that the central part of the log is left in the form of timber 25x25, 18x23, etc. Next, the core is transferred for further processing in the production line or sold in the form of timber. |

Read also: How to repair a screwdriver battery

What is a band saw?

Band saws are machines that are used for sawing various materials.

With their help, you can make shaped and straight cutting of wood, chipboard, metal, plastic, laminate, etc. Depending on the material being processed, appropriate saw blades are selected. Band saws for metal and wood leave very little waste from the original material. In addition, the advantages of such machines include a clean and even cut, which often does not require subsequent grinding, as well as low noise and vibration levels.

In our online store " PROPAB " you can select and purchase band saws of various types, classes and complexity, as well as accessories for them. These machines will become indispensable assistants in furniture production, metalworking and carpentry workshops, and more.

Manual work: using a chainsaw

For home cutting of several trunks, it is not advisable to purchase a tool whose cost is several times higher than the price of finished products. If you have the necessary skill, then it is more efficient and cheaper to do all the necessary work with a conventional chainsaw or chain equipment powered by electricity. Of course, such work requires much more physical effort and time, but the cost of the issue is significantly reduced.

Working on a garden plot requires pruning fruit trees, and it also becomes possible to additionally produce material for outbuildings without resorting to the services of specialists, so any thrifty owner will prefer to buy a chainsaw. Most often, coniferous wood is harvested for the home, and this tool does an excellent job of cutting it. Thanks to straight trunks, it is easier to mark cutting lines, which increases the speed of work. Professionals, by the way, most often use a chainsaw, since it is more powerful than an electric one and can be used anywhere, regardless of whether there are power sources at the cutting or cutting site.

To use a chainsaw to cut logs, you will need a device such as a saw attachment, as well as cutting guides and base-trunk fasteners. The frame-shaped attachment is attached to the tool so that it remains possible to adjust the distance between the chain and the frame itself. This is done to make it possible to produce finished lumber of different thicknesses. For the role of a guide, you can take either a profile of the required length, or a flat wooden plank with sufficient rigidity. A special chain is selected for the tool, designed to cut the trunk lengthwise. Its difference from the others lies in the teeth sharpened at a certain angle.

Before you start work, you need to not only prepare all the necessary tools. Regardless of whether a woodworking machine or a manual device is intended for processing the trunk, the first thing you need to do is familiarize yourself with the cutting map. This is done in order to minimize the percentage of waste and increase the yield of useful products.

The first thing you need to worry about when cutting longitudinally is the uniform density of the finished boards. To do this, a competent sawyer directs the tool from the east side of the log to the west, or in the opposite direction. This is explained by the higher density of round timber in its northern part than in the southern part.

Next, use a chainsaw to remove the slab from both sides so as to obtain a double-edged beam. It, in turn, is sawed in accordance with the cutting pattern chosen at the beginning of the work. The solution is an unedged board. If there is a certain percentage of defects in the trunk, then a circular cut is possible with the trunk turning at a right angle or 180°.

Review of the Makita 2107FW model

The Makita 2107 FW band tool is an extremely powerful device (power 710 W) that falls into the professional category. It is equipped with a reinforced gearbox that rotates the saw blade at a speed of 105 m/min. Thanks to the adjustable speed of movement, it is possible to choose the optimal speed mode depending on the material of the workpiece, or rather its density.

The soft and smooth functioning of the cutting belt is carried out using a pair of virtually wear-free bearings. Changing the dusty tape is very easy and the process will take no more than two minutes. Especially for this purpose, the tool is equipped with a quick-clamping mechanism. In order to avoid inadvertent turning on or off of the device, it has a start button stopper.

The Makita 2107 FW band saw can be used both manually and stationary, because the kit includes a platform for stationary use. The second option is more convenient, since the unit does not weigh so little that it can be kept suspended for a long time.

Advantages of the professional band saw Makita 2107 FW

Users noted the following particularly important advantages of the Makita 2107 FW:

- Comfortable control. Thanks to the ergonomically shaped non-slip handle, the device is very comfortable to hold in your hand and perform cutting. The built-in switch allows for more precise control of the saw blade. Due to its well-thought-out shape, you can work with both your right hand and your left.

- Stable stand. Thanks to the reliable cast base, the device is firmly located in a vertical position. This allows you to make more precise cuts.

- Work safety. The cutting blade with sharp teeth is covered with a special protective casing; only its working area is open. This ensures maximum safe operation of the unit.

- Versatility. The Makita 2107 saw does an excellent job of cutting rubber and various pipes when performing plumbing, electrical and assembly tasks.

- Very light weight for such a professional tool. 5.7 kg for such power and performance is nothing.

- The presence of a speed controller for working with various materials.

