Types of buttons

To install a rivet in a denim product, first of all, it is worth determining its type and diameter. Today there are several options for accessories for such clothing. When choosing it, you should take into account the size of the existing loop.

Buttons are different. It all depends on the type of fastening and the stud on which the button stands. The optimal solution for everyday wear is a button with an aluminum shank. This metal is durable and resistant. It is much easier to work with than steel products.

With round cut

A common option is buttons, complemented by a round notch.

All metal with smooth base

Often there are all-metal buttons that have a smooth base.

Smooth metal hollow inside

Another popular option is a smooth rod. It is often left empty.

How to remove a rivet – June 13, 2015

Method 3: Grinder and drill Chisel Riveting attachment

Rivets are a type of fastener that is used in everything from racing cars to yachts. The rivets are lightweight and install quickly and easily. A modern rivet consists of two parts, a punch and a head. A hole is drilled in the parts to be fastened, a rivet is inserted, and a punch is pulled out with a special tool. The punch ball flares the tube, forming a closing head, thereby securely securing the part; the rest of the rod comes off. The diameter of the rivets varies from 1.4 to 6 mm, rivets are made from brass, aluminum, steel, copper and monel. Rivet joints are cheap and strong and can be used instead of welding, screws and bolts. However, such a connection may become loose, requiring removal and replacement of the rivet. This manual describes several ways to remove a rivet without damaging the mounting hole, quickly and professionally.

Steps

Method 1 of 3: Grinder and drill

- 1 Use a grinder to grind off the head of the rivet as much as possible. Be careful not to touch the metal near the rivet.

- 2 Using a small punch and hammer, drive the punch into the rivet. This will create a hole for further drilling.

- 3 Select a drill bit that is smaller than the rivet. Drill out the remaining punch. Make sure to drill exactly in the center of the rivet and do not widen the installation hole.

- 4 Take a drill bit the same diameter as the rivet and carefully drill out the remaining rivet.

- 5 Install a suitable rivet.

Method 2 of 3: Chisel

- 1 Knock off the head of the rivet with a chisel. Insert the chisel under the edge of the head, and use a one-kilogram hammer to tap the chisel until the head of the rivet is knocked off.

- 2 Using a punch, knock out the remaining rivets. If the rivet does not budge, use a drill according to the instructions above.

Method 3 of 3: Riveter Attachment

- 1 Purchase a riveting attachment with a suitable drill bit and guide. The kit may include accessories that fit the size you need, or you can purchase them separately.

- 2 Install the riveting attachment on the drill.

- 3 Insert the guide and drill bit into the bit.

- 4 Set the drilling depth so that only the rivet is drilled out.

- 5 Drill out the rivet.

Adviсe

- Always hold the drill perpendicular to ensure all holes are straight. If you don't hold the drill straight, you can drill out the mounting hole.

- Keep a set of rivets of different sizes in reserve.

- Angle grinder and disk for it

- Punch

- Hammer 1 kg

- Drill

- 2 drills

- Chisel

- Drill attachment for removing rivets

Installation and replacement methods

Rivets on jeans can be installed in different ways. Taking this into account, the type of fasteners is selected. The repair of such elements also differs.

On a stable leg

It is easiest to replace such fittings. This type of repair can be easily done on your own. To carry out the procedure, it is recommended to perform the following steps:

- To install the button, make a hole in the denim material. For this purpose, you can use an awl or a nail. You can also use a hand punch.

- Place the nail for fastening into the hole.

- Hammer the so-called button head into it, just like driving an ordinary nail. You can't put in a lot of effort. Otherwise, the fittings will be damaged.

On a smooth nail made of solid metal, it is worth installing in a similar way. But it is recommended to shorten the product first, since it is usually a little larger than necessary. As a result, this part protrudes above the fixed button.

Rivets

At home, the easiest way to install a flat button without a notch. It may have a pin with a circular notch. To carry out the procedure, you should perform the following steps:

- Locate and mark the location of the fastener.

- Pierce the material in the installation area. It's worth doing it with a nail. You can also use an awl. An equally convenient option would be a manual punch.

- Place the nail into the hole. It is recommended to do this from the inside of the product.

- Attach a button cap. It should be placed on a hairpin. It is recommended to do this from the front.

