In the modern world, a meat grinder is still considered the most popular kitchen device. This device cannot fully replace any food processor or blender. To prepare homemade minced meat, you must correctly assemble the device, install all the parts in their places, especially the knife, because the quality of the meat component depends on it. A universal unit is necessary for preparing pates, homemade sausages, vegetable purees, juice extraction, minced meat, noodles.

Design of meat grinders: types and features

These devices are produced in a wide range, however, they come in only two types: manual and electric. The versatility of the devices is created using a large number of different attachments.

Electric analogues are especially popular at the moment. In order to process the ingredients, it is enough to place them in the meat receiver compartment, press the start button, and the products will begin to be processed. However, in addition to the advantages, this design has disadvantages:

- there is no way to control the presence of bones, and if they are caught, the device may deteriorate;

- in the absence of electricity, it is impossible to cook minced meat on such a device;

- If the engine burns out, processing of the ingredients will not work.

The design of electrical devices consists of the following parts:

- Housing made of durable plastic material;

- A motor that performs manipulations when the start key is pressed;

- Lack of handle and clamp;

- Most models have a removable meat receiver, which is installed before food processing begins;

- The presence of convexities on the surface of the knife for gentle chopping;

- At the screw end there is a plastic corrugated rod to ensure high-quality fixation.

Healthy! Plastic may pose some health hazards. To avoid this negative phenomenon, the composition of the plastic material should be clarified.

Many housewives claim that mechanical analogues are already outdated, but they continue to delight users with their reliability and durability. This type of device almost never fails; the only unfavorable factor is the dullness of the knives. These working elements can be easily sharpened with your own hands, with a minimum of effort. The body of manual meat grinders is made of reliable stainless steel, cast iron, and, less commonly, aluminum.

The design of a mechanical product includes the following components:

- The case is made of reliable metal, has a clamp to install the unit on various surfaces;

- Screw element - screw rod;

- A knife for chopping components, can be disk or with wings;

- Tightening ring for fixation;

- Handle attached with a screw;

- Grids having holes of different diameters.

Healthy! Mechanical devices are not very functional, but will last a long time without breakdowns. Such devices can handle any type of meat and will not be damaged if a bone gets in.

Additional components of the meat grinder

How to properly place a knife in a meat grinder

The assembly process itself is very simple, but it is important to know how to install the knife correctly so that the device effectively processes food. The cutting part consists of the main elements:

- Convex smooth surface;

- The flat part having cutting edges;

- A hole in the center, which is made in the form of a screw tip.

When assembling a manual meat grinder, you should follow the main rule - the knife is installed with a flat surface outward. If you miss this criterion, the device will press on the meat without chopping it. In a circular knife, the edges are clearly visible, so they should also be with the cutting surface on top. In cases where problems arise with the processing of ingredients, it is necessary to check the correct installation of the cutting part and other working parts.

In electric models, the assembly of the structure is more difficult, because two knives are used simultaneously. The double-sided element must be installed on the auger, after which the grid is fixed, a second knife and a grid with small holes are installed on top, and the structure is secured with a fixing ring.

Important! In order for the unit to grind food efficiently, all parts must be accurately installed. If processing fails, all working elements must be rechecked for correct assembly.

What does a meat grinder consist of and what is the purpose of the parts?

The design of this type of kitchen appliance consists of durable plastic. And if in the case of a manual one, the entire body consists of metal, then in this case there are only individual metal elements. A motor is built into this body, which performs the main function. By pressing the start button, the device is activated and begins to work.

Another difference is the absence of a handle. There is simply no need for it here, since the machine performs the main function independently, from the operation of the engine. Almost all models have a removable meat receiver, which must be attached to the main body before starting work.

The kit usually includes a special pusher for the food being processed, with which it is convenient to move the food towards the knife. At the end of the screw there is a corrugated plastic rod that provides fixation. And thanks to the convexities on the knife, more gentle and high-quality chopping of meat occurs. This is one of the differences between the new model and the old one.

