An electric sharpening machine intended for metal processing requires periodic editing of the emery wheel. The need to restore the shape is caused by uneven grinding of the surface (left, right or center). A special tool is used for straightening grinding wheels - a diamond pencil.

Photo No. 1: Sharpening machine (left and right - abrasive wheels)

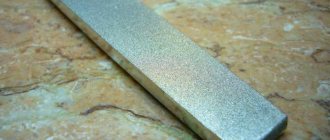

The pencil is a product with a high wear resistance class, which is used for grinding the surface of an abrasive wheel and restoring the sharpening properties of the tool. Since synthetic and natural diamonds are much harder than the material from which the grinding wheel is made, the tool removes defects and irregularities with a high degree of efficiency, restoring the properties of the stone. In this article we will talk about the structural features and basic principles for choosing a diamond pencil.

Photo No. 2: Diamond pencil for straightening circles compared to a ruler

How does a diamond pencil work?

The diamond ruling pencil has the form of a steel pin 5 cm long. Natural/synthetic diamonds are placed at the bottom of the product. The function of a connecting link is performed by a metal alloy with an expansion coefficient close to that of diamond crystals.

In domestic conditions, tools with a diameter of 80–100 mm are most often used. During operation, it is fixed in special holding devices. For profile grinding and dressing of large diameter wheels, it is rational to buy a diamond pencil with large crystals in the frame. The advantage of large diamonds is the presence of natural edges, which increase the wear resistance of the tool.

Image No. 1: Diagram of the device of diamond pencils types 01, 02, 03, 04 according to GOST

The frame of products comes in various shapes: cylinder, steps, cone. There are diamond pencils with carvings. Diamonds are held inside the product by soldering, chasing, or metal clamps. The pencil should be attached to the holder in such a way that the tool protrudes beyond the edges of the frame by a maximum of ¼ of its length.

Why do you need to edit diamond grinding wheels?

No matter how high-quality diamond grinding wheels are, they sooner or later deteriorate and wear out during use. Happens:

- smoothing in some areas;

- breaks;

- abrasion;

- salting

There are much fewer problems when using soft grinding wheels. They have the property of self-sharpening. As grains fall out, new layers are exposed. Solid instruments do not have this property. To restore the characteristics of such diamond grinding wheels, editing is needed. After it, the instruments get a new life. The cutting properties and geometric shape of products are restored.

How are diamond pencils used?

Straightening abrasive wheels with a diamond pencil is a high-precision method of restoring the properties of the working surface of a product. The tool allows you to edit the shaped profile and return the original geometry at high speeds. The straightening process involves grinding a brittle material with a denser abrasive.

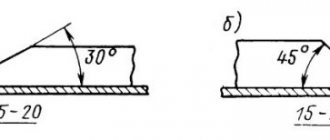

Image No. 2: Scheme of installing a pencil relative to the sanding wheel being processed

To obtain optimal results, it is recommended to install the tool at an angle of 10-15 degrees in the direction of rotation of the wheel with a slight turn in the direction of feed. This method allows you to periodically rotate the tool along the axis, reducing the load and destruction of the working part of the pencil.

Dressing grinding wheels

When the wheel wears out, the abrasive grains under the influence of the material being processed are destroyed (broken off, worn out, smoothed out) and pulled out of the bond. Uneven wear on the surface of the circle leads to a violation of its geometry. The intensity and nature of wear of abrasive wheels depend on the characteristics of the wheel itself and the material of the workpiece. If the wear of the wheel occurs only due to chipping of grains, new grains come into operation, and the so-called self-sharpening of the tool occurs. This is normal. Soft wheels have good self-sharpening properties. In wheels with high hardness, the processes of dulling (smoothing the cutting edges of the grains) and clogging prevail.

Grinding of a wheel is a process in which chips removed from the part being ground, together with worn-out abrasive grains and binders, enter the pores of the grinding wheel and fill them, as a result of which the cutting ability of the wheel is sharply reduced.

Dullness, clogging and abrasion of the abrasive causes a decrease in the cutting ability of the wheel, resulting in an increase in the likelihood of burns, a decrease in the quality of processing and productivity.

