Septic tanks "Tver" are representatives of that type of local sewerage system in which mechanical cleaning is closely connected with biological processes. This allows them to achieve the most effective results in their work and delight the owners with high-quality functioning.

You are getting:

- Free shipping

- Installation in 1 day

- 2 year warranty

Order by phone: 8

Telephone

Sewage system Tver

After treatment, it is allowed to drain the purified water from the septic tank onto the soil surface without additional purification.

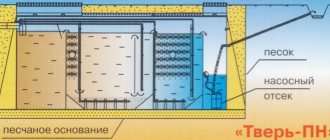

The engineering equipment of the Tver septic tank is a station consisting of several chambers.

The basic principle of the installation looks like this:

- Primary settling tank. Serves to separate various impurities: fats and small particles rise to the surface, and large suspensions fall to the bottom.

- Anaerobic chamber. Here, wastewater is purified using oxygen-free microflora.

- The first aeration tank (with expanded clay). It carries out the process of aeration and nitrification (oxidation of nitrogen to nitrates and nitrites).

- Secondary settling tank. Designed for the next stage of anaerobic treatment - denitrification (nitrates and nitrites undergo a process of reduction to nitrogen).

- Second aeration tank (with crushed limestone). Here the ammonium residues are oxidized and phosphorus residues are removed.

- Third sump (if the model is gravity-flowing, the outlet pipe is located here). Its purpose is denitrification.

- Compartment with a drain pump (available only in stations with forced discharge). This is where purified water is pumped out if it is impossible to arrange a gravity discharge.

Principle of operation

Tver is a septic tank, the design and principle of operation of which involves the use of several different methods of wastewater treatment simultaneously. This allows you to get 98% purified water at the output. All processes take place inside the container, without the use of soil post-treatment.

Diagram of the internal structure and operating principle

Wastewater processing occurs in the following sequence:

- Wastewater, passing through the sewer pipeline, enters through the inlet pipe into the first compartment of the tank - the septic tank (1). Segregation of wastewater occurs in it. Large particles settle to the bottom of the chamber, fats collect on the surface, and the settled liquid ends up in the middle part.

- At the next stage, the settled water from the first compartment flows through the overflow into the anaerobic bioreactor (2), filled with a brush load. In this compartment, purification occurs due to the work of anaerobic bacteria that enter the drains along with human waste products. Colonies of microorganisms settle on the surface of the brush load and contribute to the transformation of difficult-to-oxidize particles from wastewater into easily oxidized ones.

- The clarified liquid enters a compartment called the aeration tank (3), where the process of mixing it with activated sludge occurs. This compartment is filled with expanded clay loading. At the bottom of the chamber there is a pipeline with holes (aerator), through which air is pumped using a compressor. Air supply is necessary for aerobic bacteria covering the surface of expanded clay. This type of microorganisms for the septic tank is loaded into the device simultaneously with the expanded clay loading.

- In the fourth compartment, the secondary settling tank (4), activated sludge is separated from the liquid. Activated sludge returns along the inclined wall to the third chamber, and clarified water flows into the next compartment.

- The fifth compartment - an aerobic bioreactor (5) serves to oxidize and sorb remaining contaminants. At the bottom of the chamber there is a load of crushed limestone, which, when dissolved, binds and neutralizes phosphates. Processes in an aerobic bioreactor occur with the active supply of oxygen through aerators.

- The sixth compartment, the tertiary settling tank (6), collects purified liquid flowing from the container through the outlet pipe. In this compartment it is possible to install a special float with chlorine tablets for additional water purification.

Marking of treatment facilities Tver

The technical characteristics of the model are indicated to the user by the corresponding marking in the name:

- the letter P means the body is made of polypropylene;

- the letter M indicates that the inlet pipe is located at a depth of 0.6 m from the soil level;

- the letter H indicates the presence of a pump chamber.

For example:

- Septic tank Tver 1P - installation with a polypropylene body and a capacity of 1 cubic meter per day;

- Septic tank Tver1 PN is a station with a polypropylene body and a pump for pumping treated wastewater. Installation capacity – 1 cubic meter per day;

- Septic tank Tver 5PNM - polypropylene body with an inlet pipe depth of 0.6 m and a forced drainage system. Productivity – 5 m3/day.

Expert opinion

Dmitry Chernov

Design engineer. Experience in designing wastewater treatment plants - 18 years.

Ask a Question

When installing and using VOC Tver, it is important to follow the manufacturer's instructions. If you have any questions, it is better to seek advice from official representatives. Thanks to this, you can use the station without resorting to warranty service.

