Using an industrial laser installation for cutting sheet materials, you can achieve very precise compliance of the product with the given drawings. This is facilitated by the high automation of the process: the movements of the laser head are controlled by a computer, and the material being processed is stationary on the coordinate table.

In addition, laser cutting is carried out without mechanical impact. And the thermal effect is so local that no deformation occurs in the processed sheet, so there is no risk of cracking when processing fragile materials, such as acrylic glass or other types of plastic.

What affects the accuracy of laser cutting?

Modern equipment can provide laser cutting accuracy within 0.1 mm. However, this indicator depends on several circumstances, and if necessary, the size of the error is determined experimentally.

Laser cutting accuracy parameters are determined by several factors:

- laser beam diameter

- radiation mode (continuous or pulse-periodic)

- cutting gas

- processed material

- sheet thickness

- beam power and speed

- complexity of the drawing form: the presence of sharp corners, closely spaced contours, small details.

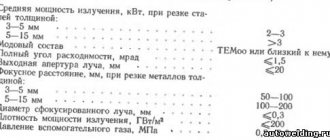

General information about the main parameters of cutting metal using a fiber laser

Using machines of the mentioned type to perform these works allows you to:

- perform cutting of particularly hard, brittle, refractory, thin metal workpieces with proper quality.

This is achieved thanks to the generated HF radiation, which forms a beam spot of minimal area. This is a significant difference between fiber models and gas models (the latter are designed to work with materials that are easier to process).

- Provide the required cutting speed (the parameter directly depends on the power of the installation, the thickness and type of material of the workpiece).

Example. With an installation power of 1 kW, the cutting speed of carbon steel will be:

- with a workpiece thickness of 1 mm – (5.0-6.0) m/min;

- 3 mm - (2.5-3.0);

- 8 mm - 0.5.

At the same time, stainless steel sheets 3 mm thick can be cut at speeds of up to 2.0 m/min.

- Select the power of the model taking into account the thickness and material of the workpiece. The market offers fiber optic lasers from 1 kW to 10 kW;

- configure the required mode in terms of radiation power, its frequency, cutting speed, and the necessary time delays during the initial burning of the processed material with a laser beam.

In the settings, when cutting thick material, you can move the burning location outside the main cutting vector. In this case, the finished workpiece will have maximum evenness of cuts.

- Optimize the cost of performing work. The price of cutting metal with a laser is significantly influenced by: the type of fusibility of the material and the thickness of the workpiece.

Cutting parameters and possible defects

The width of the cut at the beam entrance depends on the diameter of the laser (focal spot) and on modern installations is about 0.15-0.2 mm. Depending on the cutting speed, the exit width of the cut may be the same or smaller (as the speed increases), but the cut surface becomes rough.

Experts know that the diameter of the hole at the entry point of the laser beam is slightly larger than the width of the cut. In order not to compromise the manufacturing accuracy, in critical cases, burning the inlet hole in the sheet is performed with a slight offset towards the non-working part of the material - this technique is called cutting “with approach”. It is also used when it is necessary to avoid an influx or splash of evaporated material.

Another difficulty when cutting sheets are shapes with a closed contour. To prevent the product from falling out of the sheet, special bridges are left - “suspensions” 0.5-1 mm thick, which are then carefully trimmed, after which the product is removed.

Laser cutting of metal, laser cutting of sheets.

TechnoLazer company offers laser cutting services

(laser cutting) of sheet metal at our own production in the city of Shatura (Moscow region). Laser cutting is a fairly common operation; parts made using laser cutting are currently being produced:

- parts for mechanical engineering (brackets, profiles);

- cabinet products (cabinets, racks, terminals);

- components for furniture production (decorative elements, brackets);

- products for advertising (letters, stencils);

- etc.

Technologically, laser cutting is used to cut elements of original complex shapes. Laser cutting, along with other operations, is used in various fields of machine tool building, automotive industry and many others. The company NPP TechnoLazer LLC will, in a short period of time, set up production for the production of serial parts made using laser cutting.

Manufacturing parts in one place makes TechnoLaser even more attractive to our customers. You can order from us sheet metal bending, countersinking, thread cutting, turning and milling work, welding and painting (including powder).

Advantages of laser cutting:

- high speed of parts production;

- high cutting precision;

- there is no mechanical impact on the metal;

- the ability to perform the most complex, including shaped cuts;

- relatively low cost of work.

