Materials for the production of metals and alloys

For the production of cast iron, steel and non-ferrous metals the following is used:

- ore;

- fluxes;

- fuel;

- fireproof materials.

Industrial ore is a natural mineral formation containing a metal or several metals in concentrations at which their extraction is economically feasible.

Fluxes are materials loaded into a smelting furnace to form slags - low-melting compounds with gangue ore or fuel concentrate and ash.

Fuels are combustible substances, the main component of which is carbon; They are used to obtain thermal energy when burned. In metallurgical furnaces they use: coke, natural gas, fuel oil, blast furnace (top) gas. Coke is obtained from coking grades of coal by dry distillation at T = 10000C.

Refractory materials are materials and products primarily based on mineral raw materials that have a fire resistance of at least 15800C. They are used for the manufacture of the internal facing layer (lining) of metallurgical furnaces and ladles for molten metal.

Iron and steel production

Materials used in blast furnace production and their preparation for smelting.

Iron ores, fuel, and fluxes are used to smelt cast iron in blast furnaces.

Ores: Iron ores contain (55...60%) iron in various compounds (oxides, hydroxides, carbonates, etc.), as well as waste rock.

Manganese ores are used for smelting an alloy of iron and manganese - ferromanganese, as well as pig iron. Chromium ores are used for the production of ferrochrome, chromium metal and refractory materials - chromium magnesites. Complex ores are used for smelting naturally alloyed cast iron. These are ferromanganese ores, chromium-nickel ores, and iron-vanadium ores.

Fuel: coke - to obtain the required temperature and create conditions for the recovery of iron from ore; In order to save money, part of the coke is replaced with natural gas, fuel oil, and pulverized fuel.

Fluxes: this is limestone CaCO3 or dolomitized limestone containing CaCO3 and MgCO3. This is necessary to remove sulfur from the metal into which it is transferred from coke and iron ore during smelting. For normal operation of a blast furnace, the slag must be sufficiently fluid at a temperature of 14500C.

Preparation of ores for blast furnace smelting.

The purpose of this preparation is to increase the iron content in the charge and reduce harmful impurities in it - sulfur, phosphorus, as well as increase uniformity in lumpiness and chemical composition:

- crushing and sorting of ores by size serves to obtain pieces of optimal size for smelting;

- ore beneficiation: gravity (jigging) is the separation of ore from gangue by passing a stream of water through the bottom of a vibrating screen on which the ore rests. Magnetic separation is based on the difference in the magnetic properties of iron-containing minerals and gangue particles;

- agglomeration is carried out to process concentrates obtained after enrichment into lump materials of the required size;

Two methods of agglomeration are used.

- Agglomeration is the sintering of a fine charge and the removal of sulfur and arsenic. The result is a piece of porous fluxed material - an agglomerate.

- Pelleting is the rolling of a charge from crushed concentrates, flux, fuel, all of this is moistened, and when processed in rotating drums, pellet balls with a diameter of up to 30 mm are obtained.

Iron smelting.

Cast iron is smelted in shaft-type furnaces - blast furnaces (Fig. 1). The essence of the process of producing cast iron in blast furnaces is the reduction of iron oxides included in the ore with carbon monoxide, hydrogen released during combustion of fuel in the furnace and solid carbon released during combustion of fuel in the furnace. In Fig. — photograph of a mine-type blast furnace.

When the furnace is operating, the charge materials, having been melted, are lowered, and new portions of the charge are fed into the furnace through the loading device in such quantities that the entire useful volume of the furnace is filled. The useful volume of the furnace is the volume occupied by the charge from the bottom to the lower edge of the large cone of the filling apparatus when it is lowered. Modern blast furnaces have a useful volume of 2000...5000 m3. The useful height H of a blast furnace reaches 35 m.

The operating efficiency of a blast furnace is characterized by the residence time of the charge in the blast furnace (5–6 hours) and the duration of the operation (5–6 years or more of continuous operation).

Physico-chemical processes of blast furnace smelting.

