Concept of temperature scale

Some non-metallic objects also have similar properties. The most common is water. A temperature scale was developed regarding the properties of the liquid that occupies a dominant position on Earth. The reference points are the temperature of changes in the aggregative states of water:

- Transformations from liquid to solid and vice versa are taken to be zero degrees.

- Boiling (vapor formation inside a liquid) at normal atmospheric pressure (760 mm Hg) is taken to be 100 ⁰C.

Attention! In addition to the Celsius scale, in practice temperature is measured in degrees Fahrenheit and on the absolute Kelvin scale. But when studying the properties of metal objects, other scales are used quite rarely.

Metal crystal lattices

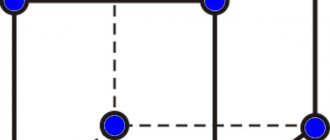

In its ideal form, it is generally accepted that metals have a cubic lattice (real substances may have flaws). There are equal distances between molecules horizontally and vertically.

A solid substance is characterized by constancy:

- shapes, the object retains linear dimensions in different conditions;

- volume, the object does not change the amount of substance it occupies;

- mass, the amount of a substance expressed in grams (kilograms, tons);

- density, unit volume contains constant mass.

When transitioning into a liquid state, having reached a certain temperature, the crystal lattices are destroyed. Now we can’t talk about constancy of form. The liquid will take the form in which it is poured.

When evaporation occurs, only the mass of the substance remains constant. Gas will take up the entire volume that will be provided to it. Here we cannot say that density is a constant value.

When liquids combine, the following options are possible:

- Liquids completely dissolve in one another, as do water and alcohol. The concentration of substances will be the same throughout the entire volume.

- Liquids are stratified by density, the connection occurs only at the interface. It is only temporarily possible to obtain a mechanical mixture. Mix liquids with different properties. An example is oil and water.

Metals form alloys in the liquid state. To obtain an alloy, each of the components must be in a liquid state. With alloys, phenomena of complete dissolution of one in another are possible. Options cannot be excluded when the alloy will be obtained only as a result of intensive mixing. In this case, the quality of the alloy is not guaranteed, so they try not to mix components that do not allow obtaining stable alloys.

The resulting substances, soluble in each other, when solidified, form crystal lattices of a new type. Define:

- Heliocentered crystal lattices are also called body-centered. In the middle there is a molecule of one substance, and four more molecules of another are located around it. It is customary to call such lattices loose, since the bonds between metal molecules in them are weaker.

- Face-centered crystal lattices form compounds in which the component molecules are located on the faces. Metallurgists call such crystalline alloys dense. In reality, the density of the alloy can be higher than that of each of the components included in the composition (alchemists of the Middle Ages were looking for options for alloys in which the density would correspond to the density of gold).

Cryoscopic method

The melting point can be determined very accurately using the cryoscopic method - using cooling curves. This method allows you to establish not only the melting point, but also the percentage of impurities. When a molten substance crystallizes in the absence of supercooling, the temperature remains almost constant, which is associated with the release of latent heat of crystallization.

The disadvantage of this method is that it requires significantly more test substance than when determining in capillaries.

Determination of the crystallization temperature of organic reagents and preparations within the range of 20-100 ° C according to the cooling curve is carried out in the Bauman-From device (Fig. 208).

The Bauman-From device consists of a thick-walled glass vessel 3, the lower part of which has a diameter of 20 mm, and the upper part has a diameter of 50 mm. Nozzle 1 in the form of a cup is placed in the upper part. At the bottom of the nozzle there are two holes for a thermometer 4 and a stirrer 5. The latter are freely suspended in the holes on cork plates 2. A cylindrical vessel with a nozzle is placed in a wide test tube 6 with a diameter of 40-45 mm. The entire device is placed in a glass with a capacity of 500 ml.

The test preparation is placed in vessel 3 and melted by immersing it in a glass of water heated to a temperature 15-20 °C above the expected crystallization temperature. The layer of the molten preparation should be 25-30 mm high.

The vessel with the molten preparation is removed from the water, wiped dry, inserted into test tube 6 and secured on a stand. Thermometer 4 and stirrer 5 are immersed in the molten preparation so that they do not touch either the bottom or the walls of vessel 3 and so that the mercury reservoir of the thermometer is completely immersed in the test substance.