Examples of products made using laser cutting

Laser cutting in ProNest software

Overview of the automatic sheet metal cutting program in ProNest

.

ProNest

is the industry's leading CAD/CAM nesting software that enables advanced mechanized cutting. This software serves as a one-stop solution for all your profile cutting needs, including plasma, laser, waterjet and oxyfuel cutting. ProNest helps manufacturers achieve greater material savings, significantly increase productivity, reduce operating costs and improve cut quality through the highest level of cutting expertise.

Advantages:

— Optimal cutting guarantees minimal sheet loss.

— ProNest allows you to perform combined cuts, which saves machine operating time.

— The user-friendly interface of the program allows you to master it in a short time.

— Ability to customize ready-made templates for cutting.

https://www.hyperthermcam.com/ru-ru/

Laser perforation of sheet metal

This is another laser cutting technology developed specifically for the manufacture of filter elements. The filter element is made of a solid sheet of metal. The laser machine in this case works like a laser punch, punching many holes in a fraction of a second. In this case, the metal punching operation takes place at a high speed of movement of the cutting head. As a result of such laser perforation, cells measuring 0.1-0.2 mm in width and length are obtained at a specified speed of movement of the head. Scope of application: filter elements. Such filter elements, unlike mass-produced mesh filters, are characterized by the fact that they can withstand large pressure differences (gases, liquids or substances) and do not tend to stretch the cells. Some applications (screening and drying) require mesh structures that can support the weight of the raw material and have a flat face.

NPP TechnoLazer LLC has been operating in the market of laser equipment and laser technologies (laser cutting) since 1991. We always guarantee an acceptable cost for laser cutting and other work.

Equipment

At NPP TechnoLazer LLC, laser cutting is carried out using laser machines based on CO2 and fiber optic lasers with a processing field of up to 1.5x3.0 m.

We provide high-quality laser cutting of parts from steel sheets

up to 12 mm thick,

stainless steel sheets up

to 6 mm

and aluminum sheets up

to 4 mm thick.

Order fulfillment times

The lead time for laser cutting orders is from 3 to 12 days.

At the same time, the cost of laser cutting is optimal in relation to execution time and quality.

Metal

At the request of the customer, laser cutting for the manufacture of parts can be made from our metal. Delivery of finished products to the customer's warehouse is ensured.

Placing an order

Send your order by email (The email address is being protected from spambots. To view the address, Javascript must be enabled in your browser.) with attached drawings of parts made in AutoCAD in *.dwg or *.dxf format. It is necessary to adhere to the rule: one part - one file, and the drawing must be made, in order to avoid errors, on a scale of 1:1. When ordering, you must indicate the name of the part, the corresponding file and the number of parts.

Placing an order (laser cutting) by email will greatly speed up its processing.

If placing an order electronically causes difficulties, we can accept the order by fax and process it.

When ordering laser cutting, you must indicate contact information (email address, telephone number, fax number and contact person), all design requirements for the ordered products.

The order will be promptly reviewed, and you will be informed of the cost of laser cutting and the timing of its execution.

Laser cutting cost

At NPP TechnoLazer LLC, the cost of laser cutting depends on the grade of metal, metal thickness, cut length and number of contours; a discount is provided for a large order volume. We value our customers, so laser cutting is produced at affordable prices. You can determine the cost of laser cutting of your part using our calculator.

At NPP TechnoLazer LLC

Modern laser cutting technology is used, thanks to which only high-quality services are provided to customers; laser cutting is a type of laser processing of sheet material, in which a focused laser beam destroys the material, a jet of compressed gas blows it out of the cutting zone, which leads to the division of the sheet into parts.

This laser technology provides high productivity and precision. In addition, laser technology allows you to cut almost any metal. The services we provide (laser cutting), depending on the intensity of radiation in the cutting area, type of material, composition and pressure of the cutting gas, are divided into several types:

1) Laser - oxygen cutting

2) Laser cutting in inert gas

3) Laser thermal chopping

4) Laser evaporation (sublimation) cutting

1. Laser - oxygen cutting

The cutting gas used for this service (laser cutting) is oxygen. This laser technology involves the interaction of oxygen with hot metal, leading to an exothermic oxidation reaction. So in the case of iron, the generated heat is usually 3-5 times greater than the supplied laser power.

The resulting oxides are blown away by the same stream of oxygen.

