The modern market offers a large selection of fasteners for a wide variety of construction tasks, and self-tapping screws are at the top today. Thanks to their special shape and thread, such elements perfectly fix materials of different structures and connect metal sheets to each other. That is why classic nails have long been abandoned in the installation of roofing - roofing screws are much more reliable. It is only important to learn to understand them and choose the right one for each type of coating, not to skimp on quality and not to calculate their length “by eye”.

Why do you need special screws for the roof?

According to experts, it is in the fastening elements that 90% of the problems that arise with the roof lie. Everywhere there is a situation where leaks occur and the roof covering corrodes, and the company’s specialists called find the reason precisely in violation of the rules for the selection and installation of roofing screws. At the same time, the self-tapping screws themselves began to be used for roofing not so long ago, and at one time they were not very successfully replaced by nails (which are still used when working with some types of coatings). The main advantage of roofing screws over nails is that self-tapping screws allow repeated tightening and even dismantling when necessary throughout the life of the roofing material.

You cannot do without them when it is necessary to pull together materials of dissimilar properties: for example, wood and metal, flexible shingles and wood, ceramic tiles and metal sheathing. Even when connecting homogeneous materials, self-tapping screws show themselves to be an order of magnitude better than simpler fastenings, and therefore you should not try to replace them with something else, even taking into account all the difficulties of their selection. Experienced roofers will say this: let's take as an example an expensive dress that was sewn from high-quality material, but with rotten threads. Of course, no one can promise you the integrity of such clothes, nor the quality of their appearance. Everything is in the details - the true truth.

Use of self-tapping screws

Fasteners should be used for their intended purpose - for working with a specific material. There are also varieties that can be used to reliably connect hard and loose materials, for example, a metal frame and chipboard, drywall.

Fasteners are used to solve the following problems:

- assemblies of metal and wooden structures;

- installation of wall, facade finishing, terrace and parquet boards;

- furniture production;

- roofing works.

Installation is mainly carried out without drilling holes, due to the sharp end, which acts as a drill. If you need to connect thick parts, then drill a hole with a diameter smaller than the fastener itself.

Specifications

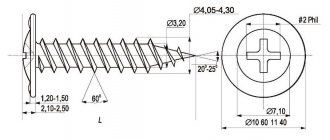

Considering roofing screws (also known as hardware or fasteners), as the section says, we can say that they consist of three parts with different functional purposes. This is: A drill or drill on the tip of a self-tapping screw, facilitating self-drilling. A body with a thread that allows screwing and deepening of fasteners into a sheathing made of wood or metal. A cap, or head, used for screwing in a self-tapping screw and further fixing the roofing material. Due to the specificity of the application, roofing screws are made of durable grades of hydrocarbon steel. Subsequent coating with zinc ensures their protection from corrosive destruction. In addition to galvanized ones, you can find specimens made of “stainless steel” on sale, but their cost is much higher.

As for the shape of the caps, in addition to the standard round shape, self-tapping screws with a shaped hexagonal cap are available for a Phillips screwdriver. It is more convenient to work with such fasteners and therefore it is most popular when installing roofs. Speaking about sizes, we mean the ratio of the diameter to the length of the product. Regarding roofing screws, the existing range of sizes is quite wide and provides reliable fastening of roofing materials with different profile configurations. Of course, the size also affects the weight of the product. But the most distinctive feature of this type of fastener is that it is equipped with a special washer. The washer is a combined structure made of metal and rubber, subject to high temperatures. Having a round shape, it is designed to press the material more tightly against the sheathing while simultaneously sealing the hole under the screw head.

How to choose high quality self-tapping screws?

The share of the cost of fasteners in the total budget allocated for the construction of the roof is a very small part, so there is simply no point in saving on them. Self-tapping screws manufactured in violation of technology have the following disadvantages:

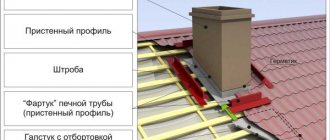

Scheme of fastening sheets of metal tiles.