The test substance in the device is cooled 2-3°C below the expected crystallization temperature and stirred carefully without touching the bottom and walls of the device.

At the moment of crystallization of the substance, the temperature spontaneously increases (at this moment stirring is stopped) and, having reached a certain maximum, remains at this level for some time, and then begins to decrease again. The highest point of temperature rise is taken as the crystallization temperature.

An example of a first-order phase transition is the melting and crystallization of solids. The melting process plays an important role in nature (melting snow and ice on the surface of the Earth, melting minerals in its depths, etc.) and in technology (production of metals and alloys, casting into molds, etc.).

Read also: Equipment for collecting firewood

Melting is the process of a body transitioning from a crystalline solid state to a liquid state.

The main characteristics of the melting of pure substances are the melting point (Tm) and heat (heat of fusion Qm), which is necessary to carry out the melting process.

During the melting process, the temperature of the crystal remains constant. This temperature is called the melting temperature Tmelt.

Each substance has its own melting point. The melting point for a given substance depends on atmospheric pressure. Tungsten has the highest melting point among pure metals (3410 °C), and mercury has the lowest (–38.9 °C).

The constancy of the temperature is explained by the fact that during melting, all the heat supplied goes to disorder the regular spatial arrangement of atoms (molecules) in the crystal lattice. For most crystals (except water and some alloys), the melting point increases with increasing external pressure, since moving atoms away from each other at higher pressure requires greater energy of thermal motion, i.e., a higher temperature.

A molten substance has a greater reserve of internal energy than in the solid state. The remaining part of the heat of fusion is spent on performing work to change the volume of the body during its melting. When melting, the volume of most crystalline bodies increases (by 3-6%), and when solidifying it decreases. But, there are substances whose volume decreases when melted, and when solidified it increases. These include, for example, water and cast iron, silicon and some others. This is why ice floats on the surface of water, and solid cast iron floats in its own melt.

Melting begins when the crystalline substance reaches Tm. From the beginning of melting until its completion, the temperature of the substance remains constant and equal to Tmelt, despite the imparting of heat to the substance (Fig. 1). It is not possible to heat a crystal to T > Tmel under ordinary conditions, whereas during crystallization, significant supercooling of the melt is relatively easily achieved.

Melting occurs with the absorption of latent heat of phase transition - heat of fusion Qpl..

Specific heat of fusion qpl. shows how much heat is needed to completely transform 1 kg of a substance from solid to liquid, taken at the melting point

:

qpl.

= Qpl./m, J/kg.

Melting is accompanied by a change in the physical properties of the substance: an increase in entropy, which reflects the disorder of the crystalline structure of the substance; increase in heat capacity and electrical resistance. During melting, shear resistance drops to almost zero, the speed of sound propagation (longitudinal waves), etc. decreases.

Rice. 1. Stopping the temperature when the crystalline body melts. The abscissa axis represents time τ, which is proportional to the amount of heat uniformly supplied to the body.

According to molecular kinetic concepts, melting is carried out as follows. When heat is supplied to a crystalline body, the vibrational energy (oscillation amplitude) of its atoms increases, which leads to an increase in the temperature of the body and contributes to the formation of various types of defects in the crystal (unfilled nodes of the crystal lattice - vacancies; violations of the periodicity of the lattice by atoms embedded between its nodes, etc. . In molecular crystals, partial disordering of the mutual orientation of the axes of molecules can occur if the molecules do not have a spherical shape. A gradual increase in the number of defects and their association characterize the pre-melting stage. With the achievement of Tmelting, a critical concentration of defects is created in the crystal, melting begins - the crystal lattice disintegrates into easily mobile submicroscopic region. The heat supplied during melting does not go to heating the body, but to breaking interatomic bonds and destroying long-range order in crystals. In the submicroscopic regions themselves, the short-range order in the arrangement of atoms does not change significantly during melting. This explains the lower values of the heat of fusion Qpl compared to the heat of vaporization and the relatively small change in a number of physical properties of substances during their melting. As the temperature increases, the molecules move more and more intensely. When heated, not only the molecular kinetic energy of a body increases, but also the potential energy of interaction of its atoms, since with an increase in the amplitude of vibrations, the atoms move away from each other at a greater distance and come closer to a smaller distance, due to which the energy of interaction of their electric charges increases. With increasing temperature, there finally comes a moment when maintaining order among strongly swaying atoms becomes impossible, and from this moment the destruction of the crystal lattice begins, as a result of which long-range order also disappears. The solid melts.