What does a classic hand-held device consist of:

- Building: A. Meat receiving area; B. Fastening clamp;

- Lever;

- Auger with left-hand thread;

- Bearing bushing;

- Cutting knife with 4 blades;

- Lattice;

- Union nut;

- Eye bolt for attaching the handle

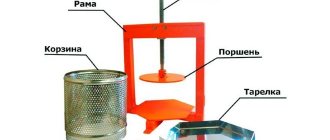

Meat grinder disassembled

The device can also be supplied with additional grates with different hole diameters, knives, attachments for making sausages, frankfurters and freshly squeezed juice.

The attachments must be sharpened regularly and should not be used for cutting too hard or stringy semi-finished meat products.

The screw shaft is an important and basic part. It has the appearance of a spiral, which during operation grinds excess meat, moving it towards the nozzles with knives. It is this mechanism that requires the use of durable metal.

Screw shaft - conductor of products inside the device

Knife and special cutting attachments. They do all the work of grinding, cutting and crushing meat or any other products. It is made mainly from stainless materials. It is necessary to sharpen knives for better and high-quality work, even though the steel is sharpened on the grate during rotation.

The structure of the knife and its shape affect the grinding of the product. For example, if a knife has a curved blade, it means that it will easily chop the veins and fibers of meat, while preventing the auger shaft from clogging.

The grid has three types of hole diameters:

- Very large - 12 mm. Grille with three or four holes. Used for stuffing sausages. Not always included.

- Large holes - 8 mm. This rack is ideal for preparing sausage mince.

- The middle holes are 4-4.5 mm. Universal grid. Suitable for preparing minced meat for cutlets. Included.

- Small holes - 3 mm. Pate lattice. It is ideal for making pate or puree.

We suggest you read How to clean a machine with soda

Using these grates you can get coarse or finely ground minced meat. It all depends on your preferences

The nut (fixing ring) clamps and secures the grid, knife and auger shaft. Sometimes it can be difficult to unscrew it after finishing work. But this problem can easily be solved with the help of ordinary cloth thrown over the nut. So, the hand does not slip, and the part can be easily unscrewed.

A manual cast iron or aluminum meat grinder, especially from Soviet times, is attached to the work surface using a threaded device (foot). And therefore, in order to prevent the device from moving on the table, you need to place something under the metal base. This can be a newspaper folded several times. In modern models, the mounting base is plastic or rubber, and therefore the device is attached to the table much more securely.

How to assemble a meat grinder: instructions

Manual meat grinder

A simple device requires special attention when connecting all the parts to obtain the desired result. In this process, the main thing is to follow the operating instructions for the unit attached to the product.

The assembly of the mechanical structure is carried out in the following steps:

- the shaft is placed inside the housing, the sealed part is located on the side of the handle, and the remaining elements are located at the narrowed end;

- the cutting part is inserted with its flat side against the grate for comfortable sliding of the knife along it, the edges are positioned outward so that the products are properly chopped;

- the disk version is also placed with the cutting parts to the lattice part;

- the grille is made with a special groove, which is inserted into a protrusion on the body of the device. This product should be fixed so that it fits tightly to the knife;

- the main ring is screwed in as a clamping part, while reliably fixing all the components located inside the housing;

- a handle is attached to create a rotating manipulation, after which the device is mounted on the edge of the table.

Assembling a manual meat grinder is not at all difficult if you follow the operating instructions. The whole process does not take much time or much effort.

How to properly assemble a manual meat grinder if you need to install an attachment

Most meat grinders are equipped with various attachments and grates for making sausages, sausages, juice and many other delicacies. But not everyone knows how to correctly insert an attachment, knife or grid into a meat grinder. After all, the procedure for assembling a meat grinder with an attachment is slightly different:

- Insert the screw shaft into the main body . The wide part of the shaft is placed in the place where the handle is attached. The thin one should be in the place where the grille is attached;

- then install the grate . It can have very large or medium holes. It all depends on the recipe and your preferences;

- then install the nozzle . Just make sure that there are no chips or roughness on it. Otherwise, you risk tearing the intestine, which is put on the nozzle when making sausages and kebbe;

- secure the structure with a clamping nut , and now all that remains is to screw the handle. That's all. Nothing complicated. Is not it?