- The button will be placed correctly if the nail fits exactly vertically into the hole.

- Press the hat. The product must lie on a flat horizontal surface. It is important that the coating is as hard as possible.

- Hit the hat. This needs to be done with a hammer. It should be firmly hammered into the fastener. It is recommended to ensure that the blow is clear and has the correct direction. However, it is not recommended to do this too much. Otherwise there is a risk of damage to the product.

Buttons, which have a plastic base and do not contain a metal shell, should be installed very carefully. When hammering a stud, it is recommended to monitor the alignment. Otherwise the pin will simply split. If you don’t want to take risks, you should refuse to purchase such accessories.

On a broken leg

It will not be possible to sew on such a button. It is recommended to place it on a strong wooden surface. To do this, you should use an ordinary or tubular smooth nail. When carrying out repairs, it is recommended to maintain alignment. However, doing this is very problematic. Therefore, it is worth preparing the bolt and tube. Its length should be approximately 10 millimeters.

It is also permissible to use a socket wrench. It is recommended to hammer the rivet into the required place and carefully evaluate the quality of the installation. To do this, the product is pulled in different directions. After such manipulations it should not pop out.

On a broken leg with a hole

Repairing such fittings has certain features. It should be installed on a solid metal nail. It is advisable to choose an aluminum product. It is permissible to use a tubular metal nail. The procedure should be carried out on a flat and level surface. It is recommended to pierce the fabric with an awl and install a button. After that, hammer it onto a nail. If it has a circular notch, the procedure will be much easier.

On a double mount

The key characteristic is the flat base of fixation. It should be pierced using 2 nails, which are fragments of fittings. After this, spikes protrude from the other side. It is recommended to bend them towards each other. This will help make the task easier and achieve better results. First, use an awl to make 2 holes in the denim.

It is recommended to take into account that when installing the fittings it may become clear that the nail is too long in relation to the material. To shorten such a product, you should use pliers.

If you do not have the required skills or tools, it is recommended that you contact a professional. They will be able to install rivets quickly and accurately using special equipment. If you want to install rivets yourself, you should first study the technique of the procedure and determine the type of fittings. This will help you achieve good results.

How to remove a blind rivet

The pop rivet is somewhat easier to remove. When dismantling it, it is necessary to remove the ring formed during fastening. If possible, when compressing the material of the structure, insert a metal saw blade, the fastening can be cut off, and the pin can be removed by pulling it out by the rod. If sawing or cutting is not possible, there is always a chance to remove the fastening using the first method - drilling.

The hidden fastening can only be removed by drilling, and the exhaust heads can be knocked off with a hammer if the strength of the material they fasten is greater than that of the fastening itself. Provided that using this method of dismantling, there is no confidence in 100% safety for your own hands and the appearance of the material, it is better to abandon it.

If you find an error, please select a piece of text and press Ctrl+Enter.

The rivet is an excellent and durable type of fastener. But unlike bolts, nuts, studs and screws, it cannot be removed without damaging it. The bolt can be unscrewed with keys or a screwdriver, after which it can be reused. The broken rivet will have to be thrown away. The question also arises: “How to rivet rivets if there is no riveter in your arsenal?”

What to do if there is no spare button

If you don’t want to look for a new rivet, and don’t have the means to turn to professional craftsmen, it is permissible to use an ordinary button instead of special fittings. It is recommended to ensure that it matches the style of the jeans and matches the diameter of the loop.

To carry out the procedure, you should perform the following steps:

- First of all, it is recommended to remove the old rivet.

- After this, the hole from it should be carefully mended. This should leave no unsightly holes.

- Sew a button next to it. It is best to use fittings on a leg.

Sometimes this type of fastener is fixed much more securely and looks much more attractive compared to standard metal rivets.

Removing a construction rivet

It is difficult to call this action dismantling as such. This is removal. To remove the rivet, you will need the regular rivet gun that was used to install it. But since you don’t have one at hand, it’s worth figuring out how to rivet a rivet without a riveter.

You can try to remove rivets in which the head or bent part protrudes above the plane of the riveted parts with a sharp chisel and hammer:

- Place the cutting part of the chisel exactly under the head (or bent part).

