Drainage and fecal - what's the difference?

There are two types of pumps for pumping wastewater: drainage and fecal. What is the difference? Drainage systems are designed to drain contaminated water containing small solids - silt, sand and other substances of approximately the same size. To prevent larger particles from getting inside, install nets. As can be seen from the description, drainage pumps are suitable for pumping clarified water from a storage well located after a septic tank, for pumping water from a storage well for drainage and storm sewers.

A sewage pump differs from a drainage pump in that it can pump viscous media with fairly large solid particles

If you need to pump out sludge from an automatic individual cleaning unit (such as Topas or others), or sediment from the bottom of a septic tank, a drainage system cannot cope with this. The medium is too thick. For a septic tank, in principle, there is a way out: stir up the sediment, pump out the suspension, add water again, shake up again and pump out again. This can be done, but the septic tank will then take a very long time to reach operating mode, so this method can only be used in extreme cases. It is better to purchase special equipment that can handle compressed sediment.

Sewage pumps are used to clean cesspools and septic tanks. They can pump highly contaminated liquids, viscous media that may contain solid particles. The particle size depends on the model, but the maximum size is 50 mm. It is not always the case that all waste in a cesspool rots to such a state. To cope with the situation, a chopper is installed at the bottom of the pump. It is usually installed on centrifugal models - additional cutting blades are installed on the shaft. The already crushed wastewater enters the working body of the pump.

So if you plan to use a fecal pump to pump out a cesspool, it is advisable that the model include a grinder. It grinds larger particles to acceptable sizes.

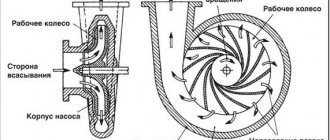

A few words about the principle of operation

The fecal pump is a device consisting of a housing, a cover, a cutting part and a motor. It works on the principle of a vortex mechanism. The housing has a flat disk that pumps water. Depending on its configuration, it can also grind effluent directly. But, in most cases, the chopper is a separate part of the structure.

Design of a fecal pump with a grinder

This design is very advantageous, because during such work not only a large amount of wastewater is captured, but also its outlet pressure increases significantly.

Automatic fecal pumps are equipped with sensors that respond to changes in pressure. When liquid hits the membrane, a mechanism for draining wastewater and grinding it is activated. After this, the remaining mass is transported further along the riser (when installed in apartment conditions) or into a separate tank.

Types of fecal pumps

Sewage pumps operate in an aggressive, chemically active environment. In addition to the fact that their body must be sealed, the materials from which it is made must be chemically neutral and resistant to aggressive environments. There are very few such materials:

- stainless steel;

- some types of plastic;

- cast iron.

The best material is stainless steel, but this material is also the most expensive. The most budget option is a plastic case. These models are the cheapest. In the middle price category there are fecal pumps for pumping out sewage with a cast iron body. Despite the fact that you rarely use this device, you should not choose cheap models. Perhaps for a dacha where you come only from time to time.

This is all a submersible sewage pump with a grinder

By type of installation, pumps for pumping out feces are:

- Submersible. They are installed at the bottom of the tank and usually operate in automatic mode. Switching on/off occurs using a float switch. The float rises/falls along with the liquid level; when it is at the bottom, the pump is turned off.

- Semi-submersible. These pumps are elongated, their suction part is located quite far from the motor. The motor remains on the surface, it floats on a special platform, the suction part is located in the thickness.

- Superficial. Only the hose connected to the inlet pipe is lowered into the tank; the device itself is located next to the tank. A surface sewer pump usually has a plastic body and low capacity. This is basically a country option.

Now we need to figure out all this diversity - when and which devices are best to use.

Conclusions and useful video on the topic

The selection of the following videos will help you navigate the variety of types of fecal pumps so that you make the most correct choice of equipment for your dacha.