When making sausages and kebbe, no knife is used. And all because ready-made minced meat is put into a meat grinder with such attachments;

Tips for care and disassembly for cleaning

Upon completion of use of the device, it must be disassembled into individual parts and thoroughly cleaned so that all contaminants are removed. It is prohibited to wash the meat grinder in the assembled state, because in a mechanical unit it will not be possible to remove food residues, and in electrical equipment such a situation can lead to a short circuit.

Key points for caring for the device:

- the removable meat receiver is removed from the body;

- the clamping nut is removed, while the internal contents must be lightly held;

- the grid and knife are removed, the screw securing the handle is unscrewed;

- the auger is removed from the structure;

- all parts are washed under running water, and the holes are cleaned with a toothpick or match;

- The products are dried on a napkin until the moisture is completely removed.

Important! It is not recommended to assemble a wet meat grinder! If moisture remains on the parts, corrosion may occur, and in electrical units the liquid can lead to motor combustion.

Minced meat dishes have always been popular in catering establishments. And in fact, not a single canteen menu is complete without cutlets, zrazy, meatballs, cabbage rolls! And to cook them in the right quantity requires a lot of minced meat. And here an electric meat grinder comes to the rescue - an indispensable kitchen equipment.

Now it is difficult to imagine a chef who enthusiastically turns the handle of a mechanical meat grinder in a restaurant kitchen, where minced meat is used not only in the usual cutlets, but also in dishes from the cuisines of many peoples of the world.

How to disassemble and clean a meat grinder?

After each use, it is important to completely disassemble and clean the household appliance to avoid food drying out and the proliferation of bacteria and pathogenic microorganisms. This can lead not only to a number of diseases, but also to the unsuitability of equipment. Washing the assembled device is not permitted!

It is simply impossible to completely clean a mechanical meat grinder when assembled, and in the case of an electric one, a short circuit and fire may occur.

Algorithm for disassembling an electric meat grinder:

- In the case of a removable meat receiver, the first step is to get rid of this particular part by pulling it out of the neck.

- Next, you need to turn the clamping nut, carefully holding all the contents.

- Take out the grate and knife blade.

- Remove the auger from the body of the electric meat grinder.

After disassembling the device, you must thoroughly rinse all parts with detergent and running water, and the grille can be cleaned with a match or toothpick. After washing the parts, it is recommended to place them on a napkin or spreader, leaving them to dry completely.

The electric meat grinder and all its parts must be stored in a dry place. Otherwise, fungus and rust may form, which will render the device unusable.

It is not recommended to wash knives with hot water, as this reduces their sharpness, rendering the device inoperable. And the body of the meat grinder, into which the motor is built, can be simply wiped with a damp cloth or cloth. It is forbidden to lower the housing under running water, as this will render the meat grinder unusable and may subsequently cause a fire, electric shock or short circuit.

Electric meat grinder in a catering kitchen

Industrial meat grinders appeared in catering kitchens in the 50s of the last century. This is one of the types of meat processing equipment. Possessing a powerful engine, such meat grinders process up to 100 kg of meat per hour.

The parts of this professional equipment are made of cast iron or steel, which is why they weigh a lot, and in professional kitchens they are installed permanently in one place. Cast iron does not wear out, and therefore the device has a long service life. In addition, such parts allow the machine to work for a long time without interruption.

These meat grinders have several knives that are used to produce minced meat of different levels of grinding. The devices have non-removable fuses, they prevent injury to the operator.

Meat grinders also have additional functions:

- sifting flour;

- loosening flour and dough;

- chopping and slicing vegetables;

- nozzles for squeezing juice;

- nozzles for making baths;

- reverse nozzle for very fine grinding, intended for sausages and sausages;

- attachment for making tomato paste;

- slicer;

- cheese grater.

Some manufacturers equip meat grinders with two handles for easy carrying.

Main types

A standard meat grinder is designed for processing raw meat and fish into varying degrees of grinding. This is their only main function. Nozzles are attached to this meat grinder

for a variety of additional functions.

A meat grinder is capable of processing frozen meat into minced meat; during such processing, the product remains fresh, protein compounds are not deformed, and meat fibers are not disturbed.