To restore the shape of the grinding wheel and its cutting properties, a dressing operation is used, which is the removal of abrasive material and binder from the surface of the wheel, carried out with special dressing tools.

Dressing of the grinding wheel may also be necessary for a new wheel if it runs out. The runout can be checked by touching the rotating circle with the tip of a marker (chalk, pencil) resting on the tool rest. If you move the marker slowly towards the surface of the rotating wheel, it will leave marks on the surface with excess material that needs to be removed when editing.

Checking the grinding wheel runout

It would be a good idea to check the wheel for hidden cracks before editing. To do this, it is removed from the machine, installed on a wooden axis (can be hung on a rope) and tapped with some object. The whole circle makes a melodious ringing, while the circle with a crack sounds short and dull.

Checking the grinding wheel for cracks

When editing wheels, a lot of dust is released into the air, so it is advisable to attach a vacuum cleaner hose to a tool and use a respirator.

Basic methods of dressing grinding wheels

Despite the technological simplicity of the wheel dressing process, there are quite a few methods and technologies for this operation.

Depending on the material of the dressing tools, dressing with diamond and non-diamond tools is distinguished. Based on the nature of the interaction between the grinding wheel and the dressing tool, dressing is divided into turning, rolling, grinding, and tangential turning. In industry, dressing by rolling (for profile grinding wheels) and free abrasive is used. At home, they use the simplest editing methods, the purpose of which may be: cleaning the wheel from clogging, leveling (restoring the profile) and reprofiling.

Cleaning is carried out if it is necessary to clear the circle of grease without changing its shape. Cleaning can be done with a fragment of any abrasive wheel with hardness R, S, T, or an abrasive stone. The stripping technology is simple. Using a piece of abrasive material resting against a tool rest, the profile surface of the rotating circle is cleaned using longitudinal movements along it.

Cleaning a dirty grinding wheel

Editing by turning

. Dressing by turning is the destruction (turning) of the abrasive material and the bond of the grinding wheel with a high-hardness dressing tool, which works in much the same way as a conventional cutter works, cutting off a layer of material from a rotating workpiece. CBN inserts or diamonds are used as working bodies of the dressing tools, fixed in mandrels using mechanical clamping, soldering or chasing.

Dressing tools have different designs. Some of them are a rod into the top of which one relatively large diamond is inserted; these tools are called diamond needles, set diamonds.

Diamond needle, diamond pencil, diamond cutter

Other tools have an extended working surface on which a number of diamonds are fixed in a certain order or randomly. Diamond pencils for editing circles, combs, and cutters have this design.

The working surface of these tools is usually located perpendicular to the handle. The depth of the diamond layer can reach significant values. The larger it is, the longer the service life of the tool. When the upper diamonds wear out, the underlying layers come into play.

When dressing a wheel, the tool rests on a tool rest and brings its working surface into contact with the rotating wheel, removing a layer of abrasive from it and leveling its surface.

Dressing the abrasive wheel with a diamond cutter

Dressing the abrasive wheel with a diamond pencil

Diamond or CBN cutters are inserted into mandrels that provide the desired feed and trajectory of the cutting part of the tool. The figure below shows several options for dressing grinding wheels using diamond needles or CBN inserts. All of them have a screw in their design, with the help of which a diamond or CBN cutter is pulled out of the device by the required amount (feed). The straightness of the tool's movement relative to the circle is ensured by a tongue-and-groove system or a protrusion on the device that rests against the edge of the tool rest.

Device for dressing grinding wheels

Device for dressing grinding wheels

In the absence of special dressing tools (needles, combs, cutters), grinding the wheel can be dressed with a CBN insert, secured in a tool holder or simply clamped with pliers.

Dressing the grinding wheel with a CBN insert

When turning with a diamond needle, the dressing tool must be fed at an angle to the surface being processed - both in the vertical and horizontal planes. Correct and incorrect installation of the tool in the vertical plane is shown in the figure below.

The position of the diamond needle in relation to the grinding wheel: a - correct, b - incorrect.

The placement of the cutter at an angle to the surface being processed allows you to change the cutting edge of the tool, turning it around its axis so that new, non-dull edges come into use.