The operating principle of the grinder in Grundfos SEG:

How to choose a sewage pump:

Review of submersible pump with chopper:

Living in a country house outside the city, most of us do not want to give up the benefits of civilization in the form of a shower, toilet and other plumbing fixtures. But all this can only be used if there is a septic tank or cesspool at the dacha.

However, if the farm does not have an electric fecal pump to clean them, then constant calls for a sewer truck will cost a considerable amount. At the same time, your own pump can be used not only for pumping out sewage, but also for watering and getting rid of melt water in the basement in the spring.

Features of operation and installation

When choosing a fecal pump for sewage, you must first of all be based on the operating conditions of the equipment. If you are selecting equipment for a summer residence, there is no need to spend money on expensive and powerful submersible models. For these purposes, small and mobile surface installations are optimal. They are good because you can take them with you for the winter - they weigh 5-12 kg, depending on the power. If you are selecting equipment for a private permanent home, it makes sense to purchase more expensive equipment that can be installed permanently.

Submersible sewage pump

This equipment can be installed permanently or mobile. For a stationary installation, a platform is made at the bottom to which the housing is attached. Pipes (usually plastic) are connected to the outlet pipe. The option is not bad, but if the need for repair or maintenance arises, it is not clear how to get the unit.

Installation options for a submersible sewage pump

How to install a submersible sewage pump yourself

The pipe coming from the pump can be led up to the surface of the earth, or it can be led into the wall and laid, say, a pipeline underground to a storage tank. This is an option for those who cannot reach their septic tank/cesspool with a regular sewage disposal truck. In this case, you need to call a special machine with a long hose. But a couple of these calls are equal to the cost of a mid-priced sump pump. Therefore, often in such cases, a storage tank is built/installed in accessible places, the residues are pumped into it using a fecal pump, and then a regular machine is called.

What it might look like when finished

The second, mobile option is better in this regard. Two rods are mounted along one of the walls of the tank. The diameter is slightly smaller than the diameter of the holes in the housing. A chain is attached to the top of the submersible sewer pump, and a corrugated pipe is connected to the outlet pipe. Next, the body is put on the installed rods, and the device is lowered to the bottom, as if on rails. With this installation method, if necessary, the pump is pulled out by the chain. There is only one drawback - the need to use corrugated pipes. Their structure leads to the fact that the pipes often become clogged; accordingly, they need to be replaced, since cleaning them is very unpleasant.

Installation options for submersible pumps for septic tank sewage, drainage and storage wells

You can avoid using a corrugated hose in models with a lower suction pipe. In this case, a rigid (plastic) pipe is mounted, its end is brought out so that the pump descending along the guides fits onto it (pictured on the right).

And the easiest installation option: simply lower the device to the bottom on a chain. When the wastewater is pumped out to the required level, the equipment is turned off and removed from the tank, washed, dried and taken to the utility room until next use.

| Name | Power | Lift height/pressure | Performance | Notes | Price |

| Grundfos SEG 40.12.2.1.502 | 1200 W | 20.5 m | 18 m3/h | Cable length 10 m, chopper | 1025$ |

| Ebara Right 75 M/A | 500 W | 8.6 m | 14 m3/h | Permissible diameter of solid inclusions 35 mm | 250$ |

| Speroni SEM 150-VS | 1700 W | 11 m | 24 m3/h | Float switch, chopper | 560$ |

| Homa Barracuda GRP 16 BD | 900 W | 20 m | 18.7 m3/h | Chopper | 1160$ |

| Ebara DW M 150 A | 1600 W | 16 m | 42 m3/h | Permissible diameter of solids 50 mm, float switch | 620$ |

| Speroni CUTTY 150/N | 1500 W | 17 m | 21 m3/h | Chopper | 770$ |

| Irtysh PFS 50/125.120 | 1100 W | 6 m | 16 m3/h | Float switch | |

| Irtysh PFS 50/125. 98 | 1100 W | 4 m | 7 m3/h | Float switch | |

| Irtysh PF2 50/140.138 | 3000 W | 22 m | 25 m3/h | Float switch | |

| Gilex Fekalnik 150/7N 5302 | 550 W | 7 m | 9 m3/h | Allowable diameter of solids 35 mm, float switch | 105$ |

