Steel hexagon has an extensive classification. It can vary in size, chemical composition of the metal, manufacturing method and many other important parameters. Depending on their combination, it is possible to obtain rolled metal with different physical and chemical properties.

There are many types of hexagons. Therefore, in order to choose an option for certain tasks, you need to know the classification of this type of rental. In this article we will talk about the types of steel hexagon and the features of its use.

The range of hexagons is quite extensive

Areas of use

Hot rolled hexagon is used in the following industries:

- production of fasteners – bolts, nuts;

- manufacturing of equipment elements for the mining and oil industry;

- installation of fences, including the production of decorative parts using hot forging and cold bending.

Areas of application of calibrated hexagonal rolled products:

- construction and architecture – decorative works;

- production of equipment for medicine and food industry;

- automobile, aircraft, shipbuilding.

Application of hexagonal rolled metal

Steel hexagon mainly serves as a raw material for the production of small parts and fasteners - nuts, bolts, screws. For this, steel grades 40X and St45 are usually used. Also, hexagonal rod serves as an excellent material for making tools - chisels, axes, hammers, screwdrivers, chisels; industrial and forging dies are made from it. For all this, rolled tool steel is usually used.

The hexagon is perfect for welding. In addition, it is very resistant to torsion, bending and other types of deformation. Therefore, steel hexagon is in great demand in construction - supporting elements of bridges and other structures are made from it, and used in the frames of high-rise buildings. True, the latter applies to a stainless hexagon. Due to their excellent weldability, the rods are simply welded together to create railings, balusters and other types of fencing.

Among the areas of application of steel hexagon are mechanical engineering, automotive industry, heavy industry, oil and gas industry and many others. Therefore, when purchasing, it is necessary to accurately calculate what characteristics the rental should have.

Hexagon classification

According to the production method, hexagonal rolled products are divided into hot-rolled and calibrated:

- The production of hot-rolled hexagons is regulated by GOST 2879-2006 (replacing GOST 2879-88). It is characterized by low dimensional accuracy; scale may be present on the surface, which is removed by etching or mechanical methods.

- To improve surface quality and increase dimensional accuracy, hot-rolled steel is calibrated by drawing and mechanical processing. The range of calibrated rolled products is regulated by GOST 8560-78. Due to additional processing, a calibrated hexagon is more expensive than a hot-rolled one. It is used in industries where dimensional accuracy and aesthetics are important.

The length of the hexagonal rod is produced:

- unmeasured length;

- measured length;

- limited length;

- length, a multiple of the measured length.

In terms of rolling accuracy, hot-rolled rods are of increased (B) and normal (C) accuracy, and in terms of curvature - classes I, II, III, IV. After hot rolling, the following processing methods are possible: hot working at high pressure, cold machining, drawing.

Production of hexagonal metal products

Rolled metal production technology determines its strength and section accuracy. There are 3 manufacturing methods:

- Hot rolling. The range of steel hexagons with this technology is from 8 to 100 mm. Here and below, the size is determined by the diameter of the circle inscribed in the hexagonal contour. This rolled product is produced in rods, but for small sections it is wound into rolls (coils). The standard for hot-rolled hexagon is GOST 2879-99. During rolling, scale forms on the product, which must be cleaned off mechanically or chemically. A hot-rolled hexagon has slightly reduced strength compared to a cold-rolled one. However, it is still suitable for wide application in various fields.

- Cold rolling. Using this method, a calibrated hexagon is produced from alloy steels (GOST 4543) and a calibrated hexagon (GOST 8560-88). The dimensions of such rolled products can be from 3 to 100 mm. Before rolling, the billets are phosphated to reduce specific loads. The calibrated hexagon is made of stainless steel. Cold-rolled steel has a denser structure compared to hot-rolled steel. Consequently, higher strength. Therefore, such products are used in particularly difficult conditions.

- Hot pressing. The blanks are placed under a press at high temperatures, where they acquire their shape. This technology uses high-strength, heat-resistant tool steel. The rod has high precision.

