Design features and scope of application

The purpose of an end mill is to form planes on the workpiece being processed for various types of processing. The tool is used for processing parts made of cast iron and steel for various purposes. The design allows the formation of ledges with different wall inclinations. A wide range of such equipment ensures single-pass milling even for large-sized products.

Unlike other types of cutters, end models have cutting edges installed only on the end side. In this case, direct processing of the horizontal plane is carried out by the tops of the cutting elements and is considered additional. The main metal removal is carried out by the side part with longitudinal feed. A large number of cutting blades and the geometry of their arrangement ensure alternate contact with the metal, which significantly improves milling modes and the durability of the equipment. Such an important parameter as the cutting angle in end models depends solely on the diameter of the tool, and not on the amount of machining allowance. The side surfaces of the blades are also capable of forming a vertical ledge or an inclined edge. The height of the ledge should not exceed the dimensions of the blade. Some foreign modifications provide the possibility of installing additional processing blades on the side surface of the body, providing a significant height of the milled edge.

Face milling cutters are structurally highly rigid and are available in both left and right rotation. Considering the location of the cutting blades along the outer radius of the working part, the processing process should begin from the edge of the workpiece, or be carried out in pre-made recesses. Working vertical feeds are rarely used in face milling.

According to their design, all end mills are divided into monolithic and tools with replaceable cutting elements. Monolithic models, at first glance, resemble conventional twist drills. The metal-cutting part made of high-speed steel and the cylindrical body are made as a single whole. In this case, the edge of the blades from the end does not intersect the entire diameter of the base

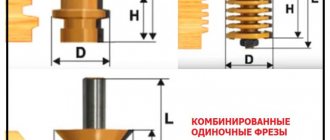

The main element of the design of an end mill with replaceable knives is the processing head. It is a shaped metal body to which removable cutting elements are attached. To achieve the required milling profile, the orientation of the blades creates a working edge on the side. Tools with replaceable blades, compared to monolithic options, have a significant range of models that provide a variety of processing features.

Also, such equipment is easier to use and does not require the use of complex operations when restoring worn cutting edges.

Classification of end mills

The wide range of applications has given rise to a large number of options for through-cut end mills. First of all, they differ in the way they are attached to the machine spindle. It is customary to subdivide tools with a shank and attachment models. Milling cutters are also divided according to the installation method and the shape of the cutting elements.

The end mill is made in the form of a single structure, including a cutting part and a shank. The latter can be either cylindrical or conical. Foreign manufacturers also offer modifications with a threaded shank. A feature of the end models is the small diameter of the cutting part. Milling cutters of this type are made in one piece or with a small number of replaceable inserts. They are used to work with small parts, as well as in hard-to-reach places.

The cutter is intended for installation on a special mandrel, for which the design provides various fastening elements. The most commonly used connection is a keyed connection. Somewhat less often, in versions intended for mounting directly on the machine spindle, threads are made. The shell cutter can have a significant body diameter, in some versions reaching up to 630 mm. This provides a wide processing area in one pass.

The method of fastening the cutting parts should ensure high rigidity of the tool as a whole and strong fastening of the individual blade. End mills are made in one piece, with inserted or replaceable knives.

Solid or monolithic end mills have small diameters, usually not exceeding 40mm. The teeth are made in the form of carbide tipped integral with the body of the tool. This design allows for regrinding if the cutting edge fails. Spiral design with a large number of entries promotes chip removal. Solid models are characterized by low durability and difficulty sharpening worn blades. In most respects they are inferior to models with replaceable elements.

Milling cutters with insert-type knives, otherwise called prefabricated cutters, allow the replacement of all or only individual cutting elements. The knives are fastened to the body of the equipment in pre-made grooves using wedges. The processing elements themselves, reminiscent of conventional cutters in design, consist of a mandrel and a soldered carbide plate. This design allows for simple sharpening of the cutting edges when restoring wear. The shape of the cutters can be customized to suit specific processing requirements.

Another option for fixing cutters is used on cutters for processing non-ferrous metals and soft alloys. It consists of installing the cutter under tension in a wedge-shaped groove. The cutter, in this case, is a solid carbide plate.

The disadvantage of equipment with insert knives is the long duration and relatively high complexity of assembling the tool. These operations may require specialized personnel. Another disadvantage is the high probability of destruction due to vibrations during operation.

End mills with mechanical fastening of multi-faceted replaceable knives are used for a wide range of jobs. During the cutting process, they are able to realize a large amount of material removed. The screw principle of fastening the plates ensures high strength and greater speed of replacement of worn elements. Different models use carbide inserts with a number of edges of three, four or five. Some imported modifications use hexagonal cutting elements. Tools with mechanical fastening of tetrahedral and pentagonal plates have become very popular. A large number of edges ensures high durability of the equipment and allows you to create modifications that provide various processing methods.

In addition to the number of faces, the end milling cutter with replaceable inserts is also characterized by the installation angle of the processing elements. Depending on the vertical position of the plate, the tool is capable of forming a side surface with different inclinations. Models that provide milling at an angle of 45, 75 or 90 degrees are widely used. Radial plate arrangement is used in most general purpose models. For heavy work, with large feed rates and cutting depths, modifications with tangential arrangement of replaceable elements are used. In such a tool, due to the larger cross-section of the knife in the cutting direction, high processing force is ensured and the load on the plate is reduced.