- Hit the chisel with a hammer. Some large rivets may take several hits to break off.

- Once the head (or bent part) is torn off, all that remains is to remove the rivet from the hole. This can be done by pushing it out with a nail or other thin object (for example, a screwdriver).

Read also: Is tungsten magnetic or not?

But more often you cannot get to the caps and curved parts, since they are, as it were, in the body of the parts being fastened. At the factory, special grooves are drilled for the caps and expanding parts in the parts, and then the rivets fit into the metal like a glove. How to rivet rivets in such a “tricky” case?

Here a screwdriver (or drill) with a metal drill selected for the diameter of the rivet will come to the rescue. Proceed as follows:

- Using a core, make a notch on the head of the rivet so that the drill does not wander, although some are accustomed to doing without serifs.

- Place the screwdriver bit on the head and drill out the inside of the rivet.

- When the drill goes through, the remains of the head and widened part fall out on their own.

Additional tips and tricks

On these clothes, fasteners with a broken rod are often damaged. Such products are constantly subjected to high loads. As a result, they simply fly off the rod. This is considered their main disadvantage.

To change the rivet, first of all, you will have to get rid of its remains. The procedure can be carried out using a side cutter. You are also allowed to use pliers. It is recommended to remove residues in one motion. You can install a new rivet using standard technology.

In this case, you should follow these recommendations:

- If the fabric is not damaged, you can purchase new accessories, then place the button stem in the recess and place the metal cap on top. Then turn the clothes over and press the hat to the table. The surface must be smooth and hard. After this, hit the rod well with a hammer. This will help secure it.

- If the fabric is damaged in the area where the rivet is located, it is recommended to first make a patch. It is made of denim material to cover the problem area well. The patch should be sewn manually or by machine. Then it is recommended to install the rivet.

If the rivets do not hold well or are constantly lost, you should choose an ordinary button. This should be done very carefully. The button must match the size of the eyelet. A piece that is too small will not securely hold the jeans buttoned up, and a piece that is too large will cause daily discomfort.

Repairing a button on jeans is fairly easy. However, first of all, it is recommended to determine the type of fittings and select the best option. After this, you need to select the type of repair and strictly adhere to the required sequence of actions.

Share link:

Good day, dear blog readers!

Despite the fact that the denim buttons themselves and their attachment to the finished garment are very durable, sometimes such buttons “fail.”

Most often this happens with buttons that are located on the waist line and are subject to increased loads there.

For example, on jeans.

Denim buttons. Kinds.

How to put a button on jeans using special tools?

Installing a denim button using available tools.

How to change a button on jeans?

1. The button is about to “break out with the meat” and fall off. And he also keeps, as they say, on his word of honor.

2. From a button with a fixed stem, the inside of which is filled with impact-resistant plastic, a nail fell out of its own accord due to “hard life.”

3. One of the button studs on the double tack broke.

4. The main part of the floating leg of the denim button has come off the additional moving part.

Here are the main types of failures that happen to denim buttons.

5. Yeah, here's another thing! By chance, in a fabric store, you caught the eye of an unearthly beauty denim button. And you immediately realized that its presence on your jeans will make them more fashionable, brighter and in general, they will become like new. But there is an old button on his jeans and he clearly has no intention of “retiring.”

However, no problem. Knowing the rules for installing denim buttons, described in several previous articles, denim buttons that have become unusable or unloved can be easily replaced with new ones.

I would like to remind you that the easiest way is to install denim buttons with a fixed leg, manually, at home, on a nail with a circular notch.

Therefore, when choosing a new denim button, it would be good to take this into account.

Well, let's get down to business.

If the button has not fallen out completely, and parts of it that are firmly embedded in the material remain, then they can be removed with side cutters.

Further. We look at the condition of the button hole. If it is not very broken, then you can install a new button in the same place. You can read how to install a denim button on a double nail. Read about installing other types of denim buttons

If the hole is, as they say, torn, with entrails sticking out of it, then you need to patch it up a little with matching threads. And the place under the button needs to be moved a little further, at least 5 mm in the direction of narrowing the volume of the belt, and a new button should be installed (as in this or this article).

But, alas, in the vast majority of cases, there is no way to move the button to another place, even if it is located very nearby. The trousers are just right.