This laser technology has the following characteristic features:

-The diameter of the focused beam is smaller than the diameter of the oxygen jet. Jet diameter is usually 1-2 mm

-The cutting width is determined by the diameter of the focused beam and the cutting speed. The thinner the sheet and the higher the processing speed, the narrower the cut. Cutting width can be less than 100 microns

-The pressure in the jet is from 3-4 atm when cutting a thin sheet to 0.3 atm when cutting a sheet 30 mm thick, and the greater the thickness of the metal being cut, the lower it is.

-As a rule, this laser cutting technology is carried out with an expanding beam, i.e. the focal point is located above the metal surface

-The gap between the nozzle section that forms the jet ranges from 0.5 mm for a thin sheet to 3 mm for a sheet 30 mm thick

-The thicker the metal, the lower the cutting speed. Minimum cutting speed 0.5-0.6 m/min. It is this fact that determines the maximum thickness of the steel sheet to be cut. Currently, this laser technology provides 30 mm with a laser power of 6 kW.

-When the cutting speed is less than 0.5 m/min, the quality of the service provided (laser cutting) drops significantly.

Characteristic defects appear on the cut surface - breaks, the width of the cut increases, and the process becomes autogenous. 2. Laser cutting in inert gas.

This laser technology is used in cases where oxidation of metal edges is undesirable, for example, when providing services - laser cutting of stainless steel, aluminum alloys and titanium. The efficiency of laser cutting in inert gas is lower than that of laser-oxygen cutting due to the absence of an additional heating source.

Characteristics:

— This laser technology involves the use of nitrogen (when cutting titanium - argon) - the most common inert cutting gas

— The cutting gas pressure is high: up to 10 atm or more, so this laser technology requires focusing lenses of increased thickness

— A supersonic jet of cutting gas is formed, blowing droplets of molten metal from the cutting area

— Radiation is focused on the lower surface of the sheet

— This laser technology ensures a minimum distance between the nozzle exit and the metal surface: 0.5-1mm

— When providing a service - laser cutting of thick metal - the nozzle diameter is quite large, up to 3 mm, so the consumption of inert gas is large, it often determines the cost of cutting.

— The cutting speed in inert gas is relatively low.

3. Laser thermal splitting of glass.

This laser technology is carried out by non-uniformly heating a fragile material, such as glass, with a laser beam and cooling it with a jet of inert gas. As a result, a crack forms. Moving the heating source along the glass surface allows you to control the direction of crack propagation and obtain a smooth interface.

4. Laser evaporation (sublimation cutting).

This laser technology is used at very high intensities of laser radiation, which is implemented in the mode of very short laser pulses of nanosecond and picosecond duration.

Characteristics:

-used in microtechnology

-minimal thermal impact on the substrate material

-this laser technology has minimal efficiency

-laser radiation wavelength is usually shorter than 1 micron (solid-state and excimer lasers, metal vapor lasers).

Our services – laser cutting of metals – are in steady demand.

LLC NPP TechnoLazer

provides services for laser cutting of sheet metal. Today, laser cutting of metal is one of the most effective metal processing processes in industry. When laser cutting there is no mechanical impact on the material being processed, it also ensures high productivity and accuracy of the process. Therefore, cutting metal using laser technology allows you to achieve high quality.

Another important advantage of the laser machine is that, if necessary, you can easily and quickly reconfigure the cutting parameters - this quality makes the machine an almost irreplaceable piece of equipment, allowing you to widely master mass production of products in a wide variety of industries, for example, in the production of machine tools, medical equipment, electrical engineering, construction industry, petrochemicals, electronics industry, as well as in the modern advertising industry (production of signs, letters, plates and other products).

Laser cutting is carried out in both continuous and pulsed modes. This makes it possible, on the one hand, to achieve high metal processing speeds, and on the other hand, if necessary, the use of a pulse mode makes it possible to produce very complex metal parts with a bridge width much smaller than the thickness of the material being processed. Our equipment carries out laser cutting of metal (carbon and stainless steel).

Using modern laser equipment and applying the latest technologies, we carry out laser cutting (plastic and metal) of materials of various compositions. Laser cutting of plexiglass is in demand today as one of the new activities of the enterprise. Materials are cut using 3 laser machines based on gas lasers. Having extensive professional experience in laser cutting of steel, aluminum and other metals, the company is responsible for the high quality of work performed.