| Gilex Fekalnik 200/10 F 5301 | 880 W | 10 m | 12 m3/h | Allowable diameter of solids 35 mm, float switch | 70$ |

| Gilex Fekalnik 255/11 N 5303 | 1100 W | 11 m | 15 m3/h | Allowable diameter of solids 35 mm, float switch | 125$ |

Despite the rather complex installation, submersible sewage pumps are the most popular. This is explained by the fact that they are usually more powerful, and they can also pump media with particles up to 50 mm in size. And it is submersible models that can be equipped with a chopper.

Advantages of submersible pumps:

- They can lift liquid from great depths.

- It can operate in automatic mode, using a float to control the liquid level.

- There is no need to worry about cooling.

- Low noise level.

It is submersible fecal pumps that can develop sufficient power to pump out contents from great depths. In the case of sewerage, this may not be so important - septic tanks are not so deep. But, if necessary, you can pump wastewater over a long distance over the surface. The main thing is that there are enough hoses.

Semi-submersible models of fecal pumps

This type of equipment combines the advantages of surface and submersible pumps. Since the engine is above the surface of the water, there is no need to waterproof it perfectly. There is also no need to tightly arrange all the parts in the case. All this has a positive effect on the price - it is significantly lower than submersible models.

The disadvantage of fecal semi-submersible pumps is the smaller particle size that it can absorb and the smaller depths at which it can operate. Another disadvantage is that a grinder cannot be installed on this type of pump. However, not all disadvantages are significant for domestic use. Too great depths are not needed for private use, and a simpler design makes repairs more accessible, so there are clearly more advantages.

One of the types of semi-submersible devices is vertical

A feature of installing semi-submersible pumps is that it must be installed so that the motor is above the water. The installation method depends on the model; it is specified in the product instructions. In general, there are several installation methods:

- They make a platform on the wall of the tank, and attach the equipment to it. With this installation method, you must ensure that the liquid level does not rise above the platform - the upper part of the housing is not sealed. You can control the level using automation - sensors that send a signal to turn it on and off.

- Installation on a floating pad. This installation method is used for small semi-submersible sewage or drainage pumps for domestic use.

- Very small models, also called “barrel” models, can be hung on board.

Despite all the advantages, this model is not used so often. Basically, a sewage pump is purchased as a submersible or surface type.

| Name/manufacturer | Power | Lift/pressure | Feed/capacity | Notes | Price |

| FGP 20/10 (L=1.3 m) | 2.2 kW | 10 m | 20 m3/hour | Maximum particle size 15 mm | 400$ |

| NCI-F100 | 0.5 kW | 8 m | 100 m3/hour | Centrifugal with chopper | 1525$ |

| FGS50-12.5 | 4 kW | 12.5 m | 50 m3/hour | Maximum particle size 15 mm | 760$ |

| FGS30-10 | 2.2 kW | 10 m | 30 m3/hour | Maximum particle size 15 mm | 515$ |

Pedrollo BCm 15/50

Main characteristics:

- Maximum head - 16 m;

- Capacity - 48 cubic meters. m/hour;

- Power consumption - 1100 W.

Frame. The body and main parts are made of cast iron and stainless steel, which allows the pump to be operated in a chemically aggressive environment with abrasive inclusions.

Engine. A single-phase electric motor with built-in thermal protection consumes 1100 W, which is enough to pump out a viscous mixture in an amount of 48 m3/hour. This flow rate corresponds to a discharge pipe diameter of 2½'. To eliminate the option of operating in dry mode, the pump is equipped with a float switch that opens the power circuit when the liquid level drops to a critical level.