You can, of course, use a denim button with a tube-shaped nail. Such studs are somewhat wider than their counterparts, all-metal, smooth and notched.

And they should fit snugly into the hole on the product left from the previous nail.

But what to do in a situation where you couldn’t buy this kind of denim button?

This means that the hole in the material needs to be properly sewn up, leaving, after all, a small hole for a new nail.

And install a new button in the same place. But before that, from a piece of leather, plastic or some other dense material, cut out a round piece twice as wide as the nail head and place it on the wrong side under the nail head.

This way, the head of the nail will have additional areas to cling to the material more tightly.

Well, we’ve learned how to install denim buttons at home and replace those that have become unusable.

I hope that a short series of articles about denim buttons will be useful for those who “surf” the “waves” of the Internet in search of this particular information.

Do you know how to cover a button with fabric? No? Come read about it in the next article.

Bye everyone! Sincerely, Milla Sidelnikova!

How to assemble a tendril button for clothes?

In much the same way as a denim button, a button is installed on a tendril-type garment. The only difference is that all manipulations must be carried out only for the top part of the button.

The lower part of the part is much easier to assemble:

- To install it, you can buy a special tool with a recess inside in the store.

- If you do not have such a tool, then you can use a metal plate with a hole similar to the size of the “bump”. You need to insert the bottom part of the button into the hole of the metal plate, and “slam” the leg with a hammer on the back side of the clothing.

Important! It is quite difficult to install the antenna button without special tools, so buy a little more of them than required.

Adviсe:

- If for some reason the buttons are not installed correctly, remove them and install new ones. Do not use damaged buttons, as they will not hold securely and will need to be replaced.

- To install a button on clothes at home, you can use the tools that are at hand: a Phillips screwdriver, a bolt, a thick nail, a dowel. To expand the cylindrical part of the button, you can use any cone-shaped device, and then use a bolt (cylindrical rod) of a suitable diameter to flare (attach) the button rod completely.

- Install the button on a smooth wooden surface, but be extremely careful not to break the button or destroy it.

- You can use a block of wood to install the bottom of the button if you don't have a suitable metal object with the right hole. Use a drill to make a hole in a wooden block (the diameter and depth should correspond to the male part). Assemble the bottom of the button and place a block on top. Tap the part with a hammer.

Important! If you decide to start thoroughly practicing sewing clothes with your own hands, you will find our articles useful:

- How to choose a sewing machine?

- How to sew a zipper with your own hands?

How to remove a denim button without damaging it. How to put a button on jeans

How to install a denim button manually on jeans? How to remove a button on jeans?

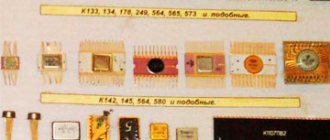

Sizes (diameter) of denim buttons: 14mm, 17mm, 19mm, 20mm, 22mm, 25mm, 26mm, 30mm, 40mm. (Important when selecting a button for a buttonhole on a product) Depending on the type of denim button, it is installed on a special denim stud: a) with a circular notch, b) smooth all-metal, c) smooth tubular metal For manual installation, denim studs made of aluminum are more suitable , try to use only them. They are easy to process and are not much inferior in strength to steel ones.

— Types of denim buttons and how to install them.

1. Denim buttons on a stable leg As a rule, this is a metal shell filled with impact-resistant plastic. The button is installed on a denim pin with a circular notch. At the installation site, the fabric (skin) is pierced with a hand punch, awl or nail. Insert a denim nail. and hammer it in like an ordinary nail, but not with all your might. Denim buttons with a stable stem are the most durable and easy to install. Denim buttons on a plastic base are also produced. Without metal shell. Require special attention during installation. When driving a denim tack, precise alignment must be maintained, otherwise the button will split. It is better not to mess with such products. 2. Denim buttons on a stable leg with a hole Manufacturers of buttons recommend installing them on smooth denim studs. All metal or tubular. Since it is difficult to install buttons on these nails, it is necessary to maintain precise alignment; you can use a denim nail with a circular notch. We install in exactly the same way as in the case described above. But we additionally flatten the tip of the denim nail after installation. in order to finally fix the denim stud. If you install it on a smooth denim stud, it often turns out to be longer than necessary. Use pliers to shorten it to the required length. And install using a bolt with a diameter of 5mm.