- Reliable fixation of the blade using four bearings on both sides.

- Instant blade replacement thanks to the clamping lever.

- Availability of fluorescent illumination of the working area.

- Independence of the flashlight switch from the main switch of the unit.

- Pendulum stroke.

- Ability to process workpieces with a diameter of up to 120 mm.

- High product strength and design reliability.

- Possibility of power supply from an ungrounded outlet.

Disadvantages of the Makita 2107 FW professional band saw

- inability to cut various products at an angle. There is no special clamp for this. Also, some users note that 5.7 kg is too much. However, if you remember how much power the Makita 2107 band saw produces, the opinion becomes completely opposite.

- dependence of the device on electricity, that is, the absence of a battery. In other words, this tool is not very portable. I would especially like to remind these people that the Makita 2107 band saw is a professional cutting device. It is suitable for manual use, but is still more suitable for stationary use.

- high cost, but the price fully corresponds to the quality.

According to users, the Makita 2107 FW unit is an ideal tool for performing large-scale cutting work on metal, rubber, wood, plastic and more. If you have the financial opportunity and have enough free space in the utility room, feel free to buy this model. You won't regret it for a minute.

Video review of the Makita 2107 FW model:

Quantity of finished material, cutting price

The yield of useful material from coniferous and deciduous trees differs in percentage. The following indicators are typical for lumber obtained from coniferous trees:

- provided that the operation is carried out by a professional and a circular sawmill is used, the percentage of finished wood will be the highest (80-85%);

- the edged material produced by the machines averages 55-70%;

- When used with a chainsaw, an unedged board leaves up to 30% waste.

The figures are given without taking into account the finished culled timber, the amount of which can reach 30%. However, such material is used for products that allow certain defects.

Finished wood products after sawing

Deciduous round timber produces 60% of the finished unedged timber and about 40% of the edged timber. This is explained by the initial curvature of the round timber. It is possible to increase the amount of products obtained: this will require forest processing machines of various types. A certain kind of device can increase the amount of lumber by 10-20%. For one cube of lumber you will need about 10 cubes of deciduous round timber. The cost of installing additional equipment will be recouped by the cost of the finished timber. Special lines provide greater volume, but their use is only advisable over a large area. The average price of sawing wood at a regular sawmill will be approximately 150-180 rubles per cubic meter of boards.

Types of Band Saws

According to the method of arrangement, band sawing machines are divided into:

- Vertical. They are equipped with a saw frame located vertically. Vertical bandsaw machines for wood are divided into small-sized and large-sized. The saw installed in small-sized devices is the main moving mechanism. In large-sized devices, the workpiece is moved by the operator in the required plane.

- Horizontal. They are equipped with a saw frame located horizontally. These devices are used for processing large-sized hardwood lumber.

In accordance with the degree of automation, the following types of sawing machines are distinguished:

- Manual. During operation of the device, the operator must independently feed wooden blanks. The procedure for cutting the bars is also carried out manually. Handheld bandsaws are most often used in home workshops.

- Semi-automatic. These devices automate the operation of the band saw and vice. Semi-automatic mechanisms are installed in furniture factories.

- Automatic. All mechanisms of these devices are fully automated. Automatic devices are used in large industrial production. They take up a lot of space.

Based on belt type, machines are divided into:

- Devices with narrow saw blades. Their width is no more than 6 cm. Narrow saws cannot be sharpened. Therefore, they must be completely replaced if worn.

- Devices with wide saw blades. Their width can reach 30 cm. Machines with wide saws are highly productive. They are capable of processing hardwood products up to 1 m thick.

Machines are classified by power and size:

- Carpentry. They are characterized by low power and small dimensions. They have a desktop modification. These machines are used in carpentry workshops.

- Dividing. They are capable of dividing logs into layers and have medium dimensions. Used in the production of furniture.

- Log saws. These machines are characterized by high power and large dimensions. They are installed at woodworking enterprises.

There are also separate classifications of band saw machines according to the number of speed modes, the volume of processed products per unit of time and the angle of rotation.

Sawing map

The sawing map is a calculation of the optimal amount of finished lumber from one log. You can calculate it yourself for each specific log diameter, or you can use a computer program that greatly facilitates the calculation, and the price of which is quite affordable.

Material yield after cutting wood

Or the source could be a regular sawmill reference book. The result is a table that is used as a basis. The sawmill attachment should always be oriented to its data in order to obtain more lumber of any type of wood.

Is your band sawmill installed and all the necessary settings made? So it’s time to proceed directly to the sawing process itself. In order to obtain truly high-quality material, it is necessary to correctly install the log and secure it with special clamps.