Water pump. The double impeller of the pump creates a fairly large pressure of 15 meters and successfully replaces the chopper. The removable cover allows you to quickly access the pump for inspection or cleaning in case of clogging.

Device Pedrollo BCm 15/50.

1. Pump housing. 2. Pump base. 3. Impeller. 4. Motor housing.

5. Engine cover. 6. Motor shaft. 7. Double mechanical mechanical shaft seal with intermediate oil chamber.

8. Bearings. 9. Capacitor. 10. Electric motor. 11. Power cable. 12. External float switch.

Application. The design of this model is designed for immersion in water to a depth of 5 meters, so the length of the power cable is 10 meters. The pump is designed for pumping fecal matter and other liquids with a temperature not exceeding 40°C. The diameter of solid particles should not exceed 50 mm. With a width of 250 mm and a height of 450 mm, it easily fits into a standard size inspection hatch.

Watch the product video

Pros of Pedrollo BCm 15/50

- Quality materials.

- Reliable shaft seal.

- High performance and fairly high pressure.

- Low noise level.

- Protection against dry running and engine overheating.

Cons of Pedrollo BCm 15/50

- Heavy.

- Expensive.

Surface Models

The easiest installation is for surface-type sewage pumps. The device itself is placed on the ground, and only the hoses are lowered into the container.

Surface models of fecal or drainage pumps are attractive for their mobility

The most serious drawback of such models is the phenomenon of cavitation, which occurs when pumping liquids from great depths. Cavitation is the saturation of the pumped medium with air bubbles. If such a mass gets into the working part of the pump, it will fail. This is why it is not recommended to use surface fecal pumps at depths greater than those for which they are intended. In the case of pumping a septic tank or storage well, the use of such models is justified. Their depth is small, and even not the most powerful motor will cope with the task. You just need to choose the right power of the unit.

| Name | Type | Power | Lift/pressure | Performance | Notes | Price |

| Caliber NBC-380 | self-priming | 380 W | 25 m | 28 l/min | No idle protection | 30-35$ |

| Whirlwind PN-370 | self-priming | 370 W | 30 m | 45 l/min | No idle protection | 38-42$ |

| Gilex Jumbo 60/35 N | self-priming | 600 W | 35 m | 60 l/min | No idle protection, maximum particle size 0.8 mm | 104$ |

| Gilex Jumbo 70/50 P 3701 with ejector | self-priming | 1100 W | 50 m | No idle protection, maximum particle size 0.8 mm | 115$ |

Please note that all surface pump models are designed to pump water. Only some of them can pump viscous liquids, and this must be indicated in the description or data sheet. The disadvantage of this equipment is that it requires a homogeneous environment - the maximum particle size that they are able to pump is 0.8 m. The price is undoubtedly attractive, but among submersible models there are very inexpensive ones - for example, Gilex and Ebara. The latter also have a stainless steel body and a wide range of models with different pressure and performance.

Sturm WP9775SW

Main characteristics:

- Immersion depth - 5 m;

- Maximum head - 11 m;

- Capacity - 18 cubic meters. m/hour;

- Power consumption - 750 W.

Frame. The body of this brand of fecal pump is entirely made of cast iron, which guarantees its reliability and protection against corrosion. There is a carrying handle with a hole for attaching a cord.

Engine. The unit is equipped with a 750 W electric motor operating from a standard 220 volt AC network. It provides a maximum head of 9 meters and a flow rate of 15 m3/hour. Its weight of 18.5 kg is typical for models with these characteristics.

Water pump. The shaft and impeller are made of stainless steel. Tightness is ensured by double sealing. The diameter of the slots in the receiving device is safe for internal working tools. No cutting device is provided. Hoses with a diameter of 2 inches are used as a pressure pipeline, connected using clamps.

No cutting element.

Use 2" hoses.