In amorphous bodies, the change in temperature over time does not have a section with a constant temperature, but only an inflection point. An increase in the temperature of a solid amorphous body is accompanied by a continuous decrease in its viscosity.

The reverse transition of a substance to a solid state is possible both from a liquid and from a gaseous state. In both cases, such a transition occurs from a state without symmetry to a state in which symmetry exists (this refers to the long-range order that occurs in crystals and which does not exist in either liquids or gases). Therefore, the transition to the solid state must occur abruptly at a certain temperature, in contrast to the liquid-vapor transition, which can occur continuously. The process of formation of a solid when a liquid is cooled is the process of crystal formation (crystallization) and it occurs at a certain temperature - the crystallization temperature. Since during such a transformation the energy of the system decreases, such a transition must be accompanied by the release of energy in the form of heat of crystallization. From the law of conservation of energy it follows that the heat of fusion and the heat of crystallization must be equal to each other.

Didn't find what you were looking for? Use the search:

Melting point of metals

Different substances have different melting points. It is customary to divide metals into:

- Low-melting - it is enough to heat them to 600 ⁰C to obtain the substance in liquid form.

- Medium-melting metals melt in the temperature range 600…1600 ⁰С.

- Refractory are metals that can melt at temperatures above 1600 ⁰C.

The table shows low-melting metals in ascending order. Here you can see that the most unusual metal is mercury (Hg). Under normal conditions it is in a liquid state. This metal has the lowest melting point.

Table 1, melting and boiling points of fusible metals:

Table 2, melting and boiling points of medium-melting metals:

Table 3, melting and boiling points of refractory metals:

Various devices are used to carry out the smelting process. For example, blast furnaces are used to smelt iron. For melting non-ferrous metals, internal heating is carried out using high-frequency currents.

Molds made of non-metallic materials contain non-ferrous metals in a solid state. An alternating microwave magnetic field is created around them. As a result, the crystal lattices begin to loosen. The molecules of the substance begin to move, which causes heating within the entire mass.

If it is necessary to melt a small amount of low-melting metals, muffle furnaces are used. In them, the temperature rises to 1000...1200 ⁰С, which is enough for melting non-ferrous metals.

Ferrous metals are melted in convectors, open hearths and induction furnaces. The process involves the addition of alloying components that improve the quality of the metal.

It is most difficult to work with refractory metals. The problem is that you need to use materials that have a temperature higher than the melting point of the metal itself. The aircraft industry is currently considering the use of Titanium (Ti) as a structural material. At high flight speeds in the atmosphere, the skin heats up. Therefore, a replacement for aluminum and its alloys (AL) is needed.

The maximum melting point of this rather light metal attracts designers. Therefore, technologists are developing technological processes and equipment to produce parts from titanium and its alloys.

Determination of specific heat of fusion

The specific heat of fusion (designated by the Greek letter “lambda” - λ) is a physical quantity equal to the amount of heat (in joules) that must be transferred to a solid body weighing 1 kg in order to completely transform it into the liquid phase. The formula for the specific heat of fusion looks like this:

$$ λ ={Q over m}$$

Where:

m is the mass of the melting substance;

Q is the amount of heat transferred to the substance during melting.

Values for different substances are determined experimentally.

Knowing λ, we can calculate the amount of heat that must be imparted to a body of mass m for its complete melting:

$$Q={λ*m}$$

Metal alloys

To design products from alloys, their properties are first studied. To study, the metals being studied are melted in small containers in different ratios to each other. Based on the results, graphs are built.

The lower axis represents the concentration of component A with component B. The vertical axis is temperature. Here the values of the maximum temperature are noted when all the metal is in a molten state.

When cooled, one of the components begins to form crystals. In a liquid state, eutectic is an ideal compound of metals in an alloy.