Read also: 220 volt reverse circuit

Next, you need to calculate, depending on the diameter of the log, the approximate amount of material that can be obtained from a given log.

The quality also depends on the correct calculation of the quantity and type of material you want to get from this log.

Having gained further experience, one glance at a log will be enough, and you will already know how much and what kind of material can be obtained from it. Learn to accurately determine where the top is and where the butt part of the log is. The butt part is usually larger in diameter than the apex. And this largely affects the thickness of the slab.

Setting up a band sawmill

The correct operation of the device depends on how correctly all the components of this complex device are configured. The first thing you need to start setting up a sawmill is installing a rail base. For normal safe operation, it is necessary to install the sawmill strictly horizontally to prevent the frame from skewing during operation or from breaking the mechanisms for fixing the log on the frame.

It is especially important to install the base of a mobile sawmill horizontally; to facilitate this process, the kit of such a sawmill includes several hydraulic levels showing the position of the equipment parts relative to the horizontal and vertical.

Setting up a band sawmill also involves calibrating and adjusting control devices. When starting work, the feed speed of the saw blade is usually reduced by ¼, this allows the metal of the belt to warm up. After 5-10 minutes of work, the saw tension is checked and if it sags a little, the tension is increased, after which the feed speed is increased.

Depending on the type of saw blade, the method of sharpening the teeth and their alignment, the choice of blade feed speed is made. The finer the tooth, the more carefully you need to choose the speed of the belt and the feed speed of the frame itself.

During operation, according to the recommendations of the equipment manufacturer, periodic calibration of the vertical feed of the tape is carried out. To do this, a control cut is made on the log and the readings of the graduated ruler on the body of the sawmill are checked with the actual dimensions of the cut.

To check the correctness of the readings of control devices, instrumentation and special equipment are used, this applies, first of all, to such indicators as the speed of rotation of the engine working shaft. When setting up, measurements are taken of its rotation speed at minimum speed, at medium speed and at maximum speed required for the operation of the unit.

Firstly.

We pay attention to all the bends and bulges of the log - a perfectly straight trunk is rare. Therefore, we try to turn it so as to get as little waste as possible from it, such as croaker. When the log is laid and fixed, you should make sure that it passes freely between the guide rollers.

Set the diameter size on the ruler of the sawmill, and to this size add the greatest height of the convexity of the log. This is the bulge that is higher than the diameter of the top or narrowest part of the log.

Using a regular tape measure, measure the height of the highest part, and from this size you begin counting the dimensions of the required material, taking into account the size of the cut, which ranges from 2 to 5 mm.

Secondly.

As soon as the width of the cut reaches the required size, and the remaining height of the log has reached the desired size, it is turned over. That is, if you cut a beam, for example, at 150, then both the width of the cut and the height of the remaining log should correspond to this value, even be greater, taking into account the removal of the slab.

Next, we know the final size of the material that needs to be obtained, and we will obtain it.

To do this, after turning the log over, start calculating from the final size until the full height of the log is used, but do not forget to take into account the size of the cut, which, as we already know, ranges from 2 to 5 mm.

For example, you have a log on your overpass that you have cut to a size of 260 mm. Let's turn the log over and continue.

The final result we want to achieve is a carriage with a thickness of 150 mm. Next, in a simple way, calculate that 260 mm-150 mm = 110 mm. We get as much as 110mm of extra material thickness. And it is precisely this that needs to be calculated correctly.

We take this additional size and calculate it to get the block, which has a size of 50 mm, 110-50 = 60, don’t forget the cut, and for us it is 2 mm, 60-2 = 58 mm, then the plank, equal to 25 mm, 58 -25-2=31 mm, hump 20 mm, 31-20-2=9 mm.

As you can see, from our calculations, we get 9 mm slab, 20 mm slab, 25 mm gorge and 50 mm block. And the final size will be 150 mm.

Main types of tape

In small sawmills, scrag and rip saws, regardless of the number of heads, blades with a width of 25, 32, 38 and 50 mm are mainly used. Basically, there are two main thicknesses of canvas on the market - 0.035” (0.9 mm) and 0.042” (1.1 mm). Naturally, there are canvases of other sizes, but they are mainly used in specific cases.

Carbon steel blades are most widely used in sawmilling. These fabrics are distinguished by the type of heat treatment to which they have been subjected:

- Constant hardness - a blade with equal hardness across the entire width of the blade. The carbon content in such a material is not high, and this does not allow it to be hardened to a hardness of more than 45-48 units on the HRc scale. This blade works well on small diameter pulleys. However, it has to be sharpened quite often.