The cleanliness of the processing can be adjusted by changing the speed of the longitudinal (along the machined surface) feed of the tool. The smaller it is, the smoother the surface of the circle is. If the wheel is intended for roughing, the feed speed must be increased to obtain a rougher surface.

You can check the quality of editing by applying a ruler to the treated surface, which should fit tightly to the circle, without gaps.

Checking the grinding wheel profile

Dressing by turning with diamond and CBN tools allows you to ensure high accuracy of the wheel geometry. Its relative disadvantage is the smoothing of the surface being processed, which may be undesirable if it is planned to perform roughing work using the straightened wheel. In this case, it is better to apply rolling correction.

Grinding wheels can be dressed with green silicon carbide stones on a ceramic bond, grit F14-F36 (125-50), hardness R, S, T. For dressing diamond wheels (possibly CBN) on a ceramic and metal bond, the grit of the stone should be approximately the same as the circle, hardness - medium-soft or medium, structure - medium or open.

Abrasive stone

However, straightening diamond wheels with abrasive stones is accompanied by a large consumption of stones and takes a lot of time. More effectively, the dressing of a diamond wheel can be carried out using an abrasive ruling wheel, which receives rotation from its drive (see below).

Editing by rolling

. When dressing abrasive wheels using the rolling method, crushing, chipping and removing abrasive grains from the surface of the wheel is done with a round-shaped tool that receives its rotation from the grinding wheel. Silicon carbide wheels, steel disks with a cemented and hardened surface, carbide rollers, and cone stars are used as dressing tools. Balloon stars are the most widely used.

Dressing an abrasive wheel by rolling

The working part of a rotating cutter for dressing abrasive wheels is a set of disks and toothed sprockets made of wear-resistant metal mounted on one axis. When in contact with a rotating grinding wheel, the discs and sprockets themselves begin to rotate, rolling and sliding along the surface of the wheel. As a result, the abrasive grains are destroyed and chipped and the wheel profile is leveled.

Rotating cutters are made not only in the form of a tool designed to be held in the hands, but also permanently mounted on a stationary base. With their help, wheels mounted on hand-held grinders can be edited.

Roller cutter for dressing abrasive wheels

Roller cutter for dressing abrasive wheels

The disadvantage of straightening using rotating cutters is large dust formation and relatively low processing accuracy. The advantages are high productivity and the absence of smoothing of the wheel surface, as happens in the case of dressing by turning with diamond or CBN tools. If the wheel is being prepared for roughing work, dressing with a rotating cutter is the best option. This method can also be used as a preliminary operation before straightening with a diamond or CBN tool. Increased dust formation is combated by connecting a dust suction hose connected to a vacuum cleaner to the hollow handle of the roller cutter.

Dressing by grinding

. Dressing by grinding is also done with a rotating tool. However, unlike rolling dressing, the dressing tool is driven by its own drive rather than by the grinding wheel.

Diamond rollers, silicon carbide, diamond or CBN wheels, and discs made of tungsten carbide hard alloys are used as grinding tools. The axis of their rotation during editing can be either perpendicular or parallel to the axis of rotation of the disk being processed. In the latter case, the direction of rotation of the dressing wheels or rollers may coincide with the direction of rotation of the grinding wheel or be directed against it.

An important feature of dressing by grinding is that the rotation speed of the wheel being dressed should be low - no more than 25 m/min (60 times slower than when grinding), while the rotation of the dressing tool should be normal. Manual rotation of the wheel is unacceptable, since uneven rotation results in non-roundness or unevenness of the working surface after dressing.

The disadvantage of dressing by grinding is that to carry it out, in addition to the dressing disks or rollers themselves, you also need to have a tool to rotate them. When editing at home, perhaps the best option is to use a grinder with a diamond wheel for editing. With its help, you can edit both electrocorundum and diamond wheels. The grinder used for straightening must have a stop device that can be secured in place of the handle.

Support on the grinder for dressing abrasive wheels by grinding

The photo below shows the process of dressing a diamond wheel by grinding using a grinder equipped with an old diamond wheel.

Dressing a diamond wheel by grinding

When dressing diamond wheels, it is recommended to use cooling, which prevents the combustion of diamond grains, which can occur at temperatures above 700-800°C.