- an uneven drilling tip made of softer metal makes an uneven hole in the roof with burrs and scratches, which quickly begins to rust;

- a gasket made of low-grade rubber does not have the necessary elasticity, hardens and crumbles under the influence of sunlight;

- The protective coating on the head and pressure washer peels off at the slightest deformation.

If you used low-quality self-tapping screws during installation, most manufacturers of roofing materials can use this fact as an argument for refusing warranty service.

Is it possible to distinguish a counterfeit fastener from a high-quality one? Yes, this is quite easy to do if you show persistence and attention to detail:

- When purchasing, note the presence of letter markings on the head of the self-tapping screw - its absence indirectly indicates a fake.

- When choosing fasteners, take one screw, remove the pressure washer and gasket from it and compress them with pliers - a low-grade product is characterized by peeling paint and crumbling gasket.

- The seller must have documents confirming the product’s compliance with quality standards and certificates. Pay attention to the packaging: it contains full information about the manufacturer, production address, etc.

How does a roofing screw for wood differ from a screw for metal?

Good day, dear readers! I am very glad to be of service to you. And today I want to bring to your attention one small article about this:

How to distinguish a roofing screw for wood from a roofing screw for metal?

APPEARANCE OF THE SCREW SELF-TAPPING

The roofing screw consists of several parts:

- Hexagonal head

(thanks to it, the self-tapping screw can pass through thicker and harder materials without breaking). - Washer with rubber seal

. Correct name: roofing washer with EPDM. Thanks to the washer, the connection between the screw and the metal is protected from moisture. As a result, it eliminates rotting at the junction. In addition, rubber dampens vibration, which means that the chance that the screw will come loose is also minimal. - Threaded part

. - Drill

(or drill, if you prefer).

APPLICATION

Self-tapping screws of this kind are used not only for roofing work. But, since they were originally invented for roofing, they are called roofing.

They are used for screwing metal sheets to a wooden or metal base: lathing, fence, profile pipe, etc.

DIFFERENCES

Roofing screws for wood are also called “ metal-wood”

“, and for metal - “

metal-to-metal

”. They are called this because:

- Metal-wood is used to screw metal to wood.

- Metal-to-metal - respectively, in order to attach metal to metal.

In fact, it is very easy to distinguish them. Here are some tips for you:

- Self-tapping screw diameter

. Roofing screws for wood are produced with a diameter of 4.8 mm. And the roofing screw for metal is 5.5 mm. - Drill width

. As you already know, at the tip of the self-tapping screw there is a drill that helps to pass through the metal. So, with metal-to-wood self-tapping screws, the drill is narrower than the thread, and for metal-to-metal self-tapping screws, the drill is practically the same diameter as the thread. A narrow drill helps to go through the metal and not drill into the wood too much, so that the threaded screw “sits” securely in the wooden base. The wide drill was also not made by chance, because such a self-tapping screw has to go through 2 layers of metal. - Length

. Sometimes, if the screws are not long, they can be distinguished by how many millimeters the length of the threaded part + drill is. Metal-wood: 4.8*28, 4.8*35 mm. Metal-to-metal: 5.5*19, 5.5*25, 5.5*32, 5.5*38 mm.

Marking

Just 10 years ago, markings on roofing screws were characteristic only of reliable manufacturers and indicated the high quality of fasteners. Now all companies that work in this area mark their products with numbers or letters. Examples of marking of roofing screws for metal:

- EDS-B8. Suitable for fastening metal tiles up to 2.5 mm thick.

- EDS-S8. Designed for fixing metal sheets up to 0.7 mm thick.

The number 4.8 indicates the diameter of the fastener.

Metal tiles (Photo: pixabay.com)

Choosing self-tapping screws for roofing: quality issues

We hope it is now quite clear to you that the use of low-quality self-tapping screws will not only lead to visual defects on the roof in the form of rusty smudges and lopsided fastenings, but may also lead to the replacement of the entire roof and subsequent complex internal repairs. That’s why, when purchasing self-tapping screws, ask for the necessary documentation, so that later you will have some evidence in case of a warranty repair claim for the roof. Here's what the most commonly used roofing screws look like:

Rules for fastening roof elements

The technological features of the fastening process depend on a number of factors: the type of products used, their thickness, characteristics of the sheathing, etc. However, in all cases, the length of the roofing screw must exceed the total thickness of the products being fastened by at least 3 millimeters.