Comparative characteristics of some septic tank models are shown in the table below:

| Biological station Tver | |||||

| 0.35P | 0.5RM | 0.75PNM | 1RM | 2PN | |

| Number of persons | 1-2 | 2-3 | 2-4 | 4-6 | 10-12 |

| Productivity indicators per day, cubic meters. | 0,35 | 0,5 | 0,75 | 1 | 2 |

| Supply | Gravity | Gravity | Gravity | Gravity | Gravity |

| Retraction | Gravity | Gravity | Forced | Gravity | Forced |

| Installation weight, kg | 90 | 120 | 170 | 180 | 350 |

The number of users of LOS Tver, depending on productivity, can vary from 1-2 to 250 or more people.

Choosing an installation location

When installing a biorefinery station on the territory of a private house, you should be guided by the requirements set out in SNiP: 2.04.03-85; 2.04.01-85; 2.04.04-84; 2.1.5.980-00 and SanPin 2.2.1/2.1.1.1200-03.

The Tver septic tank installation diagram is clearly shown in the figure.

To be completely confident in choosing the right location, experts recommend installing a septic tank:

- From a busy road and the foundation of a residential building ≤ 5m.

- From the road serving as a passage ≤ 2 m.

- Distance from plantings and garden trees ≤ 3 m.

- From the border of the site to the septic tank ≤ 2 m.

- From the reservoir ≤ 10 m.

When choosing an installation location, it is necessary to strictly observe the distance from the septic tank to drinking water tanks. The septic tank can be located at a distance of ≤ 20 m from the well (well) with drinking water.

Advantages of treatment facilities

- Ability to accommodate large volumes - the productivity of a septic tank, depending on the model, can range from 0.35 to 50 m3/day;

- Models designed for 2-5 people have a relatively light weight that does not require the use of special equipment during installation;

- No unpleasant odors, subject to operating conditions;

- Adaptability to volumetric volley discharge, which allows you to use more units of plumbing fixtures at the same time. Up to 30% of the model’s daily output can be drained at one time;

- The presence of loading wings on the body, thanks to which the station does not float up in case of high groundwater. And the stiffening ribs with which the body is equipped make it more resistant to soil pressure;

- Carrying out installation in any type of soil;

- Overflows between adjacent chambers are gravity-fed, so clogging occurs very rarely;

- The presence of an additional aeration tank and settling tank, which allows for double nitrification and denitrification;

- Bioremediation is carried out in two blocks and using expanded clay;

- A unique limestone charge can remove phosphorus;

- The kit includes inlet and outlet pipes;

- External installation of the compressor, thanks to which this unit is not afraid of flooding;

- Pumping will only be needed 1-2 times a year;

- The adaptability of certain models to preservation during irregular use.

Expert opinion

Dmitry Chernov

Design engineer. Experience in designing wastewater treatment plants - 18 years.

Ask a Question

Sludge should be pumped out from an autonomous sewer system regularly. Otherwise, the accumulated sludge will coke and require manual crushing.

Reviews:

October 24, 2019

Pumping and maintenance of septic tank Tver

The septic tank was installed in 2010, in 2021 we cleaned it ourselves and at the same time bought new components.

In October 2021, we decided to pump it out, wash it and service it professionally with the help of the company. I started calling different offices and they all said that I needed to change the brushes and chalk and pebbles. Why, because I already changed them 3 years ago. I really liked the communication at the Super-septic Company, and also the fact that they did not offer me replacement components - it was honest, and therefore surprising. They served everything wonderfully and efficiently. Irina

May 14, 2019

Septic tank Tver maintenance.

A Tver septic tank was installed in 2010 for a large house.

A few years later, the same one installed a small Tver in my bathhouse. It’s 35 meters from the road to the bathhouse. A special barrel with a long, long sleeve arrives - this is a rarity. Every time they recognized me on the phone and showed respect. I have already ordered maintenance from them several times. They come when it’s convenient for me – on weekends. Always with your own sewer truck. They work for about an hour and a half. Everything is washed, including brushes. I order service once every two years. I chose a septic tank, at one time, for a very long time and thoroughly. It was important for me that it didn’t stink and worked without electricity, during blackouts, etc. I live in Vladimir region. It’s good that the company has continued to operate all these 10 years. I really... Sergey

May 14, 2019

Septic tank Tver. Service.

Installed a super septic tank in Tver in 2021. For 5 people - 0.75 PN.

The pump threw out, at first, clean water. This year, the smell began to appear periodically. I took off the covers and there was a lot of dirty sludge floating in the pump chamber. I started calling different companies. Nobody could explain the reason. Many said this was the norm. I received excellent advice over the phone. Within 20 minutes the cause was identified. It turned out that earlier, during the installation of the container, the outlet hose was inserted into the wrong place, and primer got into it. There was an overflow. I invited their specialist and a barrel for pumping. Indeed, an engineer arrived in his car. Explained everything, showed it, set it up. The smell went away by evening. Thank you very much... Roman.