Video:

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Literature

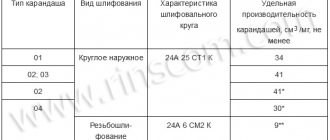

Types of pencils for editing circles

In practice, tools of several main types are usually used, differing in the arrangement of diamonds in the working part.

- Type C - arrangement of crystals in a chain.

- Type C - stones come in layers (with or without overlaps).

- Type H - crystals do not have a specific orientation.

Also, products are classified into different brands based on the number of diamonds and their weight, the size of the frame and other parameters.

Image No. 3: Correspondence table between pencil types and surface treatment options

For example, a type C pencil is made from crystals weighing 0.03–0.5 carats. The products are used to restore wheels intended for centerless shaped, internal and cylindrical grinding.

Subtype C instruments come in two brands:

- fine-grained with 10 or more diamonds in one layer;

- fine-grained with 2–5 stones per layer.

Both types of products are suitable for fine sanding of surfaces.

The C-class pencil is made from chipped and crushed diamonds and is used to restore the shape of fine-grained abrasive wheels.

Scope of application and design

One of the main problems of abrasive grinding wheels is “salting” of the surface - a decrease in abrasive qualities due to contamination and partial destruction of grains. The use of cutters allows you to remove the top contaminated layer, restore the geometry and abrasive properties of the wheel.

Structurally, a roller cutter is a round disk with teeth and a hole in the middle mounted on an axis. The teeth are made of wear-resistant steel subjected to heat treatment. The main parameters of the tool are its thickness, outer and inner diameters. The size of the cutters, along with the grain size of the wheel, must be taken into account when selecting.

Depending on the shape of the tooth, there are the following types of cutters:

- Sharp teeth - used exclusively for working with fine-grained abrasive wheels.

- Blunt - used for working with medium- and coarse-grained wheels.

Diamond Pencil Marking

To choose the right tool, pay attention to the markings. Standard product designations are specified in GOST 607-80. The regulations specify parameters such as tool size, varieties, technical requirements, etc.

The following points become mandatory:

- trademark of the company that produced the pencil;

- product designation without the first six digits;

- types of diamonds (01, 02, 03), where the letter A corresponds to natural stones, C - synthetic;

- number according to the manufacturer's marking.

The first five digits in the code are the standard designation of the location of the stones and their weight, which ranges from 0.5–2 carats.

Numbers 0051–0055

Image No. 4: Chain arrangement of natural diamonds

In these products, stones are placed along a chain. The scope of application of pencils is editing medium-density abrasive wheels. Contains natural diamonds.

Diamond weight by numbers:

- 0051–0053 — 0.5 carats;

- 0054 - 1 carat.

Numbers 0081–0085

Image #5: Layered arrangement of natural crystals

The crystals go in layers. The products are used for straightening wheels of maximum hardness. Contains natural diamonds.

Diamond weight by numbers:

- 0081–0083, 0085 — 1 carat;

- 0084 - 2 carats.

Numbers 0086–0088

Image No. 6: Layer-by-layer arrangement of technical stones

Diamonds in products are arranged in layers. The weight of all crystals is 1 carat. The stones are synthetic, suitable for grinding medium-hard wheels with a diameter of up to 600 mm.

How to choose an editing method

Various techniques are used to dress grinding wheels:

- turning by hand or using special equipment;

- rolling to level the surface;

- sanding to remove dirt and roughness;

- rolling;

- abrasive straightening.

The choice of one method or another depends on the degree of wear of the disc itself. Sometimes it is enough to sand the surface to restore the cutting edge of the wheel and remove all contaminants from the surface. In other cases, it is necessary to carry out a number of procedures to restore the operating parameters of the product.

PRICE LIST

| Outer diameter D (mm) | Inner diameter d (mm) | Tooth height h (mm) | Tooth base width s (mm) | Cone thickness (mm) | Cost RUR/piece |

| 70 | 20 | 12 | 7 | 1.5 | 31 |

| 50 | 14 | 8 | 5 | 2 | 27 |

| 38 | 13 | 6 | 3 | 1-1,2 | 21 |