In most cases, self-tapping screws can be attached to a particular material without pre-drilling. However, in some situations, through drilling may be necessary first, and then the self-tapping screw is screwed in. Most often, this is resorted to when working with thick metal products to avoid damage to the screw tip.

Pre-drilling is carried out using a drill, and the diameter of the drill should be 0.5-1 millimeter smaller than the diameter of the self-tapping screw. When working with thick metal products, some experts recommend making holes in them that are larger than the diameter of the screws. This is done in order to provide the roofing elements with some mobility, which is important in the presence of serious temperature fluctuations.

Various tools can be used for tightening, depending on the type of screw head, for example a wrench, screwdriver, screwdriver, etc.

You should be careful about the force with which the twisting process is performed. It should be sufficient to tightly press the washer with the gasket, but you should not overdo it here - this can lead to damage to the roofing materials.

It is worth briefly mentioning in which specific areas the fastening of certain roofing products is carried out. Corrugated sheeting or metal tiles are attached where there is the greatest contact with the sheathing, that is, at the base of the waves. Slate, on the contrary, is attached to the crest of the wave (for more details: “What types of slate nails are there - sizes, rules for using nails and screws for slate”). If the roof is assembled from small elements and parts, then the fastening is carried out in overlaps hidden from view.

Types of roofing screws

The ability to screw into various types of materials without pre-drilling greatly facilitates and speeds up work processes using roofing fasteners. But it is necessary to understand that, despite the apparent external similarity, self-tapping screws differ structurally in two main ways: intended for screwing into metal structures, for fastening roofs to wooden bases. These are the so-called self-tapping screws for wood and metal.

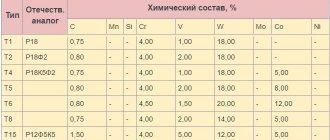

Upon visual inspection, it is not difficult to determine whether they belong to one type or another: Firstly, fasteners designed for working with metal are distinguished by a longer drill, with a diameter approximately equal to the body of the screw. Secondly, self-tapping screws for metal have a finer thread pitch than samples for woodworking. It must be taken into account that the design of the drills themselves limits the functionality of the fasteners when drilling. According to the type of drills (drills), fasteners, in turn, are divided into three types: type 1; type 3; type 3.1. Drill type Sheathing material metal/wood Minimum metal drilling thickness mm. Maximum thickness of metal drilling mm. Type 1 wood 0.91 2 Type 3 metal 0.91 5.3 Type 3.1 metal 0.91 4.17 To select the correct fasteners, it is necessary to take into account the thickness of the metal of the sheathing. Incorrectly selected screws will not only create difficulties when installing the roof, but will also not ensure high-quality fastening of the material to the supporting structures. The larger diameter of the screw body can also be attributed to the distinctive features of fasteners designed for working with metal.

This is due to the higher loads placed on the hardware at the moment of screwing into the metal. When choosing, it is very important not to neglect whether the screws belong to one type or another. It is a common mistake to assume that a screw designed for fastening to metal will be all the more suitable for use on a wooden base. The fact is that a large drill, when twisted, will break a hole that is too large in a relatively soft tree, which is why the hardware with its threaded part will not fit tightly enough into the body of the wooden structure. A smaller drill and an increased thread pitch of a wood screw will, at a minimum, create difficulties when screwing it into metal and will not allow for reliable fastening of the material.