Thanks to modern laser technologies, the company provides customers with only high-quality services. Depending on the characteristics of the material, one or another type of cutting is used (laser-oxygen, cutting in inert gas and others). Laser cutting of materials (plastic or various alloys) ordered from us, as well as laser cutting of plexiglass, will be completed in the required time frame accurately and efficiently.

We produce shaped laser cutting of various materials: steel, aluminum, copper, brass and other materials. To place shaped laser cutting in our company, you must send a drawing of the ordered parts with design requirements for them.

Taking into account the characteristics of the ordered parts and the composition of the material, our technologists will use the optimal laser cutting technology. This can be oxygen laser cutting (used when working with almost all materials), laser cutting in an inert gas environment (when working with stainless steel, aluminum), sublimation laser cutting.

The cost of services, as well as the timing of the order, are determined depending on its volume and complexity (time can range from 3 to 12 days). The cost of services will be calculated promptly by our employees after receiving the order by fax or email. The email address is being protected from spambots. To view the address, Javascript must be enabled in your browser. You can calculate the estimated cost of the order yourself using our online calculator on the website. High-quality and timely shaped laser cutting will allow you to contact our company more than once.

TechnoLaser uses 3 laser machines to carry out laser cutting (aluminum and other metals), including laser cutting of various types of steel. Laser cutting is mainly used to produce parts made of carbon and stainless steel. The use of modern equipment ensures high quality cutting of parts from steel sheets up to 12 mm thick and from stainless steel sheets up to 6 mm.

High-quality aluminum cutting is guaranteed for sheet thicknesses up to 4 mm. This type of laser cutting (aluminum and its alloys) is a more complex process that requires precise selection of cutting modes. But thanks to the developed technology, laser cutting of aluminum is carried out at our enterprise with high precision. We have been working in the market since 1991 and during this time we have gained a lot of experience. We know what laser cutting should be like for steel and aluminum, as well as other metals.

Today, laser cutting of materials is one of the most rapidly developing and in demand modern technologies, due to a number of reasons. Firstly, it is production automation, which allows processing significant volumes of metal without the use of manual labor. Secondly, there is no need for subsequent processing of the material, which is facilitated by the high accuracy and quality of laser cutting. Thirdly, there is a small amount of production waste.

High processing speed also ensures significant efficiency of laser cutting. In general, this cutting technology seems to be the best option for solving production problems where we are dealing with a large range of products and require quick changeover from one product to another and can greatly influence the cost of the product - the latter will be much lower than when processing metals using other alternative technologies. At the same time, laser cutting makes it possible to produce parts with very complex contours.

Laser cutting is used in the processing of various materials. Laser cutting technology will depend on the type of material, since each individual material has its own characteristics and requires a special approach. The company NPP TechnoLazer LLC produces high-quality laser cutting of materials such as carbon steel, stainless steel, brass, aluminum and its alloys. The company also offers its services for laser cutting of plywood and plastic.

As a rule, the cost of laser cutting is determined by a number of conditions. The cost of cutting a part depends on the grade and thickness of the sheet metal (and other materials), the length of the cut and the number of cuts.

Of course, the cost of the order is also determined by its volume - depending on the latter, our company provides discounts in one amount or another.

You can determine the approximate cost of laser cutting yourself - to do this, just refer to our online calculator on the website. The calculations include the length of the cut, the number of holes (insets), the number of parts ordered, metal thickness, and other parameters.

Calculations can be immediately added to the electronic order form and sent to us along with the application form. Our specialists will calculate the exact cost of the order.

Rules for preparing files for laser cutting:

The basis for cutting is a drawing of the part in electronic form (AutoCAD 14 or KOMPAS in *.dwg and (or) *dxf format).

By part we mean an open outer contour, inside of which there are holes (of any shape) and slots.

When creating part drawings (AutoCAD 14), you must consider the following wishes (following these rules will speed up the processing of your order):

1. Contours must be formed only by the following graphic primitives: LINE, CIRCLE, ARC. Therefore, you can use all the commands that create and work with these primitives, except for the ELLIPSE and SPLINE commands.

2. The scale of the part must be 1:1.

3. The outline of the part should not contain points or primitives superimposed on each other (lines, segments, arcs, etc.).

5. The profile must be open.

The material blank for the part should be 10 mm larger than the outer contour of the part.