Conventionally, the processes occurring in a blast furnace are divided into:

- fuel combustion;

- decomposition of charge components;

- iron recovery;

- carburization of iron;

- recovery of manganese, silicon, phosphorus, sulfur;

- slag formation;

Fuel combustion . Near the tuyeres, the carbon of the coke interacts with oxygen in the air and burns. At the same time, in the furnace slightly above the level of the tuyeres, temperatures above 20,000C develop.

Iron recovery . The charge (sinter, coke) falls towards the gas flow, and at a temperature of 500...5700C the reduction of iron oxides begins. The reduction of iron from ore in a blast furnace occurs as the charge moves down the furnace shaft and the temperature rises in several stages - from the highest oxide to the lowest:

Fe2O3 → Fe3O4 → FeO → Fe.

Carburization of iron . In the blast furnace shaft, along with the reduction of iron, its carburization also occurs when interacting with carbon monoxide (CO2), coke, and black carbon. This leads to the formation of a liquid melt, which begins to flow in drops into the furnace.

Thus, as a result of the process of reduction of iron oxides, part of the oxides of manganese and silicon, phosphates and sulfur compounds, dissolution of C, Mn, Si, P, S in iron in a blast furnace, cast iron is formed.

Slag formation . Slag formation actively occurs in steam after the completion of iron reduction processes by fusing fluxes added to the blast furnace to ensure sufficient fluidity at a temperature of 1400...15000C, waste rock oxides and coke ash. The slag flows into the furnace and accumulates on the surface of the liquid cast iron due to its lower density.

Cast iron is released from the furnace every 3...4 hours, and slag every 1...1.5 hours. Cast iron is transported to oxygen-converter or open-hearth shops for conversion into steel. Cast iron not used in liquid form is poured into the molds of a casting machine, where it solidifies into ingots weighing 45 kg.

Rice. 1. Construction of a blast furnace : 1 – hearth; 2 – air duct; 3 – shoulders; 4 – steam; 5 – shaft; 6 – fire pit; 7 – receiving funnel; 8 – filling device; 9 – trolley; 10 – small cone; 11 – bowl; 12 – bridge; 13 - large cone (prevents the release of gases from the blast furnace into the atmosphere).

To ensure uniform distribution of the charge in the blast furnace, the small cone and the receiving funnel after the next loading are rotated through an angle that is a multiple of 60°.

Rice. Mine type blast furnace

Blast furnace products.

Cast iron is the main product of blast furnace smelting:

- Pig iron is smelted to convert it into steel in converters or in open-hearth furnaces. It contains 4...4.4% C, 0.6...0.8% Si, 0.25...1.5% Mn, 0.15...0.3% P and 0.03...0.07% S.

- Foundry cast iron is used in machine-building factories in the production of shaped castings. In addition to cast iron, ferroalloys - alloys of iron with silicon, manganese and other elements used for deoxidation and alloying of steel;

- By-products of blast furnace smelting are slag and blast furnace gas. Slag wool and cement are made from slag, and blast furnace gas, after purification, is used as fuel to heat the air blown into the blast furnace.

In Fig. Figure 3 shows the release of cast iron from a blast furnace.

Rice. 3. Release of cast iron from the blast furnace into ladles

Steel production.

The essence of the process. The essence of any metallurgical processing of cast iron into steel is to reduce the content of carbon and impurities by selectively oxidizing them and converting them into slag and gases during the smelting process.

The main materials for steel production are pig iron and steel scrap ( scrap ). The content of carbon and impurities in steel is significantly lower than in cast iron.

Steel smelting processes are carried out in several stages. The first stage is melting the charge and heating the liquid metal bath.

At this stage, the temperature of the metal is low; The oxidation of iron occurs intensively, the formation of iron oxide and the oxidation of Si, P, Mn impurities. The most important task of this process is to remove phosphorus (one of the harmful impurities in steel).

The second stage - “boiling” of the metal bath - begins as it warms up to higher temperatures than in the first stage. The boiling bath is the main thing in the steel smelting process.

During the same period, conditions are created for removing sulfur from the metal. The higher the temperature, the greater the amount of FeS dissolves in the slag, i.e. more sulfur passes from the metal to the slag.