Table: use of self-tapping screws depending on size

| Size(mm) | Scope of application | Mounting type |

| 4,8×29 | Fastening corrugated sheets, siding, metal tiles and polycarbonate to wooden sheathing made of beams 30–50 mm thick and fixing ebbs | Metal-wood |

| 4,8×35 | ||

| 4,8×38 | ||

| 4,8×50 | Fastening corrugated sheets, siding, metal tiles and polycarbonate to a wooden sheathing made of 50 mm thick beams and fixing the ridge and other roofing components | |

| 4,8×60 | Fastening additional elements through a profiled sheet to a wood sheathing | |

| 4,8×65 | ||

| 4,8×70 | ||

| 4,8×80 | ||

| 5,5×19 | Connecting profiled sheets to each other and fastening polycarbonate | Metal-metal |

| 5,5×25 | ||

| 5,5×32 | Fastening profiled sheets to metal sheathing, fixing polycarbonate | |

| 5,5×38 | ||

| 5,5×51 | Fastening additional elements through a profiled sheet to a metal sheathing | |

| 5,5×64 | ||

| 5,5×76 | ||

| 6,3×19 | Connecting profiled sheets to each other (in the overlap area) | Metal-metal |

| 6,3×25 | ||

| 6,3×32 | Fastening profiled sheets to metal sheathing | |

| 6,3×38 | ||

| 6,3×45 | ||

| 6,3×51 | Fastening additional elements through corrugated sheeting to the sheathing of metal parts | |

| 6,3×70 | ||

| 6,3×100 | Fastening profiled sheets to the sheathing, with materials laid between them, for example, insulation |

Selection principles

When choosing hardware for fastening roofing sheets over a rafter structure, you need to know what criteria to pay special attention to. Need to check:

- Availability of company markings.

- Quality rubber gasket.

- Accompanying documents.

- Indication of technical characteristics of fasteners.

- Protective covering. High-quality screws are treated with zinc and paint. The protective and decorative layer must not be damaged.

To check the quality of the self-tapping screws, you can conduct a small test, for which you will need pliers. To do this, you need to squeeze the press washer. If it is not cracked, the connection will be tight and durable. You can also crimp the washer with pliers. If the paint is not cracked, the fasteners are of high quality.

Criteria

Criteria:

- rod material;

- type of anti-corrosion and finishing coating;

- the presence of a shock-absorbing gasket under the cap;

- head shape.

Rod material

Depending on the material from which the fasteners are made, their technical characteristics and price change. The most commonly used materials are lead, brass, low carbon steel, galvanized steel, stainless steel, and electrolytically galvanized steel.

Roof installation (Photo: pixabay.com)

Anti-corrosion and finishing coating

The standard anti-corrosion coating for roofing screws is 12 mm thick zinc. If installed correctly, the roof on such fastenings can easily last for more than 50 years.

For “economy class” screws, the thickness of the protective coating does not exceed 8 mm. Their service life will be several times shorter than that of high-quality self-tapping screws.

The finishing coating is not always present, but the heads of the most high-quality hardware are coated with paint of different colors. The finishing coating changes the appearance of the caps and protects them from moisture.

Manufacturers do not always use paint that can withstand mechanical stress, ultraviolet radiation, and high moisture. To check the paint, you need to take the hardware in your hands and try to wipe the paint off the cap with your fingernail. If it splits, you should not buy such fasteners.

Cushioning under the cap

To protect the roof from leaks, there should be a shock-absorbing washer under the head of the fastener. It can be made from different materials, but it is better to buy products made from EPDM rubber.

Head shape

The capabilities of roofing hardware depend on the shape of their tip. To easily secure metal sheets to the prepared base, it is better to buy pointed screws.

Strength

The documentation that comes with high-quality hardware must contain a line indicating destructive loads. This is a kind of designation of strength. Opposite this line there should be an inscription - maximum permissible.

Metal roof (Photo: pixabay.com)

Advantages and disadvantages

Advantages of metal roofing screws:

- Simple installation, which helps speed up the work of covering rafter structures with roofing material.

- High strength, reliability, resistance to heavy loads.

- High tightness of the connection due to the presence of a rubber seal. Due to this, water will not leak through the roof into the attic or attic.

- Hardware can be removed using hand or power tools without damaging the roofing.

There are practically no disadvantages to fasteners. The main thing is to choose self-tapping screws with a high-quality rubber seal so that moisture does not seep under it.

Dimensions of roofing screws with rubber gasket

There is a separate line of sizes for self-tapping screws with a gasket and washer, since due to the presence of additional elements there is no need to strengthen the fastener legs.