The principle of operation of this equipment is quite simple: meat is placed into the loading device, which passes through knives, where its primary grinding occurs, then the mass is pressed by a screw through a special matrix, and acquires the desired consistency. Such a grinder can have several screws, which speeds up the processing process. Grinders also differ from ordinary meat grinders in appearance. They have a completely closed body, shaped like a rectangle.

There are two types of meat grinders based on the placement method:

- the first ones are installed on the floor, have special legs that are included in the kit; these devices are heavy, have a powerful engine, and process a large volume of raw meat;

- the latter have lower power, and therefore less weight, and are installed on tables or stands.

Meat grinders are also classified according to the type of knives installed in them:

- Enterprise - a traditional set of knives: a grid, an auger and a one-sided knife, the same as in a home meat grinder; meat grinders with such a set are purchased for small cafes and canteens;

- semi-unger - in this version, in addition to augers and grates, there is a double-sided knife and a scoring knife; such meat grinders are found in restaurants or other large catering establishments;

- unger - there are two grates, two double-sided knives, two scoring knives, usually shaped like a trefoil; This device is bought for specialized establishments where minced meat for kupats, sausages and sausages is constantly prepared.

The manufacturer indicates the type of kit on the packaging of the meat grinder.

How to choose the right industrial meat grinder

When purchasing such equipment, several conditions :

- all parts that come into contact with the product must be made of food grade steel;

- such parts should be easy to remove;

- a good meat grinder should have a “reverse” function, which will prevent the wire from wrapping around the auger;

- grate diameter: the quality of the final product and its taste depend on it;

- the number of knives is important - the more there are, the higher the speed of meat processing and the better the quality;

- there must be a device that protects the motor from overheating;

- It is worth considering the necessary equipment;

- It should be taken into account that when companies indicate productivity, they overestimate it almost twice;

- If you need a silent meat grinder, then you should pay attention to a gearbox with an oil bath.

Here's a great idea for selling sushi to go. Read more in this article.

Dishes for a restaurant or cafe differ from ordinary home service. For what – read the article at https://vkusologia.ru/posuda/dlya-restorana.html link.

Review of popular models

"Map 300"

Russia.

Specifications:

- material: food steel;

- reverse: yes;

- power: 1.9 kW;

- voltage: 400 V;

- grating diameter: 82 mm;

- productivity: 300 kg/h;

- loading neck diameter: 40 mm;

- dimensions: 690x420x450 mm;

- weight: 51.5 kg.

Price: 46,000 rubles.

Review: Ivan Sergeevich, owner of the roadside cafe “Trassa”, Krasnodar region:

- In our cafe, minced meat is the main dish. Drivers need to eat nourishingly and inexpensively. That’s why we prepare cutlets and meatballs, we’ve now added dumplings to the menu, but for all this you need to grind a lot of minced meat. For many years now, an electric meat grinder, the Map-300 brand, has been helping out. When I bought it, I didn’t think about performance or additional options. But I bought it and was not disappointed.

"Map 150"

Russia.

Specifications:

- material: stainless steel;

- voltage: 380 V;

- power: 1,400 W;

- execution: floor;

- adjustable legs;

- full unger;

- dimensions: 410x560x690 mm;

- weight: 47 kg;

- productivity: 150 kg/h.

Price: 42,800 rubles.

Review: Alena (nickname Kucharenka):

- “Cooking is a calling for me. The kitchen is my element, so I’m glad that the owner was sane, I left the first one because I didn’t understand that for such work you need a lot of imagination with strict technology, but this one understands and therefore almost doesn’t interfere, the main thing is that everything is in order ok. Last year I set a condition: we buy an industrial electric meat grinder. Before this I used a regular household meat grinder and kitchen machine. And then production increased, and I looked at a classmate’s - industrial production produces better quality minced meat. The Map-150 meat grinder was ordered from an online store. I spent the whole evening surfing all the online stores. But I like the car. The main thing is that it is no more complicated than a household one. I’m not very tech savvy, so it’s important to me that the machine has no bells and whistles.”

Meat grinder JR-120

Harbin Commercial Machinery Co., China.