We install it from the front side of the button on a metal surface.

3. Denim buttons with a broken leg

Installation should be carried out on a smooth wooden surface. Installed on a denim nail with a smooth shaft. Or on a metal tubular one. When installing a button (hammering), it is difficult to maintain alignment. You will need a tube with an internal diameter of 9-10 mm, a length of 30-40 mm and a rod - a bolt with a smooth head with a diameter of 9 mm, a length of 60 mm. If you have a 9mm socket wrench, use it. They hammered in a denim nail, checked it, and tugged at the installed button. In case of installing a denim button on a metal tubular nail, use a tube with a diameter of 10 mm or a socket wrench with a diameter of 10 mm. And in the same way we successfully install the button in the right place. It is also necessary to take into account the length of a standard denim pin, depending on the thickness of the fabric where the button is installed. The thinner the fabric, the shorter the length of the nail should be. The length of a standard all-metal denim stud is 10-12mm, the length of a metal tubular stud is usually 8mm. If necessary, shorten the nails to the required length using pliers.

4. Denim buttons on a broken leg with a hole:

Installed on an all-metal smooth aluminum denim stud or on a metal tubular one. Install on a flat wooden or metal surface. We pierce the fabric (leather) at the installation site and insert a denim nail. If it is long, bite off the excess. And to make the top unravel more beautifully, you can grind it off with a file. Next is the process of installing the button. We use a cylindrical rod with a diameter of 4-5mm, or an ordinary bolt. The process of installing a denim button can be simplified if you use a denim nail with a circular notch. Hammer a nail like a button on a stable stem (see above). True, it will turn from concave to flat, if this does not bother you. To finally complete the installation of the button, we rivet the tip of the protruding denim nail. Since these steel nails are more difficult to rivet, the main thing is that they do not get scratched later. They riveted a little and that was enough. It is difficult to install these denim buttons on the metal tubular denim studs. They are made of steel and require considerable force to rivet them. If the alignment is not observed, the button and the stud itself can be deformed. Conclusion: The easiest way to install this type of denim buttons is on a smooth aluminum stud.

5. Double Stud Buttons:

A distinctive feature is the solid bottom of the button stem. Which is then pierced with a double denim stud. The carnation tendrils are then bent towards each other. The main disadvantage of this type of button is that one of the fastening studs often breaks off. Installing by hand is easy: Use an awl to punch two holes on the back of the button. We pierce the fabric with a nail, put a button on it and bend the ends of the nails with a narrow screwdriver into the inside of the button.

Removing the remnants of a denim button:

A typical case. A button on a pair of jeans broke on a broken leg. The property of this type of button is to jump off the shaft under increased load. Removing button remnants. Remove with a side cutter or pliers in one movement.

Attention: high-quality installation of fittings can only be done in an atelier or workshop using appropriate professional equipment.

Have questions. Write, we will answer.

Rivets for clothing are an inconspicuous but irreplaceable element of every item, from sheepskin coats, fur coats and jackets to underwear. Even expensive branded clothing is often equipped with low-quality fittings: clips, hooks, zippers. Very often, decorative rivets come off, and an expensive item becomes unwearable. In order not to seek help from a clothing repair shop, you need to learn how to work with a variety of sewing accessories yourself.

How to replace a stud button on jeans

Of course, this is not the most common breakdown, but nevertheless, this also happens: you need to replace a rivet on jeans that has failed. And then, why only on jeans? This type of button is found on both backpacks and jackets - we are talking about metal rivets that are not sewn to the fabric in the usual way with threads, but sit firmly on special nails

. This breakdown is annoying, of course, but it is not at all a reason to give up your favorite thing: repairs are extremely simple, require a minimum of money, time, effort, and do not require special/professional skills at all.

Why did the rivet break? Well, if we are talking about jeans, the easiest way to explain the breakdown is that the person decided to try on jeans that were clearly not his size. This happened to the author of the article: her husband, in the morning twilight, mixed up his jeans, and instead of his wife’s, he pulled on his wife’s, bent down to put on his socks, and the button flew off. Why he didn’t immediately notice that the jeans were not his, no clear answer was received.