The third (final) stage - steel deoxidation - involves the reduction of iron oxide dissolved in the liquid metal.

When melting, an increase in the oxygen content in the metal is necessary for the oxidation of impurities, but in finished steel oxygen is a harmful impurity, as it reduces the mechanical properties of steel, especially at high temperatures.

Steel is deoxidized in two ways:

- besiegers;

- diffusion.

Precipitating deoxidation is carried out by introducing soluble deoxidizers (ferromanganese, ferrosilicon, aluminum) into liquid steel. As a result, iron is reduced, and the resulting oxides of manganese, silicon and aluminum are removed into slag.

Diffusion deoxidation is carried out by deoxidation of slag. Ferromanganese, ferrosilicon and other deoxidizing agents in finely divided form are loaded onto the surface of the slag.

Depending on the degree of deoxidation, calm , boiling and semi-quiet steels .

Calm steel is obtained by complete deoxidation in the furnace and ladle. Boiling steel is not completely deoxidized in the furnace. Its deoxidation continues in the mold as the ingot solidifies due to the interaction of FeO and carbon contained in the metal. Gases are released in the form of bubbles, causing it to boil. Boiling steel does not contain non-metallic inclusions - deoxidation products, therefore

has good ductility.

Semi-quiet steel has an intermediate deoxidation between calm and boiling.

Alloying of steel is carried out by introducing ferroalloys or pure metals in the required quantity into the melt.

Alloying elements (Ni, Co, Mo, Cu), whose affinity for oxygen is lower than that of iron, practically do not oxidize during melting and casting, and therefore they are introduced into the furnace at any time during melting (usually along with the rest of the charge). Alloying elements whose affinity for oxygen is greater than that of iron (Si, Mn, Al, Cr, V, Ti, etc.) are introduced into the metal after deoxidation or simultaneously with it at the end of melting, and sometimes directly into the ladle.

Technological processes of steel production.

Steels are produced in metallurgical units of various operating principles: oxygen converters, electric and induction furnaces, etc.

Steel production in oxygen converters.

The oxygen-converter process is the smelting of steel from liquid cast iron in a converter with a main lining (magnesite and dolomite) and blowing oxygen through a water-cooled mold (Fig. 4.).

Before melting, the converter is tilted (Fig. 4.1), scrap is loaded through the neck using filling machines, and cast iron is poured at a temperature of 1250 - 1400 ° C. After this, the converter is turned into a vertical working position, a water-cooled form is inside it, and oxygen is supplied through it at a pressure of 0.9 - 1.4 MPa. Simultaneously with the start of blowing, lime, bauxite, and iron ore are loaded into the converter (Fig. 4.2). Oxygen jets penetrate the metal, cause it to circulate in the converter and mix with the slag. Due to the intense oxidation of cast iron impurities when interacting with oxygen, a temperature of up to 2400°C develops in the area under the tuyere.

The oxygen supply is stopped when the carbon content in the metal corresponds to the specified value. After this, the converter is turned and the steel is released into the ladle (Fig. 4, 3).

When steel is released from the converter, it is deoxidized in a ladle using the precipitation method with ferromanganese, ferrosilicon and aluminum; then the slag is drained from the converter (Fig. 4.4).

Converter capacity is 70 – 350 tons of molten cast iron.

Figure 4. Sequence of technological operations when melting steel in oxygen converters

The charge materials of the oxygen converter process are:

- liquid cast iron;

- steel scrap (no more than 30%);

- lime for removing slag;

- iron ore;

- bauxite (Al2O3) and fluorspar (CaP2), to liquefy the slag.

In an oxygen converter, due to the presence of slags with a high content of CaO and FeO, and the mixing of metal and slag, conditions are created for removing phosphorus from the metal at the beginning of purging the bath with oxygen, when its temperature is not yet high. Cast iron processed in converters should not contain more than 0.15% P and 0.07% S.

In oxygen converters they smelt: structural steels with different carbon contents, boiling and calm.