Specifications:

- processes meat frozen to -7 degrees;

- power: 11 kW;

- voltage: 380 V;

- productivity: 2 t/h;

- matrix diameter: 120 mm;

- screw rotation: 190 rpm;

- weight: 300 kg;

- dimensions: 1050x750x1300 mm.

Price: 369,000 rubles.

Review: Sergey Ivanov, owner of a sausage shop:

- “In such production, the top is needed first of all. I have a JR-120 in my workshop, Chinese. I'm not going to change it yet. Copes with large volumes."

Industrial meat grinders today are produced by many companies specializing in the production of electromechanical equipment for catering. Meat grinders differ in the shape and number of knives, power, productivity, additional equipment, design, and placement conditions. The owner can only make the right choice: choose a meat grinder that best matches the parameters of his catering enterprise.

A manual or electric meat grinder is considered a fairly popular kitchen appliance. It is used for processing meat into minced meat, squeezing juice from fruits, stuffing homemade sausage, preparing vegetable puree or preparing pasta. In order for the equipment to work correctly, you need to familiarize yourself with the nuances of its design. From our article we will learn how to assemble and disassemble a meat grinder.

Existing types and design features of meat grinders

In modern stores you can find a huge number of models of meat grinders. All of them can be divided into two types: electric and manual. Along with the devices, the manufacturer also supplies additional parts (attachments and knives), which increases their functionality.

Electric models have gained popularity among users. To obtain the final product, you do not need to expend physical effort; just press the start button and push the meat or vegetables into a special funnel.

Most modern housewives prefer to buy electric meat grinders for the kitchen, considering the manual version to be a relic of the past. In fact, these devices are reliable and easy to use, they actually do not break down. One part that can fail is the knife, but it can be easily sharpened. The body of hand-held devices is made of stainless steel, aluminum or cast iron.

Manual meat grinders are easy to use. At the same time, electric models make it possible to select the required grinding speed or reverse motion. A variety of attachments allows you to create additional products.

A manual meat grinder consists of the following elements:

- steel case with special fasteners for installing the device on different types of surfaces;

- screw auger;

- cross-shaped or circular knife (used for chopping products);

- tightening metal ring;

- handle (fixed to the device using a special screw);

- round grilles with holes and a slot for fixing on the body.

Manual models are fixed to the surface using a special foot. For final fixation, a screw with an overlay is used. Devices with a plastic foot are securely attached to the surface. When installing metal products, place a piece of soft cloth under the foot so that the device does not slip on the surface.

The structure of the electric meat grinder is as follows:

- plastic case;

- electric motor;

- removable meat receiver;

- convenient plastic pusher;

- screw;

- corrugated plastic rod (this element is installed on the auger for reliable fixation);

- metal knife of a convex shape.

Unlike manual models, there are no paws. The stability of the device is ensured by a wide platform with several rubber pads.

Installation of additional components

Most modern meat grinders come with additional knives, grates with various holes and attachments for preparing sausages or kebbe. If it is necessary to use them, the order of assembling the meat grinder may vary, which is also usually specified in detail in the instructions for the device from the manufacturer.

In this case, you should adhere to the following algorithm for assembling an electric meat grinder:

- installation in the middle of the auger body;

- attaching a ring with the largest holes to the auger (their number may vary depending on the meat grinder model and manufacturer);

- installation of a double-sided knife;

- installation of a grille with medium-sized holes;

- fastening the remaining knife;

- installation of the last grate;

- securing the clamp nut.

In the case of preparing sausages, instead of knives and grates, you will need to attach a special attachment to the auger, which is secured with a clamping nut. And for the purpose of making cookies or pasta, you can use metal or plastic shaped rings.

Often, such household appliances include a nozzle for juice and pasta. Usually they are already assembled and you just need to attach them to the main body of the meat grinder.

When assembling an electric meat grinder, it is better to follow the factory instructions from the manufacturer. If a household appliance malfunctions, it is recommended to contact a service center for diagnostics and repair if necessary.

Assembly and operation of a manual meat grinder

Before starting the main work, it is necessary to thoroughly wipe all components. Carrying out such actions will increase the service life of the device. Moisture and food residues will cause rust to appear on the body.