Considering what kind of steel hexagons are made of, we can say that with both technologies, its brands and grades do not differ. Usually these are low- and high-alloy materials, alloys with impurities of carbon, manganese, nickel and chromium in various proportions. The most popular steel grades are St20, St35, St40X and St45. For stainless hexagon - 08Х18Н10, 08Х18Н10Т, 12Х18Н10Т, 20Х13, 40Х13, 14Х17Н2 (EI 268), 45Х14Н14В2М (EI 69), 13Х11Н2В2МФ (ЭИ-961-Ш), 316L.

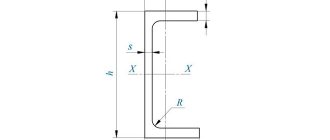

Basic geometric parameters and size range

The rental number is determined by the diameter of the inscribed circle in mm, otherwise it is called the “turnkey size”. The diameter range of hot-rolled hexagonal steel is 8-103 mm, calibrated - 3-100 mm. The range of lengths for hot-rolled products is 2-6 m, for calibrated hexagonal products – 2-6.5 m. At the customer’s request, rods of other lengths can be supplied for sale. By agreement with the consumer, small hexagons can be supplied in rolls. Standards regulate permissible cross-sectional deviations.

Table of maximum cross-sectional deviations and hexagon masses

| Diameter of inscribed circle, “key size”, mm | Hot rolled hexagon | Calibrated hexagon | Weight 1 m, kg | |||||