It is difficult to smelt steels containing easily oxidizing alloying elements in oxygen converters, so low-alloy steels (up to 2–3% of alloying elements) are smelted in them. Alloying elements are introduced into the ladle, melting them in an electric furnace, or hard ferroalloys are introduced into the ladle before releasing steel from it. Melting in converters with a capacity of 130 - 300 tons ends in 25 - 30 minutes.

Steel production in electric furnaces.

Electric melting furnaces have advantages over other melting units, since they can produce a high temperature of the metal, creating an oxidizing, reducing, neutral atmosphere and vacuum, which makes it possible to smelt steel of any composition, deoxidize the metal with the formation of a minimum amount of non-metallic inclusions - deoxidation products. Therefore, electric furnaces are used for smelting structural, high-alloy, tool, and special alloys and steels.

Arc and induction furnaces are used for melting steel (Fig. 5).

Figure 5 . Diagram of an electric arc melting furnace

The arc melting furnace operates on three-phase alternating current. Electric current from a transformer with a power of 25 - 45 kV *A. Operating voltage 160 – 600 V, current 1 – 10 kA. During operation of the furnace, the arc length is adjusted automatically by moving the electrodes. In Fig. 6 shows an arc melting furnace.

Rice. 6. DC electric arc melting furnace

Rice. 7. Production of steel from an electric arc melting furnace

The capacity of these furnaces is 0.5 - 400 tons. In metallurgical shops, electric furnaces with a basic lining are used, and in foundries - with an acid lining.

To determine the chemical composition of the metal, samples are taken and, if necessary, ferroalloys are introduced into the furnace to obtain the desired chemical composition of the metal, after which the final stage of deoxidation is performed, steel is made with aluminum and silico-calcium and the metal is released from the furnace into the ladle (Fig. 7.

When smelting alloy steels in arc furnaces, alloying elements in the form of ferroalloys are introduced into the steel.

Induction crucible melting furnace (Figure 8).

Single-phase alternating current passes through the inductor (4) from an industrial frequency generator (50 Hz) or from a high frequency generator (500 - 2500 Hz). The current creates an alternating magnetic flux that passes through the pieces of metal in the crucible. The alternating magnetic flux induces powerful Foucault eddy currents (1) in them, heating the metal until it melts and reaches the required overheating temperatures. The crucible is made from basic or acidic refractories (5). Crucible capacity 60 kg – 25 tons. (2) – roof of the crucible furnace. (3) – neck for draining metal.

Figure 8. Diagram of an induction crucible melting furnace

Induction furnaces have advantages over arc furnaces: they do not have an electric arc, which makes it possible to smelt steel with a low content of carbon, gases and low waste of elements; during melting, electrodynamic forces arise in the metal, which mix the metal and contribute to the equalization of the chemical composition and the floating of non-metallic inclusions; The small size of the furnaces allows them to be placed in chambers where any atmosphere or vacuum can be created.

However, these furnaces have low lining durability, and the temperature of the slag in them is insufficient for metallurgical processes to occur between metal and slag.

In induction furnaces with a main lining, high-quality alloyed steels with a high content of manganese, nickel, titanium, and aluminum are smelted, and in acid-lined furnaces, structural, alloyed steels are smelted.

During vacuum induction melting, an inductor with a crucible, a batch dispenser and molds are placed in vacuum chambers. Melting, introduction of alloying additives, deoxidizers, and casting of metal into molds are carried out without breaking the vacuum in the chamber. In this way, high-quality alloys with a low content of gases, non-metallic inclusions, and alloys alloyed with any elements are obtained. In Fig. 9. shows an induction crucible melting furnace.

Rice. 9. Induction crucible melting furnace

In Fig. 10 recorded the working torque of steel melting in an induction crucible melting furnace.

Rice. 10 . Melting steel in an induction crucible melting furnace

Steel casting (Fig. 11; 12; 13).

The smelted steel is released from the melting furnace into a ladle, from which it is poured into the molds or crystallizers of a continuous casting machine (CCM). In molds or crystallizers, steel hardens, and ingots are obtained, which are subjected to rolling and forging.