- Flex back - Hard Edge - blade with a flexible body/hard tooth. This canvas is called both. In the production of this blade, a tape with a high carbon content is used, which makes it possible to harden its tooth to HRc 63-65. Usually only the upper half of the tooth is hardened, which leaves the saw body practically unhardened and quite flexible. Saw body hardness – HRc 30-33. The advantage of this type of saw is that it holds an edge better while remaining quite flexible. Sometimes manufacturers heat a narrow strip on the very back of the saw, this allows the blade to be straight. Do not confuse such canvases with Hard Back type canvases.

- Hard Back – blade hardened over the entire width. This is the most technologically advanced and difficult to produce type of tape. Its tooth has a hardness of HRc 63-68, and its body HRc 48-53, and the saw body is hardened in a stretched state. High tooth hardness provides good resistance to dulling (the blade lasts longer between sharpenings), and the increased rigidity of the blade body allows sawing at high feed rates. These saws cut smoothly and straight at those feeds on which any other blade would have long ago depicted the “Amur wave.”

- There are also saws with various types of soldering and surfacing, as well as so-called bimetallic saws. All of these types of saws combine excellent flexibility with exceptional tooth resistance, but their high price makes them exotic products and we will not waste time describing them.

Possible mistakes

As you can see, there is nothing complicated here. Often, inexperienced sawmills make mistakes in calculations when they start counting from zero. For example, if the final size of the material is 150 mm, then there is no need to add 2 mm to it for the cut, otherwise it will be 150 + 2 = 152. There should not be such an error, the cut is calculated only between the material, for example, 50 mm board and 150 mm carriage, we get it as described above, 150 + 50 + 2 = 202 mm.

If it is necessary to obtain edged material, we turn the log 90 degrees and perform the same manipulations as described above.

So you have cut your first log, look at the quality of the material and the accuracy of the dimensions. Make sure your calculations are correct. The main mistake when making calculations is that they forget to take into account the size of the cut. Try to take this fact into account. And don't make such mistakes.

In the future, when you gain experience, the calculation will happen automatically in your head; it will be enough to look at the log.

We are sure that everything will work out for you, we wish you success in your work.

Band sawing allows you to work with large diameter materials.

The ability to cut large-diameter material is the second significant advantage of band sawing. But if the first advantage arises from the features of the cutting tool in the form of a band saw, then the second plus is the factor of band sawing as a process as a whole.

The fact is that humanity has not yet figured out how to use circular saws with a diameter significantly exceeding 1,000 mm in practice. When you try to go beyond this size of a circular saw during sawing, processes occur that make sawing at first too expensive (cost of the saw, machine design, kerf thickness), and production unprofitable, and then simply impossible.

Thus, from the point of view of the size of the processed materials, read the ability to cut a log into timber and boards, circular sawing is limited to a diameter of 450 ÷ 550 mm. Of course, most industrially processed wood does not exceed these size limits, however, trunks of 1,000 mm are quite common in practice.

Band sawing allows you to space the pulleys that hold the band saw to a distance that allows you to cut meter-long trunks. Of course, a band saw, or more precisely a band sawmill of a similar design, is also not cheap. But the cost of a band sawmill capable of processing a 1,000 mm thick trunk will still be cheaper or comparable to the cost of a circular saw with a 1000-1200 mm saw.

2″ comments on the post “How to properly cut a log on a band sawmill”

We take this additional size and calculate it to get a block, which has a size of 50 mm, 110-50 = “60,” don’t forget the cut, but for us it is 2 mm, 60-2 = “58″ mm, then the wood equal to 25 mm, 58-25-2=”31″ mm, hump 20 mm, 31-20-2=”8″ mm. As you can see, from our calculations, we get 8 mm slab, 20 mm slab, 25 mm gorge and 50 mm block. And the final size will be 150 mm.

Sorry, you have a mistake here. The croaker is not 8 mm but 9 mm

Hi my friend! I want to say that this article is awesome, great written and comes with almost all significant infos. I would like to see extra posts like this.

>

How to buy Vertical wood band saws

supplies vertical band saws for wood to all cities of Russia, including Moscow, St. Petersburg, Chelyabinsk, Perm, Simferopol, Ulyanovsk, Kazan, Kaluga, Novosibirsk, Yekaterinburg, Nizhny Novgorod, Kaliningrad, Samara, Omsk, Ufa, Saratov, Krasnoyarsk, Vladivostok, Rostov-on-Don, Voronezh, Volgograd, Makhachkala, Grozny and others, as well as to Belarus, Kazakhstan, Armenia and Kyrgyzstan.

It is very easy to purchase Vertical Band Saws for Wood from us:

- Select the product you are interested in in the table above

- Find out its characteristics, look at photos and videos by clicking on the model name

- Buy vertical band saws for wood: call for free from any city in the Russian Federation 8-800-333-51-02 or send a request to