Application. The pump is used for pumping liquids with varying degrees of contamination and a maximum solid inclusion size of up to 7 mm. The design is designed for immersion no deeper than 5 meters. The pumped liquid should not be heated above 35°C. Compact dimensions make it possible to install the device in limited space.

Pros of Sturm WP9775SW

- Simple and reliable design.

- Minimal maintenance.

- Triple engine protection against overheating, power surges and dry operation.

- Low cost.

Cons Sturm WP9775SW

- Small size of pumped solids.

How to calculate the required lift height

When choosing a fecal pump for sewage, you need to pay attention to two characteristics: its power (performance) and lifting height. With productivity, everything is more or less clear - it depends on the volumes that need to be pumped. The lifting height will have to be considered, because in addition to the vertical component, with which everything is clear (this is the depth of the well/septic tank from which the wastewater must be lifted), there is also a horizontal component - these wastewater must be transferred somewhere, usually into some kind of container. The distance over which the wastewater must be transferred in the horizontal plane is divided by 10. The result is added to the height of the rise from the well.

An example of technical characteristics of a fecal pump for pumping out sewerage

For example, the depth of a well is 4 meters, it is necessary to transfer waste water to 35 meters. Total we get: 4 m + 35 m / 10 = 7.5 m. The technical characteristics of the pump should include a lift height of at least this figure, or better yet 20-25% more, so that the equipment does not work at its limit, which leads to premature wear . Now you know how to calculate a sewage pump.

In-house sewerage installations

Sewage pumps are also called small-sized pumping stations, which are designed to be built directly into the sewerage system inside a country house. Structurally and in terms of operating principle, such pumps resemble analogues from washing machines.

Such models of fecal pumps belong to the premium segment of plumbing and cost a lot. However, thanks to them, toilets, showers and washbasins can be installed almost anywhere in a residential building. They calmly pump wastewater even through pipelines inclined upward.

The design of this pumping station was originally based on the principle of self-cleaning. It is undemanding in terms of maintenance; it is enough to only occasionally rinse the tank from silt deposits.

It also has a carbon filter and a check valve. The first eliminates the appearance of sewer stench in the room, and the second prevents the return of waste from the sewer back to the storage tank. Fecal pumps for toilets prevent blockages and provide forced drainage of wastewater.

Pros and cons of pumps

Below is a table showing the main advantages and disadvantages of different types of pumps.

| Pump type | Advantages | Flaws |

| Surface |

|

|

| Submersible |

|

|

| Semi-submersible |

|

|

How to choose the right fecal agent?

Important technical information should be studied. characteristics of the device for pumping fecal and other masses.

| OPTIONS | DESCRIPTION |

| Power | The ability to pump out fecal matter at a certain speed. For constant pumping, preference is given to a 1.5 kW motor. If periodic cleaning is expected, then it is better to choose a power of 0.5 kW |

| Performance | The ability of the installation to pump out liquid at a certain speed per minute. For example, a device for arranging drainage and sewerage with a power of 1500 W is capable of creating a speed of up to 650 liters per minute. The choice of this parameter depends on the intensity of wastewater accumulation. If it is low, then a heavy-duty sump pump is not needed |

| Pressure | An important parameter indicating the ability of the device to lift liquid from a certain height. For example, a self-made pump mainly has a low pressure. It is important to consider not only the vertical, but also the horizontal pumping section. As a result, the pressure depends on the previous pump performance |

| Housing material | It is preferable to purchase a device for cesspools made of steel (stainless). Especially if we are talking about its constant operation in a difficult environment |

| Cutting material | The pump used with a grinder for the garden or home allows you to pump out masses with solid and thick inclusions. Taking this into account, the cutting element must be made of good quality steel |

| Automation | Units with cutting mechanisms can be equipped with automation. For example, a submersible pump with a float. Additionally, a water sensor is installed, which sends a signal to the motor to turn it on/off |

| Brand awareness | When choosing a sewerage device for a private home, preference should be given to well-known manufacturers. The selected model must have service in your area |