Rice. 11. Scheme of pouring steel from above directly from the ladle

Rice. 12. Siphon casting of steel : where 1 - ladle, 2 - center sprue, 3 - siphon bricks, 4 - pallet, 5 - molds, 6 - slag catchers, 7 - refractory mass

Large weight ingots (up to 200 tons) are cast on top, as well as some types of alloy steel (high-speed, ball bearing, etc.), in which a minimum content of non-metallic inclusions is permissible.

Using the siphon method, from ladle 1 through center sprue 2, depending on the weight of ingots, from two to 60 are simultaneously poured.

100 molds. In this case, the metal, passing through the center sprue 2, enters through a system of channels formed by special siphon bricks 3 in a cast iron pan 4, to each mold 5. Advantages of the siphon method: a large number of ingots can be cast in one stream, the surface of the ingots is clean due to the reduction in height and the volume of the shrinkage cavity, you can obtain high-quality ingots weighing up to 20-30 g of steel. The disadvantage of siphon casting is the labor-intensive work of assembling molds for casting and the high consumption of metal on the gates. Therefore, this method is not used when casting expensive steels.

A progressive method is continuous casting of steel (Fig. 13).

Metal from the ladle is poured in a continuous stream into the intermediate device, and from it enters water-cooled crystallizers, into which steel blanks are preliminarily placed to form the bottom. When liquid metal comes into contact with these workpieces

(seeds) and the walls of the crystallizers, its rapid solidification begins, further intensifying when passing through the secondary cooling zone. The hardened billet is pulled out by rollers operating from a special mechanism to the carts of the gas cutters, cut into pieces, and then transported along a conveyor to the rolling shop. The use of the method of continuous casting of steel makes it possible to reduce metal waste from 15-20% during conventional casting to 3-5%, i.e. 5 times.

Rice. 13. Diagram of a continuous casting machine (CCM) Molds - cast iron molds for the production of ingots (square,

rectangular, round or polyhedral cross-sections). Square ingots are converted into rolled products (I-beams, channels, angles, etc.). Rectangular ingots are converted into sheets. Pipes and wheels are made from round ingots. Multifaceted ingots are used for forgings.

For rolling, ingots weighing 200 kg - 25 tons are cast; for forgings – weighing 300 tons or more. Typically, carbon calm and boiling steels are poured into ingots weighing up to 25 tons, alloy and high-quality steels into ingots weighing 500 kg - 7 tons, and some types of high-alloy steels into ingots weighing several kilograms.

Continuous casting machines can have several crystallizers, which makes it possible to simultaneously produce several ingots, which can be rolled on section mills, bypassing blooming and slabging.

Ingot structure.

The steel poured into the molds transfers heat to its walls, so the solidification of the steel begins at the walls of the mold. The thickness of the crystallized crust continuously increases, while between the liquid core of the ingot and the solid crust of the metal there is a zone in which there are simultaneously growing crystals and liquid metal between them. Crystallization of the ingot ends near its longitudinal axis.

The steel hardens into tree-shaped crystals called dendrites.

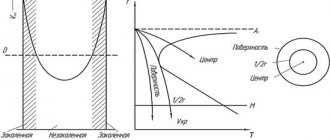

The sizes and shapes of dendrites depend on the crystallization conditions (Fig. 14).

Rice. 14. Scheme of the structure of steel ingots : a, d – mild steel; b, d – boiling steel; c, d – semi-quiet steel;

A – thin outer crust of fine-grained crystals; B – zone of large columnar crystals (dendrites); B – zone of large unoriented crystals; D – fine-crystalline zone at the bottom of the ingot.

Calm steel hardens without the release of gases, a shrinkage cavity is formed in the upper part of the ingot, and shrinkage axial looseness is formed in the middle.

Steel ingots are heterogeneous in chemical composition. Chemical heterogeneity, or segregation, occurs due to a decrease in the solubility of impurities in iron during its transition from a liquid to a solid state. Liquation is of two types - dendritic and zonal.

Dendritic segregation is the heterogeneity of steel within one crystal (dendrite) - the central axis and branches. For example, during the crystallization of steel, the sulfur content at the boundaries of the dendrite compared to the content in the center increases by 2 times, phosphorus by 1.2 times, and carbon decreases by almost half.