Metallurgists identify a special ratio of components at which the melting point is minimal. When making alloys, they try to select the amount of substances used in order to obtain a eutectoid alloy. Its mechanical properties are the best possible. Crystal lattices form ideal face-centered positions of atoms.

The crystallization process is studied by studying the hardening of samples upon cooling. They build special graphs where they observe how the cooling rate changes. Ready-made diagrams are available for different alloys. By marking the start and end points of crystallization, the composition of the alloy is determined.

Wood's alloy

In 1860, American dental technician Barnabas Wood was looking for optimal ratios of components to produce teeth for clients at minimum melting temperatures. He found an alloy that has a melting point of only 60.2...68.5 ⁰С. Even in hot water, metal melts easily. It includes:

- tin - 12.5...12.7%;

- lead - 24.5...25.0%;

- bismuth - 49.5...50.3%;

- cadmium - 12.5...12.7%.

The alloy is interesting for its low temperature, but has never found practical application. Attention! Cadmium and lead are heavy metals and contact with them is not recommended. Many people can experience poisoning from contact with cadmium.

Potassium (63.5°C)

A close relative of sodium is potassium . Element No. 19 (Kalium) also reacts violently with water, forming an alkali, and is also fusible - 63.5°C. But there are almost no edible potassium compounds, and in this it is the complete opposite of sodium. Although the body still needs (microelement) in limited small quantities.

In its pure form, potassium has no practical use. But its numerous compounds have been known since ancient times as fertilizers, detergents, and important components of many chemical processes.

Soldering alloys

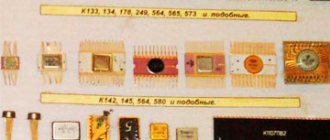

In practice, many people experience melting when soldering parts. If the surfaces of the materials to be joined are cleaned of contaminants and oxides, then they can be easily soldered with solders. It is customary to divide solders into hard and soft. Soft ones are most widespread:

- POS-15 - 278...282 °C;

- POS-25 - 258...262 °C;

- POS-33 - 245...249 °C;

- POS-40 - 236...241 °C;

- POS-61 - 181...185 °C;

- POS-90 - 217...222 °C.

They are produced for enterprises manufacturing various radio equipment.

Brazing alloys based on zinc, copper, silver and bismuth have a higher melting point:

- PSr-10 - 825...835 °C;

- PSr-12 - 780...790 °C;

- PSr-25 - 760...770 °C;

- PSr-45 - 715...721 °C;

- PSr-65 - 738...743 °C;

- PSr-70 - 778...783 °C;

- PMC-36 - 823...828 °C;

- PMC-42 - 830...837 °C;

- PMC-51 - 867...884 °C.

The use of hard solders allows you to obtain strong connections.

Attention! Wed means that silver is used in the solder. Such alloys have minimal electrical resistance.

Melting point of non-metals

Non-metallic materials can be presented in solid and liquid form. Inorganic substances are presented in table. 4.

Table 4, melting point of inorganic non-metals:

In practice, organic materials are of greatest interest to users: polyethylene, polypropylene, wax, paraffin and others. The melting points of some substances are shown in table. 5.

Table 5, melting temperature of polymer materials:

Attention! The glass transition temperature refers to the state at which a material becomes brittle.

Video: melting point of known metals.

Specific heat of fusion of certain substances

Information on specific heat values for a specific substance can be found in book reference books or in electronic versions on Internet resources. They are usually presented in table form:

Specific heat of fusion of substances

| Substance | 105 * J/kg | kcal/kg | Substance | 105 * J/kg | kcal/kg |

| Aluminum | 3,8 | 92 | Mercury | 0,1 | 3,0 |

| Iron | 2,7 | 65 | Lead | 0,3 | 6,0 |

| Ice | 3,3 | 80 | Silver | 0,87 | 21 |

| Copper | 1,8 | 42 | Steel | 0,8 | 20 |

| Naphthalene | 1,5 | 36 | Zinc | 1,2 | 28 |

| Tin | 0,58 | 14 | Platinum | 1,01 | 24,1 |

| Paraffin | 1,5 | 35 | Gold | 0,66 | 15,8 |

One of the most refractory substances is tantalum carbide - TaC. It melts at a temperature of 39900C. TAC coatings are used to protect metal molds in which aluminum parts are cast.

Rice. 3. Metal melting process.