There is also equipment with round plates, used for fine milling of planes with small allowances for processing. The shape of the plates ensures their stepless positioning during wear. Milling cutters with replaceable cutting elements are used not only to obtain horizontal planes. With their help, it is possible to form inclined surfaces, including conical ones.

Types of cutters for metal

Any novice craftsman faced with the need to process metal has to look for information about what types of cutters are available. Let us describe the most common types of cutters according to their intended purpose.

Disk

Disc cutter

Disc cutters are used for the following types of work:

- blank trimmings;

- cutting grooves;

- metal samples;

- chamfering, etc.

The cutting elements of such tools can be located on one or both sides. Depending on the type of processing (from preliminary to finishing), the size of the cutter and its teeth changes. Carbide disc cutters operate in the most difficult conditions with high vibration and the inability to effectively remove chips from the cutting area.

Among the varieties of such tools are:

- grooved;

- slotted;

- cutting;

- designed for processing metal parts on two or three sides.

The names of these tools are determined by their purpose: for example, cutting cutters are needed for cutting metal workpieces on milling machines, and with the help of slotting cutters, grooves and splines are cut.

End

Indexable face milling cutters

Such cutters work with flat and stepped surfaces of metal parts. From the name itself it is clear that the end part of the tool is the working one; accordingly, its axis of rotation is perpendicular to the plane of the part being processed. Most often, such cutters are quite massive, making it convenient to use replaceable inserts. A large number of teeth in the area of contact with the metal part allows for high processing speed and smooth operation of the tool.

Cylindrical

Milling cutters of this type can be either with straight or helical teeth. The first ones process narrow planes, while the second ones work more smoothly and therefore have received universal use.

Cylindrical cutter

The axial forces that arise under certain operating conditions of cutters with helical teeth can be very high. In these cases, double tools are used, the teeth of which are located in different directions of inclination. Thanks to this solution, the axial forces arising during the cutting process are balanced.

This type also includes corn-type rasp cutters; they are used to process ledges and cut grooves.

Cylindrical corn cutter in operation

Corner

The edge of such a metal cutter, used for processing inclined surfaces, as well as corner grooves, has a conical surface. There are both single-angled and double-angled types of tools, differing in the location of the cutting edge (in double-angled models they are located on two adjacent conical surfaces, and in single-angled models they are located on one conical surface). With the help of such cutters you can make chip grooves in various types of tools.

Dovetail corner cutter

To form grooves with beveled side surfaces, single-angle dovetail and inverted dovetail metal tools are used.

End

Most often, end (or finger) cutters for metal are used to create grooves, contour ledges and recesses, and process mutually perpendicular planes.

End mills are divided into several varieties based on the following characteristics:

- monolithic or soldered cutting elements;

- with a conical or cylindrical shank;

- for final metal processing (small teeth) or for rough processing (large teeth).

End mills

Carbide end mills are used to work with difficult-to-machine metals - steel, cast iron, etc. Among the end mills, there are also spherical (ball) cutters necessary for processing spherical-shaped recesses, radius ones, used for cutting grooves of various shapes, mushroom - carbide cutters for T- shaped grooves on workpieces made of cast iron, steel, non-ferrous metals. End mills also include engraving cutters or engraving cutters that are used for cutting precious metals, copper, brass and other materials.

Shaped

From the name it becomes clear that this type of cutting tool is designed to process shaped surfaces. Such cutters are actively used for processing metal parts with a significant ratio of the length of the workpiece to its width, since the shaped surfaces of short parts in large industries are often produced by the broaching method. Shaped cutters with a backed corner are the most difficult to sharpen.

Shaping cutter

Based on the type of teeth, shaped milling tools for metal are divided into two types:

- with pointed teeth;

- with backed teeth.

Worm

Processing is carried out using the rolling method due to the point contact of the workpiece with a tool. Hobs are divided into a number of subtypes according to the following parameters:

- solid or prefabricated;

- right or left (direction of turns);

- multi- or single-pass;

- with unpolished or ground teeth.

Hob

Annular cutters (or core drills)

Such tools are used to produce holes, and annular cutters provide approximately 4 times higher cutting speeds compared to twist drills.

There are metal cutters not only for CNC machines, but also for drills. Otherwise they are also called burrs. Their design includes a special pin for clamping in the drill chuck. Burrs can be found on sale only in the form of kits, since working with metal using a drill requires precision and cutter shapes appropriate for the specific task.

Annular cutters

For a hand router, cutters are also purchased as a set. There are edging tools with and without bearings. The former are used for processing the edges of a part using a manual milling machine, the latter can be used on any part of the workpiece, however, templates are required for more accurate work. On the domestic market, as a rule, you can find Chinese cutting tools for hand routers, but their quality can be assessed as quite high.

At home, you can use a tool such as a drill-cutter to process metal. However, it can only be used for parts of small thickness. Experts do not recommend inserting it into a hand router - it should only be used in an electric drill.