| B1 | B21) | AT 2 | AT 21) | H10 | H11 | H12 | ||

| 3,0 | — | — | — | — | -0,04 | 0,006 | -0,04 | 0,061 |

| 3,2 | — | — | — | — | -0,048 | -0,075 | -0,12 | 0,07 |

| 3,5 | — | — | — | — | 0,083 | |||

| 4,0 | — | — | — | — | 0,109 | |||

| 4,5 | — | — | — | — | 0,138 | |||

| 5,0 | — | — | — | — | 0,170 | |||

| 5,5 | — | — | — | — | 0,206 | |||

| 6,0 | — | — | — | — | 0,245 | |||

| 6,5 | — | — | — | — | -0,058 | -0,09 | -0,15 | 0,287 |

| 7,0 | — | — | — | — | 0,333 | |||

| 8,0 | +0,1/-0,3 | +/-0,2 | +3/-0,5 | +/-0,4 | 0,435 | |||

| 9,0 | 0,551 | |||||||

| 10,0 | +0,2/-0,3 | +/-0,25 | 0,68 | |||||

| 11,0 | -0,07 | -0,11 | -0,18 | 0,823 | ||||

| 12,0 | 0,929 | |||||||

| 13,0 | 1,15 | |||||||

| 14,0 | 1,33 | |||||||

| 15,0 | 1,53 | |||||||

| 16,0 | +/-0,5 | 1,74 | ||||||

| 17,0 | 1,96 | |||||||

| 18,0 | 2,2 | |||||||

| 19,0 | -0,084 | -0,13 | -0,21 | 2,45 | ||||

| 20,0 | +0,2/-0,4 | +/-0,3 | +0,4/-0,5 | 2,72 | ||||

| 21,0 | 3,00 | |||||||

| 22,0 | 3,29 | |||||||

| 24,0 | +/-0,6 | 3,92 | ||||||

| 25,0 | 4,25 | |||||||

| 26,0 | +0,2/-0,6 | +/-0,4 | +0,4/-0,7 | 4,60 | ||||

| 28,0 | 5,33 | |||||||

| 30,0 | 6,12 | |||||||

| 32,0 | -0,1 | -0,16 | -0,25 | 6,96 | ||||

| 34,0 | +/-0,8 | 7,86 | ||||||

| 36,0 | 8,81 | |||||||

| 38,0 | 9,82 | |||||||

| 40,0 | 10,88 | |||||||

| 42,0 | 11,99 | |||||||

| 50,0 | +0,2/0,9 | +/-0,55 | +0,4/-1,0 | 17,00 | ||||

| 60,0 | +0,4/-1,2 | +/-0,8 | +0,5/-1,3 | -0,12 | -0,19 | -0,3 | 24,5 | |

| 65,0 | 28,7 | |||||||

| 70,0 | — | -0,19 | -0,3 | 33,3 | ||||

| 75,0 | 38,2 | |||||||

| 80,0 | +0,5/-1,5 | +/-1,0 | +0,6/-1,7 | +/-1,3 | 43,5 | |||

| 85,0 | — | -0,22 | -0,35 | 49,1 | ||||

| 90,0 | 55,1 | |||||||

| 95,0 | 61,4 | |||||||

| 100,0 | +/-1,5 | 68,0 | ||||||

| 103,0 | — | — | — | 72,1 | ||||

Types of hexagons and their purpose

Different types of hex tools are used to work with different fasteners:

Imbusovy

This is the simplest version of this tool.

It can be used for any type of fasteners that have an internal profile with six edges.

The design of such a tool is as simple as possible: an L-shaped rod is produced with the same cross-section along its entire length.

The short part of the wrench is used to create a strong lever-like force.

T-shaped

The hexagonal version is used in cases where fastening requires particularly high force for screwing or unscrewing fasteners.

Craftsmen often use sets of these keys in their work.

Typically, a tool set includes basic dimensions.

Purchasing a whole set allows you to select a wrench or screwdriver that matches the fastener.

But there is also a universal hexagon, which has several different sizes.

This key is usually used in locksmithing, but due to its versatility, it can be useful in any field of activity.

Making a steel hexagon

The production of hexagons takes place according to European standards DIN 1015-1972.

The diameter of a hexagon is the diameter of the circle inscribed in it. The material used for manufacturing is varied. It can be alloyed, high-alloyed, or carbon steel.

It is made in rods, the length can be measured, unmeasured, multiple measures and limited measures. Rods with a length of one and a half meters, but not more than two, are considered remnants.

The hexagon standard is - length from 2 to 6.5 meters. But upon individual order it is possible to increase the length of the rods to 12 meters.

To display the mass of rolled products, as well as to determine permissible deviations, special reference books and tables have been developed. You can calculate the mass yourself, knowing the density of steel, which is 7.85 g/cm³. To mark a steel hexagon, numerical indicators of length, cross-section, steel size, and production method are used.

The hexagon consists of steel and additives that give various properties to this product, for example:

- The addition of chromium and nickel provides resistance to organic influences, increased reliability and reduced weight;

- Manufacturing with a titanium additive will provide heat resistance;

- Stainless steel grade - increased durability, increased corrosion resistance.

How to choose the right hexagon

If you choose a good set of hexagons, you can provide yourself with the right tools for all occasions: from car repairs to assembling furniture at home.

In order not to get lost in the wide selection of offers varying in price and composition, you should remember the basic rules:

1. For frequent professional use, you should choose a set consisting of at least 12 types of hexagons.

This is convenient and will save time on shopping.

In everyday life, 3-5 tools are enough.

You can purchase them individually, based on your personal needs, or in a small set at a reduced price.

2. Hexagons made of special tool steel or chrome vanadium are considered the most durable.

They will last for many years and will not deform.

3. Don’t skimp on choosing a manufacturer.

Cheap Chinese tools easily spoil the equipment and furniture with which they are used and break themselves.

How to use a hexagon

Unscrewing the fasteners with a hexagon is quite simple.

The main thing is to follow simple safety precautions and avoid striking the key or screwdriver in order to create greater leverage.

Step by step steps include:

1. Selection of a hexagon corresponding to the type and size of the fastener.

2. Inserting one side of the hexagon into the internal hole of the part so that it occupies the entire depth.

It is better to enter the L-shaped form with the short side, but if necessary, the long side can be used.

3. Applying a load to the tool and gradually increasing it until the torque is reached.

The same should be done when twisting elements.

The instructions are suitable for both external bolts and internally slotted parts.