Model: Septic tank Tver-0.75PN

All reviews

Disadvantages of the Tver biological treatment plant

- Horizontal placement of the body increases its dimensions and requires additional space on the site;

- Small thickness of the body and lugs;

- Lack of effluent recirculation - airlifts must be manually started before pumping out sludge;

- Small range of insertion depth of the supply pipe;

- The need to provide a room for installing a compressor or install it in the house. In the latter case, noise from the operation of the compressor is possible;

- The need to connect the pump using a heat-shrinkable coupling;

- No alarm that indicates overflow;

- The need to pump out sludge (with a sewer truck or independently);

- The need for periodic replacement of expanded clay and limestone.

Expert opinion

Dmitry Chernov

Design engineer. Experience in designing wastewater treatment plants - 18 years.

Ask a Question

Before pumping, you need to move the taps for pumping wastewater from the sedimentation tanks into the receiving chamber to the open position.

Elimination of defects

Some of the disadvantages of Tver treatment facilities can be easily eliminated:

- To get rid of noise, the compressor can be installed in a box next to the septic tank. The main thing is to take care of reliable protection from moisture.

- You can provide an alarm that will notify you that the station is overfilled using a remote electrical box. You can also connect a pump and heating cable to it. And in the event of a breakdown, the pump can be easily turned off.

Expert advice

Krotov Nikolay Vladimirovich, engineer for the development of autonomous treatment facilities.

The Tver septic tank today belongs to the group of technological wastewater treatment devices and is able to fully satisfy the needs of a person who wants to have an autonomous sewer system. At the same time, the cost category of this product on the market is slightly higher than that of many analogues.

In this regard, when choosing, you need to be guided by the actual required productivity (volume of water and number of people) - you should not purchase a septic tank with obviously inflated performance. This will increase the purchase price, as well as turnkey installation and subsequent maintenance costs.

Station maintenance

According to the instructions from the technical data sheet, the manufacturer recommends servicing the station in the following order:

- Once every 3-6 months (depending on the intensity of operation), using airlifts, pump excess sludge from the aeration tank and sediment from the tertiary settling tank into the septic tank. To turn on the airlifts, you must first close valves No. 1 and No. 2, and then open valves No. 3 and No. 4 one by one. Wait until the liquid pouring out changes color from dark to light (about 5-10 minutes). After pumping, return the valves and taps to their original position;

- Once every 3-6 months, regulate the flow of air into the aeration tanks and bioreactor using valves No. 1 and No. 2;

- Once a year (on average), empty the septic chamber of sediment using a sewer truck;

- Once every 2-3 years, wash the brush load with a powerful stream of water. Change it to a new one every 5-6 years;

- In the aerobic bioreactor, replenish dolomite crushed stone as it dissolves (on average once every 2-3 years);

- Once every 2-3 years, clean the walls and drains of deposits.

Attention! Do not completely pump out all the liquid from more than one chamber to avoid the septic tank from floating.

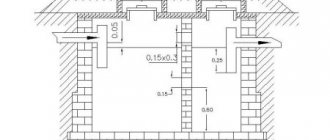

Installing a septic tank Tver with your own hands

Septic tank Tver is a reliable sewerage system for individual use. Trouble-free operation is ensured by correct installation. If it is not possible to call specialists and there is a need to install the structure on the site with your own hands, it is worth remembering that if the process is carried out by non-accredited organizations and non-specialists, then the structure loses the manufacturer’s warranty. To ensure proper functioning of the device, you need to follow a number of rules provided by the manufacturer.

The first step is to choose the location of the septic tank. Since the structure has rather large dimensions, you need to calculate the distance based on their external dimensions, adding approximately thirty centimeters on each side. Do not forget that the sludge compartment must be periodically cleaned by a sewage disposal machine, which must be provided with the possibility of access to the technological hatch. If the sewerage system is located near the fence, then you can make a removable hole in it through which it will be possible to pass the hose. Regulatory documents regulate the following installation restrictions:

- at least 5 meters from the roadway;

- more than 5 meters from a residential private house, as well as outbuildings;

- more than 3 meters from fruit trees;

- more than 10 meters from a body of natural origin;

- at least 20 meters from a well or well with drinking water, which are located on your own or nearby property.

Before starting installation, it is worth finding out the depth of groundwater. The type of removal of water that remains after treatment depends on how high the level is and how quickly the outflow occurs. It is recommended to first determine these indicators yourself if it is not possible to call specialists.