For repair you will need:

- Pliers

- Hammer

- New stud button

- Awl

- Wooden cutting board

- The jeans themselves

- Two minutes of free time.

So, we start by going to a store that sells sewing accessories

, handicrafts, or a shoe workshop - there are rivets there too. The prices for these products are ridiculous, especially considering that a single copy of the button is required: from 20 rubles, but this one will cost 40 rubles:

The main thing here is not to make a mistake with the size: there are different rivets! Therefore, we either rely on our visual memory, or we simply take the jeans with us and try them on on the spot:

Please note: this type of button consists of two elements, they are sold as a set!:

- Well, shall we get started? An optional point, but still: as a rule, when a button breaks, the entire button does not fly out, its cap just comes off, leaving a firmly seated pin in the fabric.

It is easily cut with wire cutters (girls, this is done with pliers on the side), and it is better to do this from the wrong side

- Important!

It seems completely natural to place the new rivet in place of the old one. This is not the best idea: the button will not last long, it will fly off by the roots and even take a piece of material with it. Pierce the new hole with an awl at a distance of 5-10 mm to the left/right/above/below the old one, this will make it more reliable:

- Insert the nail pin into the new hole from the wrong side so that its base is located on the fabric as follows:

- Place a hat on the point protruding from the front side of the jeans - a decorative element of the rivet:

- Important!

The following action cannot be performed on your hands, on weight or on a soft support (on a sofa) - only on a hard, durable surface, for example, on a wooden cutting board. Don’t be afraid that you will somehow damage the decorative part, or that some of its elements will malfunction: the rivet will withstand everything!

Hit it once with a hammer from above. The blow should be strong enough, as if you were driving a nail into a tree, but still without fanaticism:

Even if it seems to you that the new button is too loose, don’t pay attention, it sits perfectly tight. Try it yourself, fasten your jeans, pull the belt part in different directions, as you can see, nothing comes unfastened.

No one will even notice that your favorite pants have been in such a mess. They will not come undone, the button will not break again, and generally no unexpected embarrassment will occur.

Device and types of buttons

A common feature of denim buttons is metal pins (rods) with a cap, which are driven into the leg of the button and are:

With one or more notches; smooth, without notches, all-metal; without notches, hollow inside.

Metal - aluminum or steel. Aluminum pins are much easier to work with, and they are as strong as steel pins. A set of buttons and pins costs from five rubles. The legs and heads of the buttons themselves vary in configuration. The method and complexity of their installation depends on this.

If there is no previous practice, for self-replacement you should buy buttons with stable, fixed legs. The easiest way to install buttons is with a straight, stable stem and a hollow metal body filled with special plastic. The notched pin is easily driven into the filling and holds securely, the button does not dangle. Hollow aluminum buttons without filler have much thicker stem walls. A rod with several notches is driven into them tighter, fits less tightly, and the button can dangle. The body of the button is completely plastic, and only the front part is trimmed with metal. When hammering a pin, there is a risk that the leg may split. Such fittings are installed with great care. Buttons with a through hole in the head and leg, according to the rules, are placed on smooth solid or hollow pins, which are riveted inside the hole. It is difficult to do this without a special tool, so it is better to use a short pin with several notches from another kit. In buttons with a broken (slightly inclined) stem, with a through hole or not, a smooth steel pin is driven in and riveted with noticeable effort. It is difficult to handle such fittings without the proper tools, maintaining perfect alignment of the rod. Using a notched pin positioned absolutely exactly at the moment of impact, the button can be successfully changed independently. True, at the end of the work the angle of the cap may disappear. The front side of the buttons can be voluminous, semicircular, or have rhinestones on it. Then, in order not to damage and to ensure that the surface is exactly the same, the button at the moment of driving in the pin is placed not on a plane, but on a suitable ring. This could be a round depression in the middle of the pliers, a large washer from a nut, or a hole made with a nail on a wooden board where the rhinestone will fit.

How to remove a rivet from a metal structure

A rivet is a disposable fastener designed to fasten 2 or more parts. To install this fastener, a riveter is used. How to remove a rivet will have to be based on the availability of available tools, because there is no universal tool. In addition, the selection of metal construction materials is carried out in accordance with the technical characteristics.