Zonal segregation is the heterogeneity of steel composition in different parts of the ingot. In the upper part, due to the convection of the liquid metal, the content of sulfur, phosphorus and carbon increases several times, and in the lower part it decreases. Zonal segregation leads to metal rejection due to deviation of its properties from the specified ones. Therefore, the profitable and profitable parts of the ingot, as well as its bottom part, are cut off during rolling.

In ingots of boiling steel, no shrinkage cavities are formed: the shrinkage of steel is dispersed throughout the cavities of gas bubbles that arise during boiling of the steel in the mold. When the ingot is rolled, gas bubbles are welded.

Semi-quiet steel retains the advantages of calm and boiling steels and does not have their disadvantages.

Semi-quiet steel is partially deoxidized in the furnace and ladle, and partially in the mold. An ingot of semi-quiet steel has the structure of calm steel in the lower part, and boiling steel in the upper part. The segregation in the upper part of the semi-quiet steel ingot is less than that of the boiling steel, and is close to the segregation of the calm steel, but the semi-quiet steel ingots do not have shrinkage cavities.

Methods for improving the quality of steel.

The development of mechanical engineering and instrument making places increasing demands on the quality of the metal: its strength, ductility, and gas content. These indicators can be improved by reducing harmful impurities, gases, and non-metallic inclusions in the metal.

To improve the quality of metal use:

- processing of metals with synthetic slag;

- vacuum degassing of metal;

- electroslag remelting (ESR);

- vacuum arc remelting (VAR);

- metal remelting in electron beam and plasma furnaces, etc.

Processing metal with synthetic slag is as follows: liquid slag is mixed with liquid steel,

a reaction in which the content of sulfur, oxygen and non-metallic inclusions in steel decreases. Its ductility and strength increase. Such steels are used for the manufacture of critical machine parts.

Evacuation of steel is carried out to reduce the concentration of oxygen, hydrogen, nitrogen and non-metallic inclusions. Various methods are used for evacuation, for example, evacuation in a ladle, circulation and flow evacuation, jet and batch evacuation, etc.

Electroslag remelting (Fig. 15). ESR is used for smelting high-quality steels for ball bearings, heat-resistant steels for turbine disks and blades, compressor shafts, and aircraft structures. Metal melted in an arc furnace and rolled into round rods is subjected to remelting. The source of heat in ESR is a slag bath, heated when an electric current passes through it. An electric current is supplied to the remelted electrode, immersed in a slag bath, and to a tray installed in a water-cooled metal crystallizer in which the seed is located. In Fig. 16. shows an installation for electroslag remelting of steel.

Rice. 15. Scheme of electroslag remelting of a consumable electrode : a – crystallizer; b – switching on the installation 1 – electrode; 2 – slag bath; 3 – drops of metal; 4 – metal; 5 – crust; 6 – ingot; 7 – crystallizer; 8 – seed; 9 – pallet.

Rice. 16. Installation of electroslag remelting of steel

Vacuum arc remelting (VAR) is used to remove gases and non-metallic inclusions from metal. The process is carried out in vacuum arc furnaces with a consumable electrode. In Fig. 17. The diagram in Fig. is shown. 18. Installation of vacuum-arc steel remelting.

Rice. 17. Scheme of vacuum-arc remelting: 1 – body; 2 – water-cooled rod; 3 – electrode-cathode; 4 – drops of liquid metal; 5 – liquid metal; 6 – mold; 7 – ingot; 8 – seed-anode

Depending on the requirements for the resulting metal, a consumable electrode is produced by mechanical processing of an ingot smelted in electric furnaces or in ESR installations.

VAR ingots contain little gases and non-metallic inclusions, are characterized by a highly uniform chemical composition and improved mechanical properties. They are used to make critical parts of turbines, engines, and aircraft structures. The weight of the ingots reaches 50 tons.

Rice. 18. Installation of vacuum-arc steel remelting

Melting in electron beam furnaces (Fig. 19) is used to obtain pure and ultra-pure refractory metals (molybdenum, niobium, zirconium, etc.) and for the smelting of special alloys and steels.