Table: parameters of fasteners with gasket

| Leg diameter (mm) | Product length(cm) |

| 4,2 | 1,3 |

| 1,4 | |

| 1,6 | |

| 1,9 | |

| 2,5 | |

| 3,2 | |

| 4,1 | |

| 5,1 | |

| 7,6 |

Selecting the length of screws

There are several rules for choosing the length of a self-tapping screw that apply in different situations. When uniting/connecting two not very massive parts, the following selection rules apply:

- Whatever you connect, the sharp end of the screw should not stick out from the other side of the parts being connected. That is, in any case, it should be shorter than the parts being connected. Moreover, it is believed that maximum strength will be if at least 5-6 mm remains to the edge of the lower part. So consider it.

The length of the screw is selected depending on the parts being fastened - On the other hand, the minimum self-tapping screw should enter the lower part by at least 1/3 of the thickness of the attached part. That is, if you are fastening, say, a 100*100 mm beam, then the minimum length of the screw should be 1/3 longer. For this beam, the minimum length of the self-tapping screw is 100 + 100/3 = 133 mm. Take the nearest larger one. If you are fastening a board 28 mm thick, then the minimum length of the screw is 28 +28/3 = 37 mm (usually 42 mm is chosen).

If some thin part is attached to a massive base, a different rule applies. Then the length of the fastener should be 2-2.5 times longer than the attached part. This is how you need to select the length of the screw if you are attaching something to a wall, say, or to a concrete floor. In this case, to fasten the same 28 mm board to the wall, the length of the fastener is 56-70 mm. That's the difference.

Self-tapping screw sizes: most applicable options

How to choose the length of the screws should be clear. Now about what they generally are. The situation here is confusing. Neither screws nor self-tapping screws have a common standard. There are several standards of “worn out” years of manufacture, which specify the dimensions of certain types of self-tapping screws.

- GOST 1145-80. Countersunk self-tapping screws.

- GOST 1144-80. Round head screws.

- GOST 1146-80. Screws with a semi-countersunk head.

The situation today is that each manufacturer produces its own “lines”. They focus, of course, on demand. Well, the parameters of the heads are usually made in accordance with one or another GOST. This will at least somehow stabilize the situation. Sometimes the assortment - diameters and lengths are also made according to the standard. In this case, in the description of the screws, the diameters in which they are generally produced are indicated, and then there is a postscript: it corresponds to such and such GOST. This means that the heads comply with the specified standard, and also that the assortment corresponds.

Rules for choosing self-tapping screws for roofing material

When purchasing screws, it is recommended to carefully inspect them.

Fasteners are considered high quality if:

- there is a stamped mark on the head;

- The thickness of the zinc coating is indicated on the packaging (from 12 microns)

- the gasket is firmly fixed to the washer (does not peel off);

The screw gasket must be in tight contact with the washer

- The thickness of the washer is more than 2 mm;

- the press washer can withstand test compression using pliers;

- the paint on the washer does not crack when exposed to pliers.

To ensure that roofing screws do not fail during operation, you should not buy them at a low price.

Close attention should be paid to the gasket. If it is too porous or, conversely, extremely rigid, then self-tapping screws should be abandoned: they will not be able to protect the roofing material from shifting during exposure to strong winds. Also, bad rubber adjacent to the washer will cause roof leaks in the areas where the screws were screwed in.

Using the Snap

In order for the roofing sheets to be securely fastened and withstand heavy loads during operation, it is important to follow certain rules when installing them:

- You can screw in hardware only under the waves of metal tiles.

- When tightening the screws, it is important to keep them strictly perpendicular to the roof.

- The maximum step between fasteners should not exceed 50 cm in one row horizontally.

When screwing in hardware, do not use excessive force. There should be no dents left around the screw, and the shock-absorbing washer should press tightly against the metal surface.

To minimize the number of problems with fixing the roof, you need to buy fastening elements from well-known manufacturers. If in doubt, you can ask the seller to provide quality certificates. If they are not there, it is better to refuse to purchase this product.

What to look for when choosing roofing screws?