How to properly assemble a manual meat grinder

Now we’ll find out how to assemble a manual meat grinder step by step:

- We take the auger and insert it into the housing. The wide part of this device should be located near the handle, the narrow part - in the place where the knife is secured.

- We insert the handle into the ledge of the auger and fix its position using a special screw.

- In another part of the auger we install a cross-shaped knife, its flat part should face outward. The disc-type cutting element must be in contact with the grate with its edges.

- After the knife is installed, put on a metal round mesh (the protrusions on the body and the mesh must match).

At the final stage of work, we tighten the fixing round nut and check the functionality of the equipment by several rotations of the handle.

Operating principle of a manual meat grinder

The operating principle of a manual meat grinder is incredibly simple. It is based on the fact that you need to turn the handle, the product is pressed through, falls on the knives and turns into minced meat. The operating algorithm of a mechanical meat grinder is as follows:

- Place food in the top hole.

- They fall onto the auger.

- Then they are pressed against the grate and cut off with special knives.

They are very convenient to use for creating sausages and sausages, as well as fruit purees. A little further on you will find some valuable tips on assembling meat grinders of these models. Read carefully to connect everything correctly, and then your device will serve you very well, work great and fulfill all your desires.

Assembly and operation of an electric meat grinder

If the user has encountered assembling a manual model, he can easily figure out an electric household appliance.

How to properly assemble an electric meat grinder

The assembly diagram of the meat grinder is as follows:

- We connect the plastic gearbox to the metal rim of the auger; the grooves of the parts must align. Turn the gearbox counterclockwise until a characteristic click appears. If the parts are connected incorrectly, the engine will not be able to turn the auger.

- The inside of the auger must exactly match the outline of the hole on the body.

- We put a sharp knife on the output part of the auger and install a grate. The holes and protrusions must match. When carrying out such work, it is necessary to position the knife correctly.

- We tighten the clamping nut and install the loading hopper in the upper part of the device body.

Now that we know how to assemble an electric meat grinder, let’s get acquainted with other nuances of this process.

How to properly insert a knife into an electric meat grinder

When installing the part, the cutting part of the knife should be in contact with the grid, which will facilitate thorough chopping of the supplied products. After installing the knife, secure the grill, fixing it in a special groove, then tighten the nut. If the cutting element is installed incorrectly, the meat will clog and remain inside the device.

How to use an electric meat grinder

At the initial stage of work, we cut the processed products into small pieces; they should fit into the opening of the receiving hopper. We plug the device into the outlet, press the start button and begin to push the product using a pusher to the auger. Once on the shaft, the raw material will move and end up on the knife. Here the product is crushed and goes out into the receiving bowl.

When the engine is running, the recycling process occurs continuously. If the auger becomes clogged, the user only needs to turn on the reverse and remove the remaining product. Later they can also be used along with a new portion of meat.

There are several simple rules for using an electric meat grinder. Do not throw bones into the loading hopper together with meat. Before serving, any product is cut into small pieces. After carrying out the work, it is necessary to disassemble the household appliance, thoroughly wash and dry all parts.

How to disassemble an electric meat grinder

Previously, we learned how to assemble an electric meat grinder - this is a simple job that every user can do. Disassembling the household appliance occurs in the reverse order. First you need to unscrew the clamping nut, remove the metal grid and the knife. Then turn and pull out the auger along with the gearbox. At the final stage of work, remove the loading container. All removable parts must be cleaned of residues and rinsed in water, then wiped with a soft damp cloth.

Operating principle of an electric meat grinder

According to the principle of operation, an electric meat grinder is not much different from a mechanical one. The only and main difference is that for the meat grinder to work, you just need to load everything into the receiver and press the button. And nothing else needs to be done. Using a device from Mulinex as an example, we will tell you what happens next and how to insert the knife correctly. After the meat is loaded into the meat receiver, it is also pressed against the mesh with a screw and cut off by cutting elements. After work, you need to disassemble all the elements, wash them, and leave the meat grinder in the disassembled state until it is completely dry. Only after this can you put the device in a box and place it on a shelf for storage.