The vacuum inside the furnace, high overheating caused by an electron beam directed at the metal, and high cooling rates of the ingot help remove gases and impurities, producing metal of particularly high quality. However, when remelting a charge containing easily evaporating elements, the chemical composition of the metal is changed.

Rice. 19 Diagram of an electron beam furnace

Melting steel in plasma-arc furnaces (Fig. 20) is used to produce high-quality steels and alloys.

The heat source is low-temperature plasma (30,000°C) produced in plasma torches. In these furnaces it is possible to create a neutral environment of a given composition (argon, helium). Plasma-arc furnaces make it possible to quickly melt the charge, and in a neutral gas environment the smelted metal is degassed; the volatile elements included in its composition do not evaporate.

Rice. 20. Installation of a plasma-arc furnace

Characteristics of cast iron

Iron and carbon are also the basis of cast iron. The amount of the latter is from 2%. Raw materials are also doped with various additives: phosphorus, manganese, silicon and others.

Depending on the formed crystal lattice (cementite / graphite), the following types of cast iron are distinguished:

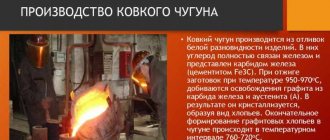

- white - the presence of cementite determines the color of the fracture, due to which the material received the name “white”; at the same time it is hard and brittle; malleable cast iron is made from it by annealing;

- gray - the content of graphite in large quantities determines the color of the raw material and its plasticity, is easy to process, the composition includes silicon, magnesium, phosphorus, sulfur;

- malleable - long-term annealing of white cast iron forms graphite, which gives the metal high ductility, toughness, hardness, and impact resistance;

- high-strength - the formation of spherical graphite during the crystallization process provides the material with increased strength;

- marginal - subject to further processing, not used as an independent unit.

The melting point of cast iron ranges from 1160 to 1250 °C, depending on the carbon content in it. The more element in the composition, the lower its temperature and the higher its fluidity when heated. This dependence determines the fragility of the material.

Production of non-ferrous metals

Copper production.

Copper is obtained mainly by pyrometallurgical methods. Pyrometallurgy is a set of metallurgical processes occurring at high temperatures. The production of copper from copper ores includes their beneficiation, roasting, smelting into an intermediate product - matte , smelting blister copper from the matte (converting) and its purification from impurities ( refining ).

For the production of copper, copper ores containing 1–6% Cu, as well as copper waste and its alloys are used.

Blister copper contains 98.4 – 99.4% Cu and a small amount of impurities. This copper is poured into molds. Blister copper is refined to remove harmful impurities and gases.

After fire refining, copper with a purity of 99 - 99.5% is obtained (Fig. 21). Pigs are cast from it for smelting copper alloys (bronze and brass) or plates for electrolytic refining. Electrolytic refining is carried out to obtain pure copper from impurities (more than 99.5% Cu).

Rice. 21. Production of refined copper

Aluminum production.

The main method of aluminum production currently is electrolytic. Electrolysis is a set of electrochemical oxidation-reduction processes that occur on electrodes immersed in an electrolyte during the passage of an electric current.

The main raw materials for aluminum production are aluminum ores: bauxite , nepheline, alunite, kaolin.

Aluminum production includes:

- obtaining anhydrous, impurity-free aluminum oxide (Al2O3 alumina). Alumina is obtained from bauxite by treating it with alkali;

- obtaining cryolite from fluorspar 2H3AlF6;

- electrolysis of alumina in molten cryolite;

During the electrolysis process, aluminum collects at the bottom of the bath under a layer of electrolyte. It is periodically removed using a special device. For normal operation of the bath, a little aluminum is left at the bottom (Fig. 22.

Aluminum produced by electrolysis is called raw aluminum. It contains metallic and non-metallic impurities and gases. Impurities are removed by refining, for which chlorine is blown through molten aluminum. Then the liquid aluminum is kept in a ladle or in an electric furnace for 30 - 45 minutes at a temperature of 690 - 730 ° C to float non-metallic inclusions and release gases from the metal. After refining, the purity of primary aluminum is 99.5 – 99.85%. In Fig. 23. photograph of the Ural Aluminum Plant.