If you are interested in the cost of laser cutting or current discounts, contact us by phone and we will be able to provide you with comprehensive information.

Modern laser cutting does not work with any materials - plastic is only one of many! Its technology is based on the evaporation of the polymer under the influence of a focused laser beam and the targeted action of dried air or inert gas, which blows out combustion products and simultaneously cools the cut surface, preventing expansion of the cut area and destruction of the material being processed.

When laser processing of plastic, the following parameters are programmed - radiation power, cutting speed, working gas pressure and others), which are dictated by certain properties of individual polymers. Our company's equipment allows laser cutting of plastics of various thicknesses. Virtually waste-free production, precision operations and the ability to create complex contours are the advantages of laser cutting of parts made of sheet plastic.

Using laser machines, it is possible to create advertising elements (letters, signs, stands), souvenirs, plastic folders and other products. If you need high-tech laser cutting for plastic, we are ready to fulfill an order of almost any complexity for you - the completion time ranges from 3 to 12 days.

One of the services that our company provides today is laser cutting of plexiglass and plastic. The advantages of laser cutting can hardly be overestimated: the accuracy and quality of workmanship, thanks to which the material practically does not require modification, the ability to work with complex contours, and a significant reduction in processing waste.

Having all the necessary equipment, we will carry out shaped laser cutting of plexiglass as quickly as possible. You can calculate the cost of the order you need using our online calculator and check it with our employees.

Modern shaped laser cutting provides us with unique opportunities for the production of high-quality products for a wide range of purposes - be it equipment parts, elements of advertising structures, or, for example, parts of a fashionable interior, souvenirs.

The most complex contours cut out on almost any material (metal, wood, plastic, fabric, plywood, glass), with perfectly conveyed accuracy and the absence of any defects in the cuts - all this can be produced today using the latest equipment, in particular our laser machines.

Plastic signs, badges, stands for jewelry or printed materials - the list of products that can be made with perfect accuracy and quickly using laser cutting is almost endless. Using a laser, you can also make inlay, which is fashionable today - cutting out letters, inscriptions, patterns for inserting them into other materials.

A unique property of laser equipment is its ease of operation and the ability to quickly change parameters depending on the task and types of material. Therefore, in the most reasonable time, using the shaped laser cutting method, we can produce both wooden art products and plexiglass products according to your sketches.

In addition to cutting metal and plastic, our company carries out laser cutting of plywood - a material suitable for the manufacture of decorative elements, including interior design elements.

Different types of plywood are cut differently. This is explained by several factors: the type of wood, the type of glue, the presence of several layers, the quality of which is not always the same, as well as the method of processing the material. The nuances and features of cutting can be determined in each specific case experimentally, which requires the work of a fairly highly qualified specialist.

Among the general patterns are better indicators in terms of quality and cutting speed of resin-free plywood made from softwood. Impregnated plywood is the worst for laser cutting. In general, the material is characterized as the most difficult of all types of wood to cut - the sheet may turn out to be uneven; when cutting with a laser, plywood can present a number of “surprises” in the form of knots hidden under the layers, which are harder than the base and can interfere with cutting and cause defective parts.

Laser cutting of aluminum is one of the materials for which we also have all the production capabilities for cutting. Aluminum alloys, due to their properties, are difficult materials to cut.

This is due to the fact that the metal has high thermal conductivity with a high reflectance of laser radiation. Therefore, it is much more difficult to cut than steel. Cutting requires programming of special modes, and its speed cannot be too high - otherwise the quality of the work will suffer (a burr that is difficult to remove will be formed).

The metal is distinguished by the presence of numerous roughnesses, burr on the cut surface; burr does not appear only when cutting sheets no thicker than 2 mm, at a relatively high gas pressure of inert gas (from 10 bar). However, the technological capabilities of our equipment and the qualifications of our specialists allow us to carry out laser cutting of aluminum sheets up to 6 mm thick at the highest quality level.

High-precision laser cutting to order at Studio Kvadrat

Using modern equipment, which is equipped at the production base of the Studio Kvadrat Group of Companies, it is possible to cut various materials with high precision. To order a laser cutting service according to your drawings, contact us by phone +7 (499) 156-4946, 156-1796 or write to [email protected] Our managers will accept your application, explain the requirements for source files, and clarify the necessary information. Our office is located at: Moscow, st. Admirala Makarov, 37, bldg. 2.