When choosing fasteners, it is important to pay attention to a number of important characteristics:

- head configuration. Determine which type of head will make it easier for you to mount products and materials. The easiest way to work is with a hex head;

- shank size. Determines the thickness of the screw. There are No. 6, 8, 10, 12, 14. The higher the indicator, the thicker the rod;

- tip sharpness. Pay attention to all hardware from the batch, which should have pointed ends;

- hardware material.

For roofing work, it is recommended to use only high-quality self-tapping screws to avoid material deformation and corrosion. The roofing configuration includes projections of corrugated sheets and metal tiles. Roofing screws are often used for industrial purposes, which expands the range of their use.

To install the roof, it is better to use hardware that will highlight the aesthetics of the roof. Experts highlight several advantages of such fasteners:

- withstand heavy loads, due to which durability can be ensured;

- durable anti-corrosion coating, which will allow the use of hardware for 50 years or more without the risk of deformation;

- special rubber gasket for roof waterproofing. It is especially important at the junctions of materials to prevent water from passing through;

- distribution of load on roofing material;

- color solutions for the aesthetics of the roof.

Types of self-tapping screws

- Bimetallic roofing screws and stainless steel fasteners. They are used for structures in wet environments. Self-tapping screws are also designed for connecting steel parts, fastening composite materials, wood to aluminum.

- For heating and ventilation. The hexagonal head makes it convenient to install air conditioning systems and air vents.

- With hex head for heavy steel. This is a type of fastener for connecting two steel products, cladding panels to steel.

- Hex head hardware for light steel. Used for roofing and cladding.

- With a metal frame. Purpose - fastening one piece of steel to another. This is the main purpose of hardware.

- Self-tapping screws for cladding panels.

- Screws with galvanized coating. Suitable only in cases where there is no risk of corrosive deformation. Most often used for fastening composite materials and wood to steel.

- Fasteners for composite panels. Hardware is suitable for fastening roofing and cladding using cold-rolled and hot-rolled methods. They are also designed for fastening cladding panels to heavy steel.

Advantages of self-tapping screws

Self-tapping screws are screws made of galvanized steel, shaped like a drill, and are universal fasteners used during installation. They can be used to connect products not only from metal, but also from wood and plastic. Self-tapping screws have the following advantages:

- Their design features allow them to penetrate the thickness of the product themselves. There is no need to pre-drill holes.

- Ease of dismantling. An important difference between self-tapping screws and other fasteners is that they are easy to unscrew without causing damage to the structure.

Description

The roof fastening element belongs to a large group of hardware. It stands out from the total mass by its design, purpose, and type of steel. The main purpose is to fasten sheet material (flat or with a shaped surface) on vertical or horizontal surfaces:

- cladding of fences (fences, walls, partitions):

- wall decoration:

- formation of roofs on buildings.

Despite the wide range of applications of hardware, the name “roofing screw” was given to the fastener due to its widespread use for fixing sheet material when covering the roof.

The most commonly used element is a screw with a sharp thread, equipped with a hex head. An additional element is a gasket made of EDPM rubber (EPDM, ethylene propylene rubber). Ensures a reliable fit of the head and seals the joint from possible moisture penetration.

Manufactured from carbon or stainless steel with additional technological operations for hardening. First, to protect against corrosion, they are coated with a layer of zinc. The minimum permissible thickness to protect against chemical damage is 12 mm.

For reliable screwing, the screw is equipped with a sharp end with high strength and hardness. Another design option helps reduce time - the presence of a drill (drill). This allows you to overcome steel thicknesses of up to 3–10 mm without additional drilling.

Fig.1 Self-tapping screw for zinc-coated roofing, equipped with a sharp end

Fig.2 Fastener with a drill at the end.

Fig.3 Fastener with a wide flat head and a sharp end (self-tapping screw with press washer)

Fig.4 Product with a drill at the end

Fig.5 Hardware with color design for the visible part of the part

The parts presented in Fig. 3 and 4 are used for vertical structures sheathed with sheet iron 1–1.5 mm thick.

Rice. 1, 2 and 5 demonstrate full-fledged fasteners used for roofing. Colored parts are intended for aesthetic design of the finished structure. They are tinted according to the RAL range.