Rice. 22. Aluminum production

Rice. 23. Ural Aluminum Plant

Magnesium production.

For the production of magnesium, the electrolytic method is most widespread (Fig. 24).

Rice. 24. Magnesium production scheme

The main raw materials for the production of magnesium are carnallite, magnesite, dolomite, and bischofite.

Magnesium production includes:

- obtaining pure anhydrous magnesium salts (magnesium chloride MgCl2);

- electrolysis of these salts in a molten state, obtaining rough magnesium which contains 5% impurities;

- refining of crude magnesium, i.e. melt it with fluxes at a temperature of 700...750°C and mix. Non-metallic impurities turn into slag. Then the furnace is cooled to a temperature of 670°C, and magnesium is poured into molds into pigs.

Steel production in converters.

The converter is a pear-shaped vessel. The upper part is called a visor or helmet. It has a neck through which liquid cast iron and steel and slag are drained. The middle part has a cylindrical shape. In the lower part there is an attached bottom, which is replaced with a new one as it wears out. An air box is attached to the bottom, into which compressed air enters.

The capacity of modern convectors is 60 - 100 tons or more, and the air blast pressure is 0.3-1.35 Mn/m. The amount of air required to process 1 ton of cast iron is 350 cubic meters.

Before pouring cast iron, the convector is turned to a horizontal position, at which the tuyere holes are above the level of the poured cast iron. Then it is slowly returned to a vertical position and at the same time a blast is applied, which prevents the metal from penetrating through the holes of the tuyeres into the air box. In the process of blowing air through liquid cast iron, silicon, manganese, carbon and partially iron burn out.

When the required carbon concentration is reached, the convector is returned to a horizontal position and the air supply is stopped. The finished metal is deoxidized and poured into a ladle.

Bessemer process. Liquid cast iron with a fairly high content of silicon (up to 2.25% and higher), manganese (0.6-0.9%), and a minimum amount of sulfur and phosphorus is poured into the converter.

Based on the nature of the reaction occurring, the Bessemer process can be divided into three periods. The first period begins after the blast is started in the converter and lasts 3-6 minutes. Small drops of liquid cast iron fly out of the converter neck along with the gases, forming sparks. During this period, silicon, manganese and partially iron are oxidized according to the reactions:

Si + O2 = SiO2,

2Mn + O2 = 2MnO,

2Fe + O2 = 2FeO.

The resulting ferric oxide partially dissolves in the liquid metal, promoting further oxidation of silicon and manganese. These reactions occur with the release of a large amount of heat, which causes the metal to heat up. The slag turns out to be acidic (40-50% SiO2).

The second period begins after almost complete burnout of silicon and manganese. The liquid metal is heated well enough that favorable conditions are created for the oxidation of carbon by the reaction C + FeO = Fe + CO, which occurs with the absorption of heat. The combustion of carbon lasts 8-10 minutes and is accompanied by a slight decrease in the temperature of the liquid metal. The resulting carbon monoxide burns in air. A bright flame appears above the convector neck.

As the carbon content in the metal decreases, the flame above the neck decreases and the third period begins. It differs from previous periods in the appearance of brown smoke above the neck of the converter. This shows that silicon, manganese and carbon have almost completely burned out of the cast iron and very strong oxidation of iron has begun. The third period lasts no more than 2–3 minutes, after which the convector is turned over to a horizontal position and deoxidizing agents (ferromanganese, ferrosilicon or aluminum) are introduced into the bath to reduce the oxygen content in the metal. Reactions occur in the metal

FeO + Mn = MnO + Fe,

2FeO + Si = SiO2 + Fe,

3FeO + 2Al = Al2O3 + 3Fe.

The finished steel is poured from the convector into a ladle and then sent for casting.

To obtain steel with a predetermined amount of carbon (for example, 0.4 - 0.7% C), blowing the metal is stopped at the moment when the carbon has not yet burned out of it, or you can allow the carbon to completely burn out, and then add a certain amount of cast iron or carbon containing a certain amount of ferroalloys.