To determine it yourself, you need to drill a hole to a depth that exceeds the freezing level. On average, it is about one and a half meters. When removing soil, you need to try to determine the type of soil: sand, clay, loam, etc. After drilling, water may appear in the ground, indicating that the first level of aquifers has been reached. Often this is the appearance of groundwater, which is released by the soil during melting snow or heavy rains. If the water appears at a level above one meter, then the septic tank is installed with an excess of 30 cm. In the case when the removed soil is clayey, it will be necessary to additionally construct a cesspool for wastewater and arrange the flow process using a pump.

Important! Most stations of individual sewer systems are not equipped with a pipe. Tver is equipped with it directly from the manufacturer, so there is no need to install it at the installation site. The usual option involves the location of the pipe located 30 cm below the top point of the body. In modified versions it is extended to 60 cm.

After marking, you need to dig a hole with dimensions that will be twenty centimeters larger than the installed septic tank on each side. The bottom of the pit must be leveled, after which a cushion of sand and crushed stone, a total layer of about 15-20 cm, must be installed. In areas where installation is complicated by quicksand or high groundwater, the walls are strengthened using wooden formwork. Also, in the case of high groundwater level, it is advisable to strengthen the bottom with a concrete foundation. After pouring, there is no need to wait until it gains strength and secure the hinges in it for installing the septic tank. This point will help to further strengthen the system, which will be secured to the concrete monolith using a special cable. Before you start immersing the container, it is worth checking once again whether everything is prepared for installation:

- individual sewerage capacity;

- HDPE pipes D10 or D20 for connection to the compressor;

- covers in the amount of 2 pcs;

- brushes for mechanical cleaning;

- compressor;

- expanded clay or sand for backfilling.

HDPE pipes are laid at the bottom of the pit in such a way that the slope is more than 2 cm per meter. It is preferable to make the line straight, but if there is a need to create a turning angle, then it should be mounted inside a specially prepared well 70cmx30cm.

Important! The Tver septic tank must be equipped with one or two vent risers. If this is not done, an unpleasant odor may spread and the system may not function properly.

After laying the pipes, the air duct route is laid, which should be arranged with an angle at an angle to the tank. This is necessary so that during the cold season at sub-zero temperatures, fumes do not accumulate and freeze inside the pipes. After this, the electrical power cable is laid. The outlet is installed on a sand bed using a D10 PVC pipe. Knowledge of soils will be useful here, since if the water drains without using a pump, then the angle of inclination should be about 1 cm per 1 meter. Place crushed stone on top to prevent freezing. If purified water is disposed of using technical equipment, then it is necessary to make an angle of inclination in the direction of the septic tank container. This is necessary so that after the pump is turned off, the liquid flows back into the sewer.

After checking everything necessary and arranging the lines, the septic tank is lowered to the bottom of the pit using a construction crane or four people. The sewerage system must not be tipped over, as this can lead to breakage and, as a consequence, failures during operation. Next you need:

- Using a building level, check the correct installation vertically and horizontally. If the container is installed skewed, then you need to add sand under the bottom of the body;

- secure the septic tank with a cable from the protrusions at the ends of the septic tank to the loops installed in the concrete base;

- the entire complex of communication systems is connected;

- then you need to fill in the water, at the same time filling the distances between the walls of the pit and the septic tank with expanded clay or sand, compacting and spilling water at each level of 30 cm;

- Mechanical cleaning brushes are lowered, expanded clay is poured into the aeration tank compartment, and dolomite is loaded into the aerobic biological reactor;

- the septic tank is insulated from above using mineral wool, which is strengthened at the top of the body;

- The sewer along with stone wool is covered with earth on top.

Important! The sand must be clean, without clay or other foreign impurities.

The air supply to the septic tank is regulated using taps according to the manufacturer's instructions. The system must be started at a positive temperature. It takes about a month to organize the working regime. If all instructions are followed, after a set period of time the bacteria will work in the required volume and the wastewater will reach optimal purification values. The process should be monitored and water samples taken at the outlet. Externally, it should be clean and transparent, without any unpleasant odor or visible particles.

Modifications

Since the operating conditions of septic tanks may be different, the manufacturer offers different modifications of this treatment plant. The first thing you need to pay attention to when choosing is the performance of the model.

This parameter is determined by water flow. The younger model is suitable for serving only 3 people, it is ideal for a summer house or a small house. In addition, the manufacturer offers different housing options. You can choose a model:

- with increased body strength, the manufacturer recommends using this option for installation in heavy and heaving-prone soils;

- with additional pump compartment. In standard models, water is discharged from the septic tank through the pipe by gravity. If this is not possible, water is pumped out using a pump. As a rule, pumping is required when installing a septic tank in clay or with a high groundwater level;

- with an increased body height, the manufacturer recommends purchasing this modification if the project provides for buried pipe laying.