Aluminum, copper, and steel vary in hardness; they are susceptible to diffusion, oxidation rates, and other physical and chemical processes to varying degrees. The only method that can be called almost universal is drilling. This process can be carried out in 3 ways, which in most cases depends on how close the fastening metal is to the elements being fastened.

- The tight fit of the fastening rod to the hole means that it will not be possible to knock it out. In this case, dismantling will have to be carried out by completely destroying the rod. It is necessary to accurately determine the diameter of the drill used to make a hole in the metal structure. The same drill diameter will be required to remove, or rather, drill out the rivet along with the rim. It is better to start work on removing the rivet at low speeds so that the drill does not damage the fastened parts. However, this method is not the most reliable for dismantling a structure that will need to be reassembled.

There is always a risk that the drill bit of a hand tool will move to the side, enlarging the hole. In this case, it will be difficult to re-fasten the parts using the old marks.

- Dismantling of aluminum rivets can be done using the corkscrew principle with a drill of a smaller diameter than the rivet itself, a self-tapping screw, a screwdriver and pliers. Despite the large list of tools, the operation will require less time. A hole is drilled in the middle of the rivet, a self-tapping screw is screwed in, and the resulting part is removed with pliers. Steel that fits tightly is almost impossible to remove in this way due to the fact that the drill gets very hot.

- Steel ones can be removed using a combined method. To begin with, it is drilled out from both sides along the rim so that the ring-clamps are separated from the rivet rod. Then, in accordance with popular wisdom, they knock out the wedge with the wedge. To do this, you will need a screwdriver with a handle that cannot be destroyed with a hammer blow. It is inserted into the middle of the rod and with gentle blows of a hammer on the end of the handle, force is applied to remove the rod from the hole; this is the only way it can be removed without damaging the metal being fastened. If the rivet was fastening a thick structure, but it comes out hard, then, if the end is large enough to be grasped with pliers, it can be pulled out. A rivet that does not yield easily can be turned, but it is not recommended to pull it out by shaking if the hole is necessary to re-fasten the structure.

Installing a button

If there is a broken pin left on the waistband of your jeans, you must carefully remove it by biting off the remains with side cutters or the biting part of the pliers. The rod cap can then be easily removed.

Place the button face down on a wooden block, plank or kitchen board. A pin is inserted into the previous hole on the waistband of the jeans so that its head is on the wrong side. The sharp part of the rod is inserted into the leg of the button and driven in with a hammer. You need to hammer in the pin by hitting its head not with one strong blow, but with several small, not sweeping ones. It is very important that the position of the rod is vertical, without distortion.

Patch

When the entire button falls out and there is a hole in its place, you need to make a patch. A circle of smaller diameter than the width of the belt is cut out of a thick piece of leather. In the middle of the leather patch, a hole is pierced with an awl or a thin nail, a pin is threaded through it, onto which a button is then placed. The patch remains on the inside of the belt. You can grab it with threads so that it doesn’t curl up later. But this is optional.

Hello, dear readers of the cutting and sewing website - “Sewing Circle”. In general, the question of how to change a button on jeans is not worth it. Although, if you know how to remove a button from jeans, then the material in question will be relevant in this case as well. By the way, buttons are removed from jeans using ordinary wire cutters, or, to put it more correctly, side cutters. Moreover, it is absolutely not necessary to resort to brute male power... In the example, the old button from the jeans cannot be removed. So why and how to put a button on jeans?

The question “why” is simple. Then, so as not to sew in jeans when reducing the volume of the waist and hips. It is assumed that weight loss happened, but did not take frightening forms. In this case, another button on the belt will not help. Changing your jeans will help. There is also the option of voluminous hips and a narrow waist. Or rather, their ratio. In this case, often the jeans sadly puff up at the back of the waist. The second button will solve this problem too. Voluminous hips themselves also mean that jeans will stretch faster after washing, and after a couple of days they will simply begin to slip.

Of course, you can use a belt when wearing jeans. But he can only make things worse by emphasizing this bulge that everyone will stare at ;). Many people find belts very uncomfortable and are looking for other solutions.

The proposed solution to the problem of jeans that bulge at the back of the waist is also as economical as possible.